Development and verification of fuel assembly bowing model in software package PCM

-

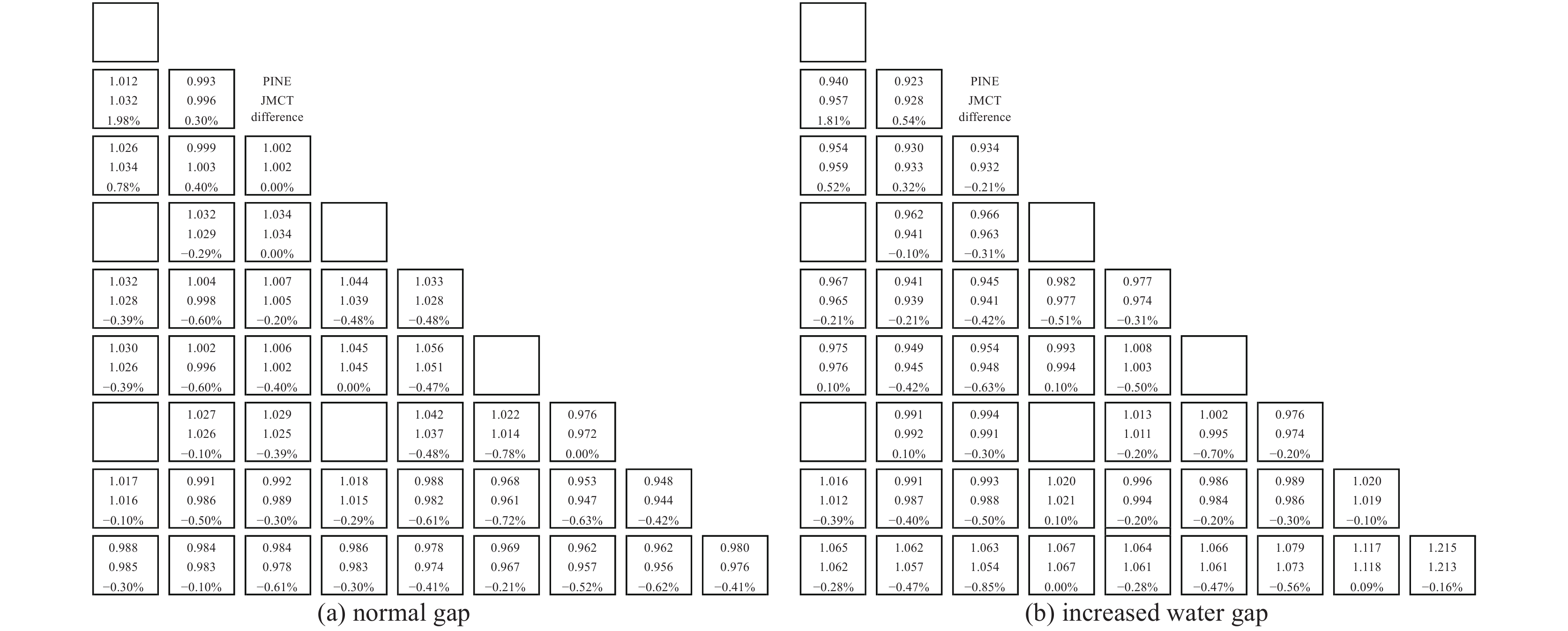

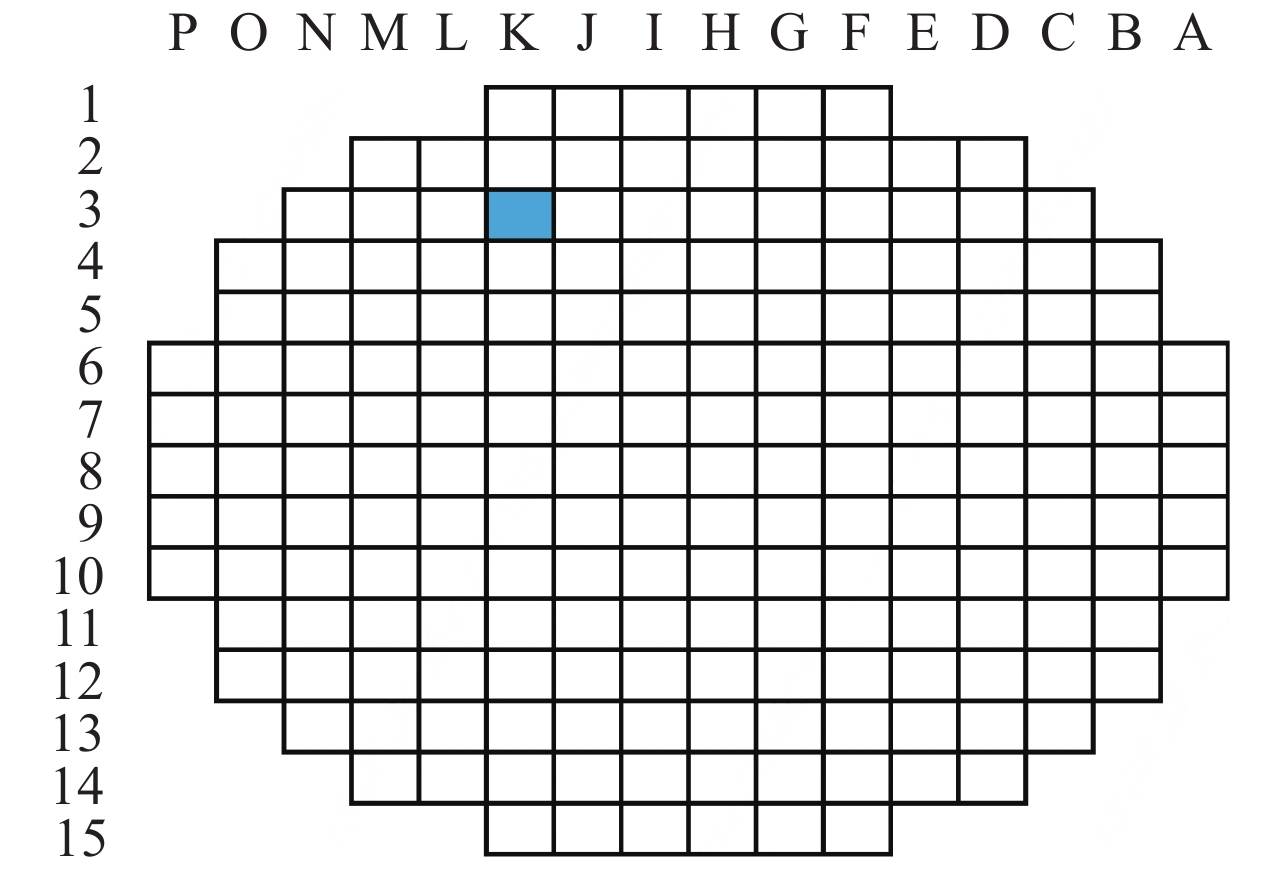

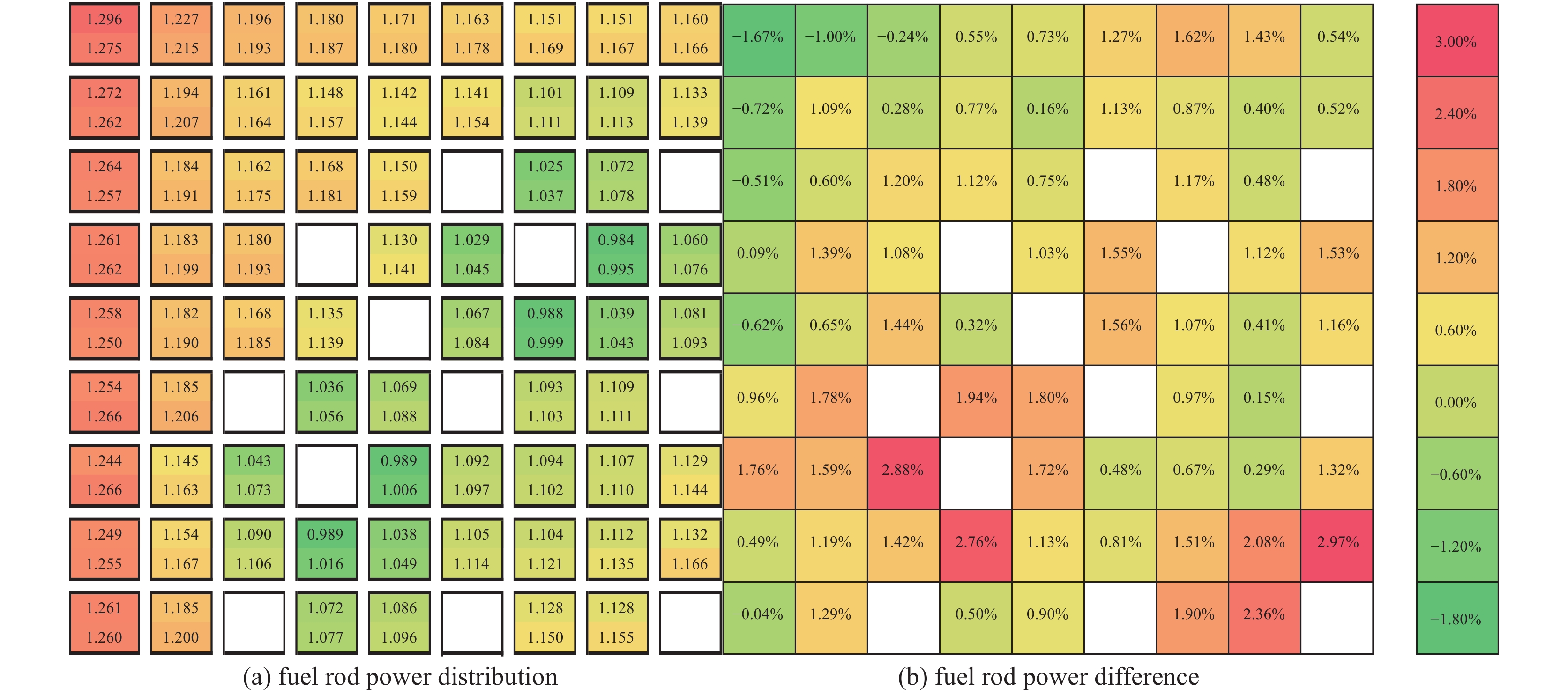

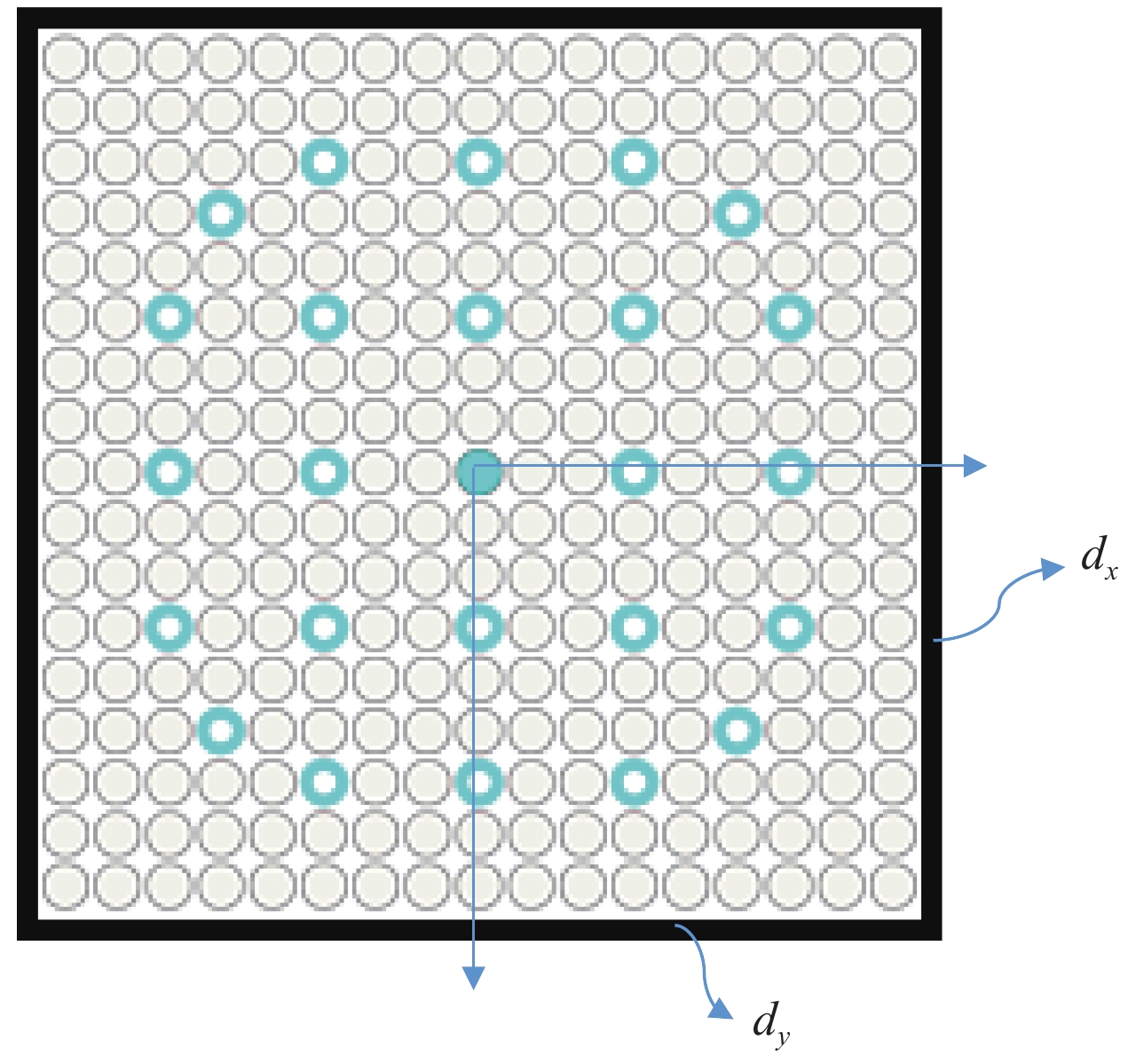

摘要: 燃料组件在反应堆内受压紧力等作用会发生弯曲,该弯曲会显著改变反应堆局部位置的中子慢化。基于中广核核设计软件包PCM中的组件中子截面计算软件PINE和堆芯核设计软件COCO,开发了专门的燃料组件弯曲模型,以分析燃料组件弯曲对堆芯局部功率分布的影响,并和蒙特卡罗软件JMCT做了对比验证计算。计算结果表明,PCM软件包燃料组件弯曲模型的计算结果与JMCT吻合良好,该软件包可以用于燃料组件弯曲的分析计算。燃料组件的弯曲对于堆芯的局部功率分布有显著的影响,需要在设计中予以特别关注。Abstract: The fuel assemblies bow with different stresses in the PWR reactor core and this phenomenon can significantly affect the local neutron moderation in the reactor core. Based on the CGN’s in-house software package PCM, which is composed of the fuel assembly neutron cross section software PINE and the core design software COCO, this study developed a specific model for fuel assembly bowing to analyze the impact on local power distribution, and compared the results with that of the Monto Carlo code JMCT. The study shows that the results of fuel assembly bowing model in PCM have good consistency with those of JMCT, and that PCM is valid in fuel assembly bowing analysis. The fuel assembly bowing has a significant impact on core local power distribution. This phenomenon shall be specially considered in the PWR reactor design.

-

Key words:

- fuel assembly bowing /

- core power distribution /

- PCM /

- water gap /

- neutron cross section

-

表 1 燃料组件主要参数

Table 1. Fuel assembly main parameters

enrichment/% assembly configuration normal water gap/mm increased water gap/mm 4.45 17×17 0.76 3.80 表 2 燃料组件均匀化中子截面的比较

Table 2. Homogeneous neutron cross section of fuel assembly

fast group

transport cross

section/cm−1thermal group

transport cross

section/cm−1fast group

absorption cross

section/cm−1thermal group

absorption cross

section/cm−1fast group

fission cross

section/cm−1thermal group

fission cross

section/cm−1case 1 2.37744×10−1 8.80051×10−1 9.99930×10−3 1.04927×10−1 3.24601×10−3 7.22189×10−2 Case 2 2.35261×10−1 9.07776×10−1 9.48205×10−3 9.92312×10−2 3.06870×10−3 6.71697×10−2 case 3 2.36489×10−1 8.94271×10−1 9.73666×10−3 1.02015×10−1 3.15638×10−3 6.96360×10−2 results from Eq.(2) 2.36460×10−1 8.94392×10−1 9.73174×10−3 1.01981×10−1 3.15429×10−3 6.96071×10−2 difference 0.012% −0.014% 0.051% 0.034% 0.066% 0.042% -

[1] 李伟才, 肖忠. 压水堆燃料组件弯曲变形机理及规避措施[J]. 核动力工程, 2008, 29(2):55-57. (Li Weicai, Xiao Zhong. Mechanism fuel assembly bowing preventive measures[J]. Nuclear Power Engineering, 2008, 29(2): 55-57 [2] Franzen A. Evaluation of fuel assembly bow penalty peaking factors for Ringhals 3 – Based on a cycle specific core water gap distribution[D]. Uppsala Universitet, 2017. [3] Rochman D, Mala P, Ferroukhi H, et al. Bowing effects on power and burn-up distributions for simplified full PWR and BWR cores[C]//International Conference on Mathematics & Computational Methods Applied to Nuclear Science & Engineering. 2017. [4] Chionis D, Dokhane A, Belblidia L, et al. Development and verification of a methodology for neutron noise response to fuel assembly vibrations[J]. Annals of Nuclear Energy, 2020, 147: 17669-107683. [5] Yamamoto A, Endo T, Nagano H, et al. A simple treatment of increased gap due to fuel assembly bowing through correction of cross sections[J]. Journal of Nuclear Science and Technology, 2019. [6] Franceschini F, Fetterman R, Little D. Modification of the ANC nodal code for analysis of PWR assembly bow[C]//Proc PHYSOR. 2008. [7] Fetterman R, Franceschini F. Analysis of PWR assembly bow[C]//Proc PHYSOR. 2008. [8] 卢皓亮, 莫锟, 李文淮, 等. 自主化堆芯三维核设计软件COCO研发[J]. 原子能科学技术, 2013, 47(s1):327-330. (Lu Haoliang, Mo Kun, Li Wenhuai, et al. Development of self-reliant three-dimensional core nuclear design code COCO[J]. Atomic Energy Science and Technology, 2013, 47(s1): 327-330 [9] 卢皓亮, 陈俊, 王军令, 等. 自主化堆芯核设计软件COCO验证与确认[J]. 原子能科学技术, 2017, 51(8):1460-1463. (Lu Haoliang, Chen Jun, Wang Junling, et al. Verification and validation of self-reliant core nuclear design code COCO[J]. Atomic Energy Science and Technology, 2017, 51(8): 1460-1463 [10] 邓力, 雷炜, 李刚, 等. 高分辨率粒子输运MC软件JMCT开发[J]. 核动力工程, 2014, 35(S2):221-223. (Deng Li, Lei Wei, Li Gang, et al. Development of high resolution particle transport Monte Carlo code JMCT[J]. Nuclear Power Engineering, 2014, 35(S2): 221-223 -

下载:

下载: