| [1] |

Novoselov K S, Geim A K, Morozov S V, et al. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306(22): 666-669.

|

| [2] |

Morozov S V, Novoselov K S, Katsnelson M I, et al. Giant intrinsic carrier mobilities in graphene and its bilayer[J]. Phys Rev Lett, 2008, 100: 016602. doi: 10.1103/PhysRevLett.100.016602

|

| [3] |

Nair R R, Blake P, Grigorenko A N, et al. Fine structure constant defines visual transparency of graphene[J]. Science, 2008, 321(6): 1308.

|

| [4] |

Lee C, Wei X, Kysar J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene[J]. Science, 2008, 321(18): 385-388.

|

| [5] |

Krauss B, Lohmann T, Chae D H, et al. Laser-induced disassembly of a graphene single crystal into a nanocrystalline network[J]. Phys Rev B, 2009, 79: 165428. doi: 10.1103/PhysRevB.79.165428

|

| [6] |

Qian M, Zhou Y S, Gao Y, et al. Formation of graphene sheets through laser exfoliation of highly ordered pyrolytic graphite[J]. Appl Phys Lett, 2011, 98: 173108. doi: 10.1063/1.3584021

|

| [7] |

Lee S, Toney M F, Ko W, et al. Laser-synthesized epitaxial graphene[J]. ACS Nano, 2010, 4(12): 7524-7530. doi: 10.1021/nn101796e

|

| [8] |

Park J B, Xiong W, Gao Y, et al. Fast growth of graphene patterns by laser direct writing[J]. Appl Phys Lett, 2011, 98: 123109. doi: 10.1063/1.3569720

|

| [9] |

Huang L, Liu Y, Ji L C, et al. Pulsed laser assisted reduction of graphene oxide[J]. Carbon, 2011, 49(7): 2431-2436. doi: 10.1016/j.carbon.2011.01.067

|

| [10] |

Roberts A, Cormode D, Reynolds C, et al. Response of graphene to femtosecond high-intensity laser irradiation[J]. Appl Phys Lett, 2011, 99: 051912. doi: 10.1063/1.3623760

|

| [11] |

Zhou Y, Bao Q L, Varghese B N, et al. Microstructuring of graphene oxide nanosheets using direct laser writing[J]. Adv Mater, 2010, 22(1): 67-71. doi: 10.1002/adma.200901942

|

| [12] |

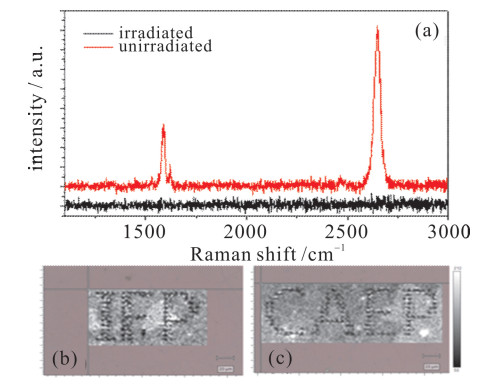

吴凌远, 李阳龙, 刘国栋, 等. 1064 nm纳秒激光对石墨烯的损伤效应研究[J]. 强激光与粒子束, 2015, 27: 081009. doi: 10.11884/HPLPB201527.081009Wu Lingyuan, Li Yanglong, Liu Guodong, et al. 1064 nm nanosecond laser induced damage effect on graphene. High Power Laser and Particle Beams, 2015, 27: 081009 doi: 10.11884/HPLPB201527.081009

|

| [13] |

Jani K, Christian B, Yigal L, et al. Toward two-dimensional all-carbon heterostructures via ion beam patterning of single-layer graphene[J]. Nano Lett, 2015, 15(9): 5944-5949. doi: 10.1021/acs.nanolett.5b02063

|

| [14] |

Chen Y, Zhang N, Li Y F, et al. Microscal E-patterned graphene electrodes for organic light-emitting devices by a simple patterning strategy[J]. Adv Optical Mater, 2018, 13: 1701348.

|

| [15] |

Ethan B S, Pradyumna L P, Kanan P, et al. Inkjet printing of high conductivity, flexible graphene patterns[J]. J Phys Chem Lett, 2013, 4(8): 1347-1351. doi: 10.1021/jz400644c

|

| [16] |

南洋, 张建寰, 张陈涛. 激光直写制备石墨烯研究进展[J]. 化工新型材料, 2015, 43(12): 1-3. https://www.cnki.com.cn/Article/CJFDTOTAL-HGXC201512001.htmNan Yang, Zhang Jianhuan, Zhang Chentao. Progress in laser direct writing synthesis of graphene. New Chemical Materials. 2015, 43(12): 1-3 https://www.cnki.com.cn/Article/CJFDTOTAL-HGXC201512001.htm

|

| [17] |

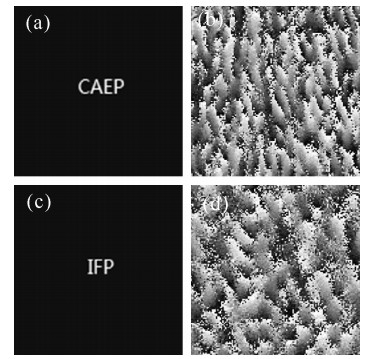

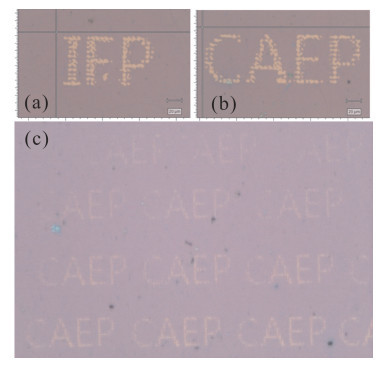

Chen H Y, Han D D, Tian Y, et al. Mask-free and programmable patterning of graphene by ultrafast laserdirect writing[J]. Chemical Physics, 2014, 430: 13-17. doi: 10.1016/j.chemphys.2013.12.005

|

| [18] |

Chang T L, Chen Z C, Chen W Y, et al. Patterning of multilayer graphene on glass substrate by using ultraviolet picosecond laser pulses[J]. Microelectronic Engineering, 2016, 158(1): 1-5.

|

| [19] |

Lee K, Ki H. Fabrication and optimization of transparent conductive films using laser annealing and picosecond laser patterning[J]. Applied Surface Science, 2017, 420(1): 886-895.

|

| [20] |

Pechlivani E M, Papas D, Mekeridis C, et al. Ultra-short pulse laser for patterning high quality graphene electrodes[J]. Materials Today: Proceedings, 2017, 4(4): 5074-5081. doi: 10.1016/j.matpr.2017.04.116

|

| [21] |

Kumar R, Singh R K, Singh D P, et al. Laser-assisted synthesis, reduction and micro-patterning of graphene: Recent progress and applications[J]. Coordination Chemistry Reviews, 2017, 342: 34-79. doi: 10.1016/j.ccr.2017.03.021

|

下载:

下载: