Restraining mid-spatial-frequency error of large-size off-axis parabolic mirrors by multi-tool NC polishing

-

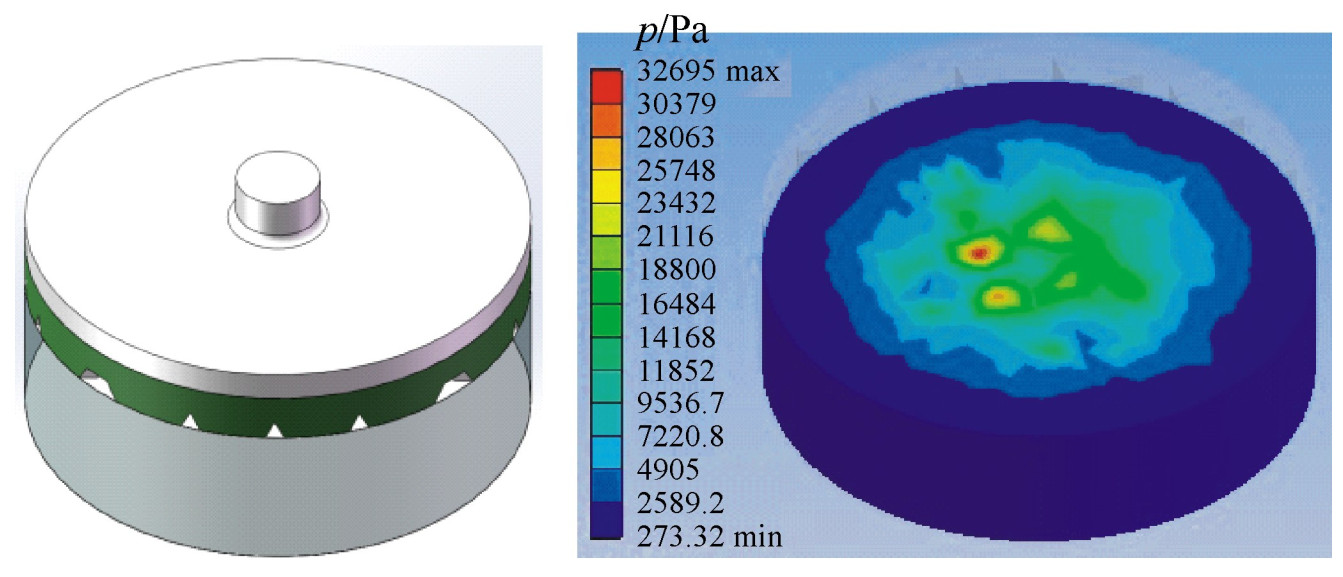

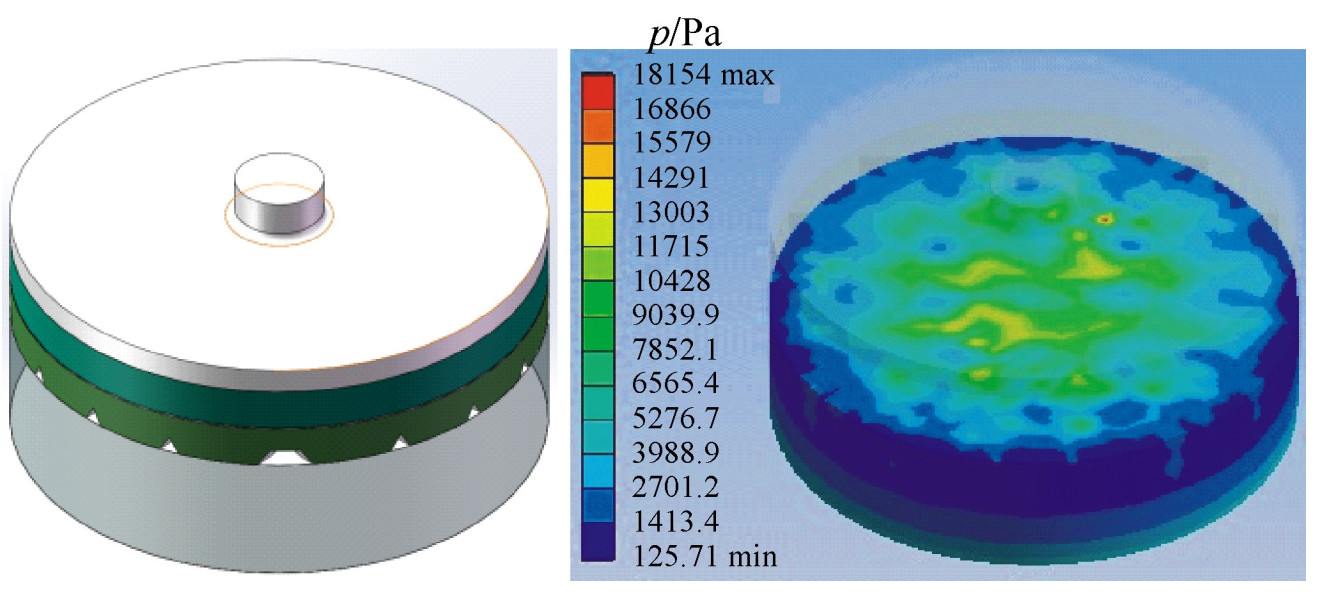

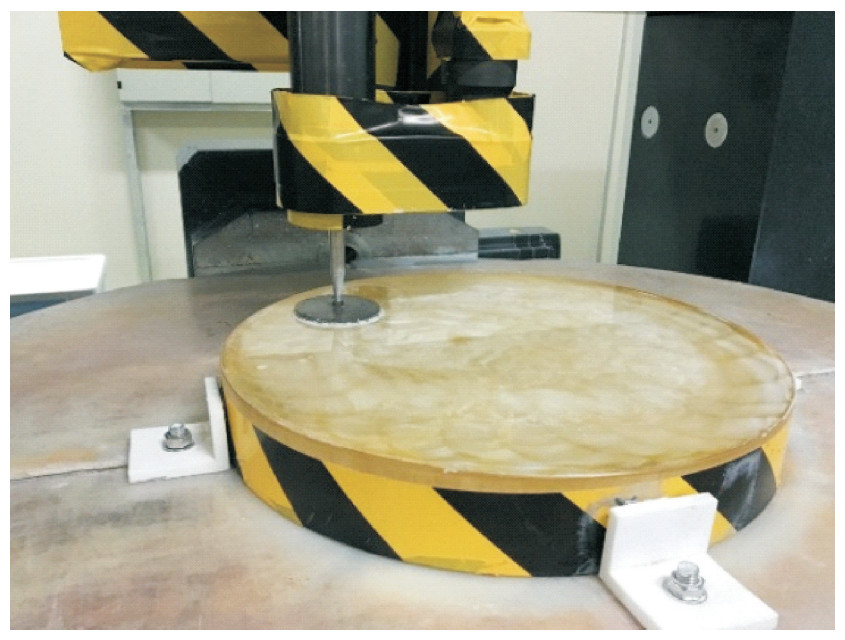

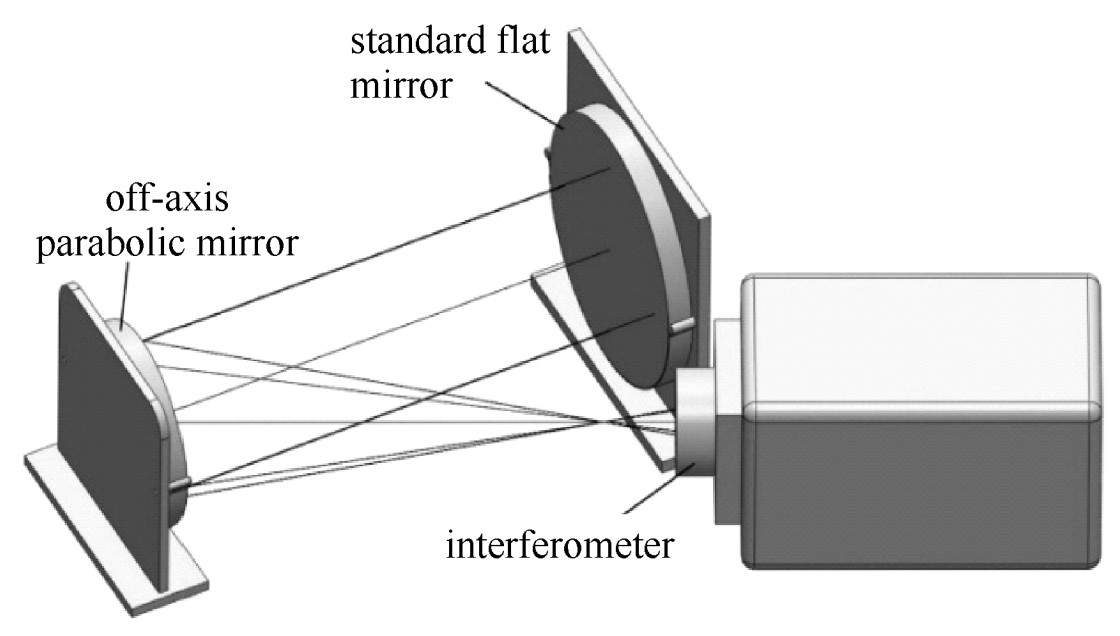

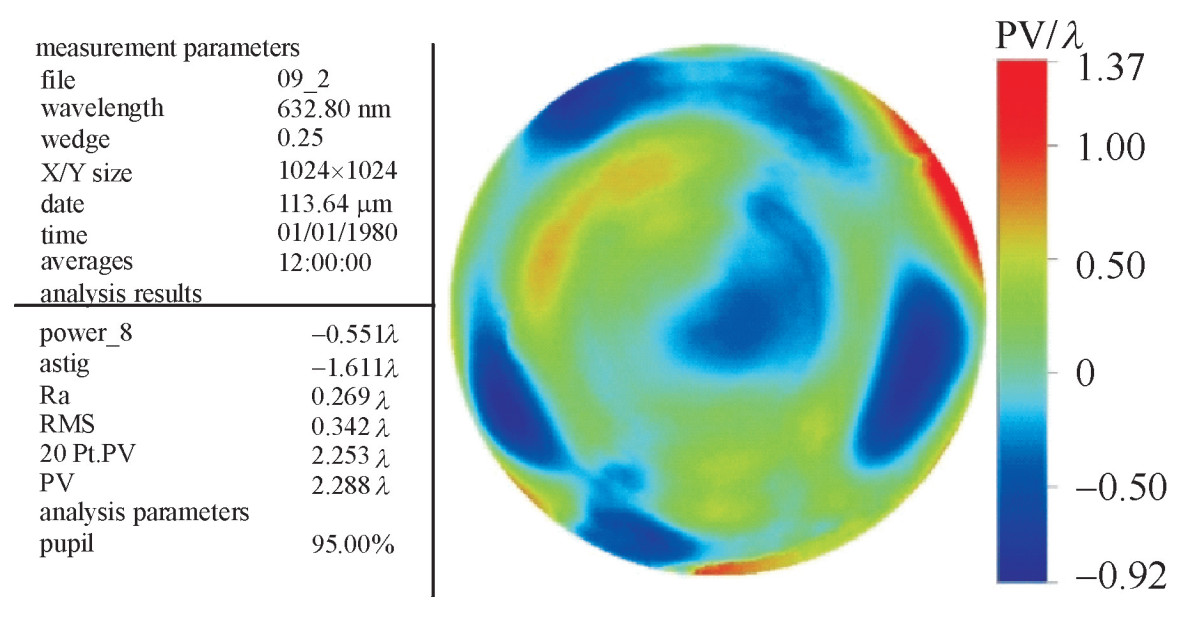

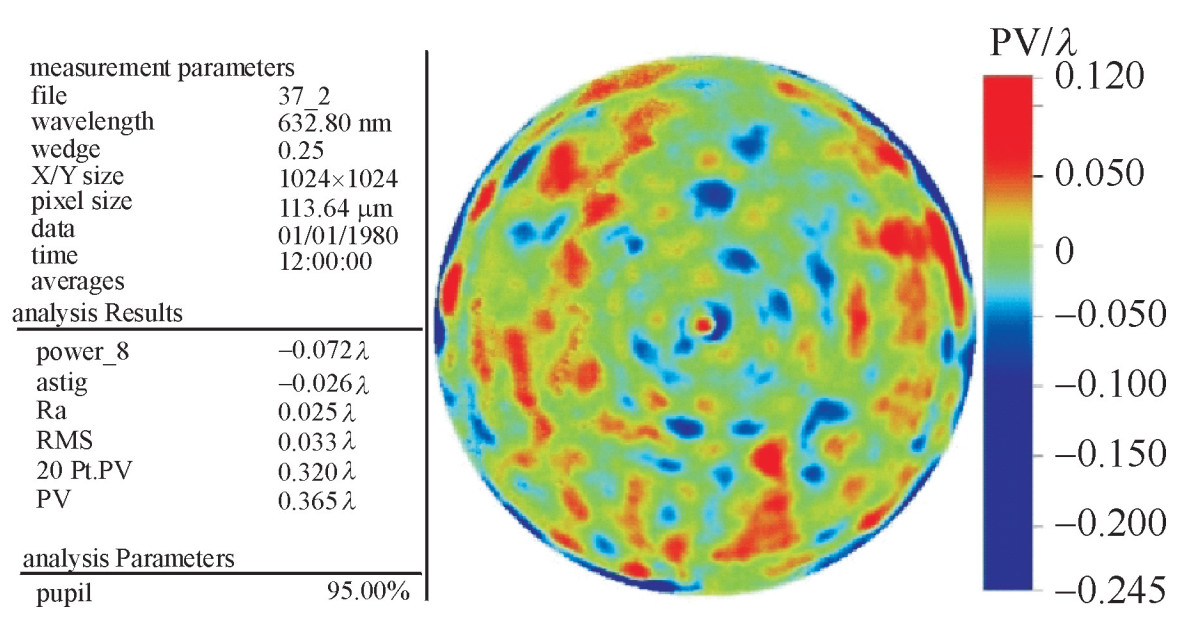

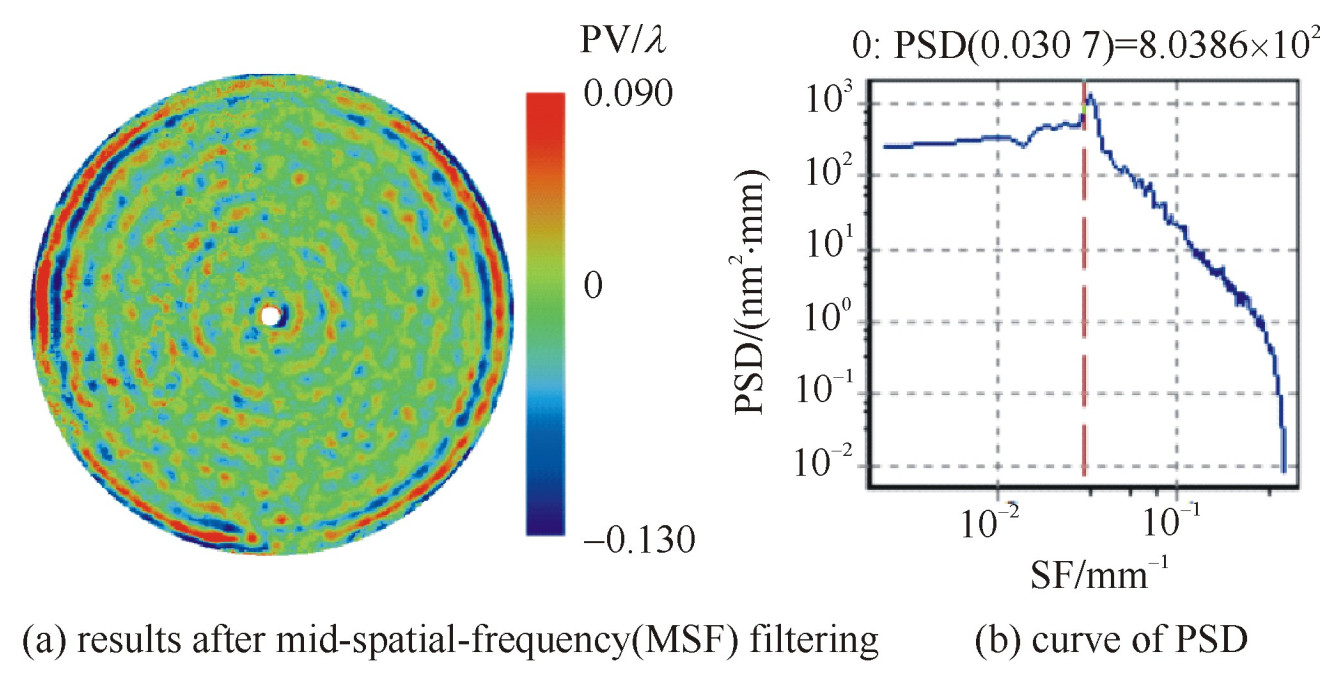

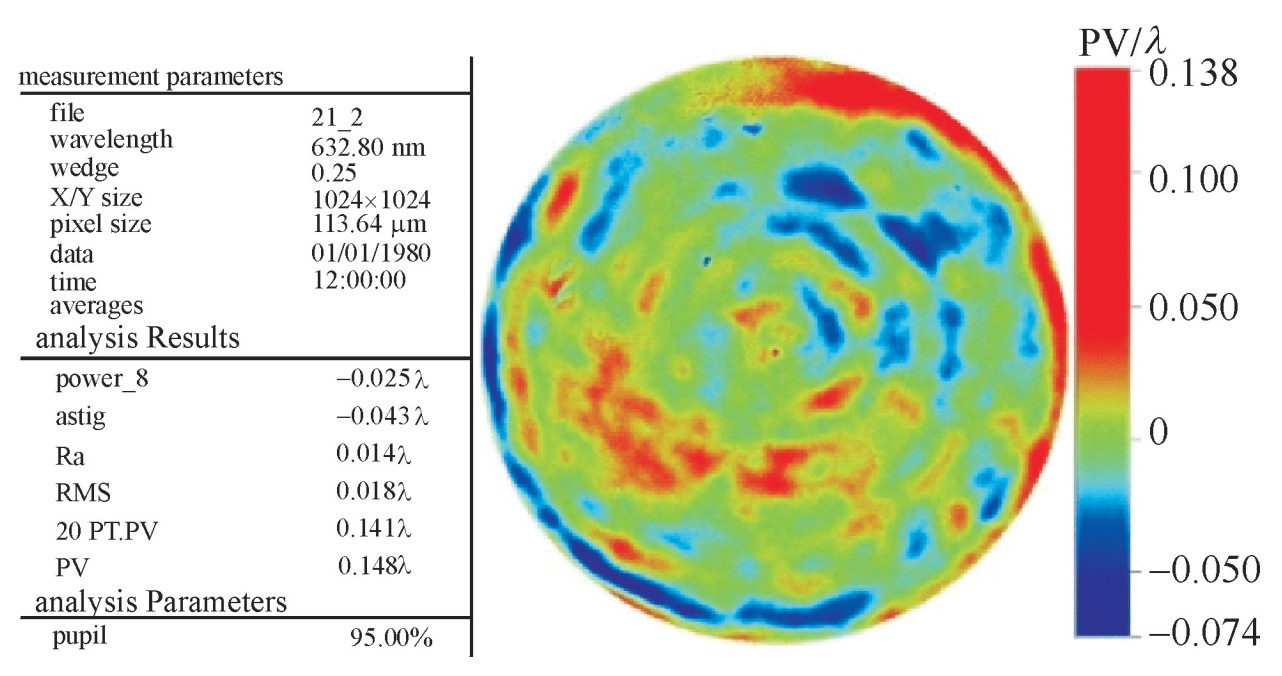

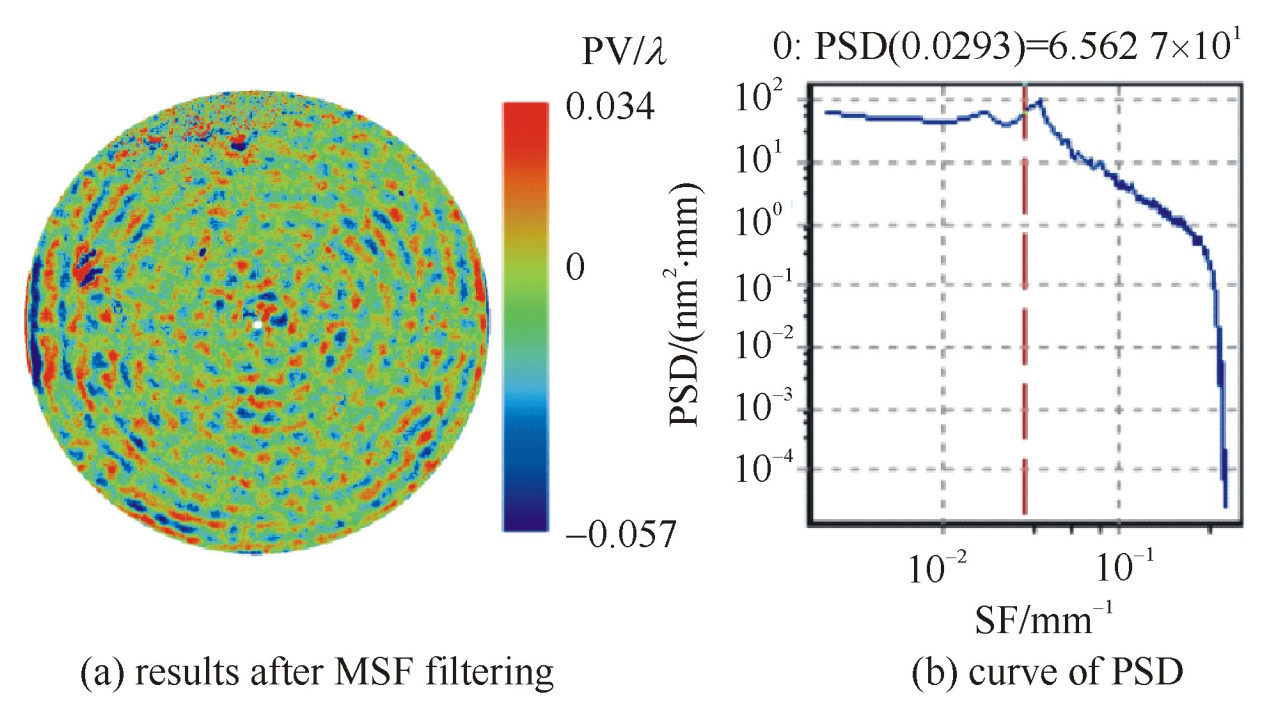

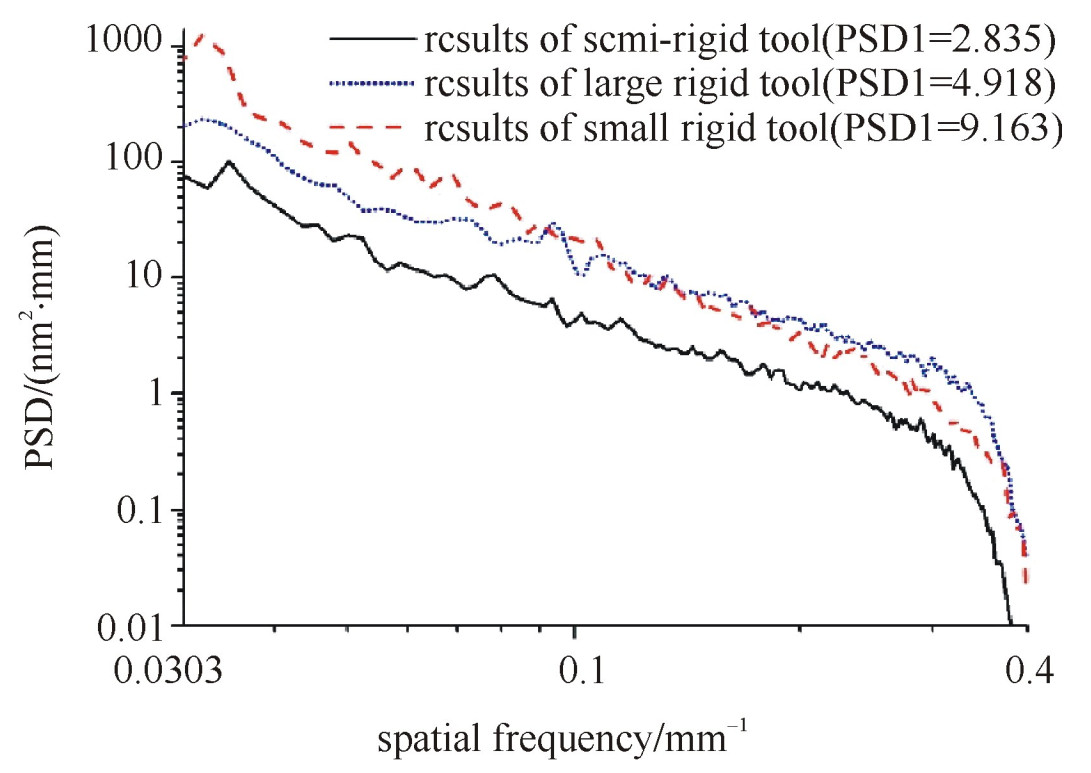

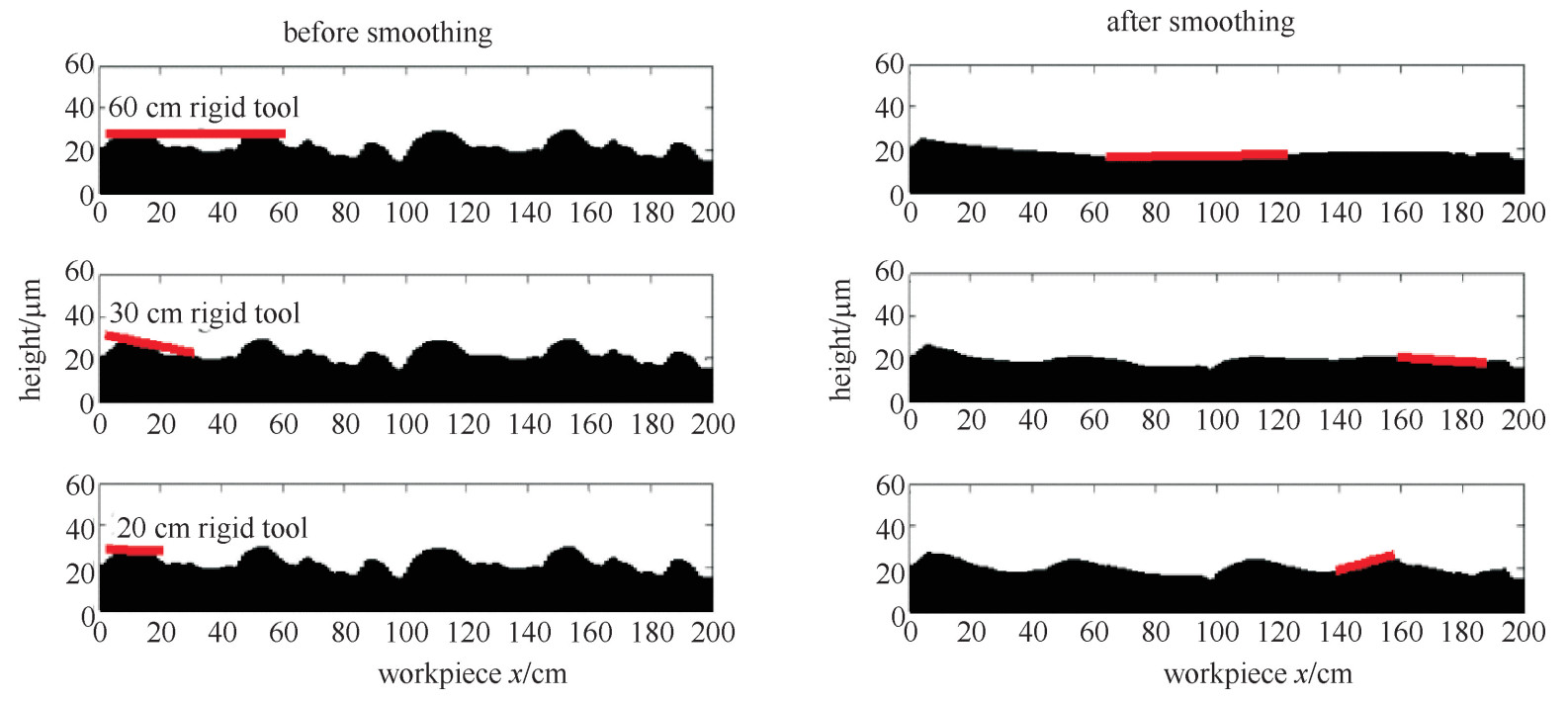

摘要: 大口径非球面光学元件的面形中频误差对光路中的光斑扩散函数精度以及高能激光的能量散射有着直接的影响,针对该问题,提出一种计算机控制的多磨头组合抛光技术,用于对非球面元件中频误差的有效控制。对半刚性抛光盘抛光过程进行了力学有限元分析,并基于Bridging模型对半刚性抛光盘抛光过程进行了理论模拟,对其贴合特性进行了研究分析。实验结果表明:采用多磨头组合抛光的技术能够有效改善大尺寸非球面元件的面形中频误差,加工的两件ϕ460 mm离轴抛物面元件面形PSD1值相对于之前降低了近70%,达到2.835 nm,并且PV小于0.16λ(632.8 nm),RMS小于0.02λ。Abstract: The mid-spatial-frequency error (MSFR) of large aperture aspherical optical elements have a direct influence on the precision of the beam diffusion function and the energy scattering of the high energy laser. To solve this problem, we put forward a kind of multi-tool NC polishing technology of computer controlled optical surfacing(CCOS) for effective suppression of MSFR. The polishing process of semi-rigid polishing tool is analyzed by finite element methods, and the polishing process is theoretically simulated based on Bridging model. The experimental results show that the MSFR of large aperture aspherical optical elements can be effectively reduced by multi-tool polishing technology. The wavefront PSD1 value of specific spatial frequency has been restrained effectively. For the two finished ϕ460 mm elements, the wavefront PSD1 value has a 70% descend down to 2.835 nm. Besides, the PV value is less than 0.16λ(632.8 nm) and the RMS value is less than 0.02λ.

-

表 1 四件实验样件抛光后各指标值对比

Table 1. Indices of four test samples after polishing

sample number polishing procedures PV/λ RMS/λ PSD1/nm total time/h before polishing after polishing before polishing after polishing ϕ110-1 large RT(rigid tool)→small RT→large RT 2.897 0.163 0.388 0.019 6.816 21 ϕ110-2 large RT→small RT→semi-rigid tool 3.026 0.172 0.394 0.019 4.236 20 ϕ110-3 large RT→small RT→semi-rigid tool→large RT 2.725 0.176 0.367 0.020 5.102 24 ϕ110-4 large RT→small RT→large RT→semi-rigid tool 2.788 0.157 0.370 0.018 3.245 18 -

[1] Malacara D. Optical shop testing[M]. New York: Wiley, 1992. [2] Roger B Huxford. Wide FOV head mounted display using hybrid optics[C]//Proc of SPIE. 2004, 5249: 230-237. [3] Zhang X J. Manufacturing of a three mirror anastigmat telescope[C]//Proc of SPIE. 2003, 4829: 884-885. [4] Jones R A. Computer-controlled optical surfacing with orbital tool motion[C]//Proc of SPIE. 1985, 540: 41-48. [5] Pollicove H M, Fess E M, Schoen J M. Deterministic manufacturing processes for precision optical surfaces[J]//Proc of SPIE. 2003, 5078: 90-96. [6] Tinker F, Xin K. Fabrication of SiC aspheric mirrors with low mid-spatial error[C]. Proc of SPIE. 2013: 88370M. [7] Harvey J E, Kotha A. Scattering effects from residual optical fabrication errors[C]//Proc of SPIE. 1995, 2576: 155-174. [8] Aikens D M. Origin and evolution of the optics specifications for the National Ignition Facility[C]//Proc of SPIE. 1995, 2536: 2-12. [9] Martin H M, Cuerdun B, Dettmann L R, et al. Active optics and force optimization for the first 8.4 m LBT mirror[C]//Proc of SPIE. 2004, 5489: 826-837. [10] Kurz P, Antoni M, Dinger U. Optics for EUV lithography[C]//International Microprocesses & Nanotechnology Conference. 2010: 264. [11] Kim D W, Park W H, An H K, et al. Parametric smoothing model for visco-elastic polishing tools[J]. Opt Express, 2010, 18(21): 22515-22526. [12] Mehta P K, Reid P B. A mathematical model for optical smoothing prediction of high-spatial frequency surface errors[C]//Proc of SPIE. 1999, 3786: 447-459. -

下载:

下载: