Effect of Al and Nd on microstructure and properties of nickel-based cladding layer on Cr12MoV steel surface

-

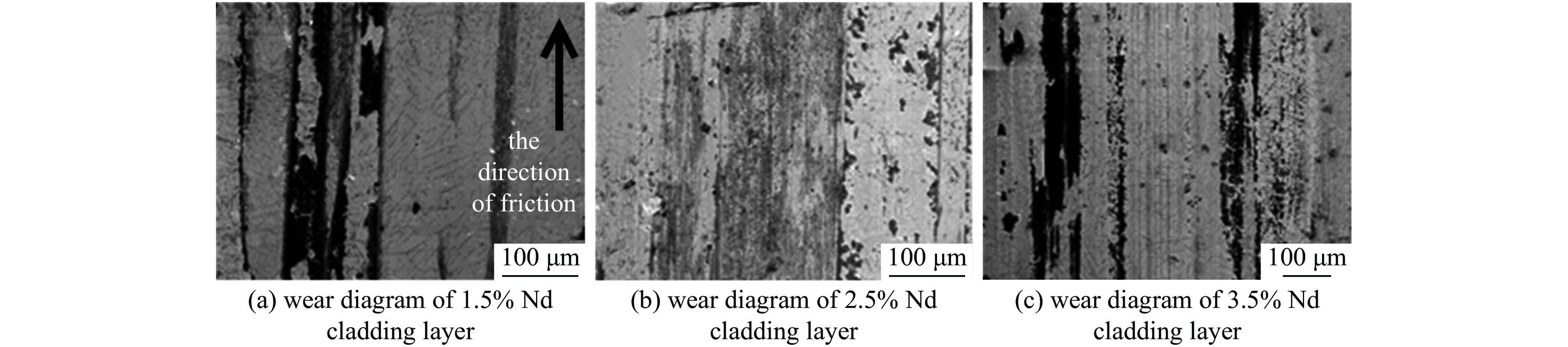

摘要: 为了解决Cr12MoV钢溶蚀、表面碎裂等问题,利用Al-Ni、Nd-Ni粉末在Cr12MoV钢上进行激光熔覆实验,研究了Al、Nd对镍基覆层的宏微观形貌、组织及表面性能的影响。结果表明:Al可以减少熔覆层裂纹的产生,同时降低覆层硬度,使熔覆层中产生具有减磨作用的硬质相Al2O3等,降低覆层磨损量,14%Al覆层磨损量比2%Al的覆层磨损量低44.5%,Al较优质量分数为14%;Nd的晶粒细化作用明显,显著提升覆层显微硬度,2.5%Nd覆层平均硬度比基体平均硬度高36.8%,Nd较优质量分数为2.5%。Abstract: To solve the problems of dissolution and surface fragmentation of Cr12MoV steel, laser cladding experiments were carried out on Cr12MoV steel using Al-Ni and Nd-Ni powders. The effects of Al and Nd on the macro and micro morphology, microstructure and surface properties of nickel base cladding were studied. The results show that Al can reduce the crack generation of cladding layer and reduce the hardness of cladding layer, so that the hard phase Al2O3 with anti-wear effect is generated in cladding layer, and the wear amount of cladding layer is reduced. The wear amount of 14% Al cladding layer is 44.5% lower than that of 2% Al cladding layer, and the optimal Al content is 14%. The grain refinement effect of Nd is obvious, and the microhardness of the coating is significantly increased. The average hardness of the coating is 36.8% higher than that of the substrate, and the optimal content of Nd is 2.5%.

-

Key words:

- laser cladding /

- remanufacturing /

- process parameters /

- microhardness /

- dilution rate

-

表 1 Cr12MoV钢化学成分

Table 1. Toughening chemical composition of Cr12MoV

composition mass fraction/% C 0.15 V 0.50 Si 0.25 Mo 0.30 Cr 11 Mn 0.55 Fe The rest 表 2 NFZCr-4镍基合金粉末化学成分(%)

Table 2. Chemical composition of NFZCR-4 Ni-base alloy powder (%)

composition mass fraction/% Si 3 B 3 Cr 18 Fe 4 C 0.6 Ni The rest -

[1] Sun Fei, Zhang Dongqiao, Cheng Ling, et al. Microstructure evolution modeling and simulation for dynamic recrystallization of Cr12MoV die steel during hot compression based on real metallographic image[J]. Metals and Materials International, 2019, 25(4): 966-981. doi: 10.1007/s12540-019-00249-8 [2] Abdulhadi H A, Aqida S N, Ishak M, et al. Thermal fatigue of die-casting dies: an overview[J]. MATEC Web of Conferences, 2016, 74: 00032. doi: 10.1051/matecconf/20167400032 [3] Hong Sheng, Wu Yuping, Wang Bo, et al. Improvement in tribological properties of Cr12MoV cold work die steel by HVOF sprayed WC-CoCr cermet coatings[J]. Coatings, 2019, 9: 825. doi: 10.3390/coatings9120825 [4] Courant B, Hantzpergue J J, Benayoun S. Surface treatment of titanium by laser irradiation to improve resistance to dry-sliding friction[J]. Wear, 1999, 236(1/2): 39-46. [5] Liu Shenglin, Zheng Xueping, Geng Gangqiang. Dry sliding wear behavior and corrosion resistance of NiCrBSi coating deposited by activated combustion-high velocity air fuel spray process[J]. Materials & Design, 2010, 31(2): 913-917. [6] Liu Yanan, Ding Ye, Yang Lijun, et al. Research and progress of laser cladding on engineering alloys: a review[J]. Journal of Manufacturing Processes, 2021, 66: 341-363. doi: 10.1016/j.jmapro.2021.03.061 [7] Huang Lei, Zhou Jianzhong, Xu Jiale, et al. Microstructure and wear resistance of electromagnetic field assisted multi-layer laser clad Fe901 coating[J]. Surface and Coatings Technology, 2020, 395: 125876. doi: 10.1016/j.surfcoat.2020.125876 [8] Ye Hong, Peng Shixin, Yan Zhonglin, et al. Microstructure and properties of laser cladding Fe-Al intermetallics[J]. Advanced Materials Research, 2013, 659: 39-42. doi: 10.4028/www.scientific.net/AMR.659.39 [9] Bourahima F, Helbert A L, Rege M, et al. Laser cladding of Ni based powder on a Cu-Ni-Al glassmold: Influence of the process parameters on bonding quality and coating geometry[J]. Journal of Alloys and Compounds, 2019, 771: 1018-1028. doi: 10.1016/j.jallcom.2018.09.004 [10] Quazi M M, Fazal M A, Haseeb A S M A, et al. Effect of rare earth elements and their oxides on tribo-mechanical performance of laser claddings: a review[J]. Journal of Rare Earths, 2016, 34(6): 549-564. doi: 10.1016/S1002-0721(16)60061-3 [11] Zou Honghui, Zeng Xiaoqin, Zhai Chunquan, et al. Effects of ND on the microstructure and mechanical property of ZA52 alloy[J]. Materials Science Forum, 2005, 488/489: 161-164. [12] 庞铭, 刘全秀. 超高强钢表面激光和等离子制备钕和镍基复合涂层界面的控形模拟研究[J]. 热加工工艺, 2021, 50(2):111-116 doi: 10.14158/j.cnki.1001-3814.20200157Pang Ming, Liu Quanxiu. Simulation study on morphology control of interface to composite coatings of neodymium and nickel-based alloy applied by plasma spraying and laser on super-strength steel[J]. Hot Working Technology, 2021, 50(2): 111-116 doi: 10.14158/j.cnki.1001-3814.20200157 [13] Feng Xiaoli, Wang Haifeng, Liu Xuechao, et al. Effect of Al content on wear and corrosion resistance of Ni-based alloy coatings by laser cladding[J]. Surface and Coatings Technology, 2021, 412: 126976. doi: 10.1016/j.surfcoat.2021.126976 [14] Jiang Huiren, Hirohasi M, Lu Yun, et al. Effect of Nb on the high temperature oxidation of Ti–(0–50 at. %) Al[J]. Scripta Materialia, 2002, 46(9): 639-643. doi: 10.1016/S1359-6462(02)00042-8 [15] Ansara I, Dupin N, Lukas H L, et al. Thermodynamic assessment of the Al-Ni system[J]. Journal of Alloys and Compounds, 1997, 247(1/2): 20-30. [16] Wang Di, Song Changhui, Yang Yongqiang, et al. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts[J]. Materials & Design, 2016, 100: 291-299. [17] 袁涛, 蔡养川, 罗震, 等. Al2O3陶瓷颗粒对镍基合金涂层耐磨性能的影响[J]. 上海交通大学学报, 2016, 50(10):1635-1639Yuan Tao, Cai Yangchuan, Luo Zhen, et al. Effect of Al2O3 composite ceramic reinforcement on wear behavior of laser cladding Ni-based alloys coatings[J]. Journal of Shanghai Jiaotong University, 2016, 50(10): 1635-1639 [18] Singh K, Sharma S. Effect of rare earth on microstructure and wear behaviour of Ni based microwave clad[J]. Indian Journal of Engineering and Materials Sciences 2020, 27(3): 564-572. [19] Yu Youjun, Zhou Jiansong, Chen Jianmin, et al. Preparation, microstructure and tribological properties of Ni3Al intermetallic compound coating by laser cladding[J]. Intermetallics, 2010, 18(5): 871-876. doi: 10.1016/j.intermet.2009.12.020 [20] Jerred N D, Khanal R, Benson M T, et al. Nd, SbNd and Sb3Nd4 and their interactions with the cladding alloy HT9[J]. Journal of Nuclear Materials, 2020, 541: 152387. doi: 10.1016/j.jnucmat.2020.152387 [21] Mirzadeh H. Quantification of the strengthening effect of rare earth elements during hot deformation of Mg-Gd-Y-Zr magnesium alloy[J]. Journal of Materials Research and Technology, 2016, 5(1): 1-4. doi: 10.1016/j.jmrt.2015.03.001 [22] Pagounis E, Lindroos V K, Talvitie M. Influence of matrix structure on the abrasion wear resistance and toughness of a hot isostatic pressed white iron matrix composite[J]. Metallurgical and Materials Transactions A, 1996, 27(12): 4183-4191. doi: 10.1007/BF02595666 -

下载:

下载: