Activation calculation and analysis for rotary target chamber irradiated by D-T neutron

-

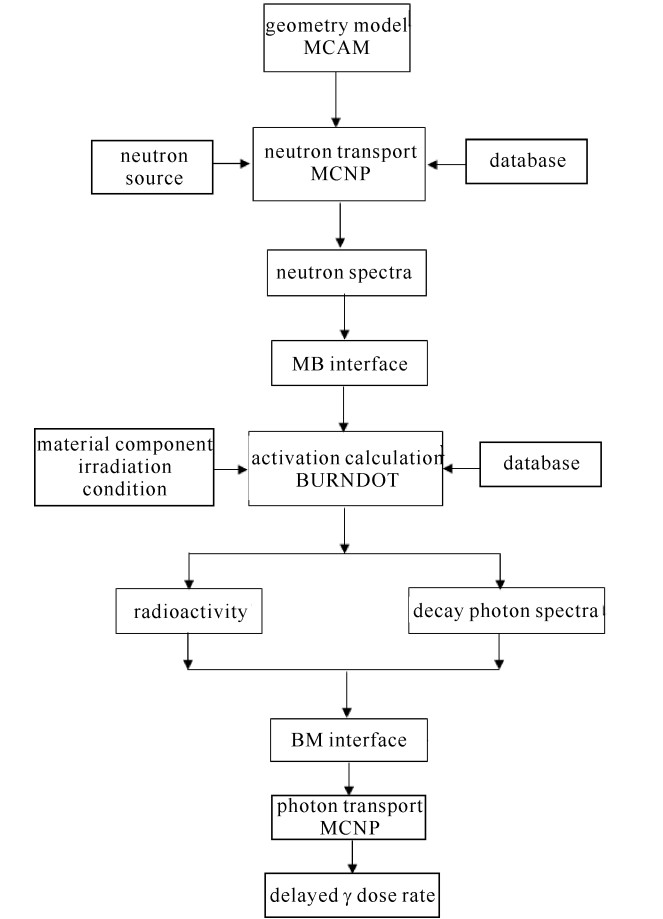

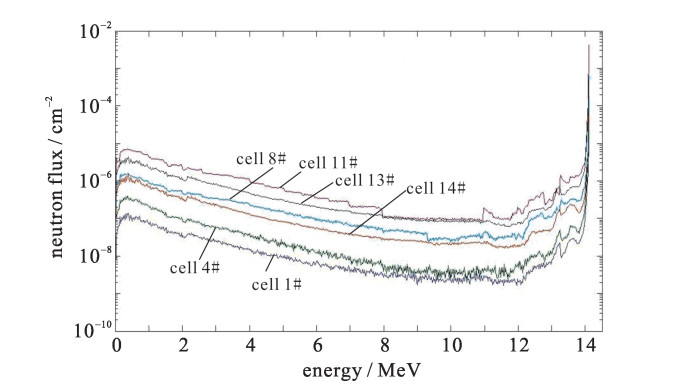

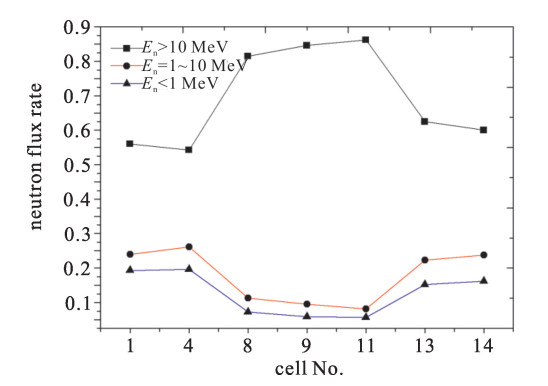

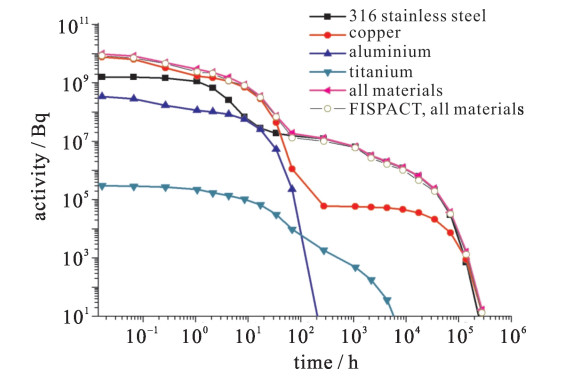

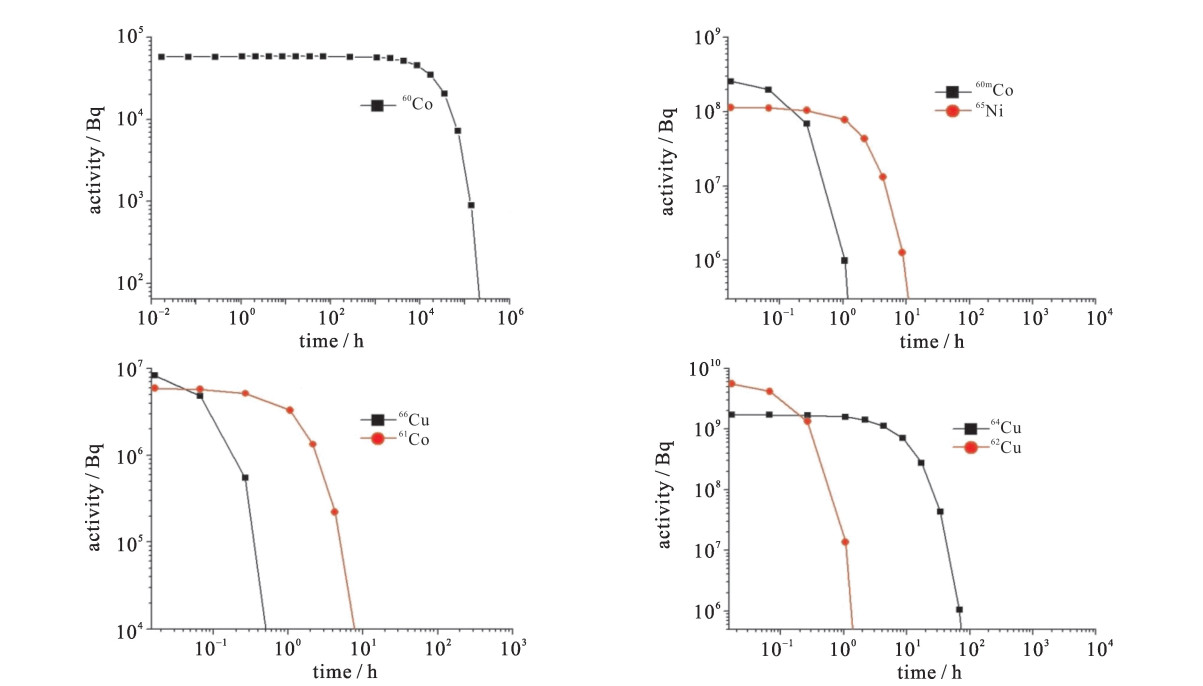

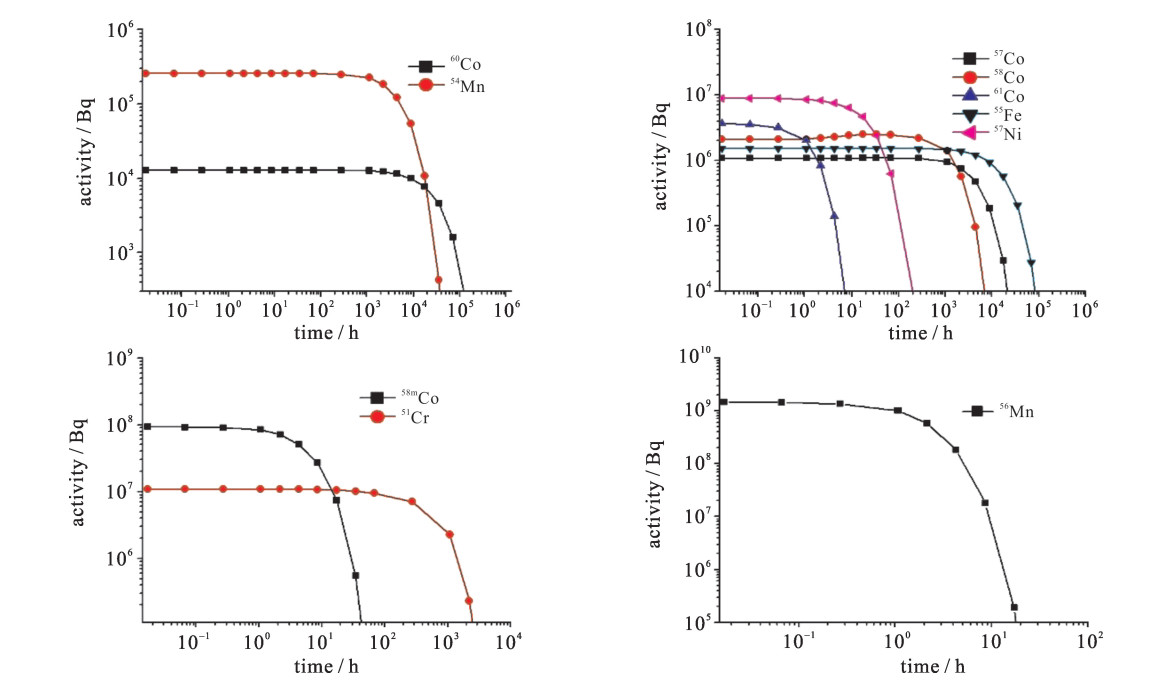

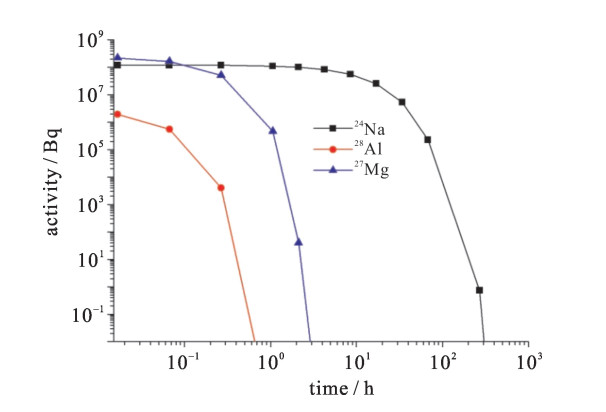

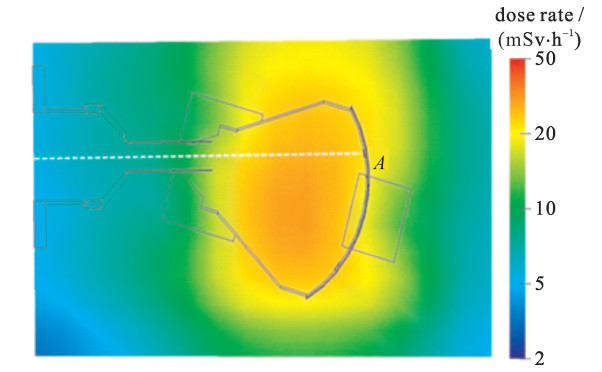

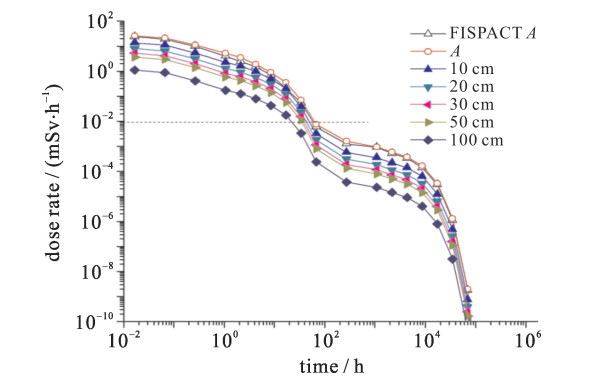

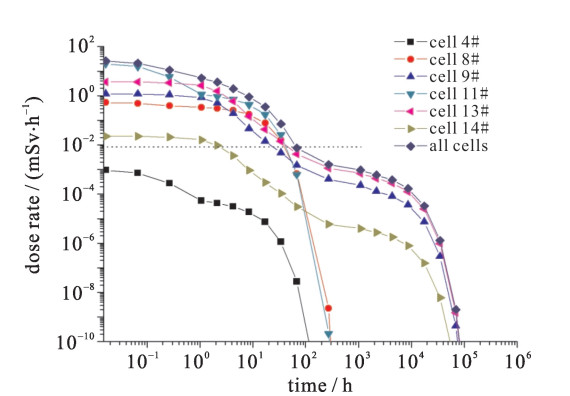

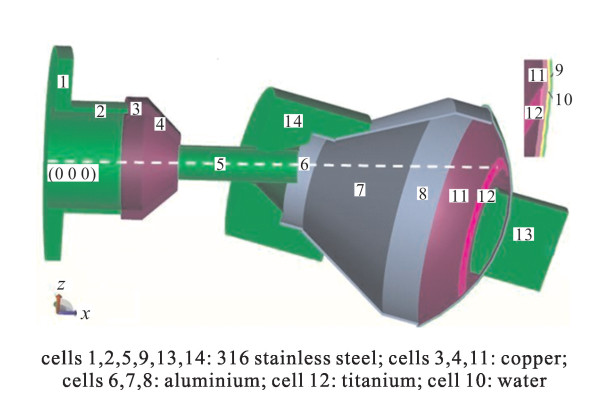

摘要: 为实现14 MeV D-T中子源旋转靶活化特性计算与分析,首次采用一种新的技术途径,将自主研发的活化程序BURNDOT与蒙特卡罗自动建模系统MCAM、蒙特卡罗粒子输运程序MCNP相结合,通过中子输运、材料活化、光子输运模拟计算的耦合,考察了材质、栅元、主要活化核素对靶室活化特性的影响。结果表明,约以辐照后68 h为界,材料铜、316不锈钢先后作为旋转靶室活度的主要贡献者,前者其产生的缓发γ剂量因62Cu, 64Cu核素的存在而达到活化剂量最大值,后者因有长半衰期核素55Fe, 57Co, 54Mn等的存在,但其产生的剂量率值低于安全限值10 μSv/h。采用新方法的计算结果与采用欧洲活化程序FISPACT-2007的计算结果符合较好。Abstract: To realize the calculation and analysis for the neutron activation character of the 14 MeV D-T rotary target chamber, a new approach coupling the self-developed activation code BURNDOT with the Monte Carlo particle transport calculation code MCNP and the MCNP Automatic Modeling (MCAM) was developed, which integrates the functions of neutron transport, activation of materials and decay gamma transport.The influence of the factors including materials, cells and main activated nuclides on activation character of rotary target chamber at different time after the irradiation was analyzed in detail.The results show that the time about 68 hafter neutron radiation acts as a boundary, before it the copper material is the major contributor for activity instead of the 316 stainless steel after it.For the former, the delayedγdose rate up to maximum is due to 62 Cu and 64 Cu, and for the latter, the delayedγdose rate is influenced by the long life-time nuclides such as 55 Fe, 57 Co and 54 Mn and it is under the level of 10μSv/h.In addition, the results were compared with the data of the European activation code FISPACT-2007.

-

Key words:

- BURNDOT /

- rotary target chamber /

- radioactivity /

- radioactive nuclide /

- dose rate

-

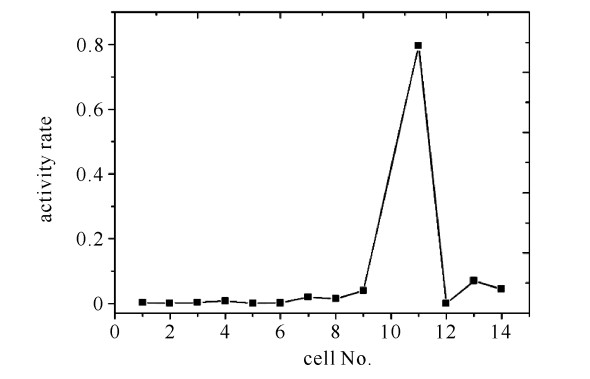

表 1 旋转靶室栅元结构参数

Table 1. Structure parameters of cells consisting the rotary target chamber

cell No. material volume/cm3 mass/g function 1 316 stainless steel 401.730 3 166.20 activation 2 316 stainless steel 90.714 714.94 activation 3 pure copper 69.115 619.27 activation 4 pure copper 90.085 807.16 activation 5 316 stainless steel 11.819 93.15 activation 6 pure aluminum 18.148 49.00 activation 7 pure aluminum 147.800 399.06 activation 8 pure aluminum 64.280 173.56 activation 9 316 stainless steel 48.119 379.24 activation 10 water 16.840 16.84 cooling 11 pure copper 89.892 805.43 activation 12 pure titanium 0.204 0.92 activation 13 316 stainless steel 382.910 3 017.80 activation 14 316 stainless steel 1 146.400 9 035.20 activation -

[1] 李德平, 潘自强. 辐射防护手册[M]. 北京: 原子能出版社, 1987.Li Deping, Pan Ziqiang. Radiation protection manual. Beijing: Atomic Energy Press, 1987 [2] Shypailo R J. Stability evaluation and correction of a pulsed neutron generator prompt gamma activation analysis system[J]. J Radioanal Nucl Chem, 2016, 307: 1781-1786. doi: 10.1007/s10967-015-4440-7 [3] Vuolo M, Bonifetto R, Dulla S, et al. Evaluation of the neutron activation of JET in-vessel components following DT irradiation[J]. Fusion Engineering and Design, 2014, 89: 2071-2075. doi: 10.1016/j.fusengdes.2014.02.050 [4] Forrest R A. FISPACT-2007: User manual[R]. UKAEA FUS 534, 2007. [5] Croff A G. User's manual for Origen2 computer code[R]. ORNL/TM-7175, 1980. [6] Liu Xiaoping, Luo Yuetong, Tong Lili, et al. Development and application of MCNP auto-modeling tool: Mcam 3.0[J]. Fusion Engineering and Design, 2005, 75/79: 1275-1279. doi: 10.1016/j.fusengdes.2005.06.236 [7] Briesmeister J F. MCNP―A general Monte Carlo N-particle transport code[R]. LA-370-M, 2000. [8] Rodenas J. Application of the Monte Carlo method to estimate doses due to neutron activation of different materials in a nuclear reactor[J]. Radiation Physics and Chemistry, 2017, 140: 442-446. doi: 10.1016/j.radphyschem.2017.02.015 [9] Rodenas J, Gallardo S, Weirich F, et al. Application of dosimetry measurements to analyze the neutron activation of a stainless steel sample in a training nuclear reactor[J]. Radiat Phys Chem, 2014, 104: 368-371. doi: 10.1016/j.radphyschem.2014.05.013 [10] Rodenas J, Abarca A, Gallardo S. Analysis of dose rates received around the storage pool for irradiated control rods in a BWR nuclear power plant[J]. Applied Radiation and Isotopes, 2011, 69: 1104-1107. doi: 10.1016/j.apradiso.2010.10.019 -

下载:

下载: