Research on non-fixed ring belt double-side polishing technology

-

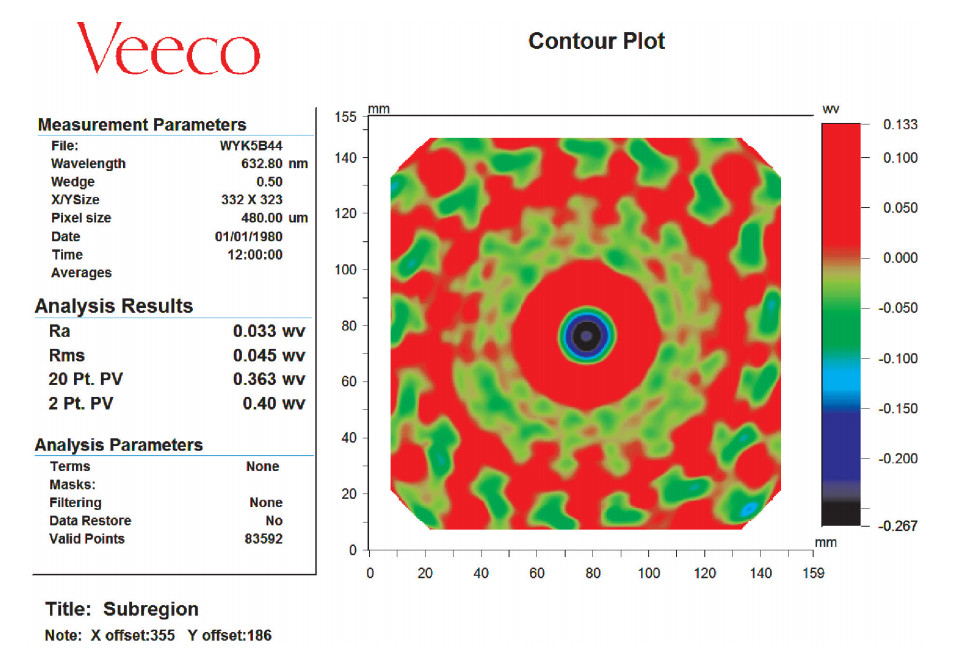

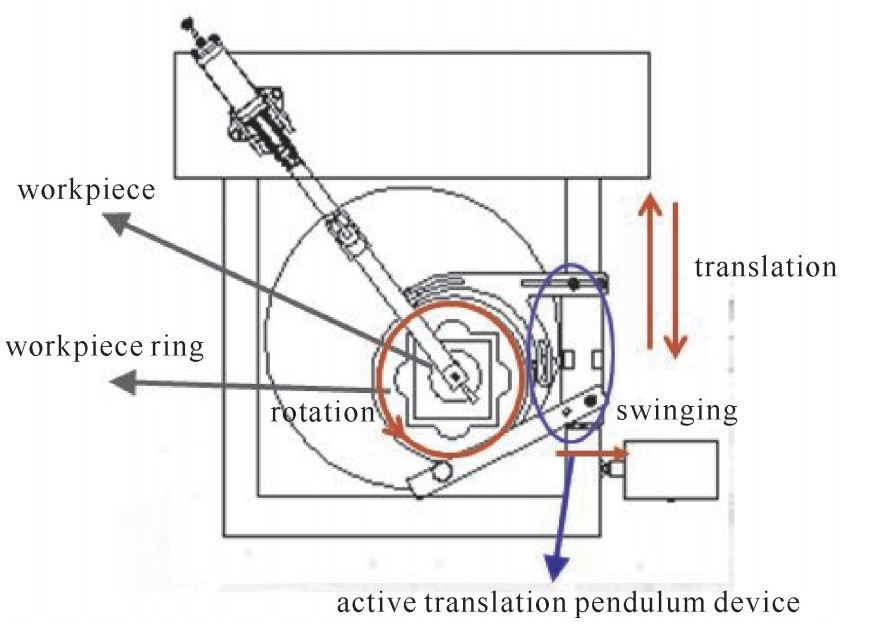

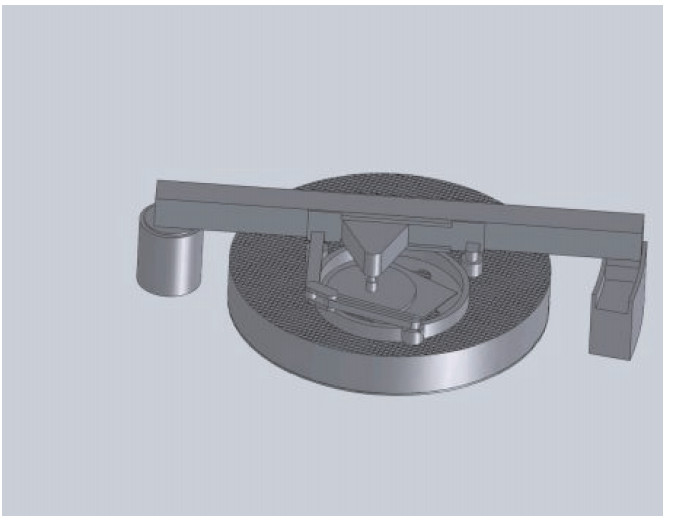

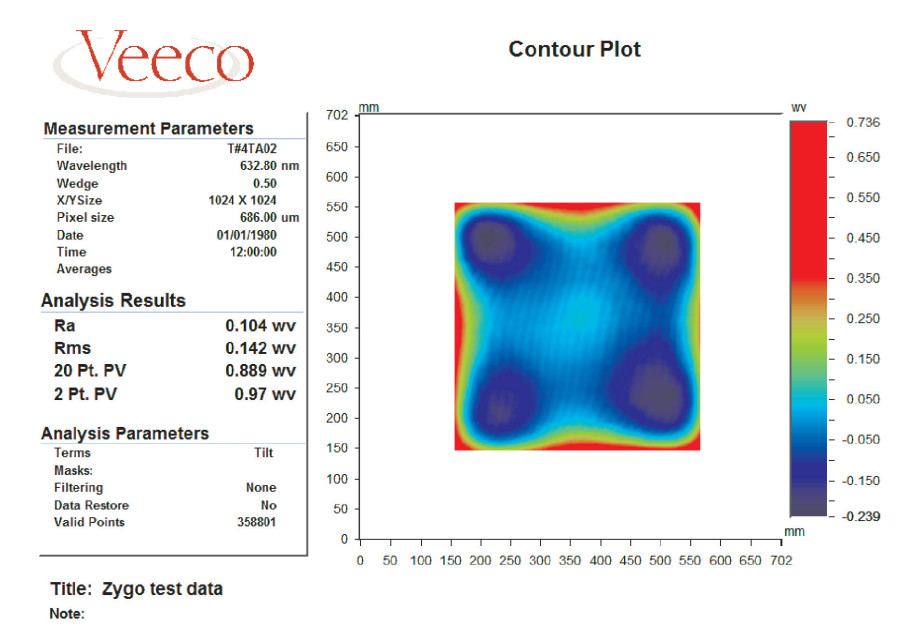

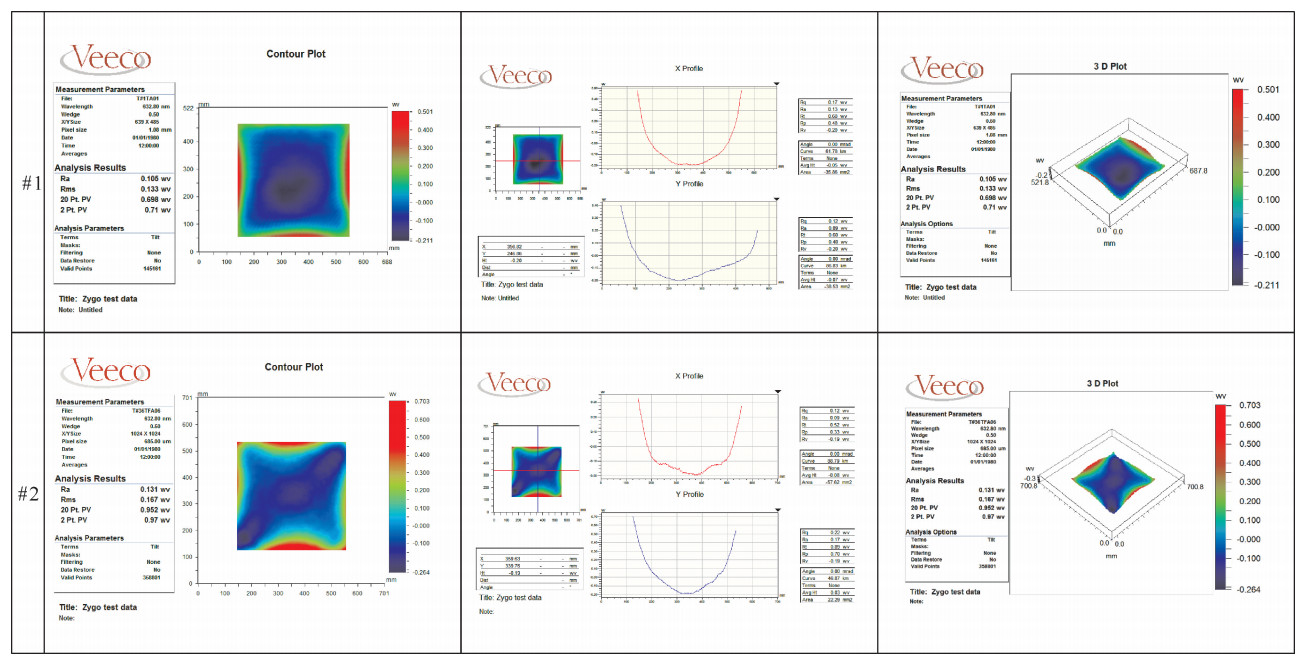

摘要: 提出了一种基于平移偏摆运动的非固定环带随机双面抛光的方法,通过设计平移偏摆装置使得工件运动方式脱离固定环带的限制,借助随机性运动进行迭代,解决了行星式双面抛光等固定环带抛光过程中产生的周期性轨迹问题;通过优化运动方式组合,在随机性运动叠加情况下实现了大口径超薄元件面形稳定收敛控制。与行星式双面抛光相比,不仅面形精度更好,而且没有明显的周期性加工痕迹。该方法可以应用到对表面激光损伤阈值有特殊要求的超薄件批量生产当中。Abstract: We have proposed a method of non-fixed ring belt random double-side polishing based on the technology of translational pendulum. A device based on translation and pendulum out of limits to fixed ring belt was designed. The iterations were carried out by random motion which solved the periodic trajectory problem in the process of fixed ring belt polishing. We developed a device coupling with double-side polishing based on active translation and pendulum. We have achieved stable control of the large-aperture ultra-thin component surface shape in the random motion superposition by optimizing the combination of movement mode. Compared with planetary double-side polishing, our method not only has better surface shape, but also has no obvious periodic processing trace. The method can be applied to batch production of ultra-thin parts with special requirements for laser damage threshold of surface.

-

表 1 非固定环带随机双面抛光模拟仿真参数设置

Table 1. Parameter setting of computer simulation of non-fixed ring belt random double-side polishing

simulation size rotation rate of bottom polishing disk/(r·min-1) rotation rate of workpiece/(r·min-1) translation cycle of workpiece/(r·min-1) swinging cycle of workpiece/(r·min-1) 430 mm×430 mm (one dot per 2.5 mm,dot array 166×166) 9 6 5 (translation stroke 200 mm) 10 (swinging stroke 200 mm) -

[1] 乔战峰, 卢兴强, 赵东峰, 等. 神光Ⅱ升级装置终端光学组件的排布设计[J]. 中国激光, 2008, 35: 1328-1332. doi: 10.3321/j.issn:0258-7025.2008.09.006Qiao Zhanfeng, Lu Xingqiang, Zhao Dongfeng, et al. Arrangement design of the final optics assembly for SG-Ⅱ upgrading laser. Chin J Laser, 2008, 35: 1328-1332 doi: 10.3321/j.issn:0258-7025.2008.09.006 [2] Peng H, Zhang X M, Wei X, et al. Status of the SG-Ⅲ solid state laser project[C]//Proc of SPIE. 1999, 3492: 25-33. [3] 蒋勇. 熔石英光学元件表面损伤修复的理论和实验研究[D]. 成都: 电子科技大学, 2012: 173-178.Jiang Yong. Theoretical and experimental study on surface damage repaire of fused silca optics. Chengdu: University of Electronic Science and Technology of China, 2012: 173-178 [4] 章春来, 刘春明, 向霞, 等. 裂纹或气泡对熔石英损伤修复坑场调制的近场模拟[J]. 物理学报, 2012, 61(12): 319-330. https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201212042.htmZhang Chunlai, Liu Chunming, Xiang Xia, et al. Near-field modulated simulation of repaired site contained crack or bubble in fused silica subsurface. Acta Physica Sinica, 2012, 61(12): 319-330 https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201212042.htm [5] Bass I L, Draggoo V G, Guss G M, et al. Mitigation of laser damage growth in fused silica NIF optics with a galvanometer scanned CO2 laser[C]//Proc of SPIE. 2006, 62612A. [6] Campbell J H, Hawley-Fedder R A, Stolz C J, et al. NIF optical materials and fabrication technologies: An overview[C]//Proc of SPIE. 2004, 5341: 84-101. [7] Preston F W. Class technology[J]. Journal of the Society of Class Technology, 1927, 11(24): 277-281. [8] Zhao Y W, Chang L A. Micro-contact and wear model for chemical mechanical polishing of silicon wafer[J]. Wear, 2002, 252(3/4): 220-226. [9] Fu G H, Chandra A, Guha S A. Plasticity-based model of material removal in chemical-mechanical polishing(CMP)[J]. IEEE Trans Semiconductor Manufacturing, 2001, 14(4): 1698-1701. [10] Runnrls S R, Eyman L M. Tribology analysis of chemical-mechanical polishing[J]. Electrochem SOC, 1994, 14(6): 69-71. https://ui.adsabs.harvard.edu/abs/1994JElS..141.1698R/abstract#:~:text=%EE%80%80Tribology%20analysis%20of%20chemical-mechanical%20polishing%EE%80%81.%20To%20better%20understand,considerable%20depending%20on%20whether%20or%20not%20the%20 -

下载:

下载: