| [1] |

刘文妍. Nd: YAG固体激光放大器的参数优化研究[D]. 长春: 长春理工大学, 2009.Liu Wenyan. Optimizing study on parameter of Nd: YAG solid[D]. Changchun: Changchun University of Technology, 2009

|

| [2] |

陶毓伽. 大功率固体激光器冷却研究[D]. 北京: 中国科学院工程热物理研究所, 2010.Tao Yujia. Study on the cooling of high-power solid-state lasers[D]. Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences, 2010

|

| [3] |

Youssef B, Rageey M. Modeling the effect of a spray on a liquid film on a heated surface[D]. Morgantown: West Virginia University, 2007.

|

| [4] |

Jungho K. Spray cooling heat transfer: The state of the art[J]. International Journal of Heat and Fluid Flow, 2006, 28(4): 753-767.

|

| [5] |

Mudawar I. Assessment of high-heat-flux thermal management schemes[J]. IEEE Transactions on Components and Packaging Technologies, 2001, 24(2): 122-141. doi: 10.1109/6144.926375

|

| [6] |

Sung M K, Mudawar I. CHF determination for high-heat flux phase change cooling system incorporating both micro-channel flow and jet impingement[J]. International Journal of Heat and Mass Transfer, 2009, 52(3/4): 610-619.

|

| [7] |

Milan V, Issam M. Theoretical and experimental study of the effects of spray inclination on two-phase spray cooling and critical heat flux[J]. International Journal of Heat and Mass Transfer, 2008, 51(9/10): 2398-2410.

|

| [8] |

Visaria M, Mudawar I. A systematic approach to predicting critical heat flux for inclined sprays[J]. Journal of Electronic Packaging, 2007, 129(4): 452-459. doi: 10.1115/1.2804095

|

| [9] |

Chen R-H, Chow L C, Navedo J E. Optimal spray characteristics in water spray cooling[J]. International Journal of Heat and Mass Transfer, 2004, 47(23): 2095-2099.

|

| [10] |

Chen R H, Chow L C, Navedo J E. Effects of spray characteristics on critical heat flux in subcooled water spray cooling[J]. International Journal of Heat and Mass Transfer, 2002, 45(19): 4033-4043. doi: 10.1016/S0017-9310(02)00113-8

|

| [11] |

程文龙, 韩丰云, 刘期聂, 等. 系统压力影响下的喷雾冷却特性及温度均匀性[J]. 化工学报, 2010, 61(12):3086-3091. (Cheng Wenlong, Han Fengyun, Liu Qinie, et al. Effect of system pressure on spray cooling heat transfer and surface temperature uniformity[J]. Journal of Chemical Industry and Engineering, 2010, 61(12): 3086-3091

|

| [12] |

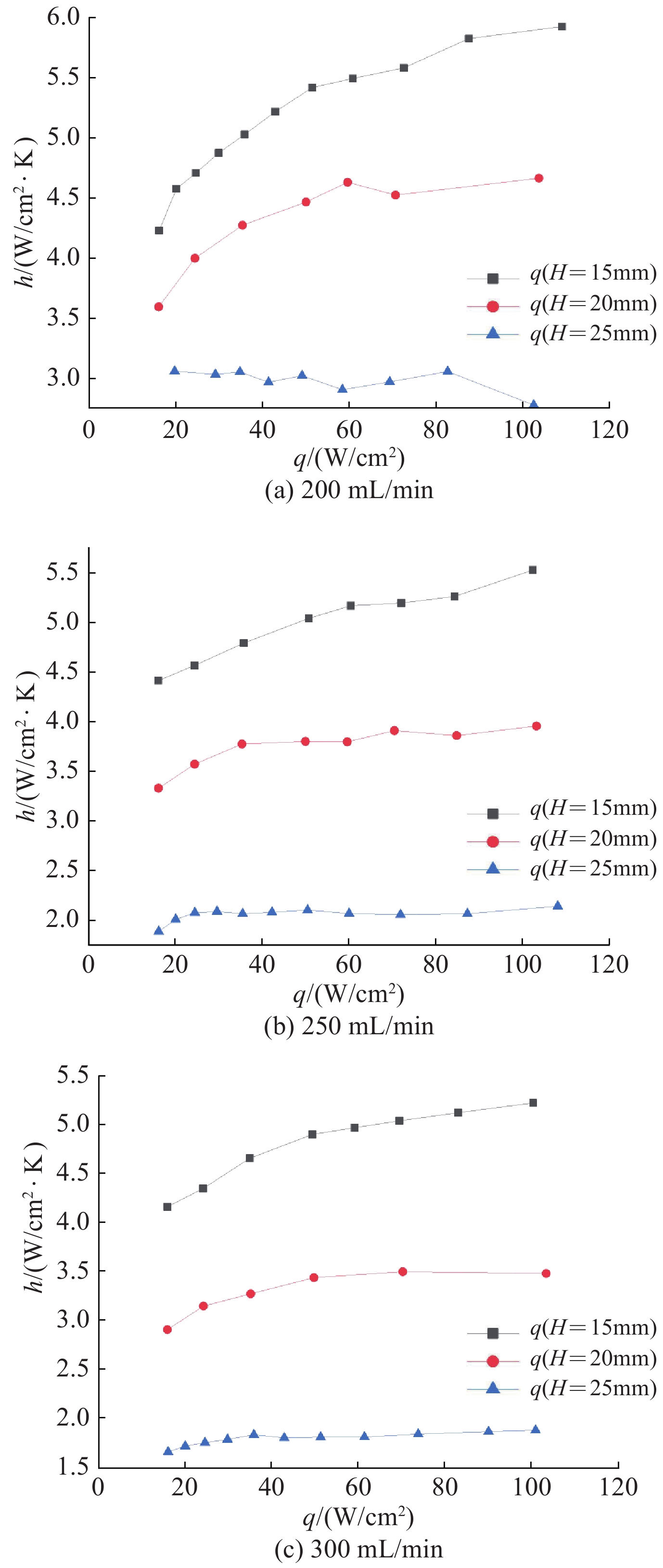

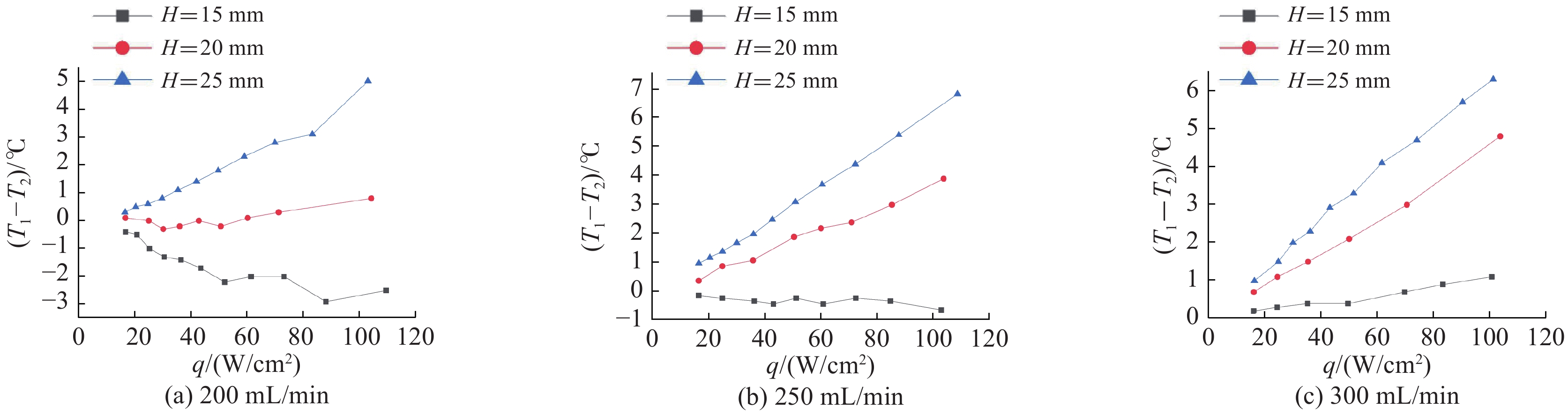

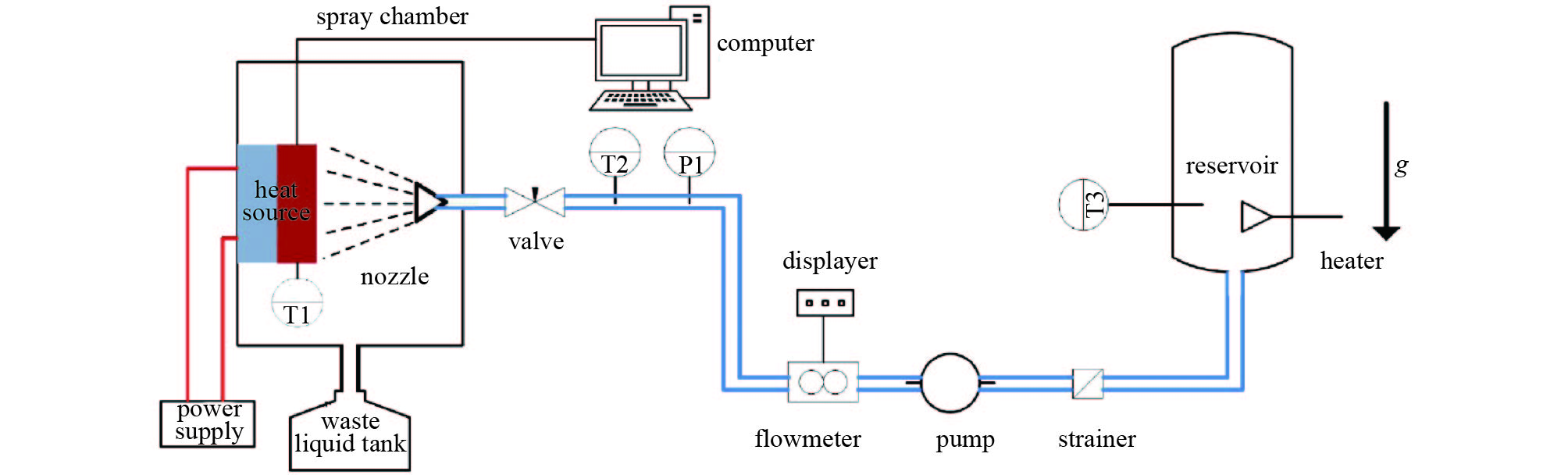

胡士松, 刘伟, 章玮玮, 等. 单相阶段板式多喷嘴阵列喷雾冷却的试验研究[J]. 流体机械, 2015, 43(7):1-5. (Hu Shisong, Liu Wei, Zhang Weiwei, et al. Experimental study on spray cooling with plate multi-nozzle array in the non-boiling regime[J]. Fluid Machinery, 2015, 43(7): 1-5 doi: 10.3969/j.issn.1005-0329.2015.07.001

|

| [13] |

王亚青, 刘明侯, 刘东, 等. 大功率激光器喷雾冷却中无沸腾区换热性能实验研究[J]. 中国激光, 2009, 36(8):1973-1978. (Wang Yaqing, Liu Minghou, Liu Dong, et al. Experiment study on non-boiling heat transfer performance in spraying cooling for high-power laser[J]. Chinese Journal of Lasers, 2009, 36(8): 1973-1978 doi: 10.3788/CJL20093608.1973

|

| [14] |

王亚青. 喷雾冷却无沸腾区换热特性研究[D]. 合肥: 中国科学技术大学, 2010.Wang Yaqing. Studying the heat transfer performance in the non-boiling regime of spray cooling[D]. Hefei: University of Science and Technology of China, 2010

|

| [15] |

王亚青, 刘明侯, 刘东. 小流量下喷雾冷却的理论及实验研究[J]. 工程热物理学报, 2010, 31(6):1027-1030. (Wang Yaqing, Liu Minghou, Liu Dong. Theoretical and experiment investigation of heat transfer performance of spray cooling under low mass flux[J]. Journal of Engineering Thermophysics, 2010, 31(6): 1027-1030

|

| [16] |

周年勇, 蒋彦龙, 王瑜. 以H2O为冷却剂的开式喷雾冷却系统实验研究[J]. 世界科技研究与发展, 2016, 38(2):286-291. (Zhou Nianyong, Jiang Yanlong, Wang Yu. Experiment and investigation on open spray cooling system with H2O[J]. World Sci-Tech R&D, 2016, 38(2): 286-291

|

| [17] |

王瑜, 蒋彦龙, 周年勇. 机载喷雾冷却换热特性关键影响因素实验研究[J]. 中国测试, 2016, 42(5):18-23. (Wang Yu, Jiang Yanlong, Zhou Nianyong. Experimental investigation on the influence of key parameters to aircraft spray cooling system[J]. China Measurement & Test, 2016, 42(5): 18-23 doi: 10.11857/j.issn.1674-5124.2016.05.004

|

| [18] |

周年勇. 机载喷雾冷却特性的实验与研究[D]. 南京: 南京航空航天大学 2016.Zhou Nianyong. Experiment and study on the performance of airborne spray cooling[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016

|

| [19] |

Jia W, Qiu H H. Experimental investigation of droplet dynamics and heat transfer in spray cooling[J]. Experimental Thermal and Fluid Science, 2003, 27(7): 829-838. doi: 10.1016/S0894-1777(03)00015-3

|

下载:

下载: