Simulation of rod-pinch diode at hundreds of thousands of volts

-

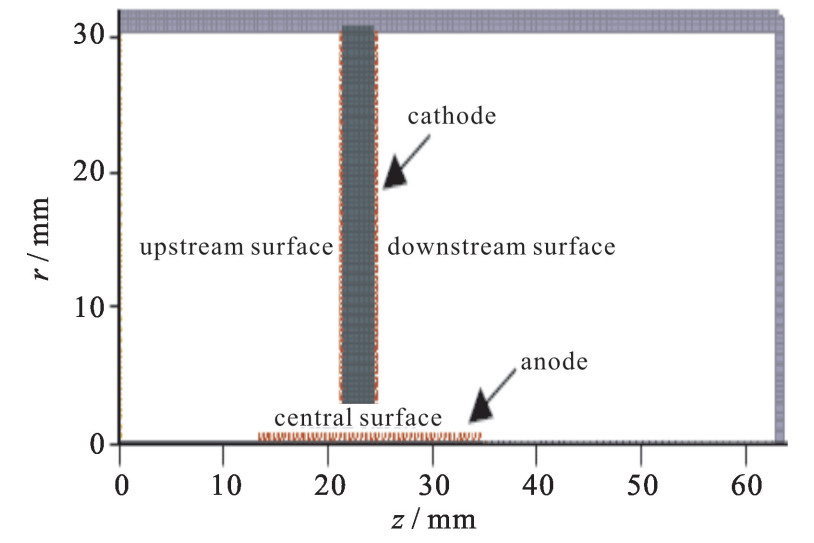

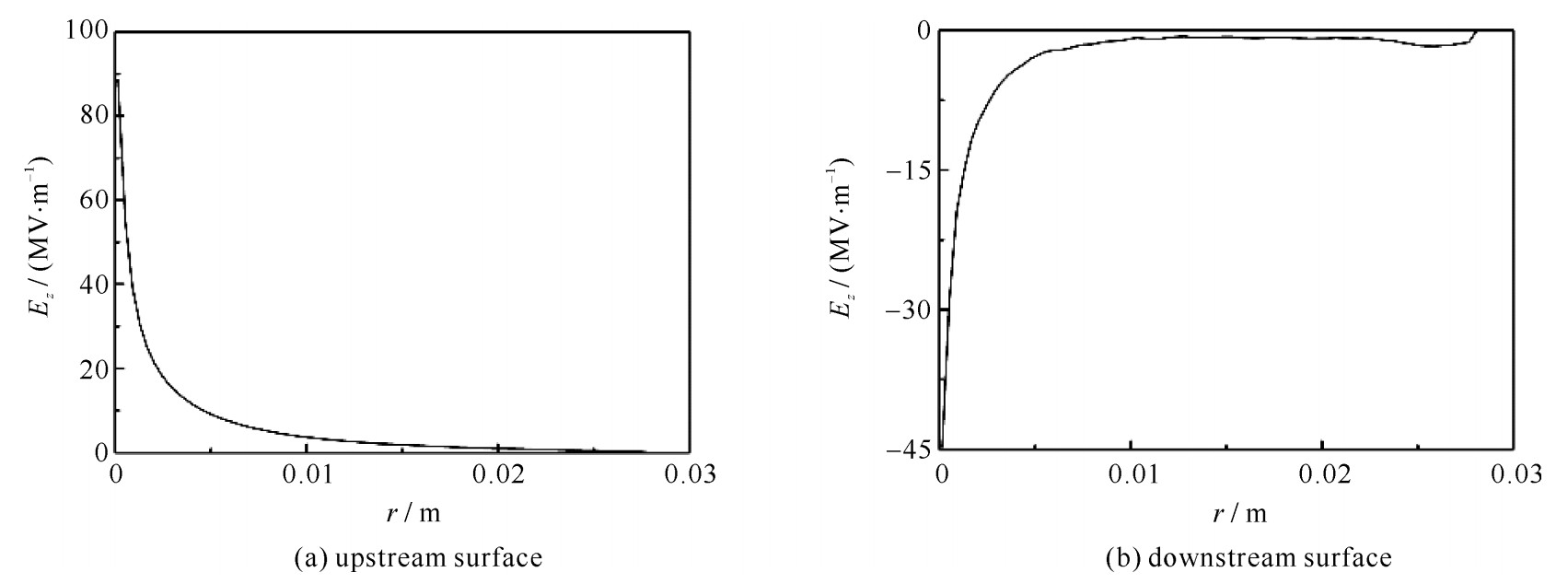

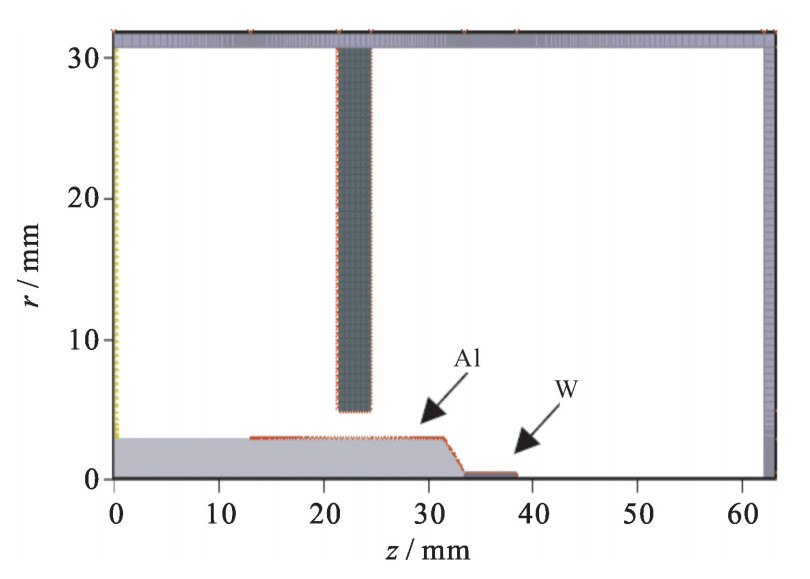

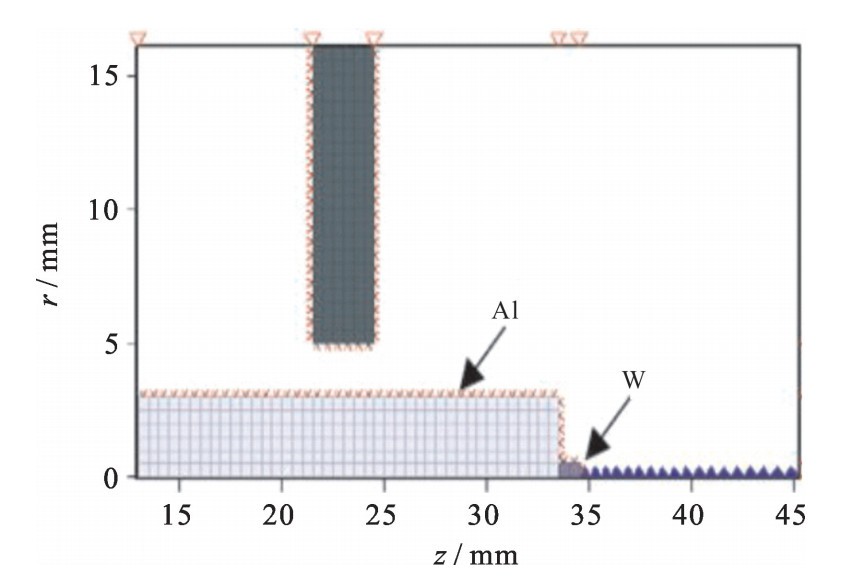

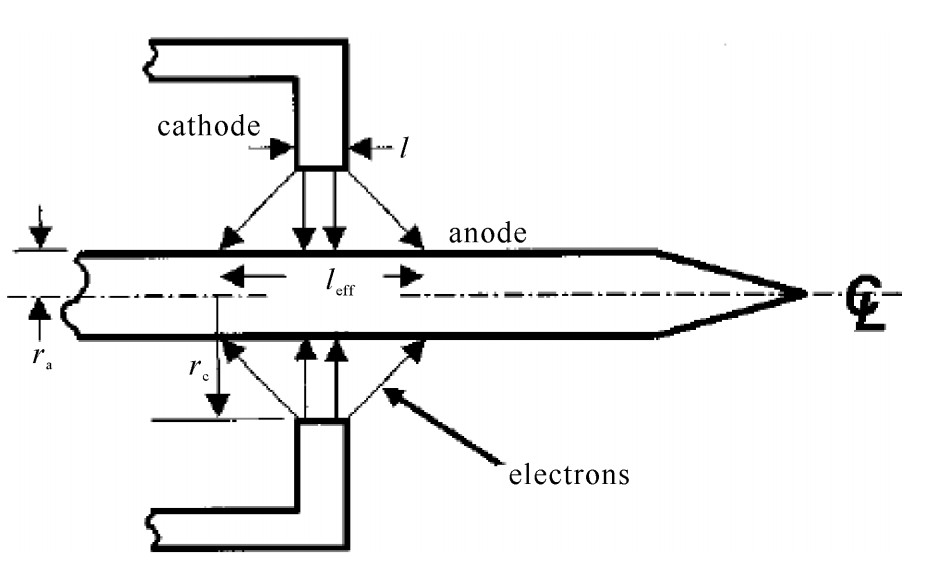

摘要: 为了探索杆箍缩二极管(RPD)在冲击加载下物质低密度区成像应用中的可行性,开展了低电压(≤500 kV)运行条件下RPD箍缩物理特性模拟研究。基于Particle-in-cell(PIC)模拟方法,从二极管加载电压幅值、阴极盘厚度、阴阳电极孔径比等方面开展了二极管模拟,从电子箍缩效率、质子流、电子利用率、电场和磁场分布等角度对箍缩物理过程进行了分析。模拟表明:低电压运行条件下普通结构二极管电流较低,不能为电子提供足够的磁场力从而导致较低的电子箍缩效率;采用组合杆结构,并优化阳极杆到轫致辐射靶区的过渡区设计,是在低电压条件下实现小焦斑、高剂量辐射光源的值得探索的技术途径。Abstract: In order to explore the feasibility of low density imaging of rod pinch diode (RPD) under impact loading, a simulation study on physical properties of RPD under low voltage operation (≤500 kV) is carried out. Based on particle-in-cell (PIC) simulation method, a simulation is carried out on amplitude of loading voltage of diode, thickness of cathode plate, aperture ratio of cathode and anode, etc. The physical process of pinch is analyzed according to the angle of electron pinch efficiency, proton flow, electron utilization, electric field and magnetic field distribution. The simulation results show that the current of RPD is low under low voltage operation, and can't provide enough magnetic force for the electron, resulting in low electron pinch efficiency. It is a technical approach to realize high dose and small focal spot light source under low voltage condition by using composite rod-pinch diode and optimizing design of the transition region of anode rod to bremsstrahlung target region.

-

Key words:

- rod-pinch diode /

- PIC simulation /

- flash radiography /

- pinch efficiency /

- radiation imaging

-

表 1 峰值电压对电子箍缩影响的模拟结果

Table 1. Simulated influence of peak voltage on the pinch process

voltage/MV total current/A proton current/A proton current ratio/% electron current of tip/A pinch efficiency/% electron utilization rate/% 0.10 1 992.54 98.30 4.93 447.69 22.47 23.63 0.20 5 639.03 433.01 7.68 2 058.09 36.50 39.53 0.30 8 344.14 867.37 10.40 3 340.06 40.03 44.67 0.40 10 697.93 1 582.46 14.79 5 685.94 53.15 62.38 0.50 12 909.94 2 286.52 17.71 7 055.76 54.65 66.42 0.80 19 729.17 4 961.93 25.15 12 952.09 65.65 87.71 1.20 28 994.01 8 825.76 30.44 19 764.02 68.17 98.00 2.00 48 026.66 17 201.69 35.82 30 617.14 63.75 99.33 3.00 72 542.22 29 250.44 40.32 42 672.25 58.82 98.57 表 2 不同发射面的箍缩结果

Table 2. Results of different emission surface

position electron current of anode/A electron current of tip/A electron utilization rate/% central surface 6 466.67 3 529.74 32.76 upstream surface 1 563.32 920.92 8.55 downstream surface 2 744.71 2 572.93 23.88 表 3 不同距离发射面的箍缩效率

Table 3. Pinch efficiency of emission surfaces at different distances

position electron current of anode/A electron current of tip/A electron utilization rate/% central surface 6 466.67 3 529.74 54.58 0~5 mm 2 551.53 1 891.37 74.13 5~10 mm 633.37 614.15 96.97 10~15 mm 380.30 337.99 88.87 others 704.04 631.63 89.71 表 4 不同厚度阴极盘的箍缩效率

Table 4. Pinch efficiency of cathode at different thickness

thickness of cathode/mm total current/A proton current/A electron current of anode/A electron current of tip/A pinch efficiency/% 1 10 376.21 1 344.14 9 032.07 5 865.90 56.53 3 10 697.93 1 582.46 9 115.47 5 685.94 53.15 6 10 678.08 1 753.06 8 925.02 5 583.16 52.29 表 5 不同阳、阴电极孔径比的箍缩效率

Table 5. Pinch efficiency of different aperture ratio of anode and cathode

ra/rc total current/A proton current/A proton current radio/% electron current of tip/A pinch efficiency/% 1/5 10 697.93 1 582.46 14.79 5 685.94 53.15 3/7 35 391.88 7 029.56 19.86 21 727.15 61.39 6/10 70 214.48 15 973.78 22.75 48 480.16 69.05 表 6 阳极杆尖1 mm的电子箍缩效率

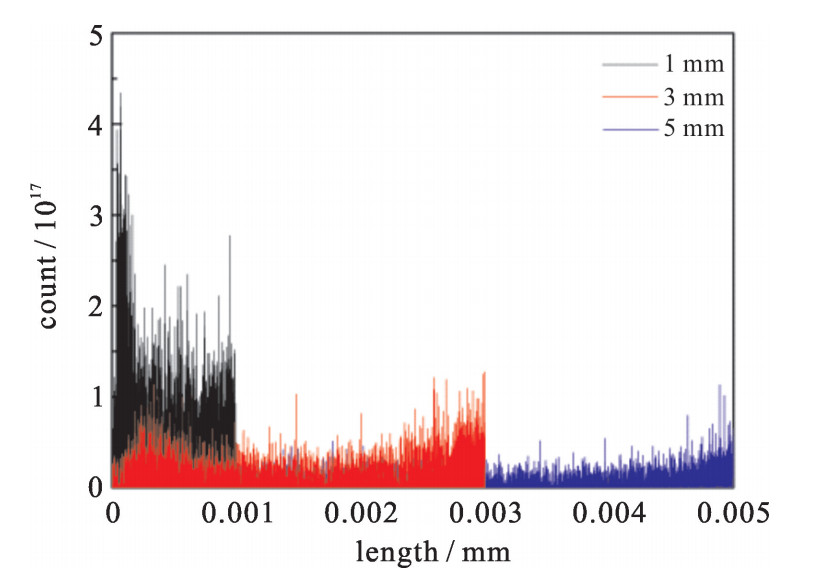

Table 6. Pinch efficiency of 1 mm anode tip

ra/rc total current/A proton current/A proton current ratio/% electron current of tip of 1 mm/A pinch efficiency/% composite rod 48 370.27 4 473.12 9.25 11 356.30 23.48 1/5 10 697.93 1 582.46 14.79 4 702.89 43.96 6/10 70 214.48 15 973.78 22.75 44 261.66 63.04 表 7 不同长度钨杆的箍缩效率

Table 7. Pinch efficiency of tungsten rod of different length

length of tungsten rod/mm total current/A proton current/A proton current ratio/% electron current/A electron current of tip/A electron current of rod of W/A pinch efficiency/% electron utilization rate/% 1 48 370.27 4 473.12 9.25 43 897.15 11 356.30 11 356.30 23.48 25.87 3 51 341.77 5 341.77 10.40 46 000.00 9 640.41 13 803.70 18.78 20.96 5 49 782.90 5 468.99 10.99 44 313.90 8 143.43 12 900.09 16.36 18.38 表 8 直接过渡组合式二极管的箍缩效率

Table 8. Pinch efficiency of tungsten rod of different length with direct transition anode

length of tungsten rod/mm total current/A proton current/A proton current ratio/% electron current/A electron current of tip/A pinch efficiency/% electron utilization rate/% 1 62 277.78 8 469.14 13.60 53 808.64 22 209.47 35.66 41.27 -

[1] Breaux B A, Debes J M, Cooper W L. Techniques for capturing radiographic images of high speed penetration events through sand[R]. ADA532132/XAB, 2010. [2] Hinshelwood D, Allen R J, Commisso R J, et al. High-power pinched-beam diode development for radiographic applications[C]//IEEE International Pulsed Power Conference. 2007: 603-608. [3] Ma X, Yuan J, Liu H, et al. Investigation on emission characteristics of metal-ceramic cathode applied to industrial X-ray diode[J]. Review of Scientific Instruments, 2016, 87: 063301. [4] Kumar R, Biswas D, Chandra R, et al. Parametric study of rod-pinch diode using particle-in-cell simulation[C]//IEEE International Symposium on Discharges and Electrical Insulation in Vacuum. 2014: 329-331. [5] Satyanarayana N, Basu S, Rajawat R K, et al. Experimental development of rod pinch diode radiographic source using modified Kali 1000 pulsed power system[C]//IEEE International Symposium on Discharges and Electrical Insulation in Vacuum. 2014: 337-339. [6] Satyanarayana N, Rajawat R K, Basu S, et al. Note: On the generation of sub-300 keV flash-X-rays using rod-pinch diode: An experimental investigation[J]. Review of Scientific Instruments, 2014, 85: 096107. doi: 10.1063/1.4894201 [7] Commisso R J, Cooperstein G, Hinshelwood D D, et al. Experimental evaluation of a megavolt rod-pinch diode as a radiography source[J]. IEEE Transactions on Plasma Science, 2002, 30(1): 338-351. doi: 10.1109/TPS.2002.1003878 [8] Menge P R, Johnson D L E E, Maenchen J E, et al. Experimental comparison of 2-3 MV X-ray sources for flash radiography[R]. SAND2002-0082, 2002. [9] 马勋, 邓建军, 姜苹, 等. 流体动力学实验用闪光X光机研究进展[J]. 强激光与粒子束, 2014, 26: 010201. doi: 10.3788/HPLPB201426.010201Ma Xun, Deng Jianjun, Jiang Ping, et al. Review of flash X-ray generator applied to hydrokinetical experiments. High Power Laser and Particle Beams, 2014, 26: 010201 doi: 10.3788/HPLPB201426.010201 [10] Cooperstein G, Boller J R, Commisso R J, et al. Theoretical modeling and experimental characterization of a rod-pinch diode[J]. Physics of Plasmas, 2001, 8(10): 4618-4636. doi: 10.1063/1.1403016 [11] Gao Y, Qiu A, Zhang Z, et al. Research on pinching characteristics of electron beams emitted from different cathode surfaces of a rod-pinch diode[J]. Physics of Plasmas, 2010, 17: 073108. doi: 10.1063/1.3455536 [12] 高屹, 邱爱慈, 吕敏, 等. 抑制阴极不同表面电子发射对阳极杆箍缩二极管电子束箍缩特性的影响[R]. 中国核科学技术进展报告(第一卷). 2009: 6-12.Gao Yi, Qiu Aici, Lü Min, et al. Influence on rod-pinch diode performance of suppressing electron emission from different cathode surfaces. Progress Report on China Nuclear Science & Technology(vol 1st), 2009: 6-12 [13] 马勋, 袁建强, 祁康成, 等. 影响阳极杆箍缩二极管窗口前向辐射剂量的因素[J]. 强激光与粒子束, 2016, 28: 050201. doi: 10.11884/HPLPB201628.050201Ma Xun, Yuan Jiamqiang, Qi Kangcheng, et al. Factors affecting rod pinch diode dose. High Power Laser and Particle Beams, 2016, 28: 050201 doi: 10.11884/HPLPB201628.050201 [14] Commisso R J, Young F C, Allen R J, et al. Overview of the 6-MV, rod-pinch experiment on ASTERIX[C]//IEEE International Pulsed Power Conference. 2003, 1: 479-482. [15] Mosher D, Alien R J, Commisse R J, et al. Characterization of composite rod-pinch-diode radiographic sources at 5 to 6 MV on Asterix[C]//IEEE International Pulsed Power Conference. 2004, 2: 983-986. [16] Commisso R J, Young F C, Bayol F, et al. Characterization of the rod-pinch diode at 2 to 4 MV as a high-resolution source for flash radiography[C]//IEEE 14th International Conference on High-Power Particle Beams (BEAMS). 2002, 1: 183-186. [17] Bennett N, Mitchell S E. Plasma dynamics in the rod-pinch diode at 2 MV[C]//IEEE Pulsed Power Conference. 2015: 1-5. -

下载:

下载: