Research on bonding test of 5052 aluminum alloy based on laser texturing technology

-

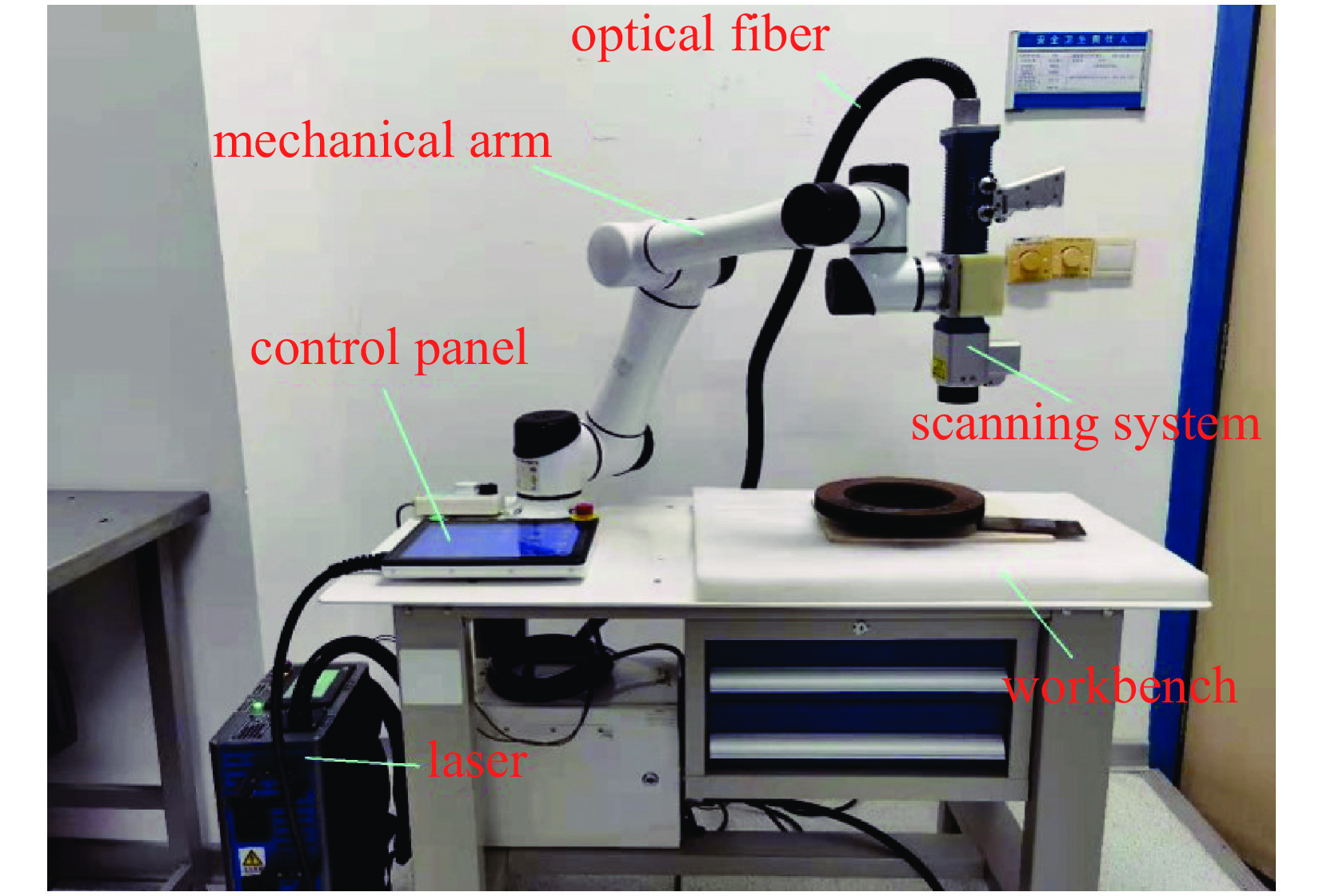

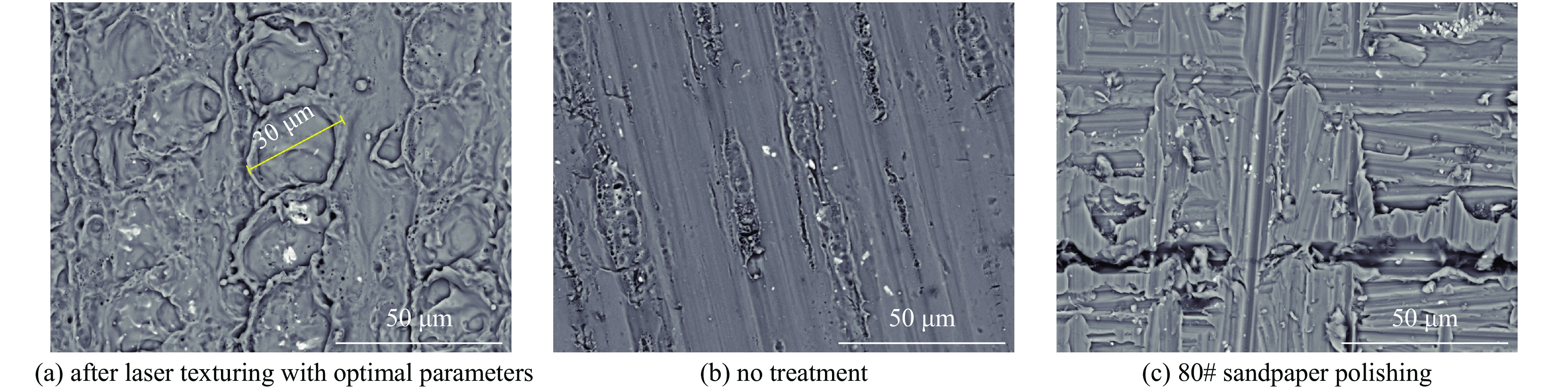

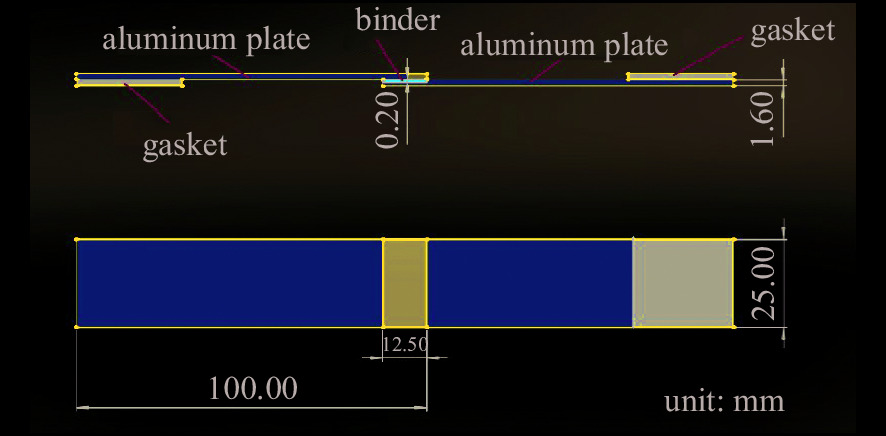

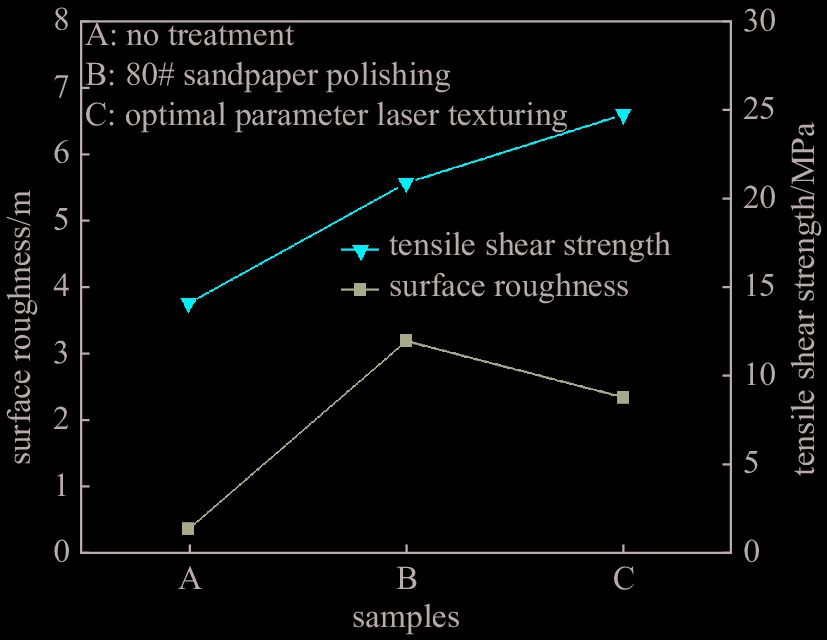

摘要: 为了提高5052铝合金的粘接性能,利用脉冲光纤激光的短脉冲和高峰值功率的特性,对铝合金试件进行了激光毛化试验研究。通过正交实验法,研究了平均功率、扫描速度、脉冲频率和脉冲宽度等工艺参数对激光毛化质量的影响,以及各工艺参数的影响权重,并求得最佳工艺参数,最佳工艺参数为平均功率90 W、扫描速度10 mm/s、脉冲频率1000 kHz、脉冲宽度200 ns。根据优化后的工艺参数,加工获得了粗糙度2.35 μm,然后对激光毛化后的铝合金试件进行单搭接拉伸试验,研究发现粘接强度随着粗糙度的增大而增大,当粗糙度到达一定程度时,粘接强度反而会随着粗糙度的增大而减小。另外,粘接强度还跟铝合金表面的微织构的类型及疏密程度都有很大关系。Abstract: To improve the bonding performance of 5052 aluminum alloy, the laser texturing experiment on aluminum alloy specimens was carried out by using the short pulse and high peak power characteristics of pulsed fiber laser. Through the orthogonal experiment method, the effects of process parameters such as the average power, scanning speed, pulse frequency, pulse width and other parameters on the quality of laser texturing, as well as the influence weight of each process parameter, and the best process parameters are obtained. The best process parameters are average power 90 W, scanning speed 10mm/s, pulse frequency 1000 kHz, and pulse width 200 ns. According to the optimized parameters, a good area with roughness 2.35 μm is obtained. Then a single-lap tensile test on the aluminum alloy specimens after laser texturing was carried out. The study found that the bonding strength would increase with the increase of roughness, when the roughness reached a certain level, the bonding strength would decrease with the increase of roughness. In addition, the bonding strength is also closely related to the type and density of the microtexture on the surface of the aluminum alloy.

-

Key words:

- laser texturing /

- process parameter /

- orthogonal experiment /

- single-lap tensile test

-

表 1 因素水平表

Table 1. Factor level table

level power/W scan speed/(mm·s−1) frequency/kHz pulse width/ns 1 30 10 500 100 2 60 20 1000 200 3 90 30 1500 300 表 2 正交试验设计及结果

Table 2. Orthogonal experimental design and results

number power/W scan speed/(mm·s−1) frequency/kHz pulse width /ns surface roughness/μm 1 30 10 500 100 0.661 2 30 20 1000 200 0.383 3 30 30 1500 300 0.413 4 60 10 1000 300 1.540 5 60 20 1500 100 0.394 6 60 30 500 200 0.836 7 90 10 1500 200 2.270 8 90 20 500 300 1.221 9 90 30 1000 100 1.810 表 3 极差分析

Table 3. Range analysis

project surface roughness/μm power A scan speed B frequency C pulse width D K1 0.486 1.490 0.906 0.955 K2 0.923 0.666 1.244 1.163 K3 1.767 1.020 1.026 1.058 range 1.283 0.824 0.338 0.208 表 4 3种方式下的粗糙度值

Table 4. Roughness value of three types

samples surface roughness/μm no treatment 0.38 80# sandpaper polishing 3.2 optimal parameter laser texturing 2.35 表 5 5052铝合金力学性能参数

Table 5. Mechanical properties of 5052 aluminum alloy

density /(g·cm−3) elastic modulus /GPa Poisson’s ratio yield strength/MPa 2.68 69 0.32 65 表 6 胶粘剂材料参数

Table 6. Material parameters of adhesive

component curing temperature/℃ density/(kg·m−3) curing time/min Poisson’s ratio J-69F1 epoxy resin 130 1200 75 0.12 表 7 拉伸剪切试验

Table 7. Tensile shear test

samples number failure load/N tensile shear strength/MPa average tensile shear strength/MPa no treatment 1 6033.89 14.7 14.12 2 5805.84 14.3 3 5869.37 14.2 4 5785.77 13.8 5 5937.81 13.6 80# sandpaper polishing 1 7269.78 21.77 20.88 2 5922.89 19.42 3 6877.25 21.16 4 7333.92 22.04 5 6237.23 20.03 optimal parameter

laser texturing1 8726.94 24.39 24.72 2 8108.42 24.94 3 8242.04 25.17 4 7625.57 23.46 5 8363.43 25.62 -

[1] 朱民. 碳达峰碳中和必将重构中国经济[N]. 联合时报, 2021-05-11(006)Zhu Min. China’s economy will be restructured with carbon peaking and carbon neutraling[N]. United Times, 2021-05-11(006) [2] 慕文龙. 湿热-力耦合作用对CFRP/铝合金粘接接头力学性能的影响[D]. 长春: 吉林大学, 2020Mu Wenlong. Effect of hygrothermal-loads coupling on the mechanical properties of adhesively bonded CFRP/aluminum alloy joints[D]. Changchun: Jilin University, 2020 [3] Liedl G, Bielak R, Ivanova J, et al. Joining of aluminum and steel in car body manufacturing[J]. Physics Procedia, 2011, 12: 150-156. doi: 10.1016/j.phpro.2011.03.019 [4] 石玗, 梁琪, 张刚, 等. 激光毛化对铝/钢电弧熔钎焊接头界面与性能的影响[J]. 焊接学报, 2020, 41(5):25-29. (Shi Yu, Liang Qi, Zhang Gang, et al. Effect of laser texturing on the interface and properties of aluminum/steel arc fusion brazed joints[J]. Transactions of the China Welding Institution, 2020, 41(5): 25-29 doi: 10.12073/j.hjxb.20190916002 [5] 陈晓辉, 钟志平, 陆辛. 车用铝合金连接技术的研究进展与应用[J]. 热加工工艺, 2016, 45(11):5-8. (Chen Xiaohui, Zhong Zhiping, Lu Xin. Research progress and application of joining technology of aluminum alloy for automobile[J]. Hot Working Technology, 2016, 45(11): 5-8 [6] 李波, 袁挺, 方基永. 车用铝合金结构胶应用研究[J]. 中国胶粘剂, 2020, 29(11):52-55. (Li Bo, Yuan Ting, Fang Jiyong. Study on application of structural adhesive for automotive aluminum alloy[J]. China Adhesives, 2020, 29(11): 52-55 [7] 崔俊佳, 梁伟, 李光耀. AA5182铝合金胶接接头动态剪切性能研究[J]. 塑性工程学报, 2020, 27(10):185-191. (Cui Junjia, Liang Wei, Li Guangyao. Study on dynamic shear properties of AA5182 aluminum alloy adhesive joint[J]. Journal of Plasticity Engineering, 2020, 27(10): 185-191 doi: 10.3969/j.issn.1007-2012.2020.10.026 [8] 张昱龙. 激光表面处理对金属/复合材料粘接界面的影响研究[D]. 大连: 大连理工大学, 2020Zhang Yulong. The influences of laser surface treatment on the bonding interface of metal/composites[D]. Dalian: Dalian University of Technology, 2020 [9] 陈爔, 王菲, 吴琼, 等. 3A21铝合金表面激光毛化坑点形貌演变规律[J]. 激光与光电子学进展, 2019, 56:241404. (Chen Xi, Wang Fei, Wu Qiong, et al. Pit morphology evolution law of 3A21 aluminum alloy surface in laser texturing[J]. Laser & Optoelectronics Progress, 2019, 56: 241404 [10] Dunn A, Carstensen J V, Wlodarczyk K L, et al. Nanosecond laser texturing for high friction applications[J]. Optics and Lasers in Engineering, 2014, 62: 9-16. doi: 10.1016/j.optlaseng.2014.05.003 [11] Bonse J, Kirner S V, Griepentrog M, et al. Femtosecond laser texturing of surfaces for tribological applications[J]. Materials, 2018, 11: 801. doi: 10.3390/ma11050801 [12] Guo J D, Li Y, Lu H L, et al. An effective method of edge deburring for laser surface texturing of Co-Cr-Mo alloy[J]. The International Journal of Advanced Manufacturing Technology, 2018, 94(1): 1491-1503. [13] 蔡颂, 陈根余, 周聪, 等. 单脉冲激光烧蚀青铜砂轮等离子体物理模型研究[J]. 光学学报, 2017, 37:0414001. (Cai Song, Chen Genyu, Zhou Cong, et al. Research of plasma physical model for single pulsed laser ablation of bronze-bond grinding wheel[J]. Acta Optica Sinica, 2017, 37: 0414001 doi: 10.3788/AOS201737.0414001 [14] 蔡春波, 吉泽升, 王国军, 等. 激光毛化对3003铝合金织构及性能的影响[J]. 材料热处理学报, 2009, 30(3):111-114. (Cai Chunbo, Ji Zesheng, Wang Guojun et al. Effect of laser-texturing of cold roll on texture and mechanical properties of 3003 aluminiam alloy[J]. Transactions of Materials and Heat Treatment, 2009, 30(3): 111-114 [15] 杨文锋, 侯秋园, 李绍龙, 等. 民机铝合金蒙皮的激光织构化处理[J]. 电镀与涂饰, 2020, 39(8):492-498. (Yang Wenfeng, Hou Qiuyuan, Li Shaolong, et al. Laser texturing of aluminum alloy used as civil aircraft skin[J]. Electroplating & Finishing, 2020, 39(8): 492-498 [16] Won S J, Kim H S. Effects of laser parameters on morphological change and surface properties of aluminum alloy in masked laser surface texturing[J]. Journal of Manufacturing Processes, 2019, 48: 260-269. doi: 10.1016/j.jmapro.2019.10.034 [17] Kuznetsov G V, Feoktistov D V, Orlova E G, et al. Droplet state and mechanism of contact line movement on laser-textured aluminum alloy surfaces[J]. Journal of Colloid and Interface Science, 2019, 553: 557-566. doi: 10.1016/j.jcis.2019.06.059 [18] Zhou Xikang, Xue Wei, Liu Wenwen, et al. Quadri-directionally anisotropic droplets sliding surfaces fabricated by selective laser texturing of aluminum alloy plates[J]. Applied Surface Science, 2020, 509: 145406. doi: 10.1016/j.apsusc.2020.145406 [19] 邹国文. 激光毛化形貌成形机理的数值模拟与实验研究[D]. 镇江: 江苏大学, 2018Zou Guowen. Numerical simulation and experimental research on formation mechanism of laser texturing topography[D]. Zhenjiang: Jiangsu University, 2018 [20] 陆建, 倪晓武, 贺安之. 激光与材料相互作用物理学[M]. 北京: 机械工业出版社, 1996Lu Jian, Ni Xiaowu, He Anzhi. Physics of laser-material interaction[M]. Beijing: China Machine Press, 1996 -

下载:

下载: