Adaptability analysis and optimization design of modular Marx generator in mechanical environment

-

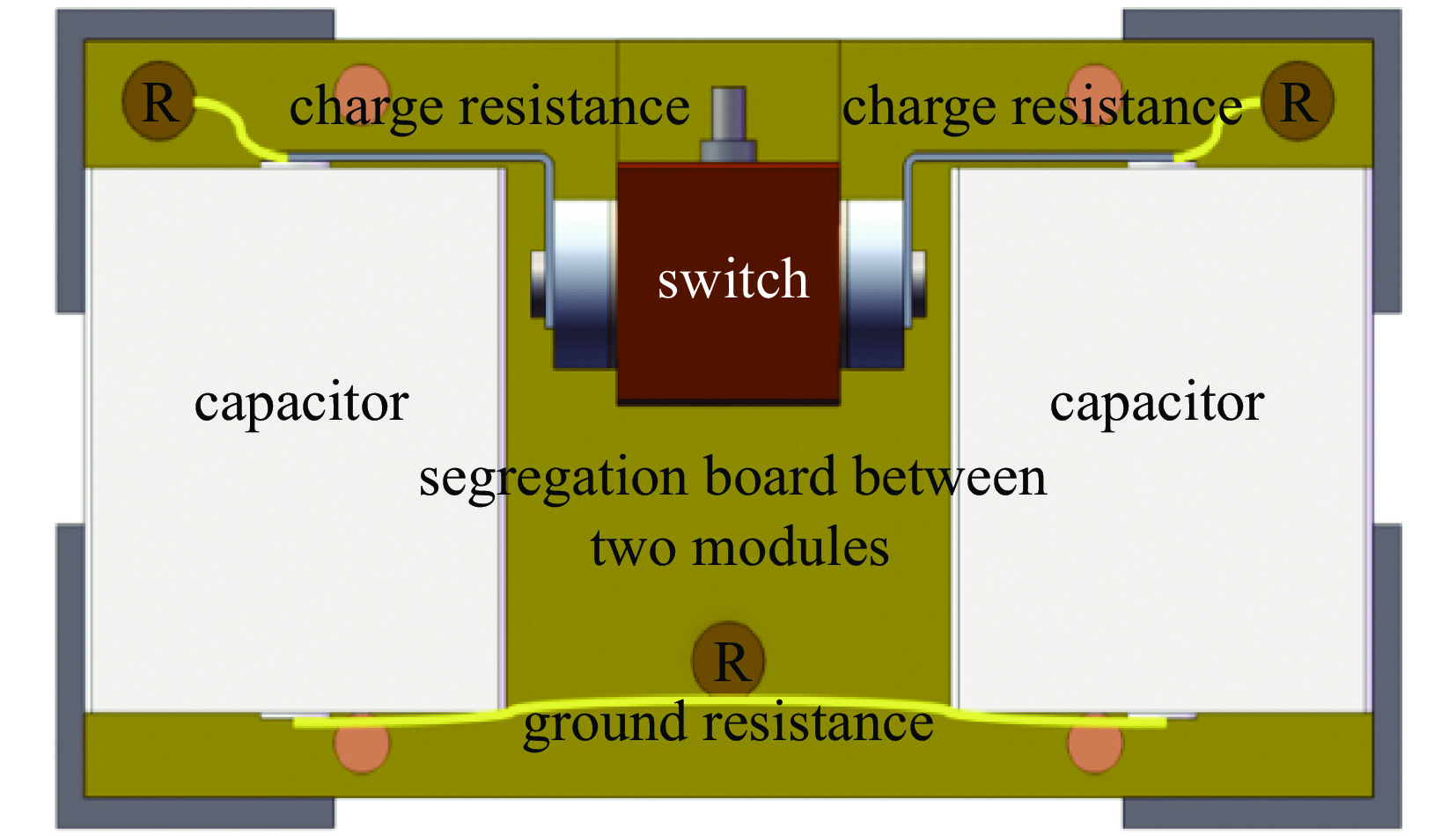

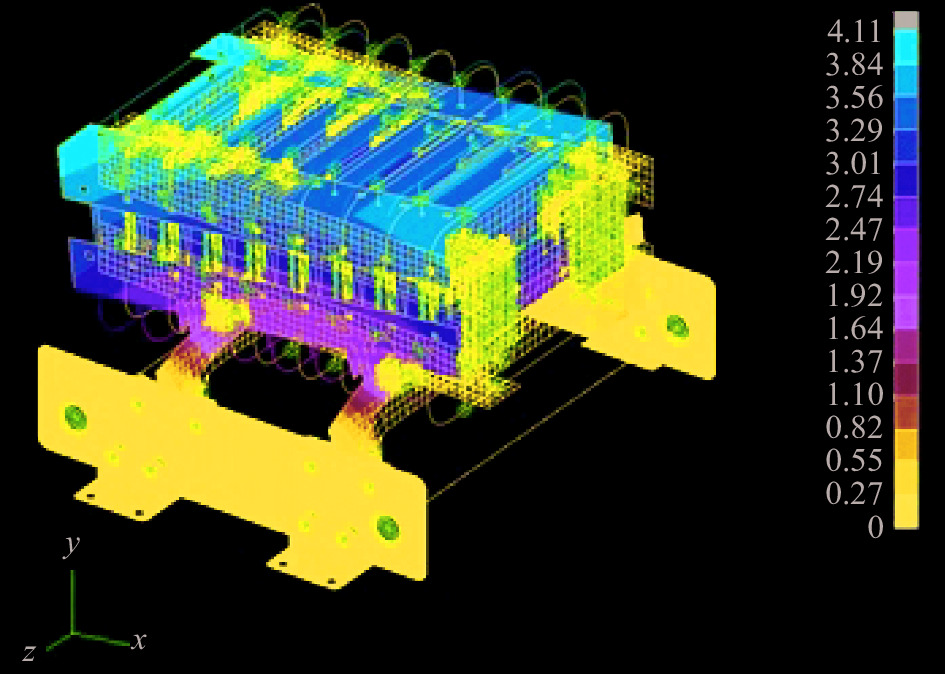

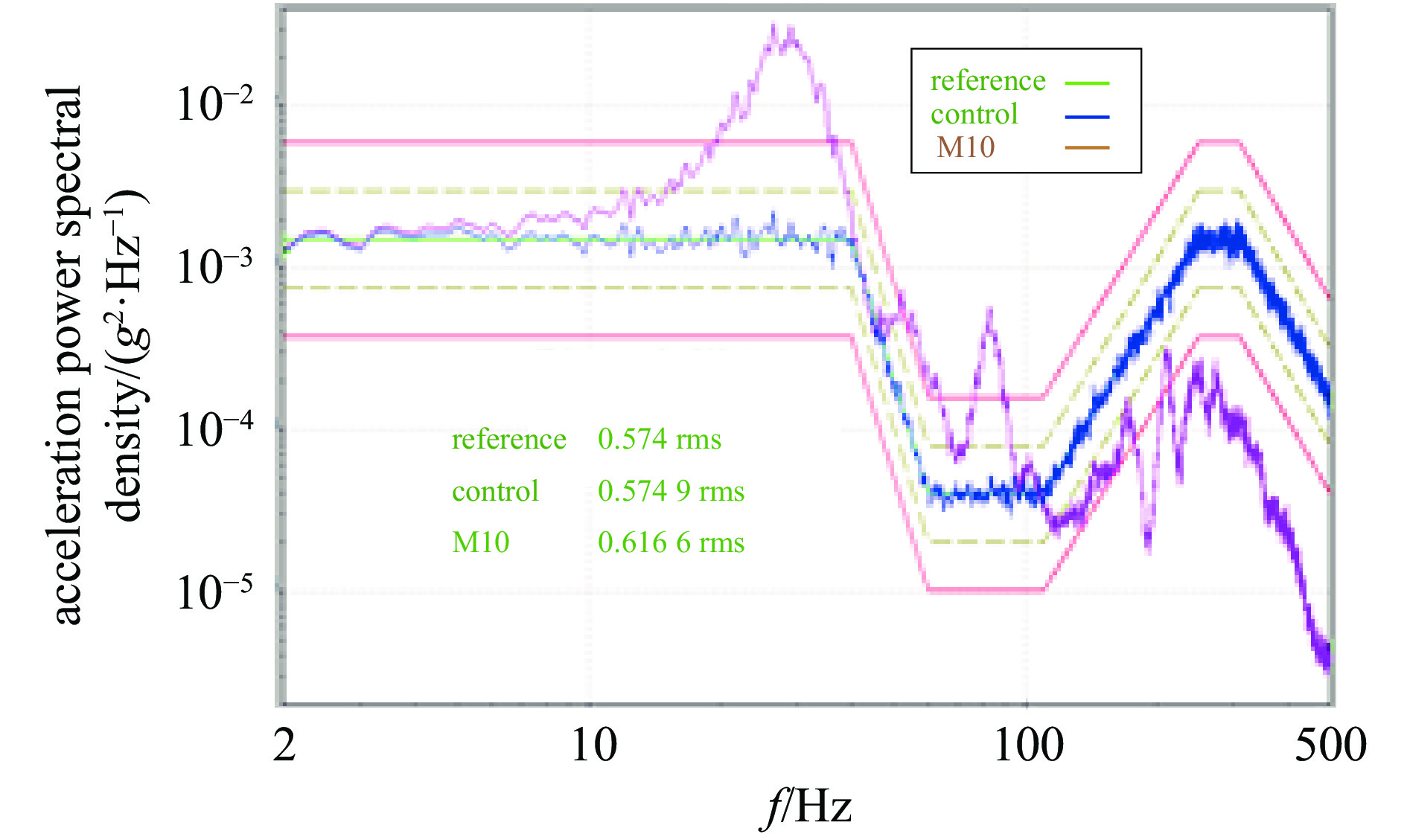

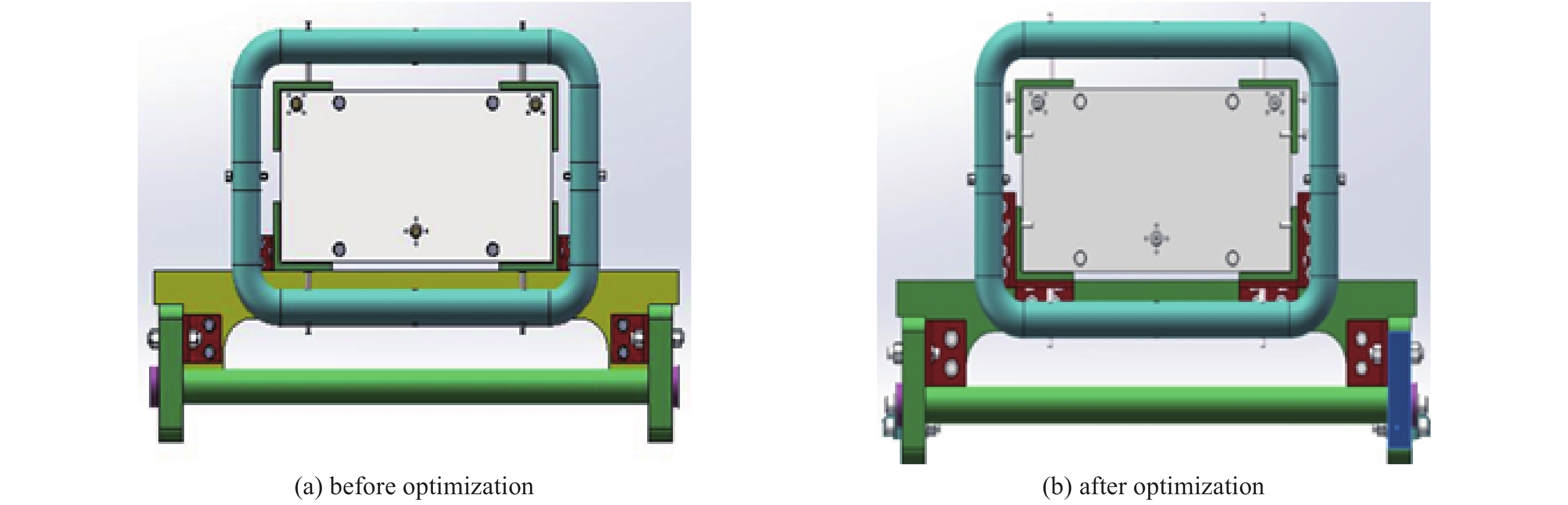

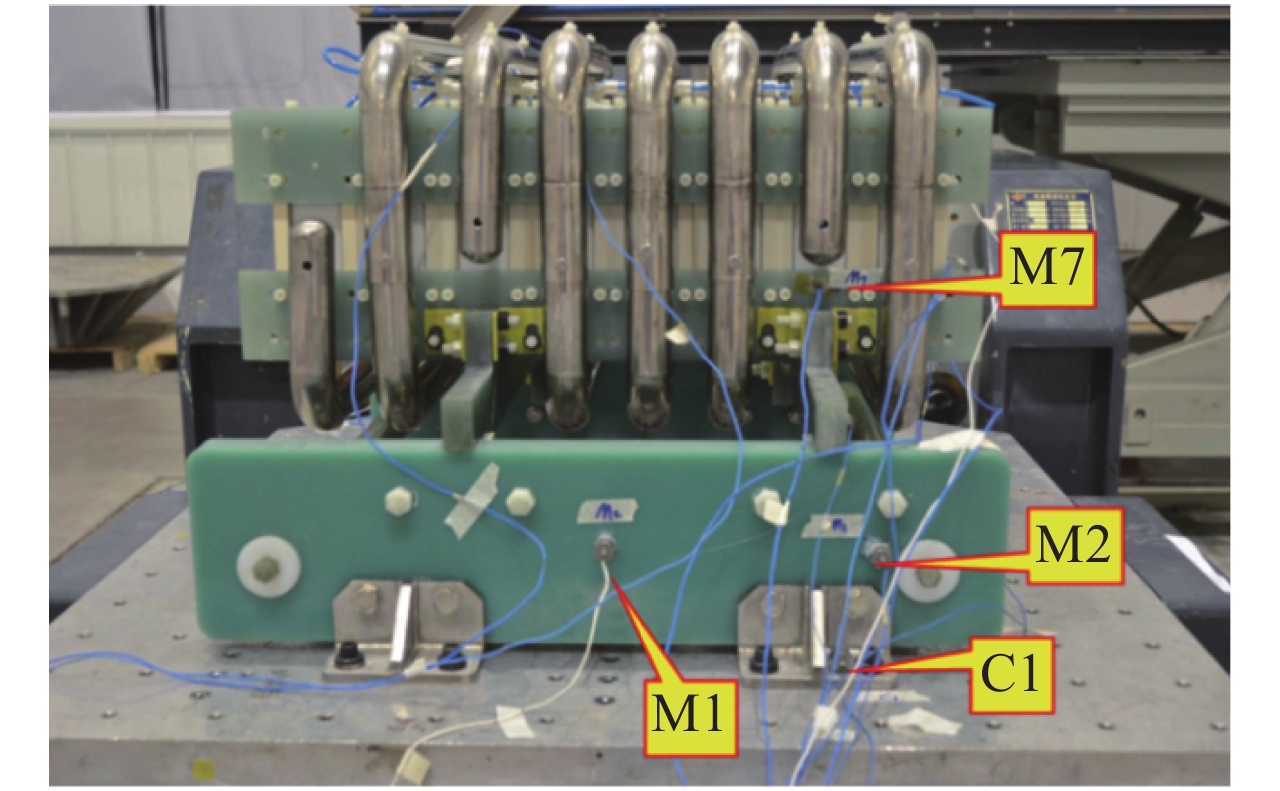

摘要: 为研究Marx发生器机芯在公路运输条件下的力学环境适应性,基于随机振动理论和有限元分析方法对Marx机芯进行了仿真分析和随机振动试验。首先,建立了八级模块化Marx机芯的有限元动力学仿真模型,模拟确定了机芯的应力集中点;然后,通过振动台运输振动摸底试验修正了有限元模型,对机芯结构进行了优化设计,使Marx机芯整体一阶频率由15.4 Hz提高到19.7 Hz,降低了整机垂向的动力学响应,提高了机芯的力学环境适应性。试验结果表明,Marx发生器结构设计需要重点考虑其在垂直方向的可靠性;振动过程中,机芯整体连接稳定,振动应力集中于机芯与U型支撑杆连接处、支撑杆与支撑板连接的角片处,以及开关连接件处,是结构设计的薄弱环节。Abstract: To study the adaptability of the modularized Marx generator in mechanical environment, simulation and vibration experiment of the generator are conducted based on the random vibration theory and finite element analysis method. Firstly, the finite element simulation model of an 8-stage Marx generator is established, and the stress concentration positions are identified. Secondly, the finite element model is corrected according to the initial results of shaking table test. Then an optimization scheme is proposed to modify the Marx generator. As a result, the first-order frequency of the Marx generator is increased from 15.4 Hz to 19.7 Hz. It is helpful to reduce the dynamic response in vertical direction and enhance the mechanical environment adaptability. Results show that more attention should be paid to the reliability in vertical direction when a Marx generator is being designed. The connection of the generator is stable in the vibration experiment, and the stresses mainly concentrate on the corner pieces between the generator and the U-shape support plates, the connections between U-shape support plates and side support plates, and the switch junctions, which are the weak points in design.

-

Key words:

- Marx generator /

- random vibration /

- finite element analysis /

- optimization design

-

表 1 材料参数

Table 1. Parameters of the material

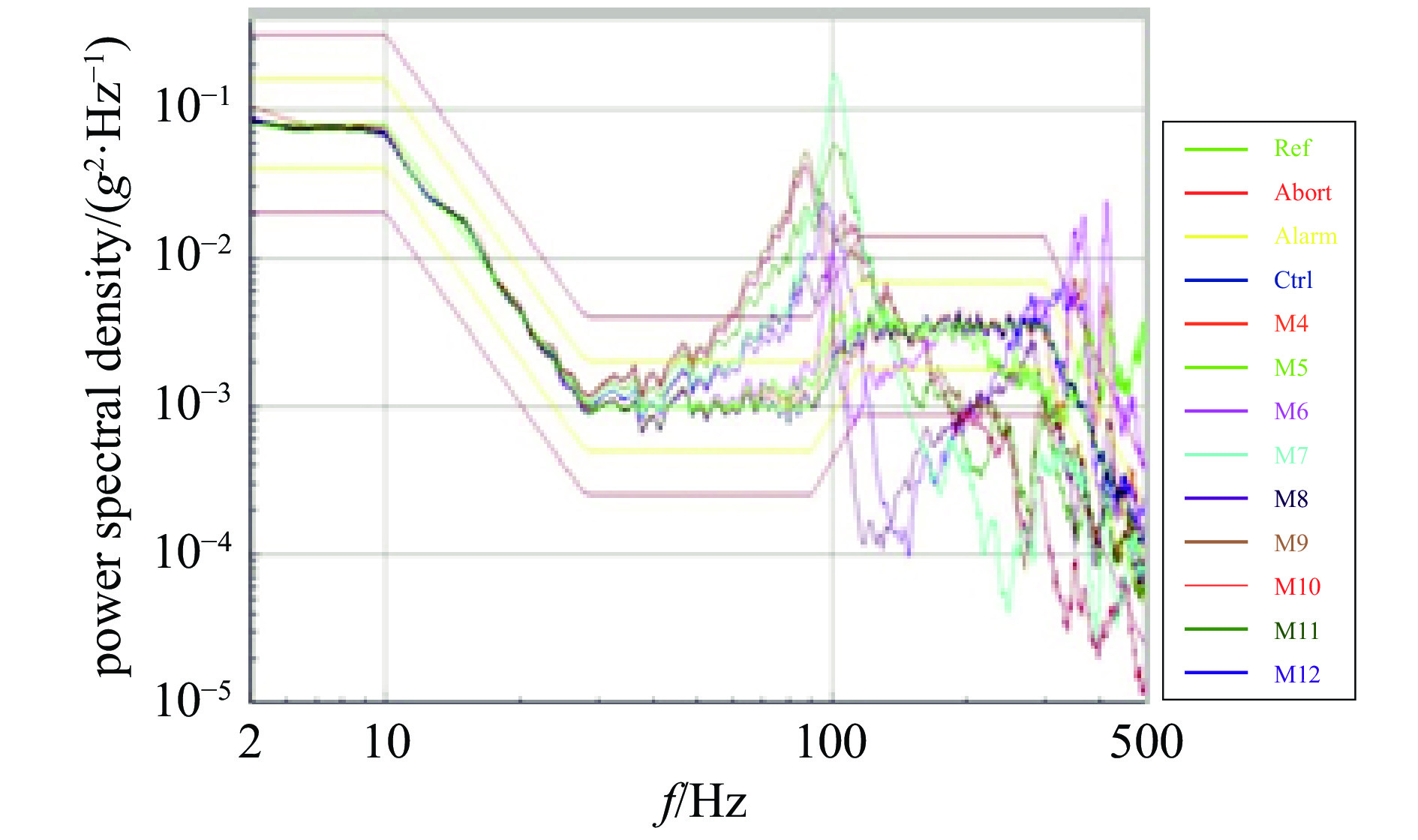

material Young’s modulus/GPa Poisson ratio density/(kg·m−3) stainless steel 190.0 0.33 8000 glass fiber reinforced plastics 37.2 0.25 2440 MC nylon 31.9 0.40 1150 表 2 Marx发生器机芯几个位置的总均方根加速度

Table 2. Acceleration response at several points of the Marx generator

position total root mean square acceleration/g vertical extraction lateral extraction longitudinal extraction U-shape support pole 2.01 1.55 0.99 support board of glass fiber 2.59 1.29 0.50 switch 1.58 0.89 0.23 random load 1.36 0.58 0.37 表 3 Marx发生器机芯几个位置的总均方根应力

Table 3. Acceleration response of the Marx generator

position total root mean square stress/MPa vertical extraction lateral extraction longitudinal extraction swtich connector 32.2 12.6 7.4 segregation board between

two modules9.8 1.3 6.4 angle plate that connects the angle iron

and U-shape support pole6.8 2.3 1.4 U-shape support pole 0.4 0.1 0.2 angle plate that connects the U-shape support pole and support board of glass fiber 13.3 3.8 4.9 表 4 改进结构八级Marx机芯垂向随机振动扫频结果

Table 4. Random vibration results of the improved 8-stage Marx pulser in vertical direction

testing positions root mean square of

random vibration/gmagnification

factor1st sweep frequency/Hz before vibration after vibration support board of glass fiber 0.57 2.8 87.8 87.8 angle iron of glass fiber 1.29 6.5 97.9 96.1 U-shape support pole 0.73 3.7 87.8 87.8 switch connector of the 1st module 2.06 10.3 88.6 87.8 switch and capacitor connectors of the 1st module 2.00 10.0 88.6 88.6 switch and capacitor connectors of the 4th module 1.09 5.5 88.6 87.8 表 5 机芯改进前后整体结构的模态特性

Table 5. Mode characteristic comparison before and after improvement of the Marx generator

modes frequency/Hz modal descriptions before modification after modification before modification after modification 1st order 15.4 19.7 longitudinal vibration on upper Marx longitudinal vibration on upper Marx 2nd order 26.7 30.7 local vibration in switch local vibration in switch and over all vibration -

[1] Wei Hao, Yin Jiahui, Zhang Pengfei, et al. Development of a 4-MV, 80-kA-induction voltage adder for flash X-ray radiography[J]. IEEE Transactions on Plasma Science, 2019, 47(11): 5030-5036. doi: 10.1109/TPS.2019.2946685 [2] 邓明海, 曹宁翔, 马成刚, 等. 200 kV重复频率Marx发生器研制[J]. 强激光与粒子束, 2019, 31:055003. (Deng Minghai, Cao Ningxiang, Ma Chenggang, et al. Development of 200 kV repetitive Marx generator[J]. High Power Laser and Particle Beams, 2019, 31: 055003 doi: 10.11884/HPLPB201931.190369 [3] 樊旭亮, 孙旭, 潘亚峰, 等. 基于磁开关的固态近方波Marx发生器初步模拟设计[J]. 现代应用物理, 2018, 9:041201. (Fan Xuliang, Sun Xu, Pan Yafeng, et al. Design of a solid state rectangular pulse Marx generator based on magnetic switch[J]. Modern Applied Physics, 2018, 9: 041201 [4] 刘锐, 曾乃工, 王新新. 1.2 MV全封闭Marx发生器的绝缘结构设计[J]. 高电压技术, 2005, 31(4):69-70. (Liu Rui, Zeng Naigong, Wang Xinxin. Insulation design for a 1.2 MV enclosed Marx generator[J]. High Voltage Engineering, 2005, 31(4): 69-70 doi: 10.3969/j.issn.1003-6520.2005.04.026 [5] Elgenedy M A, Massoud A M, Ahmed S, et al. A modular multilevel voltage-boosting Marx pulse-waveform generator for electroporation applications[J]. IEEE Transactions on Power Electronics, 2019, 34(11): 10575-10589. doi: 10.1109/TPEL.2019.2899974 [6] 宋法伦, 李飞, 龚海涛, 等. 高功率重复频率Marx型脉冲功率源小型化技术研究进展[J]. 强激光与粒子束, 2018, 30:020201. (Song Falun, Li Fei, Gong Haitao, et al. Research progress on miniaturization of high power repetition frequency Marx type pulse power source[J]. High Power Laser and Particle Beams, 2018, 30: 020201 doi: 10.11884/HPLPB201830.170337 [7] 贾伟, 陈志强, 郭帆, 等. 典型布局Marx发生器内部过压形成与分布[J]. 华中科技大学学报(自然科学版), 2018, 46(10):110-115. (Jia Wei, Chen Zhiqiang, Guo Fan, et al. Formation mechanism and distribution of internal overvoltage of Marx generator with typical layouts[J]. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2018, 46(10): 110-115 [8] Pouncey J C, Lehr J M, Giri D V. Erection of compact Marx generators[J]. IEEE Transactions on Plasma Science, 2019, 47(6): 2902-2909. doi: 10.1109/TPS.2019.2915034 [9] 西北核技术研究所. 一种紧凑型结构的Marx发生器: 103475255A[P]. 2013-12-25Northwest Inst Nuclear Tech. Marx generator with compact structure: 103475255A[P]. 2013-12-25 [10] Sharma J K. Theoretical and experimental modal analysis of beam[M]//Ray K, Sharan S, Rawat S, et al. Engineering Vibration, Communication and Information Processing. Singapore: Springer, 2019: 177-186. [11] 瞿金秀, 石长全, 王磊超, 等. 不同老化状态黏弹夹层结构的模态分析[J]. 振动与冲击, 2020, 39(11):69-75. (Qu Jinxiu, Shi Changquan, Wang Leichao, et al. Modal analysis of viscoelastic sandwich structure with different aging states[J]. Journal of Vibration and Shock, 2020, 39(11): 69-75 [12] 韩帅, 曹亚文, 邓长华, 等. 液体火箭发动机三轴向虚拟振动试验技术研究[J]. 火箭推进, 2018, 44(6):68-74. (Han Shuai, Cao Yawen, Deng Changhua, et al. Research on test technology for three-axial virtual vibration of liquid rocket engine[J]. Journal of Rocket Propulsion, 2018, 44(6): 68-74 doi: 10.3969/j.issn.1672-9374.2018.06.011 [13] 顾乾磊, 张万福, 张尧, 等. 基于微元轨迹的密封动力特性系数理论识别方法[J]. 振动与冲击, 2019, 38(16):22-28. (Gu Qianlei, Zhang Wanfu, Zhang Yao, et al. A theoretical identification method for dynamic coefficients of seals based on infinitesimal trajectory of rotors[J]. Journal of Vibration and Shock, 2019, 38(16): 22-28 [14] 李勤建, 高翠琢, 边国辉. 组件的模态分析和随机振动分析[J]. 半导体技术, 2012, 37(10):810-814. (Li Qinjian, Gao Cuizhuo, Bian Guohui. Modal analysis and random vibration analysis on a module[J]. Semiconductor Technology, 2012, 37(10): 810-814 doi: 10.3969/j.issn.1003-353x.2012.10.015 [15] 张建斌. 带橡胶减振器的箭载电子设备动力学响应分析研究[D]. 哈尔滨: 哈尔滨工业大学, 2019Zhang Jianbin. Research on dynamic response of the electronic equipment with Bubber shock absorber on the rockets[D]. Harbin: Harbin Institute of Technology, 2019 [16] Randall R B, Antoni J, Smith W A. A survey of the application of the cepstrum to structural modal analysis[J]. Mechanical Systems and Signal Processing, 2019, 118: 716-741. doi: 10.1016/j.ymssp.2018.08.059 [17] 李星占, 董兴建, 岳晓斌, 等. 振动响应传递率的动力学特性研究及其在工作模态分析中的应用[J]. 振动与冲击, 2019, 38(9):62-70. (Li Xingzhan, Dong Xingjian, Yue Xiaobin, et al. Dynamic characteristics of vibration response transmissibility and its application in operational modal analysis[J]. Journal of Vibration and Shock, 2019, 38(9): 62-70 -

下载:

下载: