Simulation and experimental study on temperature field of ion thruster's grids assembly

-

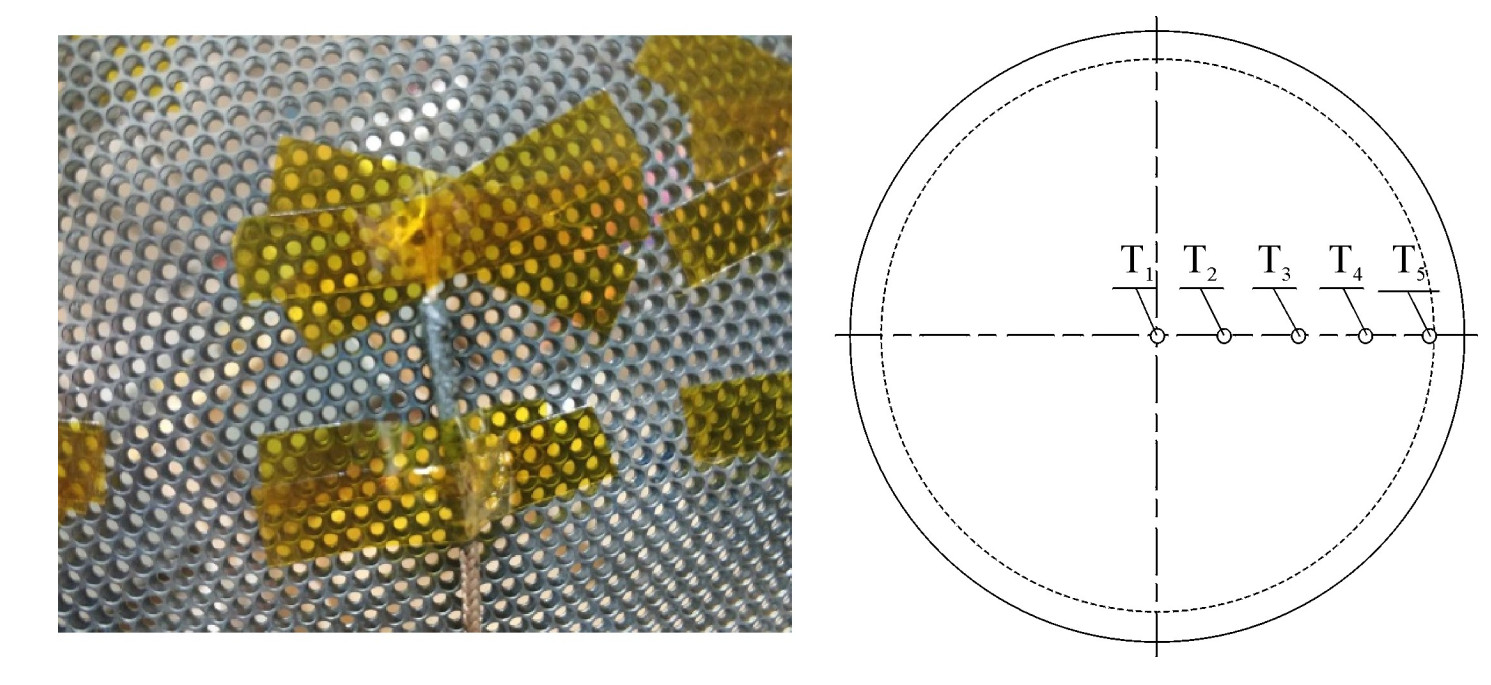

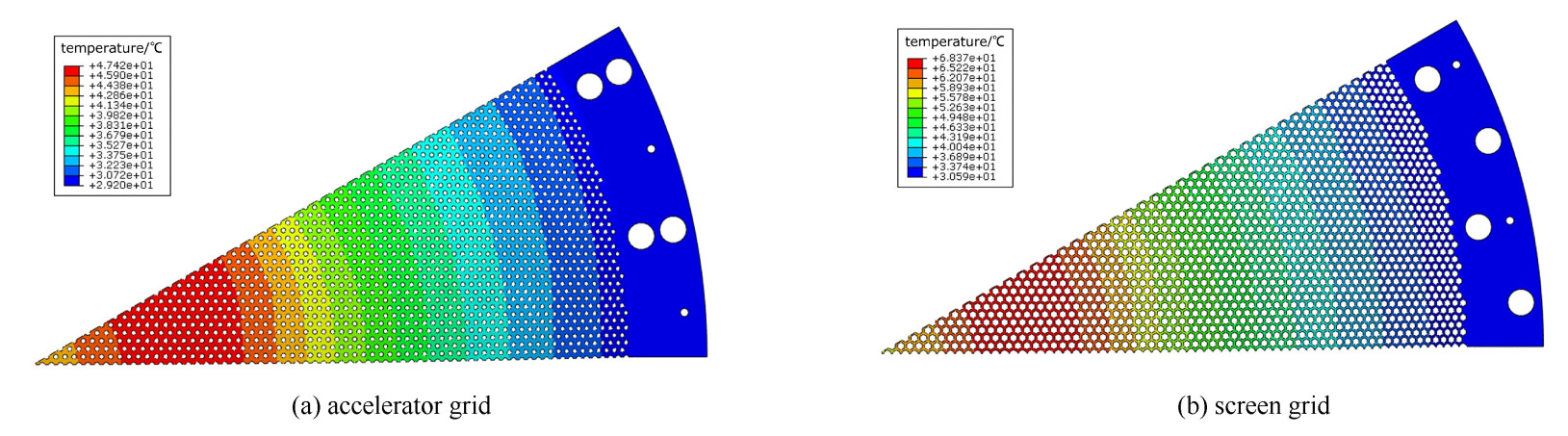

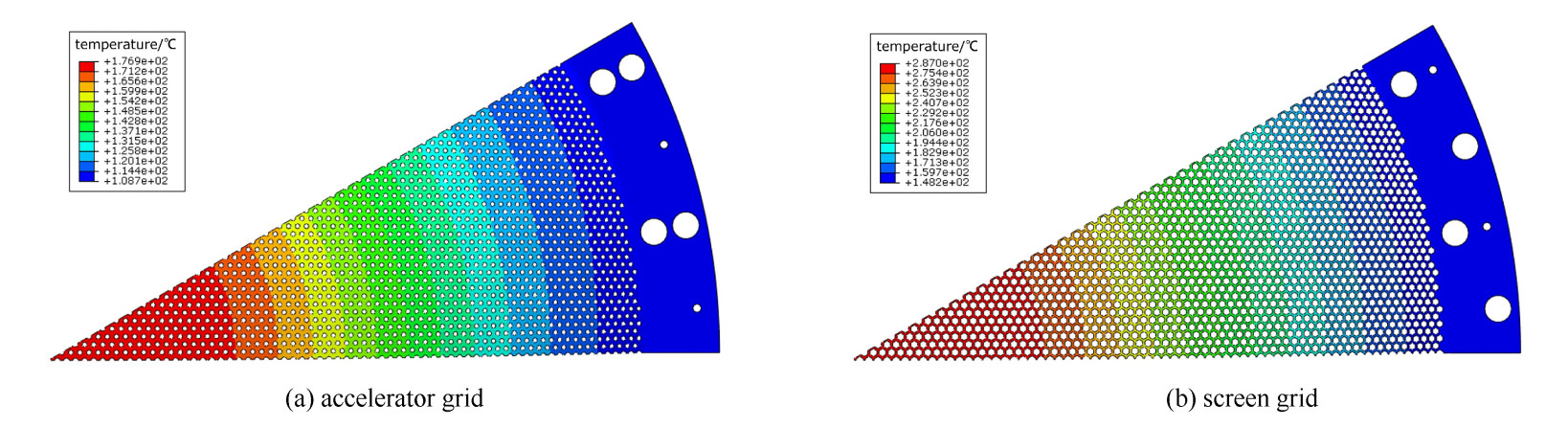

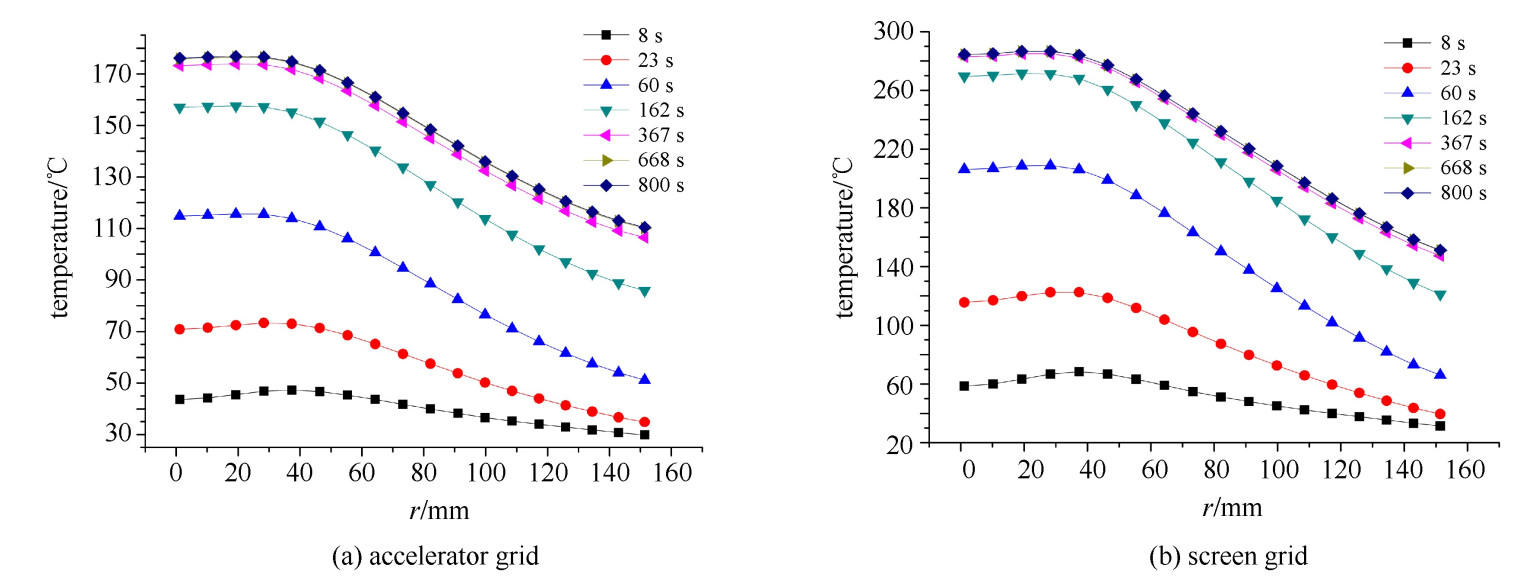

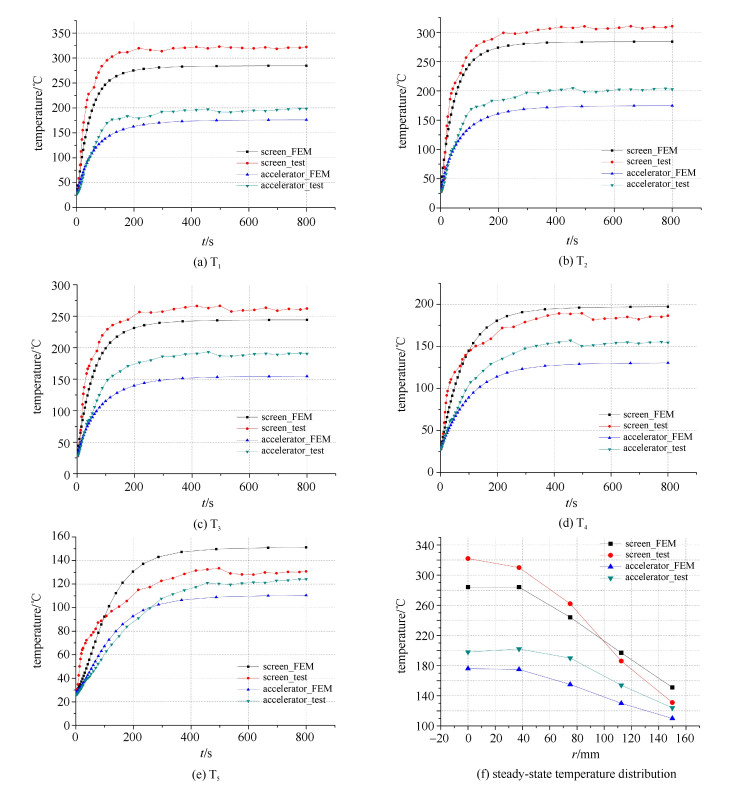

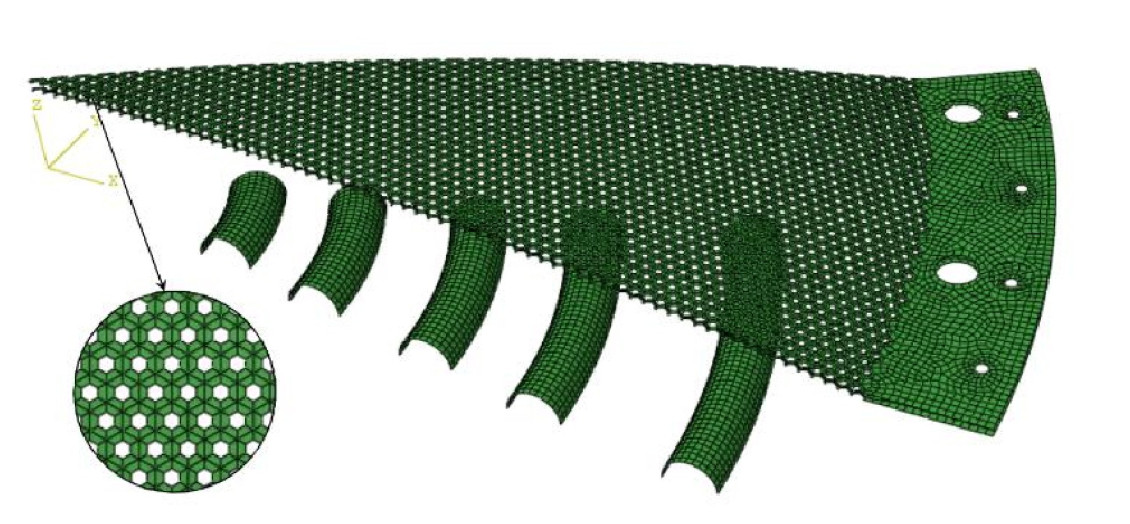

摘要: 栅极组件热变形是影响离子推力器工作性能及工作寿命的主要因素,为研究栅极组件升温过程中温度场分布及变化规律,探索能较准确模拟栅极温度场的方法,建立了栅极组件1/12全尺寸有限元模型进行温度场仿真计算。同时,基于实验室搭建的温度测量平台,测量了大气环境下加热时栅极组件的瞬态温度变化。对比有限元分析求解与试验过程中的温度场,加速栅平均误差为14.4%,屏栅平均误差为9.7%,双栅最大误差不超过18.4%,验证了有限元模型及方法的可信度和合理性。Abstract: The thermal deformation of grids assembly is the main factor affecting the working performance and working life of the ion thruster. In order to study the distribution and variation of the temperature field in the process of grids assembly heating, the method of accurately simulating the grid temperature field is explored. The full size finite element model of the 1/12 grids assembly is established for the heat transfer analysis. Meanwhile, the temperature measurement platform built in the laboratory, the transient temperature changes of the grids assembly in the atmosphere are measured. Comparison between the finite element analysis and test results shows that, the average error of the accelerated grid is 14.4%, the average error of the screen grid is 9.7%, the maximum error of two grids is less than 18.4%, and the credibility and rationality of the finite element model and the method is verified.

-

Key words:

- ion thruster /

- grids assembly /

- temperature field /

- FEM model /

- thermal analysis

-

表 1 各加热管表面温度

Table 1. Surface temperature of heating tubes

heating tube number temperature/℃ 1 635 2 608 3 512 4 455 5 422 表 2 加速栅测温点稳态温度试验与仿真对比

Table 2. Comparison of steady-state temperature between simulation and experiment for accelerator grid

thermocouple point temperature of FEM/℃ temperature of experiment/℃ error /% T1 176 198 11.1 T2 175 202 13.4 T3 155 190 18.4 T4 130 154 16.0 T5 110 124 11.3 表 3 屏栅测温点稳态温度试验与仿真对比

Table 3. Comparison of steady-state temperature between simulation and experiment for screen grid

thermocouple point temperature of FEM/℃ temperature of experiment/℃ error /% T1 284 322 11.8 T2 284 310 8.4 T3 244 262 6.9 T4 197 186 5.9 T5 151 131 15.3 -

[1] Hayakawa Y, Yoshida H, Miyazaki K, et al. Validation of an ion-thruster grid thermal model with experiments[C]//AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. 2010. [2] Hayakawa Y, Yoshida H, Miyazaki K, et al. Thermo-elastic analyses of ion-thruster grids[C]//AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. 2006. [3] 孙明明, 张天平, 贾艳辉. 30 cm离子推力器栅极组件热形变位移分析研究[J]. 真空与低温, 2017, 23(6): 349-354. doi: 10.3969/j.issn.1006-7086.2017.06.008Sun Mingming, Zhang Tianping, Jia Yanhui. The thermal deformation displacement analysis of the grids for a 30 cm diameter ion thruster. Vacuum & Cryogenics, 2017, 23(6): 349-354 doi: 10.3969/j.issn.1006-7086.2017.06.008 [4] 孙明明, 张天平, 王亮, 等. 30 cm离子推力器栅极组件热应力及热形变计算模拟[J]. 推进技术, 2016, 37(7): 1393-1400. https://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201607026.htmSun Mingming, Zhang Tianping, Wang Liang, et al. Thermal stress and thermal deformation analysis of grids assembly for 30 cm diameter ion thruster. Journal of Propulsion Technology, 2016, 37(7): 1393-1400 https://www.cnki.com.cn/Article/CJFDTOTAL-TJJS201607026.htm [5] Trava-Airoldi V J, Garner C E, Pivirotto T J, et al. An optical technique to measure ion engine grid distortion due to differential thermal expansion[C]//21st International Electric Propulsion Conference. 1990. [6] MacRae G S, Zavesky R J, Gooder S T. Structural and thermal response of 30 cm diameter ion thruster optics[C]//25th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. 1989. [7] Soulas G, Frandina M. Ion engine grid gap measurements[C]//40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference. 2004. [8] Bundesmann C, Tartz M, Scholze F, et al. In situ thermal characterization of the accelerator grid of an ion thruster[J]. Journal of Propulsion & Power, 2011, 7(27): 532-537. [9] 梁秀强, 袁杰红, 周仕明. 离子推力器栅极组件有限元的建模及热变形研究[J]. 真空与低温, 2018, 24(4): 242-245. doi: 10.3969/j.issn.1006-7086.2018.04.006Liang Xiuqiang, Yuan Jiehong, Zhou Shiming. Study on finite element modeling and thermal deformation of ion thruster's grids assembly. Vacuum & Cryogenics, 2018, 24(4): 242-245 doi: 10.3969/j.issn.1006-7086.2018.04.006 [10] 赵镇南. 传热学[M]. 2版. 北京. 高等教育出版社, 2008.Zhao Zhennan. Heat transfer. 2nd ed. Beijing: Higher Education Press, 2008 [11] Holman J P. Heat transfer[M]. New York: McGraw-Hill, 1990. [12] 孙明明, 张天平, 陈娟娟, 等. LIPS-200离子推力器热特性模拟分析研究[J]. 强激光与粒子束, 2014, 26: 084002. doi: 10.11884/HPLPB201426.084002Sun Mingming, Zhang Tianping, Chen Juanjuan, et al. Thermal analysis of LIPS-200 ion thruster. High Power Laser and Particle Beams, 2014, 26: 084002 doi: 10.11884/HPLPB201426.084002 -

下载:

下载: