Structure design and optimization of a dump beam window

-

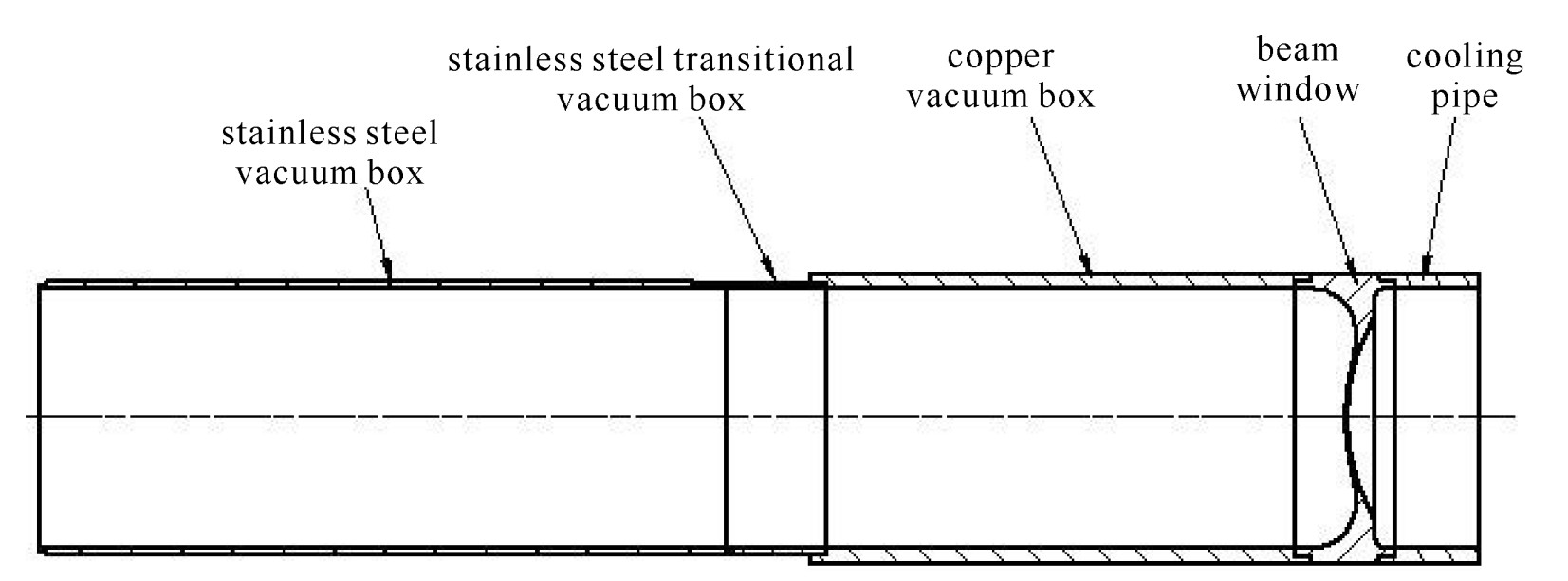

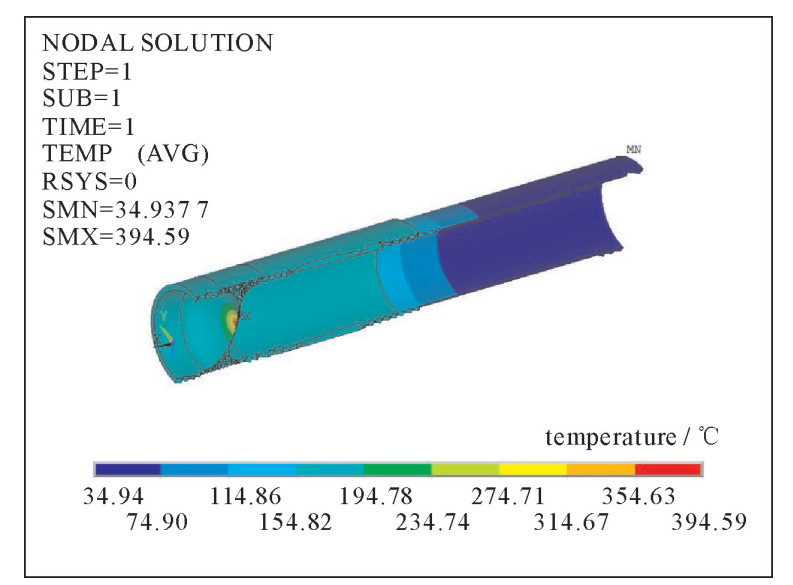

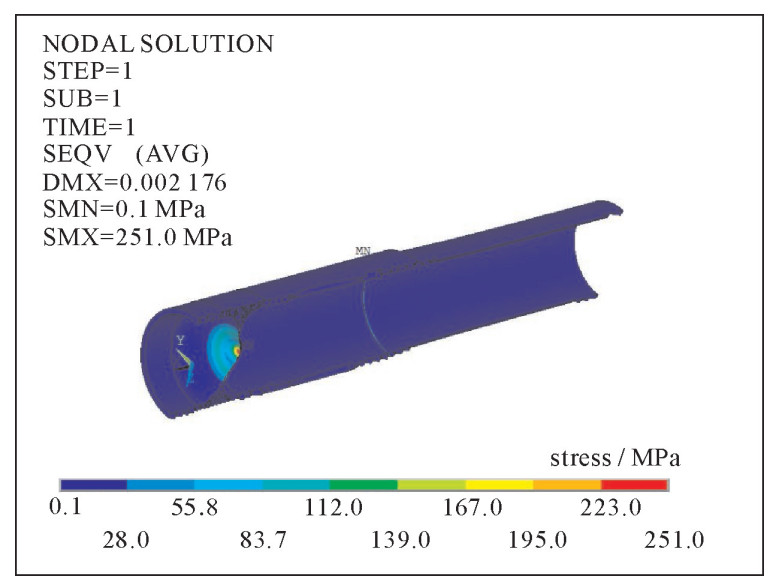

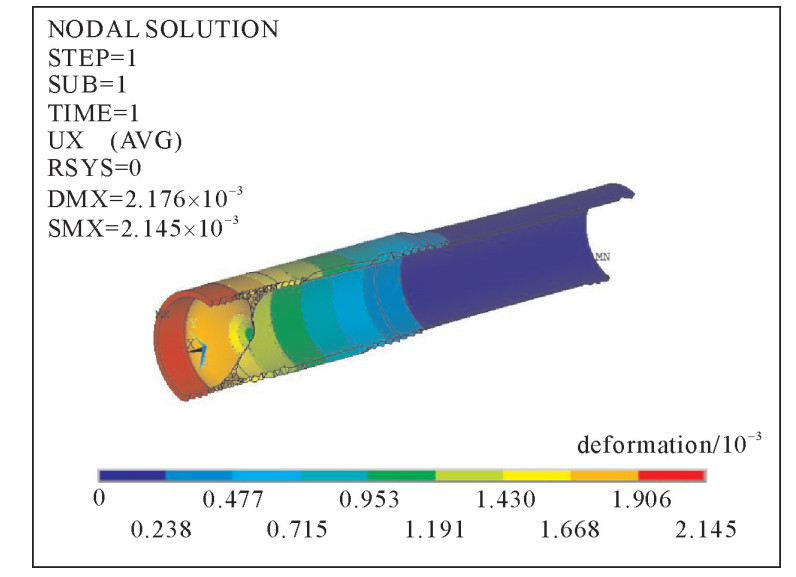

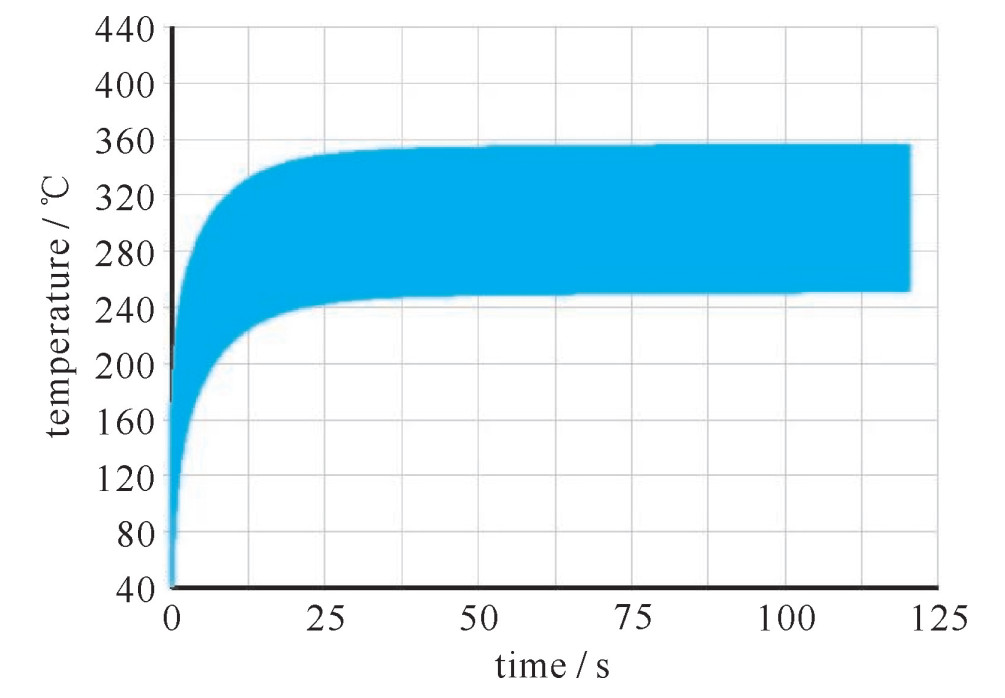

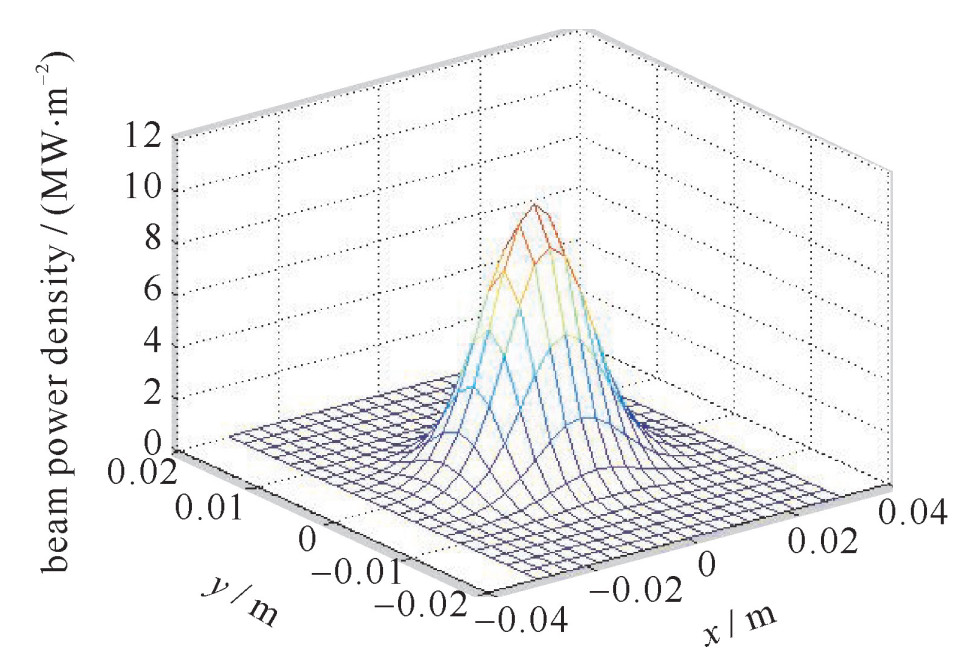

摘要: 废束站束窗是废束站的重要部件。利用束流的束斑尺寸及功率确定束窗能量的高斯分布方式;通过蒙特卡罗方法计算束窗的沉积能量。利用ANSYS稳态分析确定束窗的材料、截面形状和厚度。通过计算比较束窗在不同材料、截面形状和厚度条件下的温度、应力和变形,得出合适的束窗材料、截面形状和厚度,从而确定束窗的最终结构。最后利用瞬态方法模拟束窗调束时的温度分布情况。Abstract: Dump beam window is an important part of the dump. The Gaussian distribution of energy was decided by the beam size and power. The energy deposition was calculated by the Monte Carlo method. The thermal steady-state analysis of ANSYS was applied to decide the material, section shape and thickness of the dump beam window. The temperature, stress and deformation with different materials, section shapes and thickness were analyzed and compared to get the suitable material, section shape and thickness for the dump beam window. The final structure of the dump beam window was decided accordingly and the temperature of the window was simulated by the transient analysis of ANSYS.

-

表 1 废束站INDUMP束流参数

Table 1. Beam parameters of INDUMP

beam power/kW beam energy/MeV beam size/mm pulse width/ms frequency/Hz 2.0 80 (x: 51, y: 22) 0.4 25 表 2 几种束窗材料能量损失

Table 2. Energy loss of the materials for the dump window

material energy loss Q/W Inconel718 513.94 Glidcop® AL-15 552.87 316L 482.42 Ti-6Al-4V 278.62 A5083 181.78 表 3 几种束窗材料的最高温度、最大应力和变形

Table 3. The highest temperature, stress and deformation for the alternative materials of the beam window

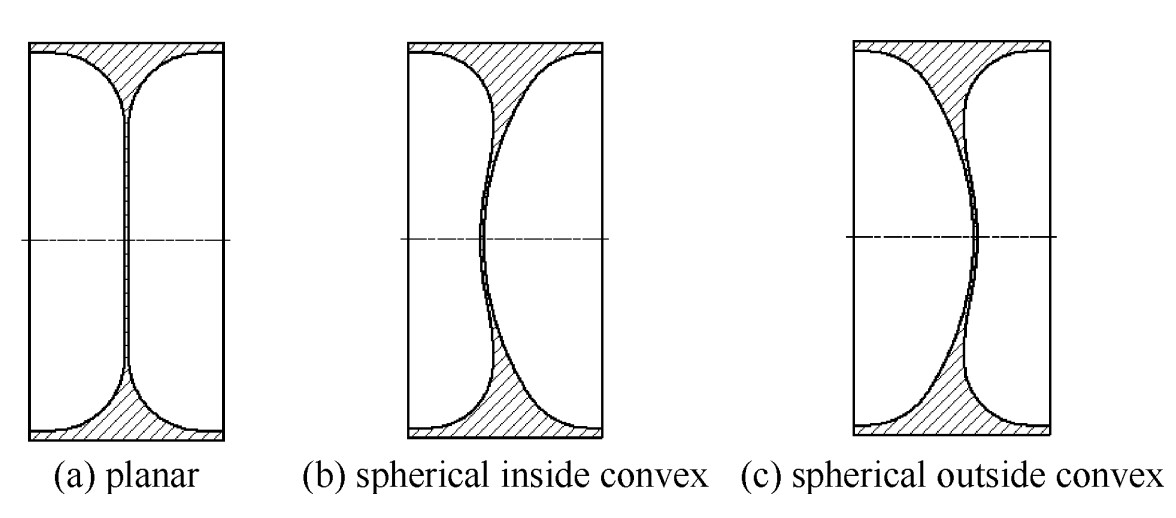

material highest temperature/℃ highest stress/MPa deformation in the center/mm melting point/℃ yield limit/MPa Inconel718 6995 - - 1260-1336 1100 Glidcop® AL-15 766 301 1.35 1082 255-300 316L 4824 - - 1370-1400 290 Ti-6Al-4V 6086 - - 1604-1660 880 A5083 431 200 1.62 590.6-638 190 表 4 三种截面束窗的最高温度、最大应力和变形

Table 4. The highest temperature, stress and deformation for the three alternative section shapes of the INDUMP beam window

section shape highest temperature/℃ highest stress/MPa deformation in the center/mm spherical inside convex 769 301 1.35 spherical outside convex 766 311 3.30 planar 788 385 2.00 表 5 束窗不同厚度的能量损失及温度受力情况

Table 5. Energy loss, temperature and stress status for different thickness of the INDUMP beam window

window thickness/mm energy loss/W highest temperature/℃ highest stress/MPa deformation in the center/mm 1.0 200.85 294 166 0.11 1.5 309.21 343 208 0.34 2.0 423.25 394 251 0.95 2.5 546.94 450 290 1.55 3.0 692.44 519 336 1.92 -

[1] 田佳甲. C-ADS中的质子束窗的物理设计研究[D]. 合肥: 中国科学技术大学, 2012, 5: 32-38.Tian Jiajia. Physical design and research for the proton beam window of C-ADS. Hefei: University of Science and Technology of China, 2012, 5: 32-38 [2] Meng Cai, Tang Jingyu, Jing Hantao, et al. Scattering effect in proton beam windows at spallation targets[J]. High Power Laser and Particle Beams, 2011, 23(10): 2773-2780 doi: 10.3788/HPLPB20112310.2773 [3] Wang Haijing, Liu Weibin, Qu Huamin, et al. Thermal analysis and optimization of proton beam window for the CSNS[J]. Chinese Physics C, 2013, 37(7): 1-6. [4] 陈和生, 韦杰, 奚基伟, 等. 散裂中子源项目建议书[R]. 2007, 6: 101-103.Chen Hesheng, Wei Jie, Xi Jiwei, et al. Proposals for the project of Chinese spallation neutron source. 2007, 6: 101-103 [5] 庞成果, 苏有武, 徐俊奎, 等. 强流重离子加速器中由于质子束流损失引起的次级辐射场计算研究[J]. 原子能科学技术, 2015, 49(sl): 573-577. https://www.cnki.com.cn/Article/CJFDTOTAL-YZJS2015S2020.htmPang Chengguo, Su Youwu, Xu Junkui, et al. Calculation and research on the secondary radiation field caused by the loss of the proton beam in the accelerator of high current heavy ion. Atomic Energy Science and Technology, 2015, 49(sl): 573-577 https://www.cnki.com.cn/Article/CJFDTOTAL-YZJS2015S2020.htm [6] 张朝晖. ANSYS 12.0热分析工程应用实战手册[M]. 北京: 中国铁道出版社, 2010, 8: 357-464.Zhang Chaohui. ANSYS 12.0 practical handbook for the engineering thermal analysis. Beijing: China Railway Press, 2010: 357-464 [7] 燕鹏, 林晨光, 崔舜, 等. 弥散强化铜合金的研究与应用现状[J]. 材料导报, 2011, 25(6): 101-106. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201111023.htmYan Peng, Lin Chenguang, Cui Shun, et al. Research and application status of the dispersion-strengthened copper alloy. Materials Review, 2011, 25(6): 101-106 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201111023.htm [8] Murdoch G, Decarlo D, Henderson S, et al. Beam dump window design for the Spallation Neutron Source[C]//Proceedings of the 2003 Particle Accelerator Conference. 2003: 1464-1469. [9] Park B S, Cho Y S. Mechanical properties of the external beam window for the PEFP[J]. Journal of the Korean Physical Society, 2009, 54(5): 1961-1965. -

下载:

下载: