Analysis and calculation on core neutronics affected by the assembly bowing in pressurized water reactor nuclear power plant

-

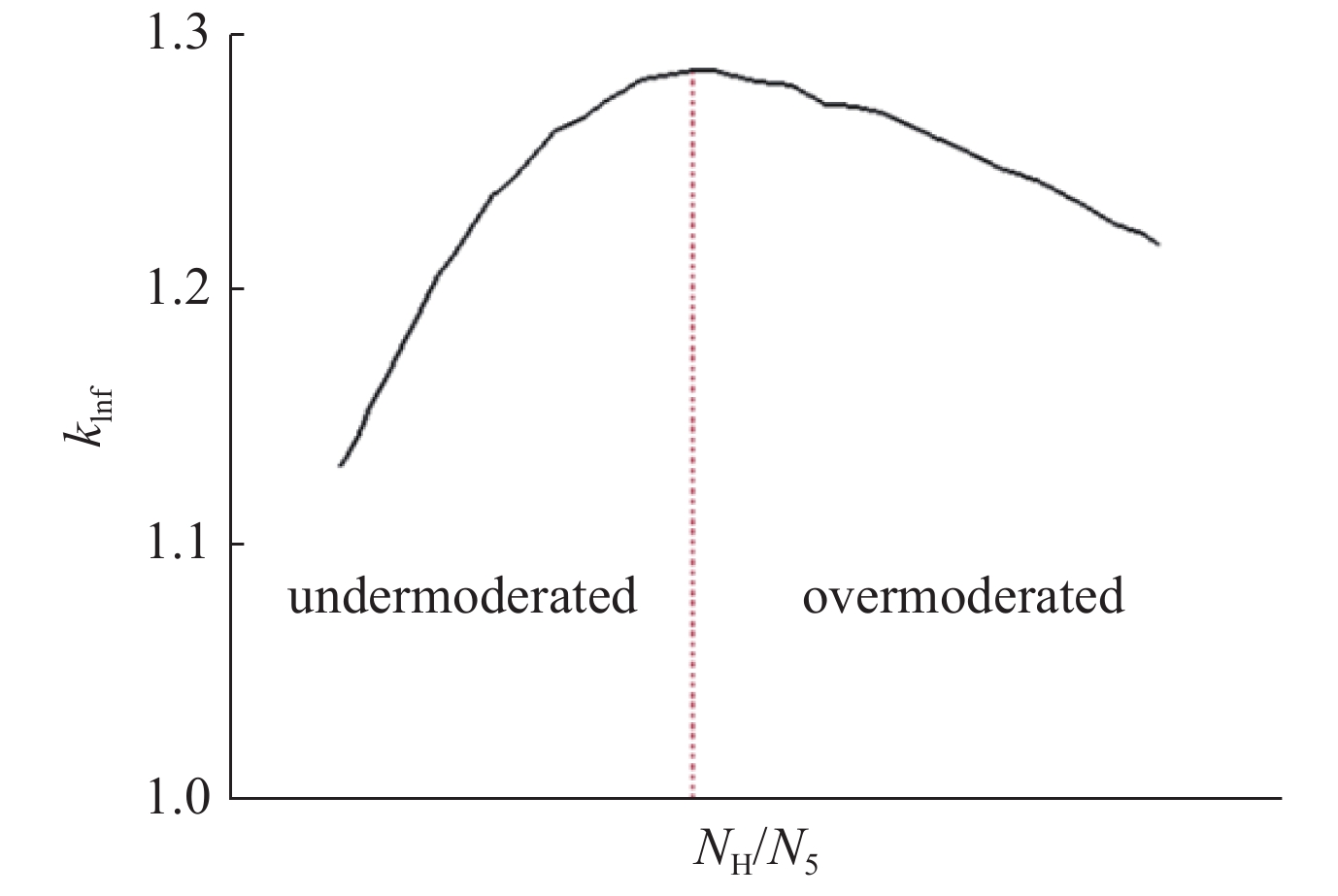

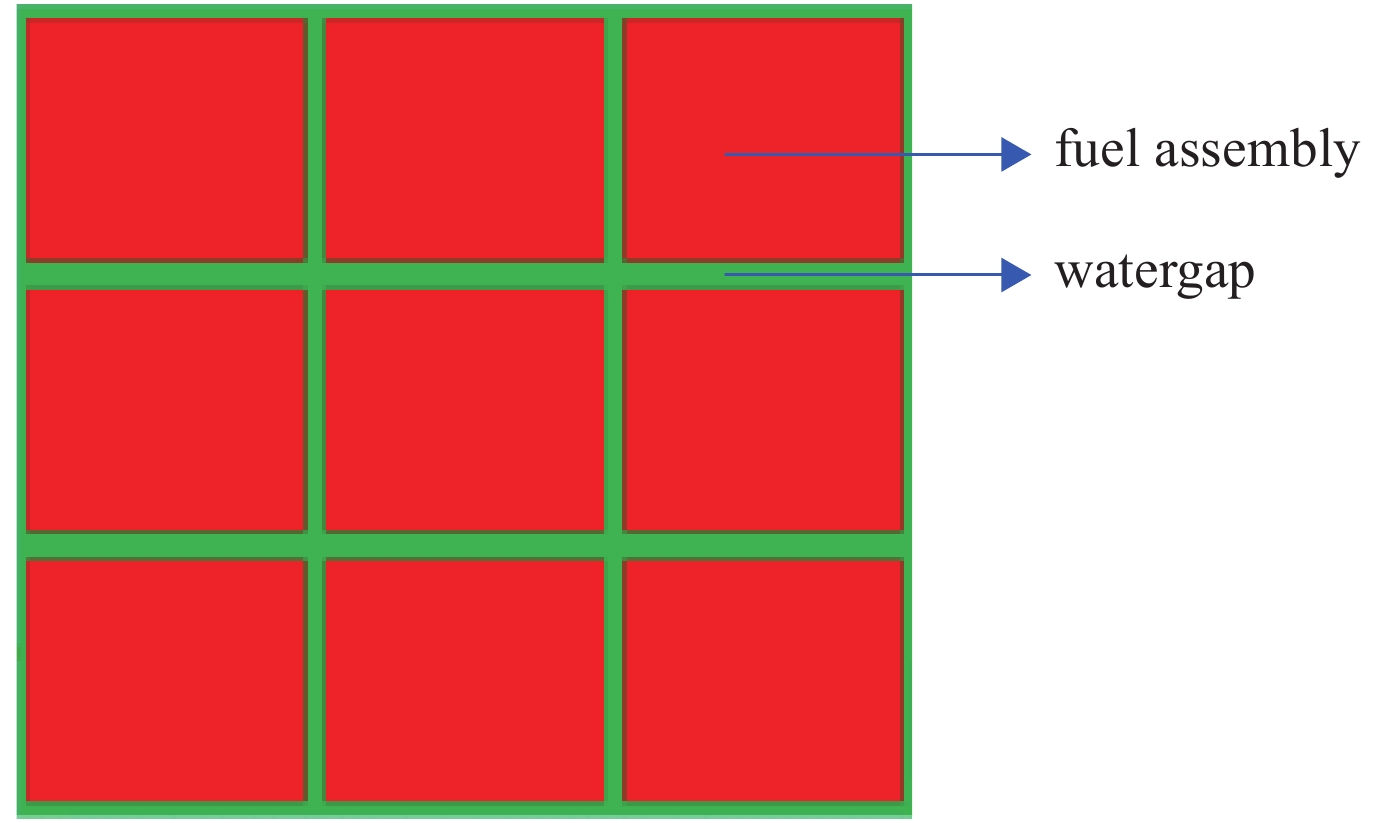

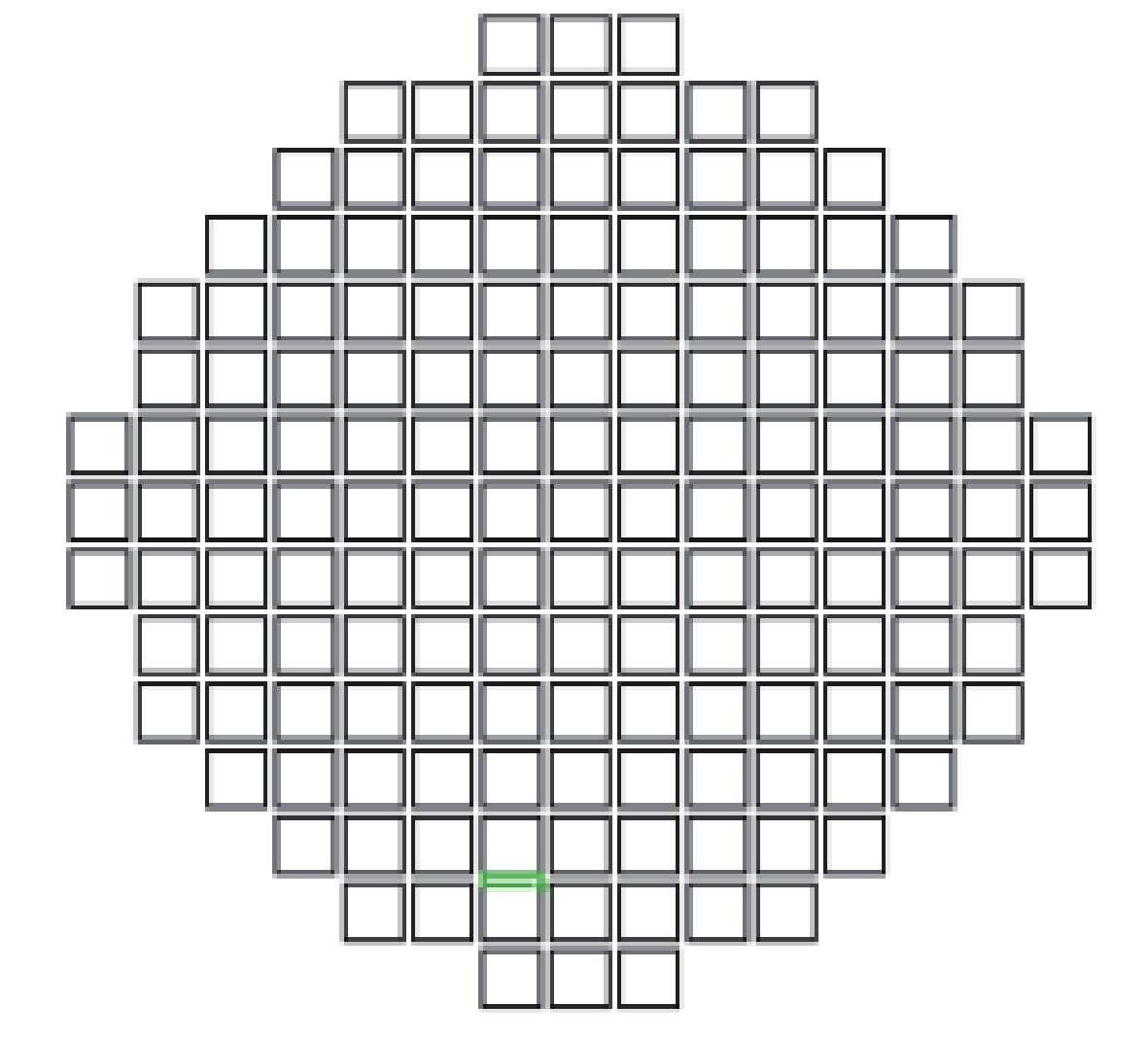

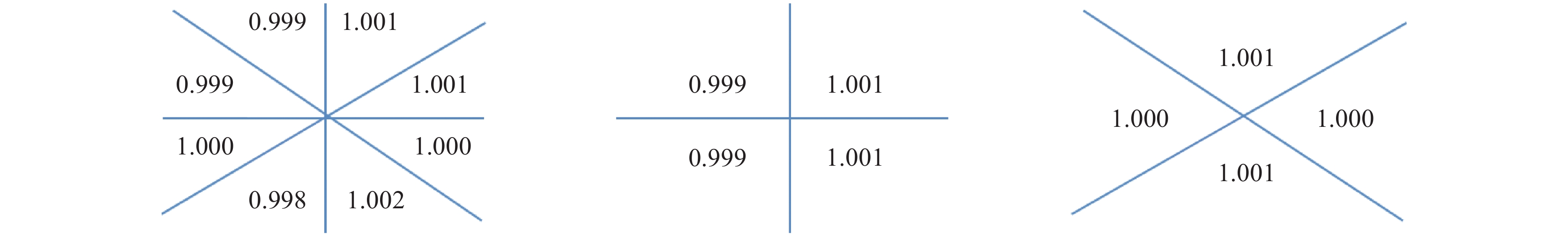

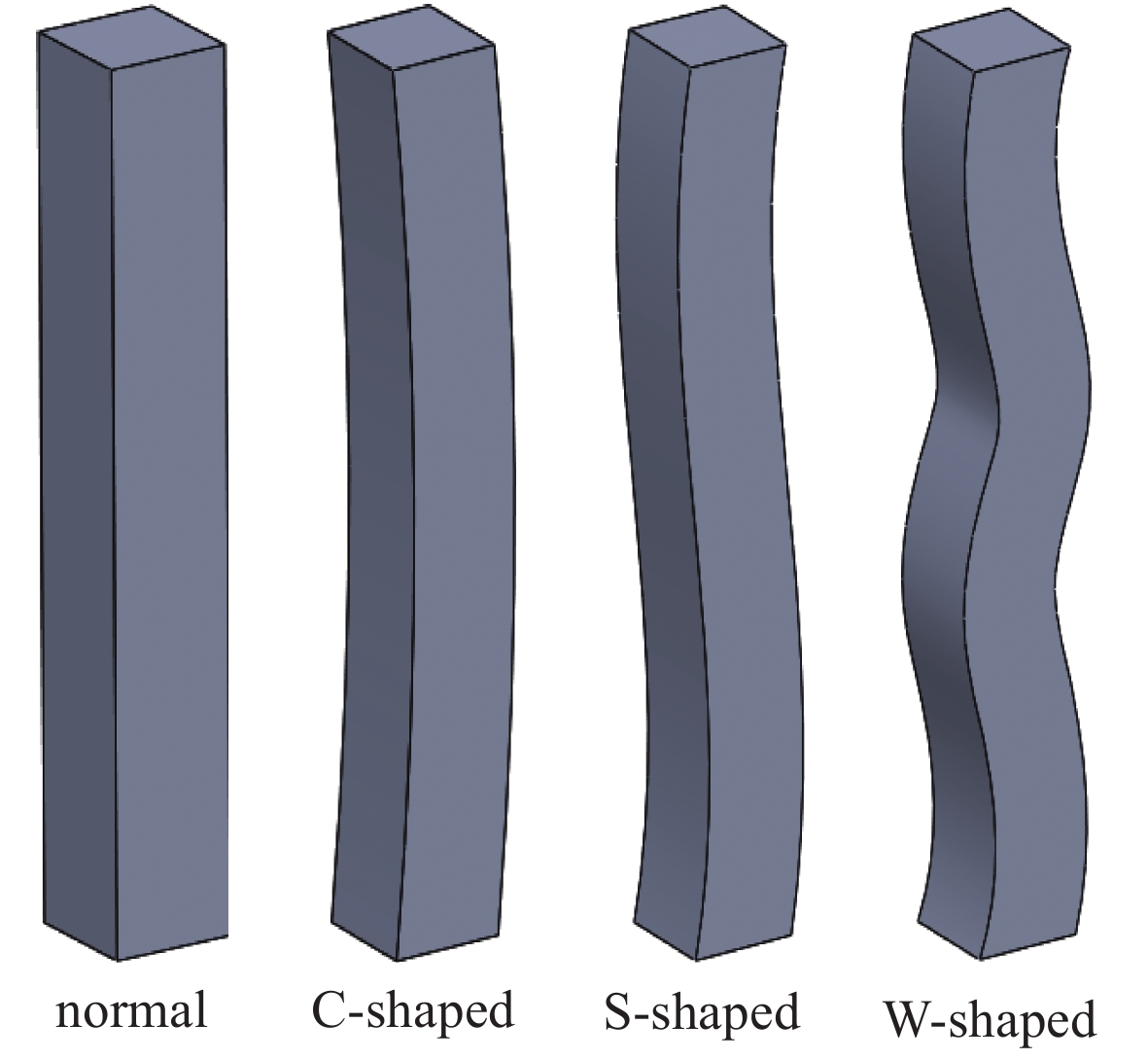

摘要: 在压水堆核电站中,由于燃料组件装配的压紧力、冷却剂流动、辐射蠕变、燃耗等因素会导致燃料组件的弯曲,燃料组件的弯曲对组件间的水隙分布产生影响,从而影响中子的慢化行为及堆芯的传热性能,进而对反应堆堆芯的运行参数造成影响。本文分析了组件弯曲的成因及机理、影响及后果(包括对堆芯功率分布、径向功率倾斜、焓升因子、热点因子等参数的影响),并使用蒙特卡罗软件JMCT,对组件弯曲的确定论计算程序的正确性进行了验证。最后通过确定论的计算程序模块,对CPR1000核电站的组件弯曲情况进行了模拟分析,计算结果表明:在某一燃耗下,随着水隙增加或减小,燃料组件功率会随之增加或减小,使堆芯的功率分布发生倾斜,影响核电站的安全运行。Abstract: In a pressurized water reactor nuclear power plant, the compression force of the fuel assembly, coolant flow, radiation creep, burnup and other factors will cause the bowing of the fuel assembly. The bowing of the fuel assembly affects the distribution of the water gap between the assemblies. It affects the slowing behavior of neutrons and the heat transfer performance of the core, which in turn affects the operating parameters of the reactor core. This paper discusses the cause and mechanism, influence and consequences of assembly bowing (including the influence on core power distribution, core radial power tilt, nuclear enthalpy rise hot channel factor, heat flux hot channel factor and other parameters), and uses Monte Carlo software JMCT to verify the correctness of the calculation program of component bowing PCM. Finally, through the deterministic calculation program, a simulation analysis of the assemblies bowing of the CPR1000 nuclear power plant is carried out. The calculation results show that: at certain fuel consumption, as the water gap increases or decreases, the fuel assembly power will increase or decrease, the power distribution of the core will tilt, affecting the safe operation of nuclear power plants.

-

Key words:

- fuel assembly bowing /

- core neutronics /

- Monte-Carlo code /

- deterministic code

-

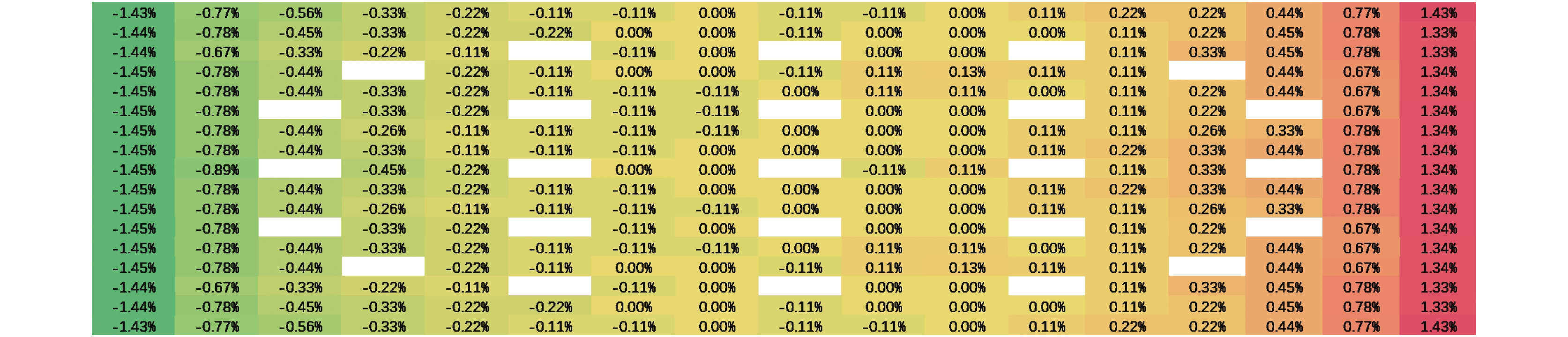

表 1 3×3组件中心组件弯曲前后棒功率对比表

Table 1. Comparison of the rod power before and after bowing of the center assembly in a 3×3 assemblies group

enrichment magnification

of watergapdiscrepancy of power

after bowing (PCM)discrepancy of power

after bowing (JMCT)difference between PCM

and JMCT1.80% 9 29.38% 31.88% −2.50% 4.45% 9 44.93% 47.49% −2.56% 表 2 组件弯曲PCM与蒙特卡罗软件对比表

Table 2. Comparison of the PCM and JMCT on the assembly bowing

power discrepancy of

H08 assembly (PCM)power discrepancy of

H08 assembly (JMCT)difference between PCM

and JMCTcase1 1.70% 3.40% 2.80% case2 5.60% 6.60% −2.30% -

[1] Lambert S, Campioni G, Faucher V, et al. Modeling the consequences of fuel assembly bowing on PWR core neutronics using a Monte-Carlo code[J]. Annals of Nuclear Energy, Elsevier Masson, 2019, 134: 330-341. doi: 10.1016/j.anucene.2019.06.017 [2] Wang Y, Chen J, Wei L. A method for calculating the assembly bowing reactivity coefficients in sodium fast reactor[J]. Annals of Nuclear Energy, 2021, 155: 108176. doi: 10.1016/j.anucene.2021.108176 [3] 卢皓亮, 陈俊, 王军令, 等. 自主化堆芯核设计软件COCO验证与确认[J]. 原子能科学技术, 2017, 51(8):1459-1463. (Lu Haoliang, Chen Jun, Wang Junling, et al. Verification and validation of self-reliant core nuclear design code COCO[J]. Atomic Energy Science and Technology, 2017, 51(8): 1459-1463 doi: 10.7538/yzk.2017.51.08.1459 [4] 李刚, 张宝印, 邓力, 等. 蒙特卡罗粒子输运程序JMCT研制[J]. 强激光与粒子束, 2013, 25(1): 158-162Li Gang, Zhang Baoying, Deng Li, et al. Development of Monte Carlo particle transport code JMCT. High Power Laser and Particle Beams, 2013, 25(1): 158-162 [5] 李朋洲, 李琦. 压水堆燃料组件研发中的力学问题[J]. 核动力工程, 2015, 36(5):136-139. (Li Pengzhou, Li Qi. Mechanic problems in PWR fuel assembly research and development[J]. Nuclear Power Engineering, 2015, 36(5): 136-139 [6] 沈增耀. 压水堆核电厂核岛设计. 总论[M]. 北京: 原子能出版社, 2010: 15-16Shen Zengyao. Design of nuclear island for pressurized water reactor nuclear power plant[M]. Beijing: Atomic Energy Press, 2010: 15-16 [7] 李伟才, 肖忠. 压水堆燃料组件弯曲变形机理及规避措施[J]. 核动力工程, 2008, 29(2):55-57. (Li Weicai, Xiao Zhong. Mechanism of fuel assembly bowing in PWR and preventive measures[J]. Nuclear Power Engineering, 2008, 29(2): 55-57 [8] Grimm P, Jatuff F, Murphy M. Experimental validation of channel bowing effects on pin power distributions in a Westinghouse SVEA-96+ Assembly[J]. Journal of Nuclear Science and Technology, 2006, 43(3): 223-230. doi: 10.1080/18811248.2006.9711084 [9] Plaschy M, Jatuff F, Grimm P, et al. Comparisons of deterministic neutronic calculations with Monte Carlo results for an advanced BWR fuel assembly with hafnium control blades[J]. Journal of Nuclear Science & Technology, 2006, 43(11): 1298-1310. [10] 王超, 杨铄龑, 彭思涛, 等. 自主PCM核设计软件包的自动化验证[J]. 核动力工程, 2018, 39(S2):46-49. (Wang Chao, Yang Shuoyan, Peng Sitao, et al. Automated validation of CGN nuclear software package PCM[J]. Nuclear Power Engineering, 2018, 39(S2): 46-49 -

下载:

下载: