Mechanical properties analysis of a 20 cm diameter ion thruster

-

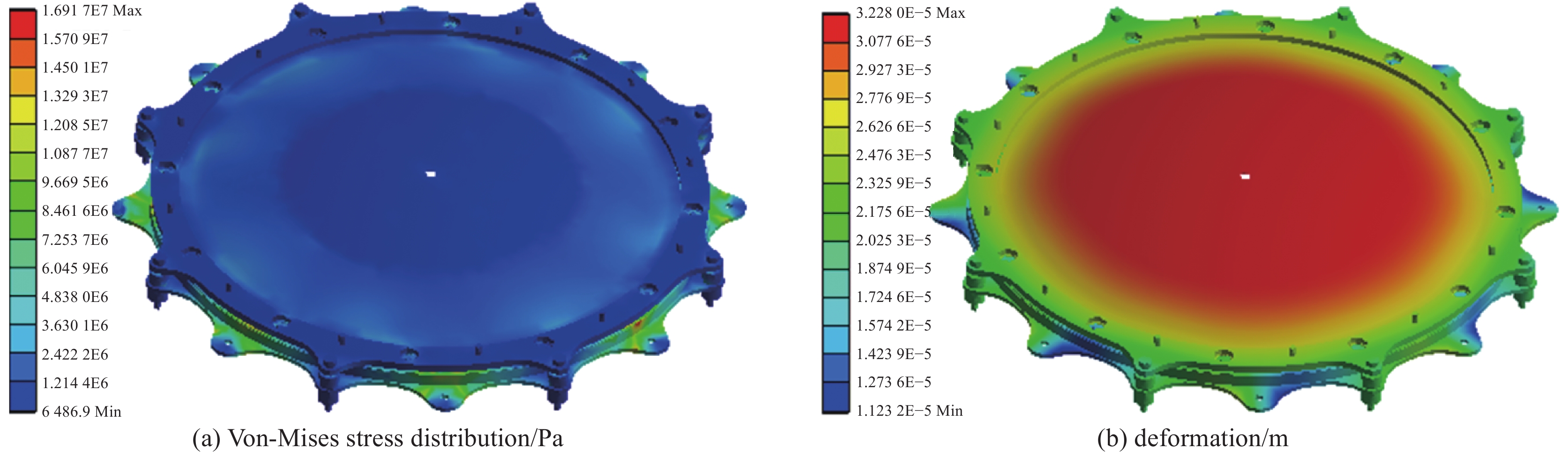

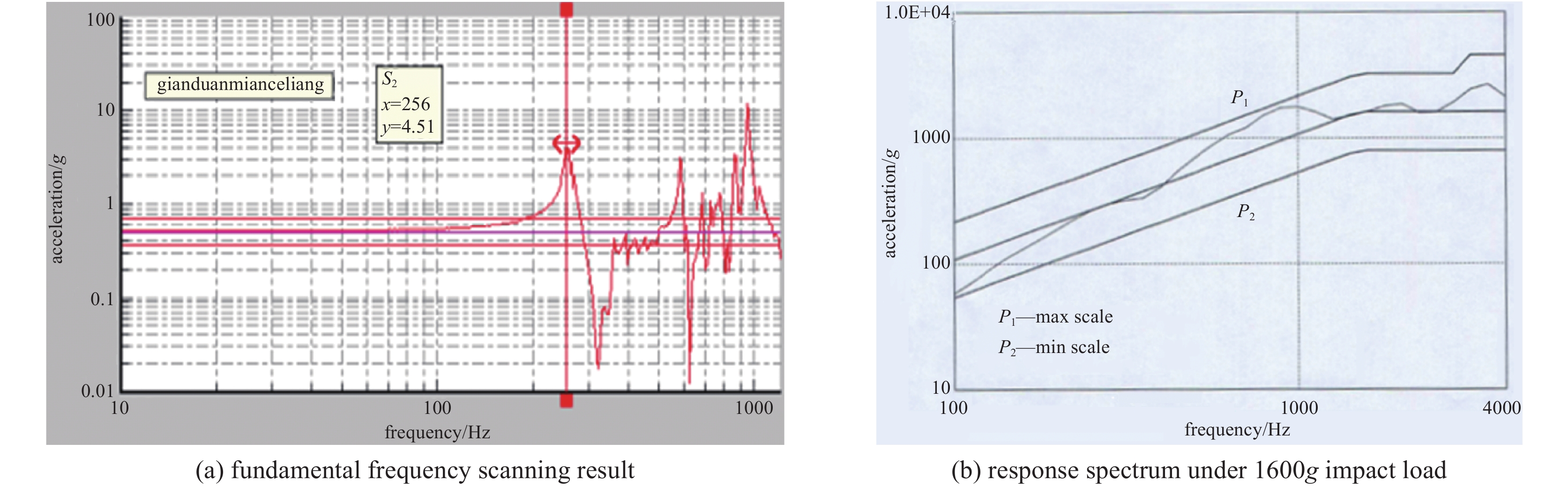

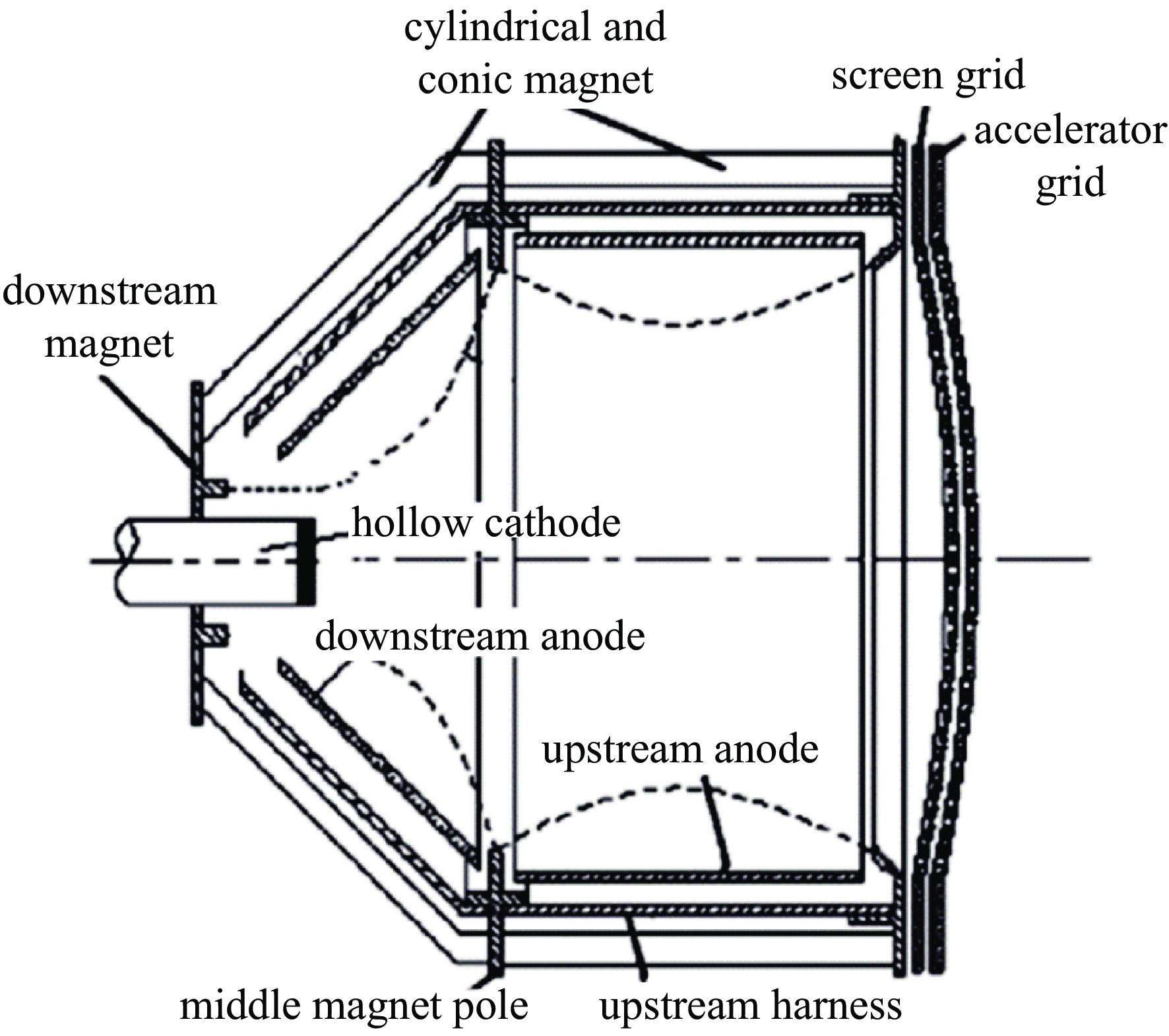

摘要: 为了提升20 cm离子推力器的抗冲击性能,对现有结构开展了力学分析和试验验证。对栅极组件进行结构等效处理后,采用有限元方法分析了整机的模态和冲击响应谱。分析结果显示,栅极组件结构等效前后的分析结果对比差距8.3%~11.9%;推力器的3个轴向基频分别为246,248,336 Hz,栅极组件和中间极靴是离子推力器的力学薄弱环节并对整体结构稳定性具有重要影响;在冲击载荷1600 g下,栅极组件表面应力主要集中在小孔区边缘处,且形变也主要发生在小孔区;在采取刚度为1000 kN/m的减振措施后,栅极组件的整体形变位移降低了60%~82%。试验结果显示,在10~1200 Hz的低频扫描过程中,推力器3个轴向的基频分别为256,258,348 Hz,与仿真结果基本一致,采用减振措施后的20 cm口径离子推力器通过了1600 g的冲击试验。

-

关键词:

- 离子推力器 /

- 力学特性 /

- Von-Mises应力 /

- 形变位移

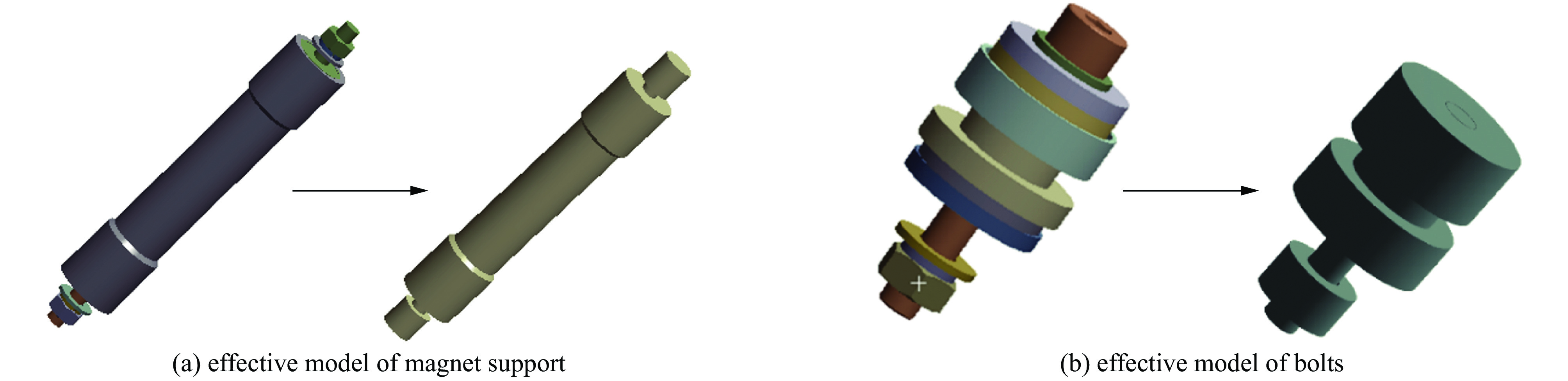

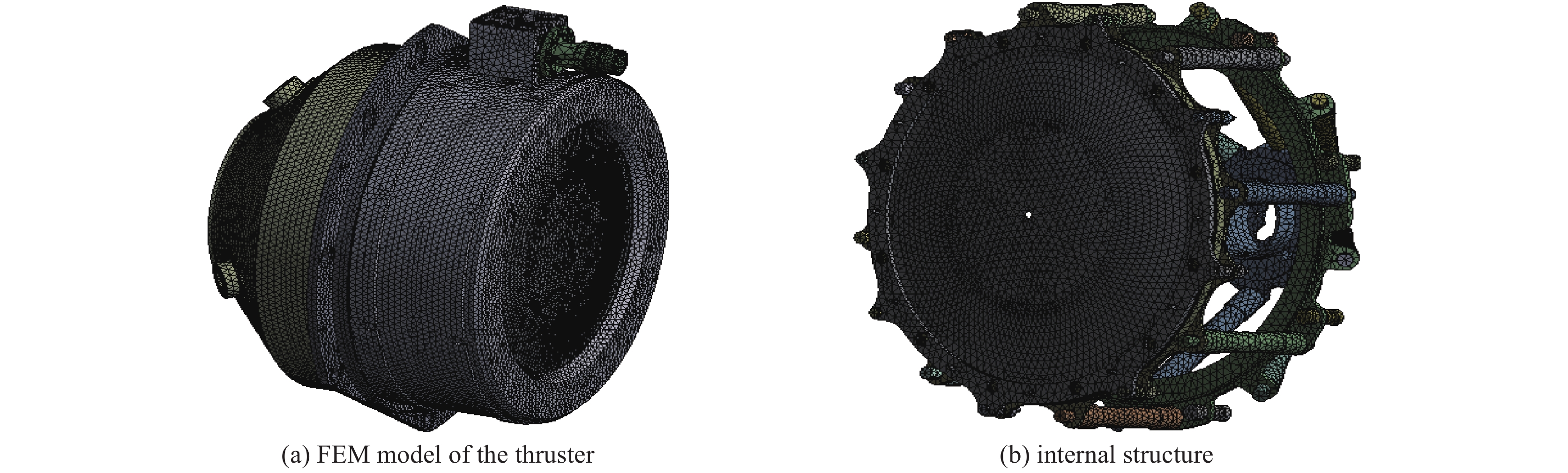

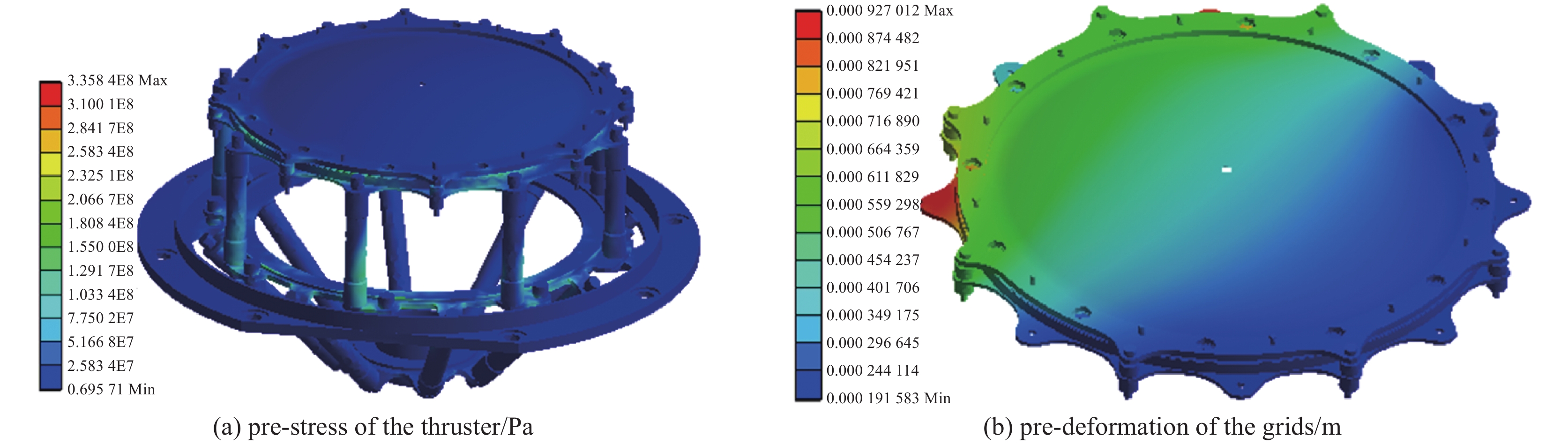

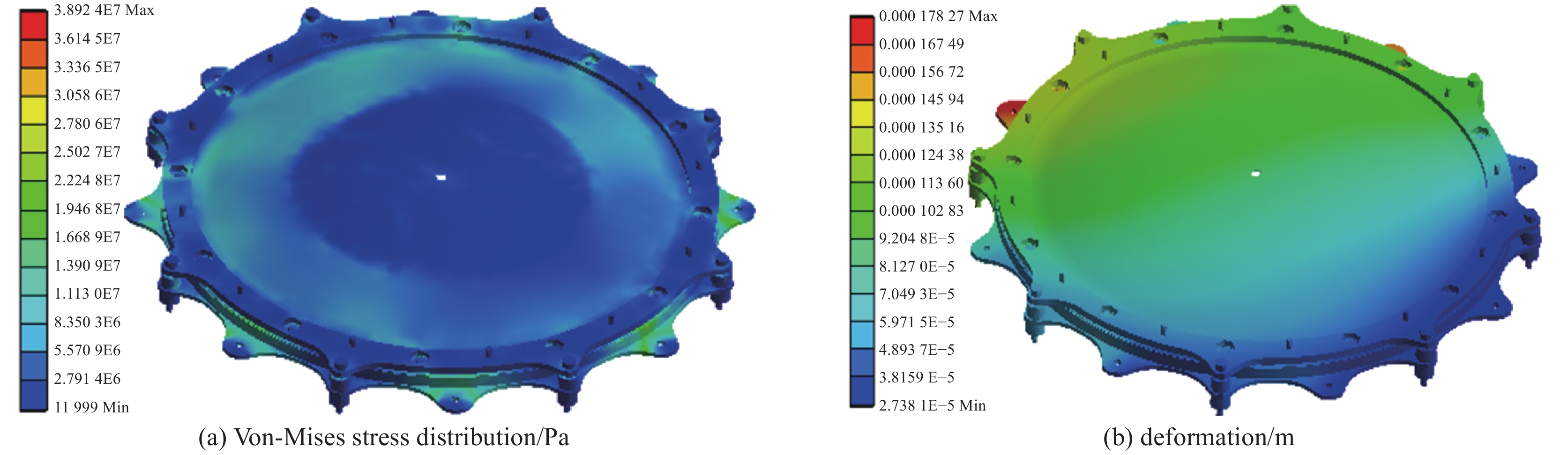

Abstract: To improve the anti-mechanical performance of the 20 cm diameter ion thruster, the mechanical analysis and experimental verification of its existing structure were carried out. After the grids were handled equivalently, the modal analysis and impact response spectrum analysis of ion thruster were carried out based on finite element analysis. The modal analysis results were validated by the fundamental frequency sweep test. Finally, the impact response of the thruster after adopting the damping structure was simulated and verified by experiments. The obtained results indicate that after the grids assembly being handled equivalently, the analysis results’ difference are about 8.3%−11.9%. The modal analysis result shows that the base frequencies of the thruster in the x, y and z directions are 246, 248 and 336 Hz respectively. The grids and middle magnet pole are the weak links in the mechanics of the ion thruster and affect the overall structural stability. The 1600g response spectrum analysis results indicate that 1600g, the surface stress of the grids concentrates on the rim of the aperture region, furthermore the deformation largely occurs in this region. When the vibration damping effect with the stiffness of 1000 kN/m is taken, the overall deformation of the grids is reduced by 60%−82%. Mechanical test results show that, during the low-frequency scanning process of 10−1200 Hz, the base frequencies of the thruster x, y and z directions are 256, 258 and 348 Hz respectively, basically consistent with the simulation results. Secondly, the 20 cm diameter ion thruster with damping measures passed the 1600 g impact test.-

Key words:

- ion thruster /

- mechanical properties /

- Von-Mises stress /

- deformation

-

表 1 20 cm离子光学系统结构等效后的材料力学特性

Table 1. Effective property of the grids of 20 cm ion thruster

component material transparency effective density/(kg·m−3) effective Young’s modulus

/GPaPoisson ratio the screen grid Mo 0.69 2973 99.2 0.31 the accelerator grid Mo 0.27 7001 233.6 0.31 表 2 不同加速栅有限元模型下的模态分析结果对比

Table 2. Comparison of modal analysis for different FEM models of the accelerator grid

structure modal analysis results of the accelerator grid/Hz 1st step 2nd step 3rd step 4th step 5th step 6th step with-aperture (reality) 51.815 207.55 251.89 303.24 427.88 474.92 without-aperture (effective) 47.193 194.05 237.34 293.65 405.02 453.04 表 3 20 cm离子推力器不同部件的材料力学属性

Table 3. Different components material property of 20 cm ion thruster

components material density/(kg·m−3) Young’s modulus/GPa Poisson ratio extension strength/MPa mount ring 2A12 2700 72 0.31 265 up/down harness 2A12 2700 72 0.31 265 magnet (effective) — 4105 72 0.31 265 up/down magnet pole DT4 7830 81 0.29 170 hollow cathode 1Cr18Ni9Ti 7930 193 0.31 200 bolts TC-4 4620 96 0.34 825 表 4 推力器前6阶模态分析结果及不同方向的有效质量百分比

Table 4. Primary 6 step modal frequencies and effective mass percentage of thruster

modal frequency/Hz x-direction/% y-direction/% z-direction/% 1 246.066 35 1 1 2 248.167 1 37 0 3 338.722 4 0 50 4 404.484 0 17 0 5 411.324 15 0 3 6 605.016 0 0 1 -

[1] 刘文一, 杨涓, 毛根旺, 等. 电子回旋共振推力器C/C复合材料栅极的力学性能[J]. 推进技术, 2007, 28(6):692-696. (Liu Wenyi, Yang Juan, Mao Genwang, et al. Mechanical property evaluation of C/C composite material grids for electron cyclotron resonance thruster[J]. Journal of Propulsion Technology, 2007, 28(6): 692-696 doi: 10.3321/j.issn:1001-4055.2007.06.022 [2] MacRae G S, Zavesky R J, Gooder S T. Structural and thermal response of 30 cm diameter ion thruster optics[C]//Proceedings of the 25th Joint Propulsion Conference. AIAA, 1989. [3] Brophy J R, Mueller J, Brown D K. Carbon-carbon ion engine grids with non-circular apertures[C]//Proceedings of the 31st Joint Propulsion Conference and Exhibit. AIAA, 1995. [4] Haag T. Mechanical design of carbon ion optics[C]//Proceedings of the 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. AIAA, 2005. [5] Mueller J, Brophy J R, Brown D K. Endurance testing and fabrication of advanced 15-cm and 30-cm carbon-carbon composite grids[C]//Proceedings of the 31st Joint Propulsion Conference and Exhibit. AIAA, 1995. [6] Haag T, Soulas G. Performance of 8 cm pyrolytic-graphite ion thruster optics[C]//Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. AIAA, 2002. [7] Hayakawa Y, Kitamura S, Miyazaki K. Endurance test of C/C grids for 14-cm xenon ion thrusters[C]//Proceedings of the 38th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. AIAA, 2002. [8] 郑茂繁. 离子发动机栅极组件的热应力分析[J]. 真空与低温, 2006, 12(1):33-36. (Zheng Maofan. Analysis of thermal stress of ion thruster’s grid[J]. Vacuum & Cryogenics, 2006, 12(1): 33-36 doi: 10.3969/j.issn.1006-7086.2006.01.007 [9] Haag T, Soulas G C. Performance and vibration of 30 cm pyrolytic ion thruster optics[C]//Proceedings of the 39th Joint Propulsion Conference and Exhibit. AIAA, 2003. [10] Meckel N, Polaha J. Structural analysis of pyrolytic graphite optics for the HiPEP ion thruster[C]//Proceedings of the 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. AIAA, 2004. [11] Hassani B, Hinton E. A review of homogenization and topology optimization I—homogenization theory for media with periodic structure[J]. Computers & Structures, 1998, 69(6): 707-717. [12] Hassani B, Hinton E. A review of homogenization and topology optimization II—analytical and numerical solution of homogenization equations[J]. Computers & Structures, 1998, 69(6): 719-738. [13] Hassani B, Hinton E. A review of homogenization and topology optimization III—Topology optimization using optimality criteria[J]. Computers & Structures, 1998, 69(6): 739-756. [14] 浦广益. ANSYS Workbench基础教程与实例详解[M]. 3版. 北京: 中国水利水电出版社, 2013: 240-241Pu Guangyi. ANSYS Workbench basic tutorial and example explanation[M]. 3rd ed. Beijing: China Water Power Press, 2013: 240-241 [15] 李会勋, 胡迎春, 张建中. 利用ANSYS模拟螺栓预紧力的研究[J]. 山东科技大学学报(自然科学版), 2006, 25(1):57-59. (Li Huixun, Hu Yingchun, Zhang Jianzhong. Study on simulating bolt pretension by using ANSYS[J]. Journal of Shandong University of Science and Technology (Natural Science), 2006, 25(1): 57-59 [16] 祖炳锋, 付光琦, 徐玉梁, 等. 车用柴油机缸孔在缸盖螺栓预紧力下变形的数值模拟与试验研究[J]. 内燃机工程, 2010, 31(2):98-104. (Zu Bingfeng, Fu Guangqi, Xu Yuliang, et al. Numerical simulation and experimental investigation on cylinder bore deformation of automotive diesel engines under cylinder-head bolt pretightened[J]. Chinese Internal Combustion Engine Engineering, 2010, 31(2): 98-104 doi: 10.3969/j.issn.1000-0925.2010.02.020 [17] 黄侨, 胡健琛, 黄志伟, 等. 考虑减振装置弹簧刚度的斜拉索等效索长及索力测量[J]. 东南大学学报(自然科学版), 2012, 42(4):724-728. (Huang Qiao, Hu Jianchen, Huang Zhiwei, et al. Equivalent length of stayed-cable considering spring stiffness of damping device and measurement of cable-force[J]. Journal of Southeast University (Natural Science Edition), 2012, 42(4): 724-728 doi: 10.3969/j.issn.1001-0505.2012.04.028 [18] 苏荣华, 彭晨宇. 振动筛橡胶弹簧非线性刚度实验及仿真研究[J]. 应用基础与工程科学学报, 2011, 19(6):986-994. (Su Ronghua, Peng Chenyu. Experiment and simulation research on nonlinear stiffness of vibrating screen rubber spring[J]. Journal of Basic Science and Engineering, 2011, 19(6): 986-994 doi: 10.3969/j.issn.1005-0930.2011.06.016 -

下载:

下载: