Optimization design for vibration environmental adaptability of coaxial pulse forming line

-

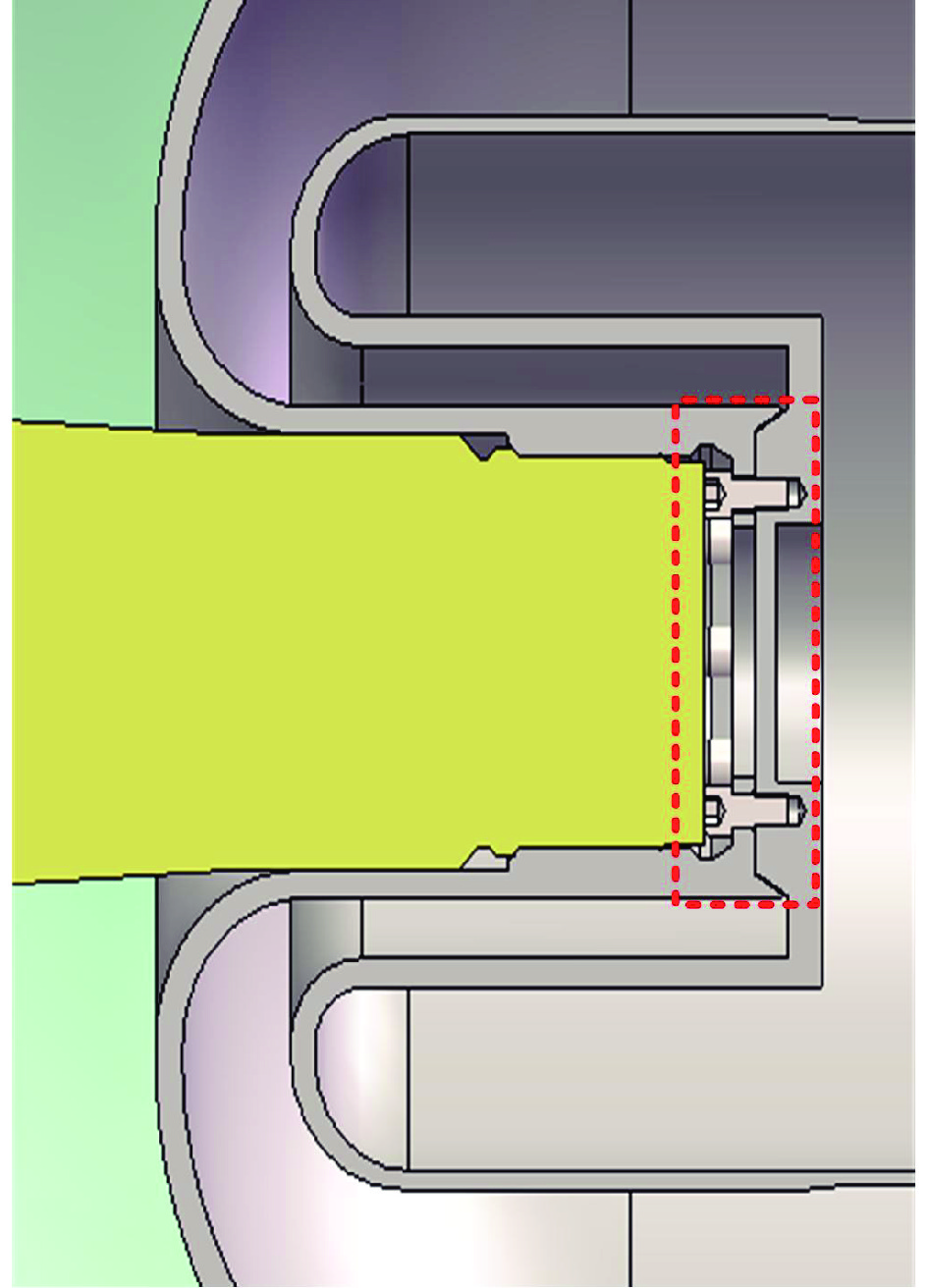

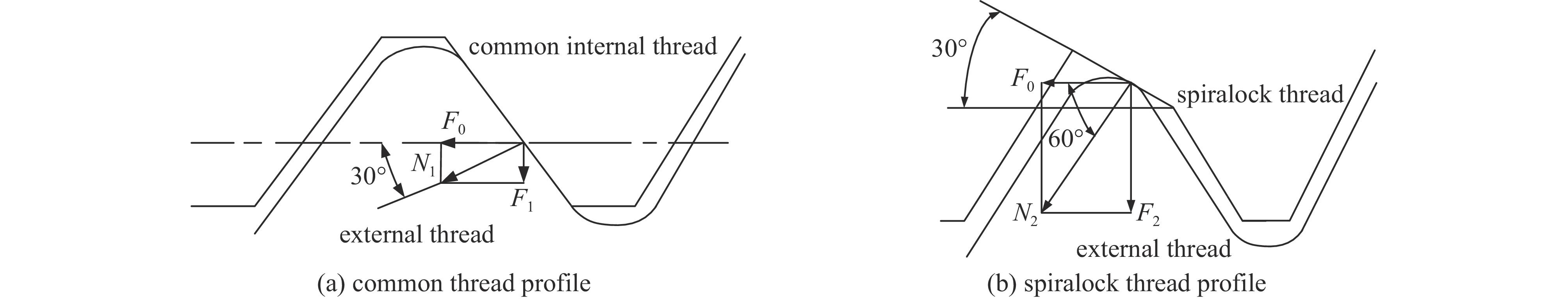

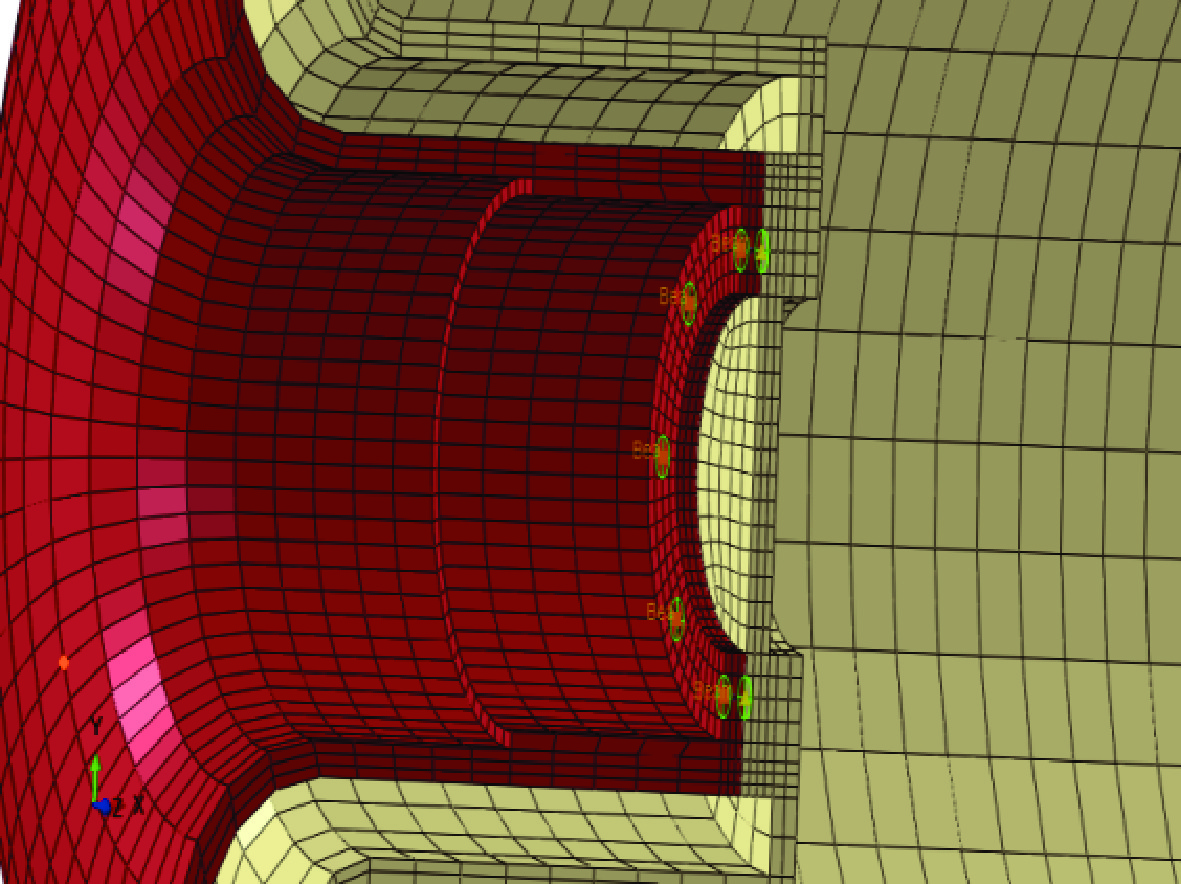

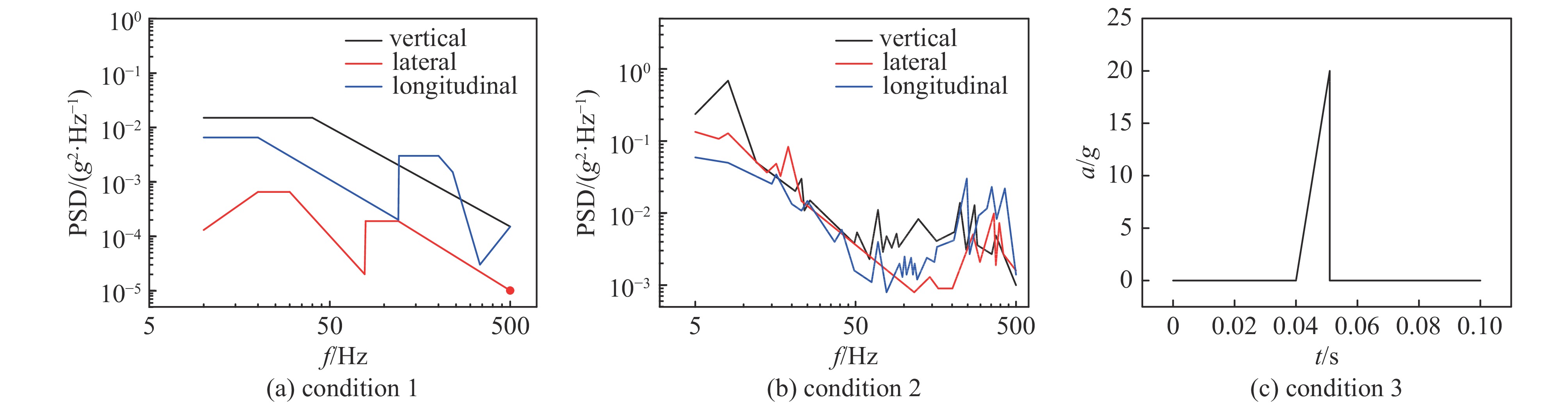

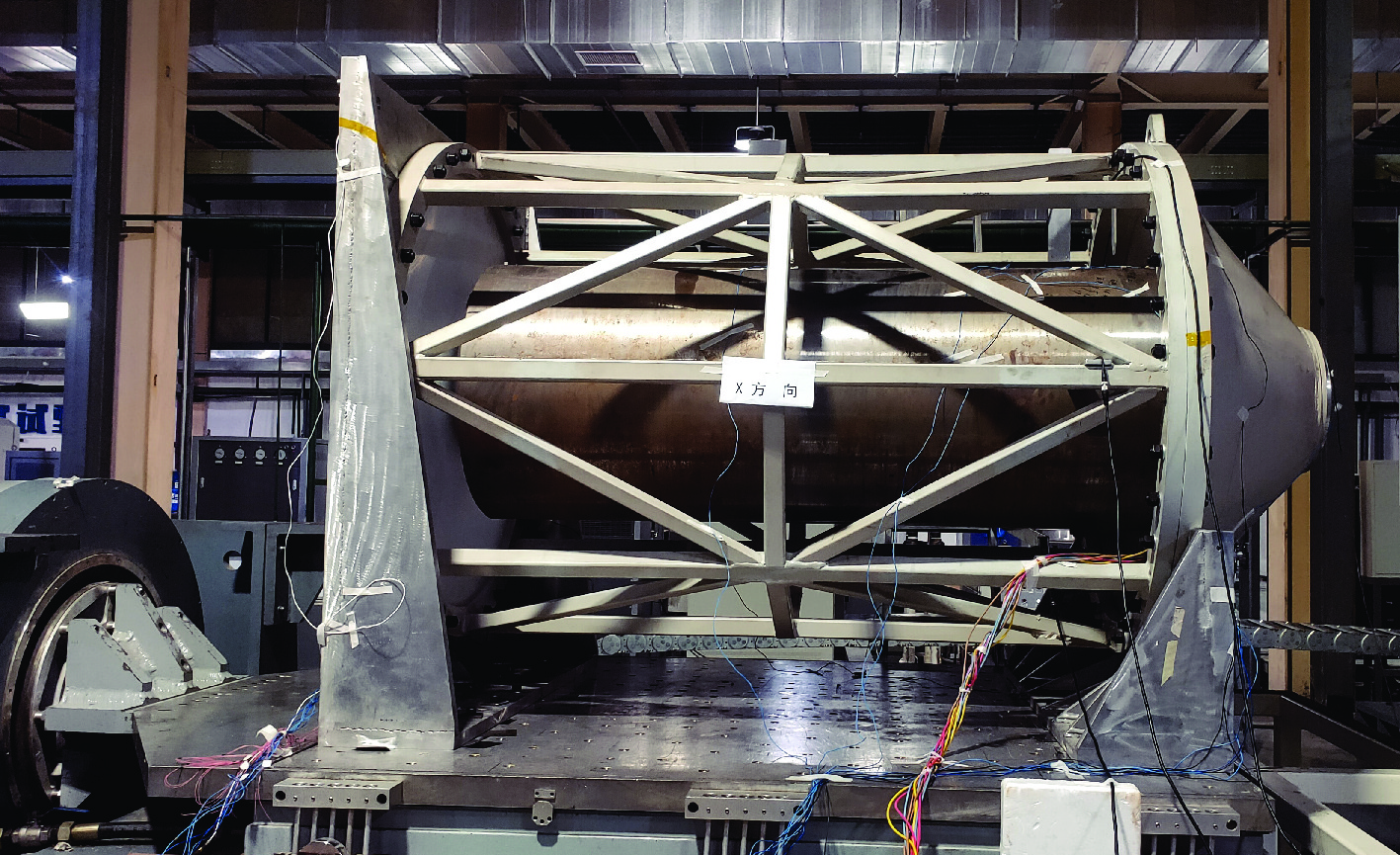

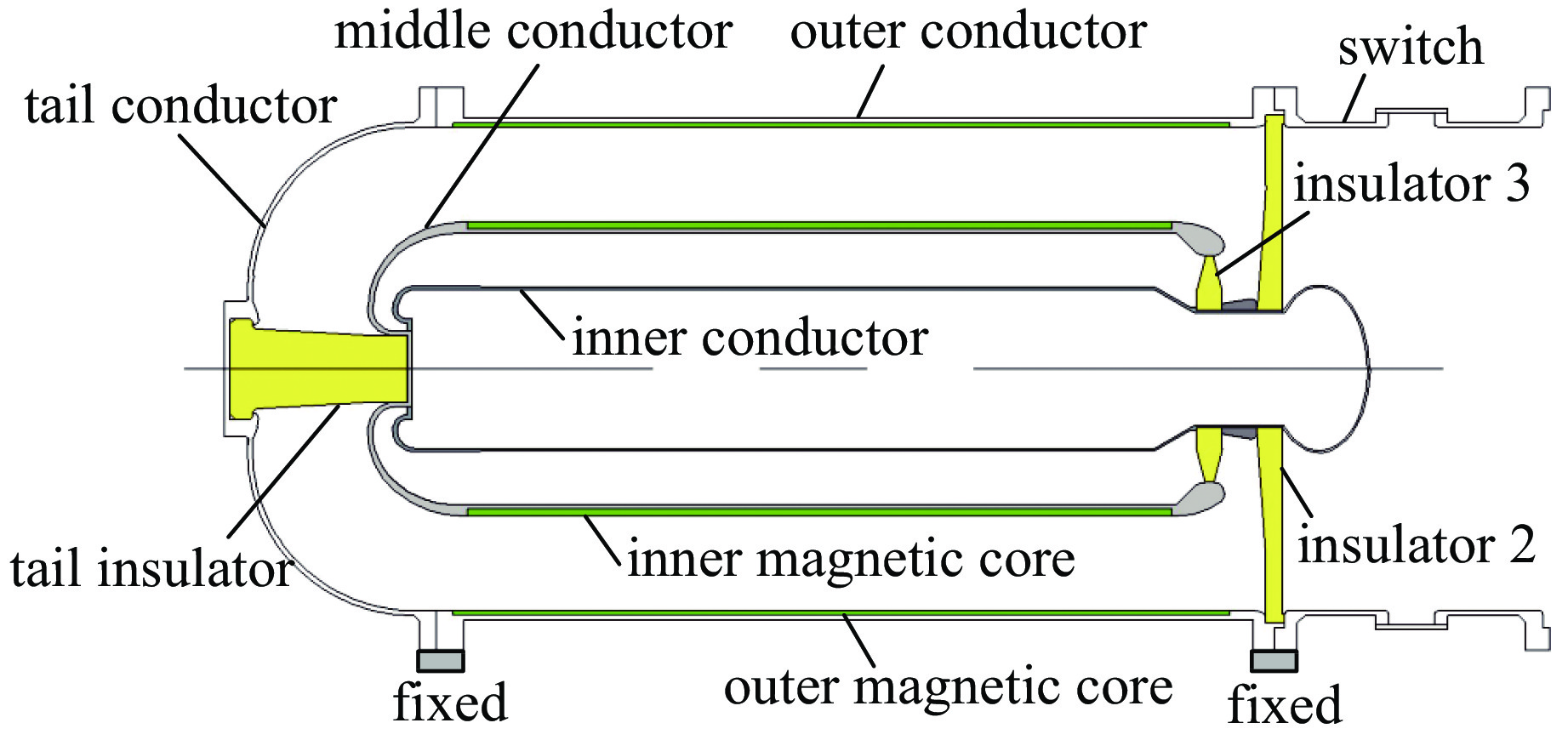

摘要: 以带有悬臂结构的同轴脉冲形成线为研究对象,开展提高振动环境适应性的优化设计。首先,通过实际工况分析及仿真计算,确定形成线内筒的盲孔螺钉可采用的防松措施有:使用施必劳螺纹并涂抹防松胶;优化螺钉数量。其次,通过仿真分析和绝缘试验,优化尾端绝缘子材料,提高悬臂支撑的中内筒连接刚度。最后,开展振动试验考核,优化后的形成线等效件可以通过长时间的振动考核,相比优化前的振动环境适应性有很大提高,验证了优化设计的有效性。该研究结果对同类型脉冲功率源的振动环境适应性设计具有参考意义。Abstract: Taking the coaxial pulse forming line (PFL) with cantilever structure as the research object, we carried out an optimization design for improving the vibration environmental adaptability. Firstly, through the analysis of the actual working condition and simulation calculation, the available anti-loosening measures for the blind hole screw in the inner conductor were determined as follows: using spiralock thread, applying anti-loosening glue and optimizing the number of the screws. Secondly, the insulator material was preferred to improve the connection stiffness of the inner conductor and the middle conductor according to the simulation analysis and the insulation test results. Finally, the vibration test was carried out to verify the effectiveness of the optimization design. The result show that the optimized equivalent parts of PFL could pass the long-term assessment, indicating that the vibration environment adaptability was greatly improved. The research results have reference significance for the vibration environment adaptability design of the same type of pulse power source.

-

表 1 中内筒连接螺钉谐响应计算结果

Table 1. Harmonic response calculation results of screws for connecting middle conductor with inner conductor (vertical vibration)

condition maximum axial force/kN maximum shear force/kN 6 screws 21.54 3.96 8 screws 14.18 2.96 表 2 绝缘测试结果汇总

Table 2. Summary of insulation test

material electric field value of bulk breakdown/(kV·mm−1) electric field value of surface flashover/(kV·mm−1) PEEK 41.4 13.9 glass fiber reinforced PEEK 38.9 12.1 nylon 66 33.8 11.1 glass fiber reinforced nylon 66 19.3 7.1 表 3 不同弹性模量的模态计算结果

Table 3. Modal calculation results with different elastic modulus

number modal shape inherent frequency/Hz elastic modulus of 3.6 GPa elastic modulus of 8 GPa 1 lateral bending of inner conductor 32.86 45.78 2 vertical bending of inner conductor 32.63 42.9 3 twisting of inner conductor 42.88 46.03 4 bending of inner conductor along the axial direction 55.89 65.73 表 4 优化设计前后振动试验考核结果对比

Table 4. Comparison of vibration test results before and after optimization design

test condition direction before optimizing after optimizing condition 1 longitudinal 40 min with full order of magnitude 2 h with full order of magnitude lateral 30 min with full order of magnitude 2 h with full order of magnitude vertical 30 min with full order of magnitude 2 h with full order of magnitude condition 2 longitudinal 10 min with full order of magnitude 40 min with full order of magnitude lateral 10 min with full order of magnitude 40 min with full order of magnitude vertical 10 min with full order of magnitude 40 min with full order of magnitude condition 3 three direction 5g 20g 表 5 安装不同材质尾端绝缘子时中筒尾端响应结果

Table 5. Response results of middle conductor with different insulator materials

test condition response with PEEK response with glass fiber reinforced PEEK longitudinal frequency sweep 0.59g@38.1 Hz 1.38g@39.4 Hz longitudinal wheel vehicle transportation (condition 2) 1.10g, RMS 1.90g,RMS lateral frequency sweep 1.87g@24.6 Hz 1.31g@32.1 Hz vertical frequency sweep 1.23g@23.6 Hz 0.52g@37.9 Hz vertical wheel vehicle transportation (condition 2) 2.73g, RMS 2.60g, RMS -

[1] 康强, 常安碧, 李名加, 等. 带脉冲形成线的1.0 MV 100 Hz紧凑型Tesla变压器的研制[J]. 强激光与粒子束, 2006, 18(3):451-454Kang Qiang, Chang Anbi, Li Mingjia, et al. Development of a 1.0 MV 100 Hz compact Tesla transformer with PFL[J]. High Power Laser and Particle Beams, 2006, 18(3): 451-454 [2] 石磊, 朱郁丰, 卢彦雷, 等. 紧凑Tesla变压器型纳秒脉冲源[J]. 强激光与粒子束, 2014, 26:125001 doi: 10.11884/HPLPB201426.125001Shi Lei, Zhu Yufeng, Lu Yanlei, et al. Compact GW nanosecond pulse generator based on Tesla transformer[J]. High Power Laser and Particle Beams, 2014, 26: 125001 doi: 10.11884/HPLPB201426.125001 [3] 王刚, 张喜波, 王俊杰, 等. 基于Tesla变压器和Blumlein线的低抖动重频脉冲发生器[J]. 强激光与粒子束, 2016, 28:045005 doi: 10.11884/HPLPB201628.125005Wang Gang, Zhang Xibo, Wang Junjie, et al. Low-jitter repetitive pulsed generator based on Tesla transformer and Blumlein pulse forming line[J]. High Power Laser and Particle Beams, 2016, 28: 045005 doi: 10.11884/HPLPB201628.125005 [4] 张喜波, 苏建仓, 潘亚峰, 等. 倍宽脉冲形成线[C]//第四届全国脉冲功率会议. 2015: A38Zhang Xibo, Su Jiancang, Pan Yafeng, et al. Multiple-width pulse forming lines[C]//4th Chinese Pulse Power Conference. 2015: A38 [5] 范红艳, 张喜波, 刘胜, 等. Tesla型脉冲功率源随机振动响应分析[J]. 现代应用物理, 2018, 9:031003Fan Hongyan, Zhang Xibo, Liu Sheng, et al. Random vibration analysis of Tesla-type pulse generator[J]. Modern Applied Physics, 2018, 9: 031003 [6] 范红艳, 王俊杰, 刘胜, 等. 同轴脉冲形成线的运输振动环境适应性研究[J]. 强激光与粒子束, 2021, 33:055004 doi: 10.11884/HPLPB202133.210067Fan Hongyan, Wang Junjie, Liu Sheng, et al. Research on transportation vibration environmental adaptability of coaxial pulse forming line[J]. High Power Laser and Particle Beams, 2021, 33: 055004 doi: 10.11884/HPLPB202133.210067 [7] Junker G H. New criteria for self-loosening of fasteners under vibration[J]. SAE Transaction, 1969, 78: 314-335. [8] Sakai T. Investigations of bolt loosening mechanisms: 1st report, on the bolts of transversely loaded joints[J]. Bulletin of JSME, 1978, 21(159): 1385-1390. doi: 10.1299/jsme1958.21.1385 [9] Pai N G, Hess D P. Three-dimensional finite element analysis of threaded fastener loosening due to dynamic shear load[J]. Engineering Failure Analysis, 2002, 9(4): 383-402. doi: 10.1016/S1350-6307(01)00024-3 [10] Pai N G, Hess D P. Experimental study of loosening of threaded fasteners due to dynamic shear loads[J]. Journal of Sound and Vibration, 2002, 253(3): 585-602. doi: 10.1006/jsvi.2001.4006 [11] 方子帆, 吴行, 曹钢, 等. 动态组合载荷作用下螺栓连接结构松动机理研究[J]. 机械强度, 2017, 39(2):386-391 doi: 10.16579/j.issn.1001.9669.2017.02.024Fang Zifan, Wu Hang, Cao Gang, et al. Research on bolt connection loose mechanism under dynamic tension compression and shear load[J]. Journal of Mechanical Strength, 2017, 39(2): 386-391 doi: 10.16579/j.issn.1001.9669.2017.02.024 [12] 王传华, 王文莉, 林清源, 等. 基于精确建模的横向振动工况下螺栓松动机理研究[J]. 宇航总体技术, 2018, 2(4):43-51,64Wang Chuanhua, Wang Wenli, Lin Qingyuan, et al. Study on bolt loosening mechanism in vibration condition based on precise model[J]. Astronautical Systems Engineering Technology, 2018, 2(4): 43-51,64 [13] 方子帆, 吴祖双, 朱畅, 等. 输电塔横担螺栓铝合金防松垫片的防松性能研究与改进设计[J]. 三峡大学学报(自然科学版), 2022, 44(3):74-78 doi: 10.13393/j.cnki.issn.1672-948X.2022.03.012Fang Zifan, Wu Zushuang, Zhu Chang, et al. Design and research on aluminum alloy anti-loosening washer for cross arm bolt of transmission tower[J]. Journal of China Three Gorges University (Natural Sciences), 2022, 44(3): 74-78 doi: 10.13393/j.cnki.issn.1672-948X.2022.03.012 [14] 唐羽. 内六角圆柱头螺栓多重防松措施设计[J]. 机械工程与自动化, 2017(2):200-201 doi: 10.3969/j.issn.1672-6413.2017.02.084Tang Yu. Multiple locking design of inner-hexagon bolt[J]. Mechanical Engineering & Automation, 2017(2): 200-201 doi: 10.3969/j.issn.1672-6413.2017.02.084 [15] 董得义, 李志来, 杨利伟, 等. 防松胶对螺纹连接预紧力影响试验研究[J]. 振动与冲击, 2015, 34(22):121-124,137 doi: 10.13465/j.cnki.jvs.2015.22.021Dong Deyi, Li Zhilai, Yang Liwei, et al. Experiment study on the influence of locking adhesive on the preload of screw thread connection[J]. Journal of Vibration and Shock, 2015, 34(22): 121-124,137 doi: 10.13465/j.cnki.jvs.2015.22.021 [16] 关洋, 徐武彬, 王国安. 螺纹锁固胶的防松效果探讨[J]. 机械研究与应用, 2013, 26(2):170-172 doi: 10.3969/j.issn.1007-4414.2013.02.062Guan Yang, Xu Wubin, Wang Guo’an. Anti-loosening effect discussion of thread locking glue[J]. Mechanical Research Application, 2013, 26(2): 170-172 doi: 10.3969/j.issn.1007-4414.2013.02.062 -

下载:

下载: