Attractive electromagnetic force flanging method for small tube fittings with magnetic field shaper

-

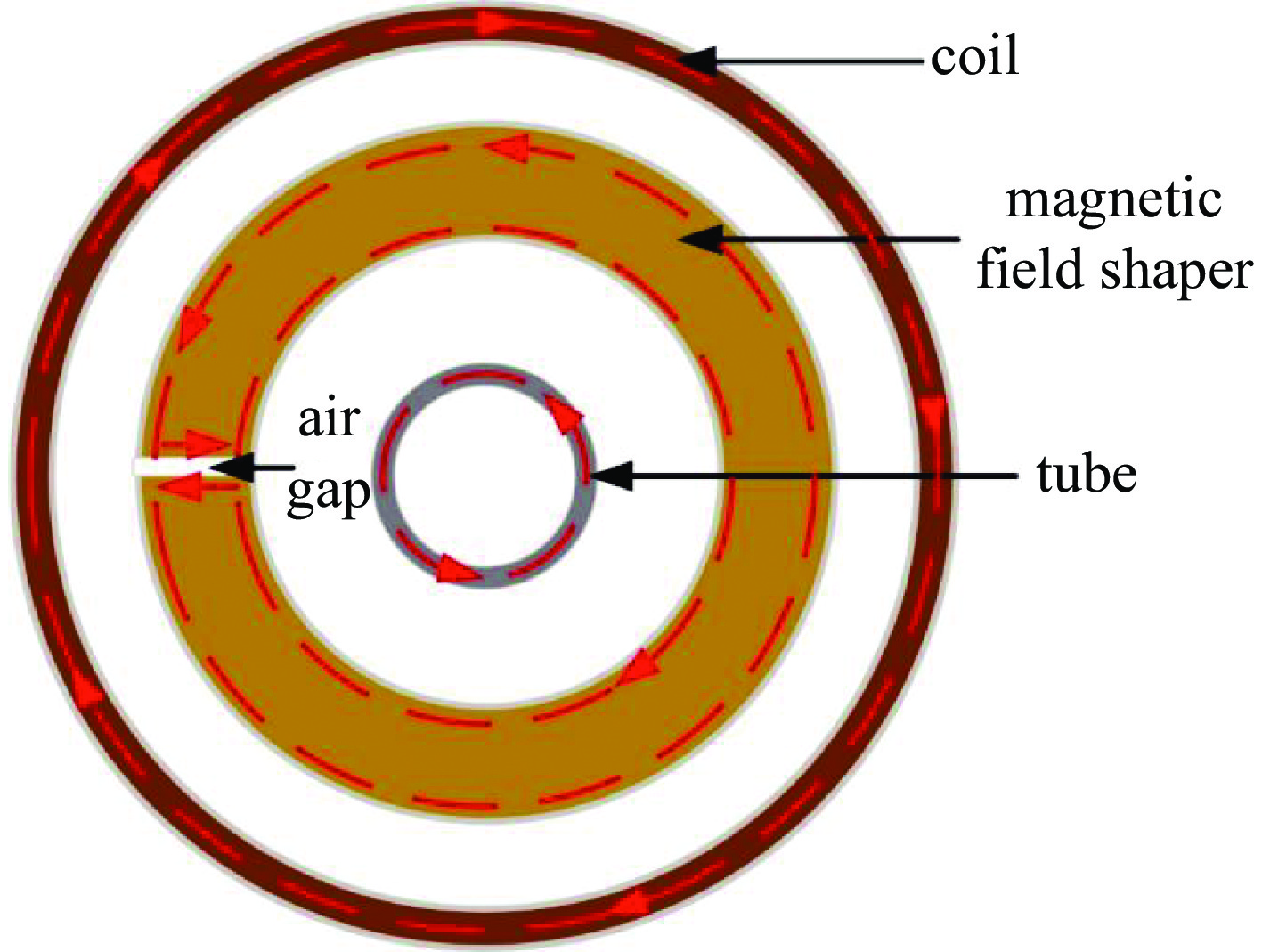

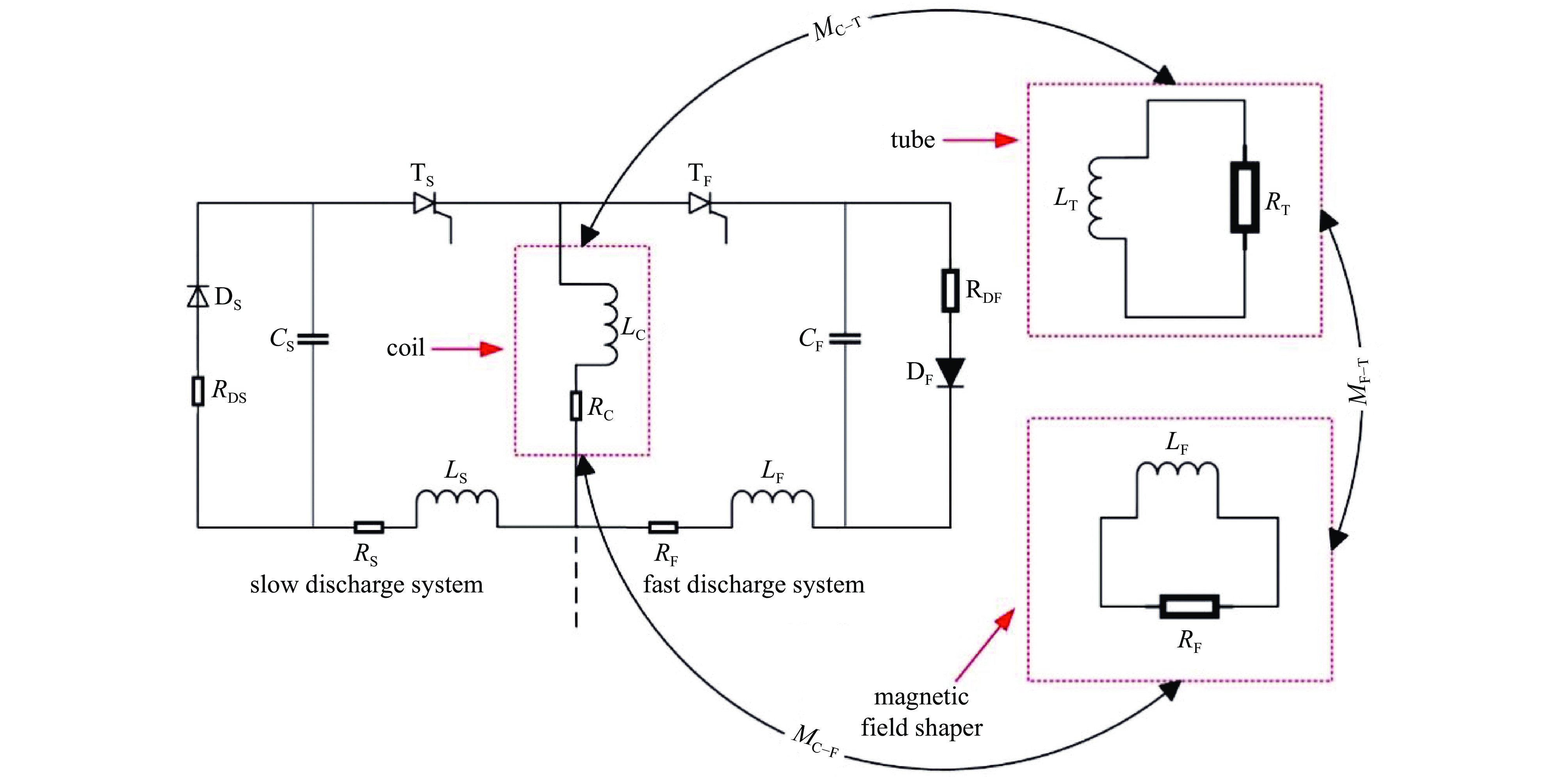

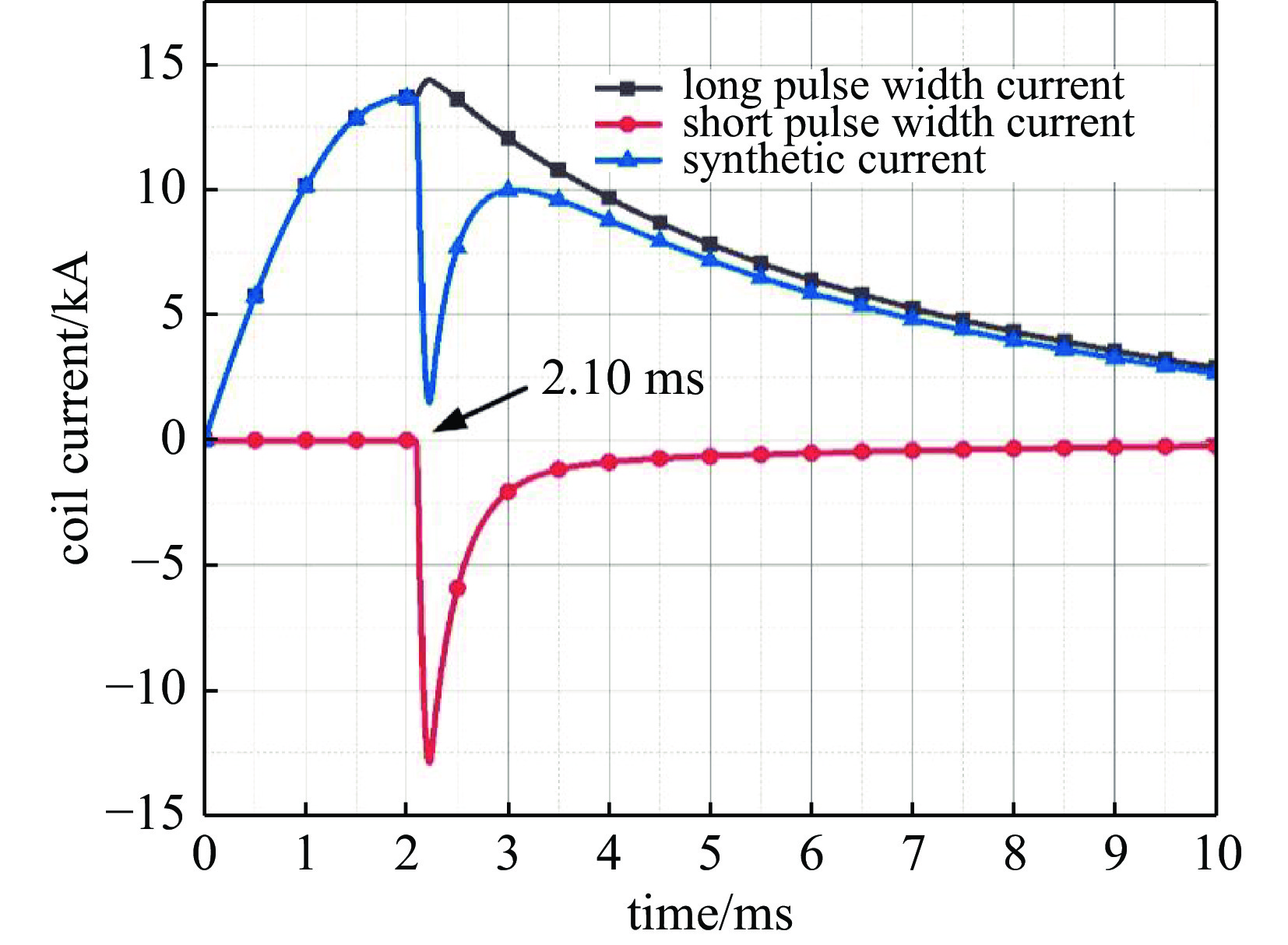

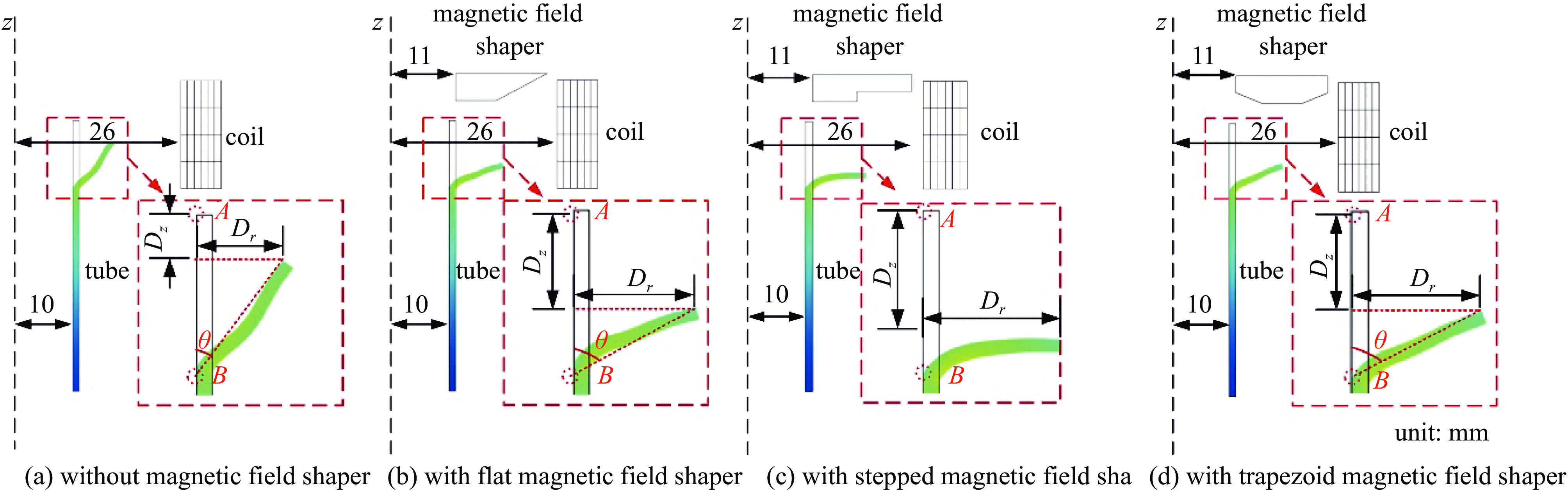

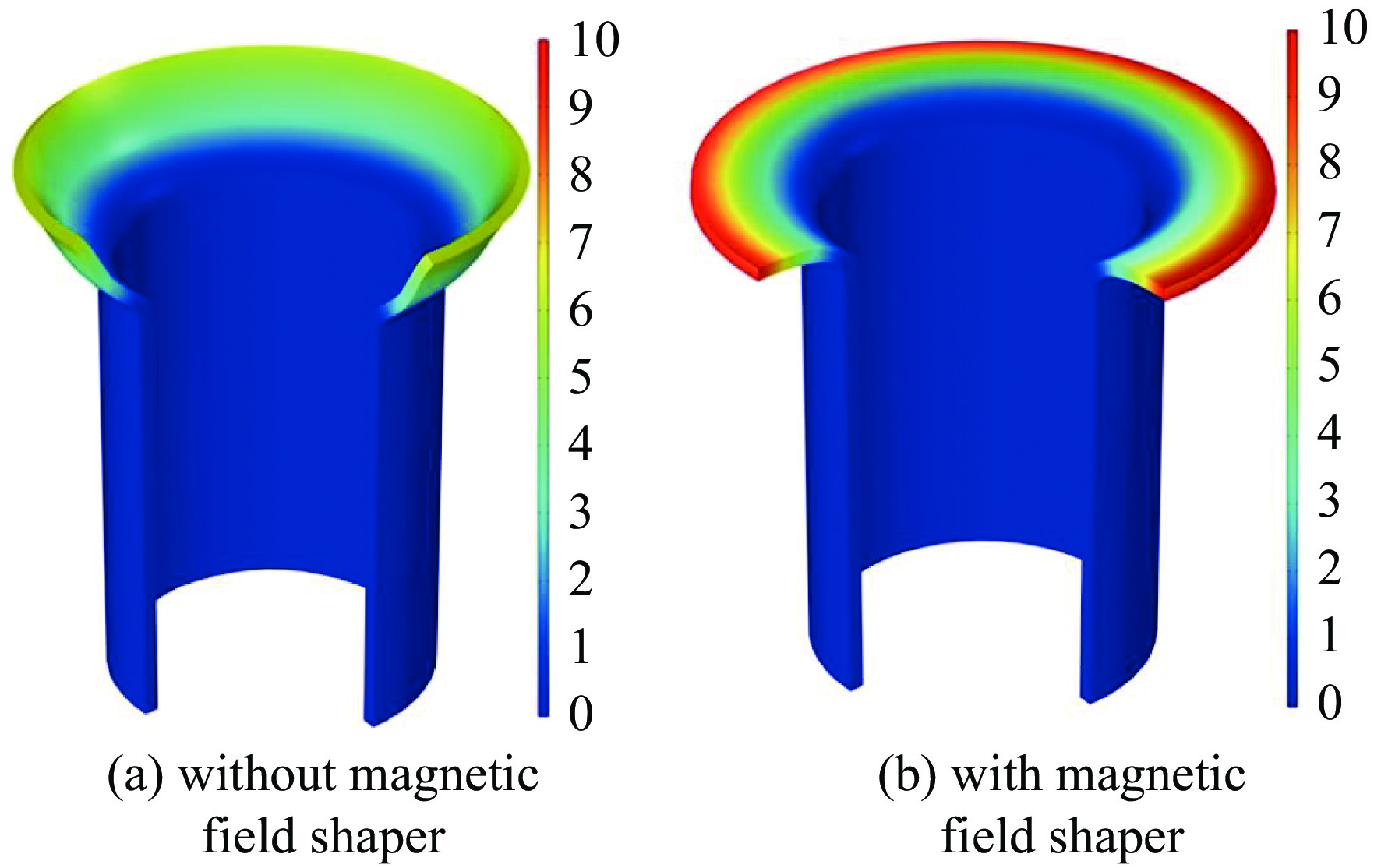

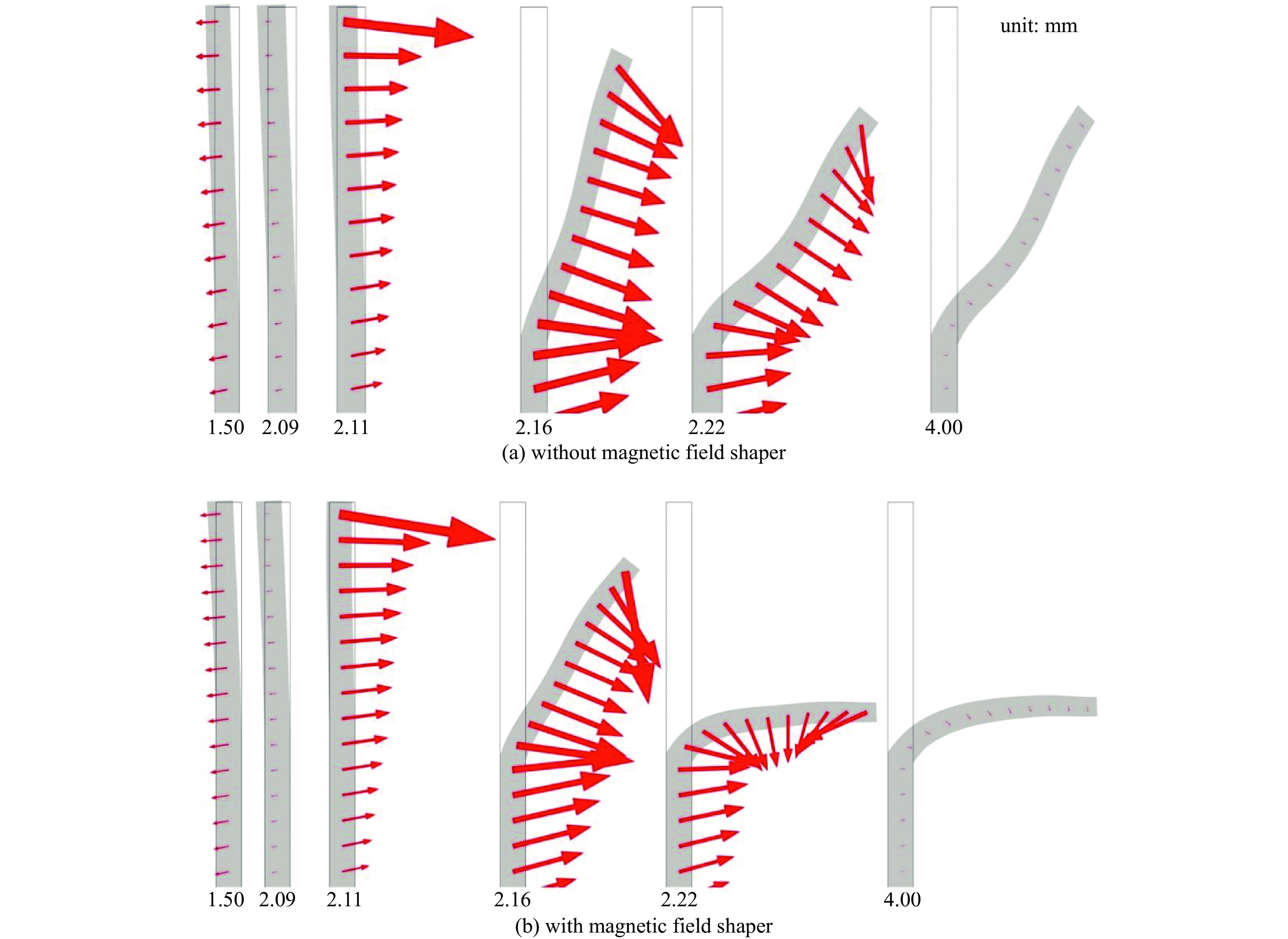

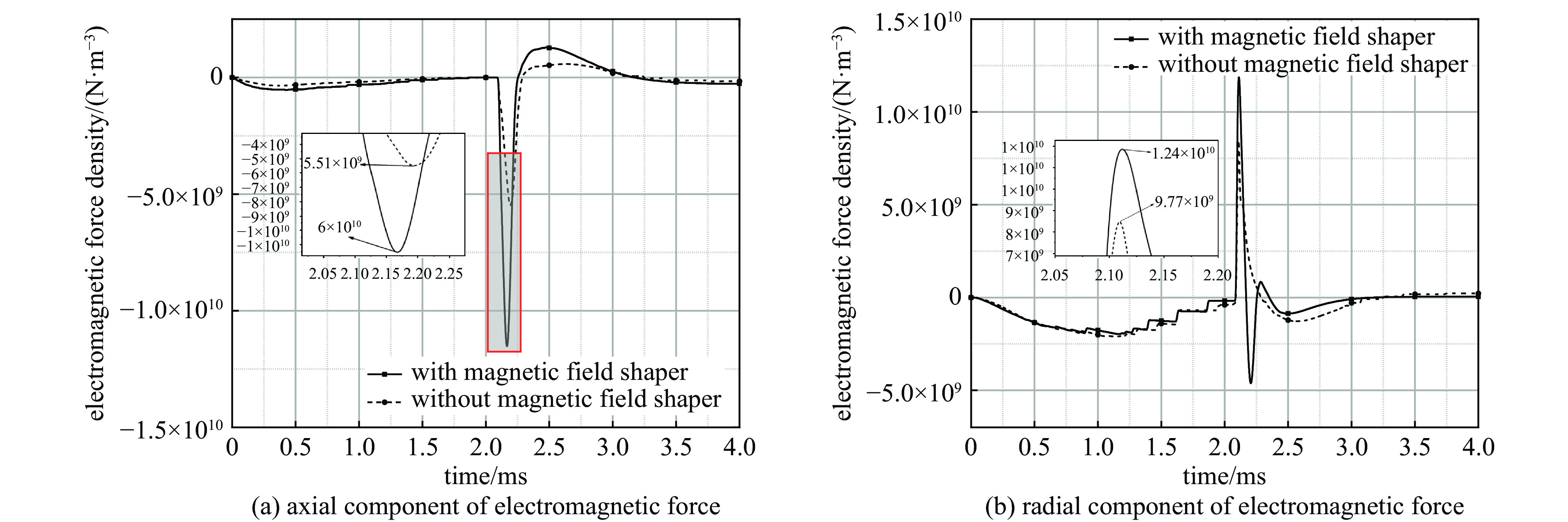

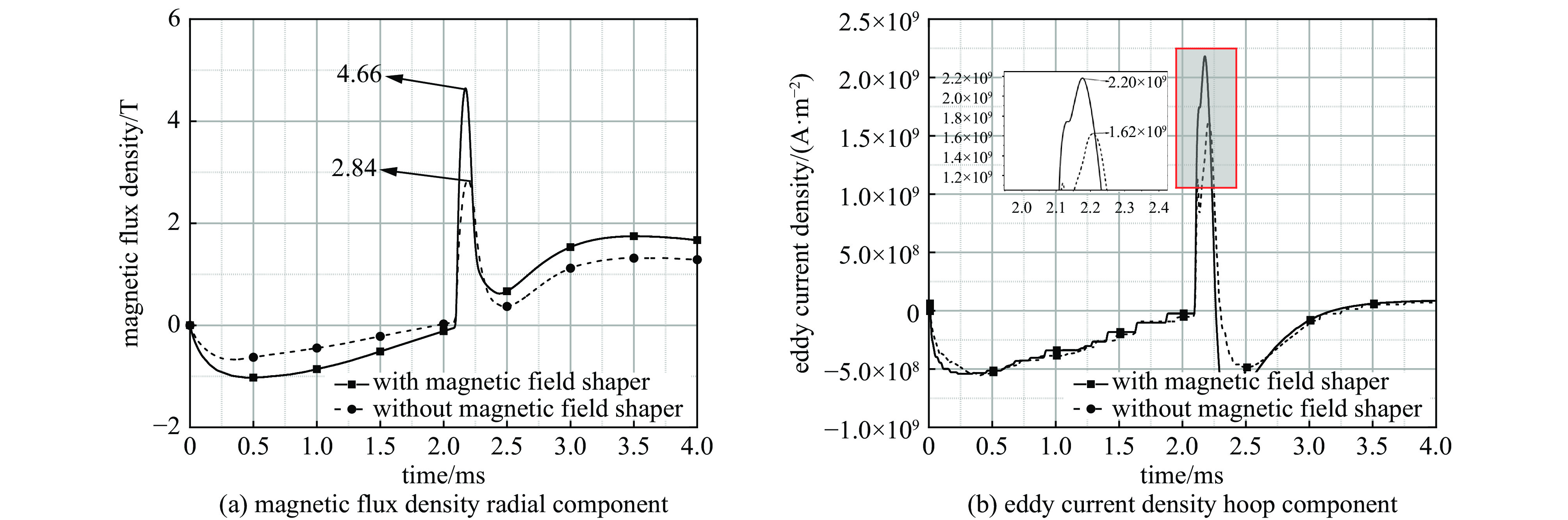

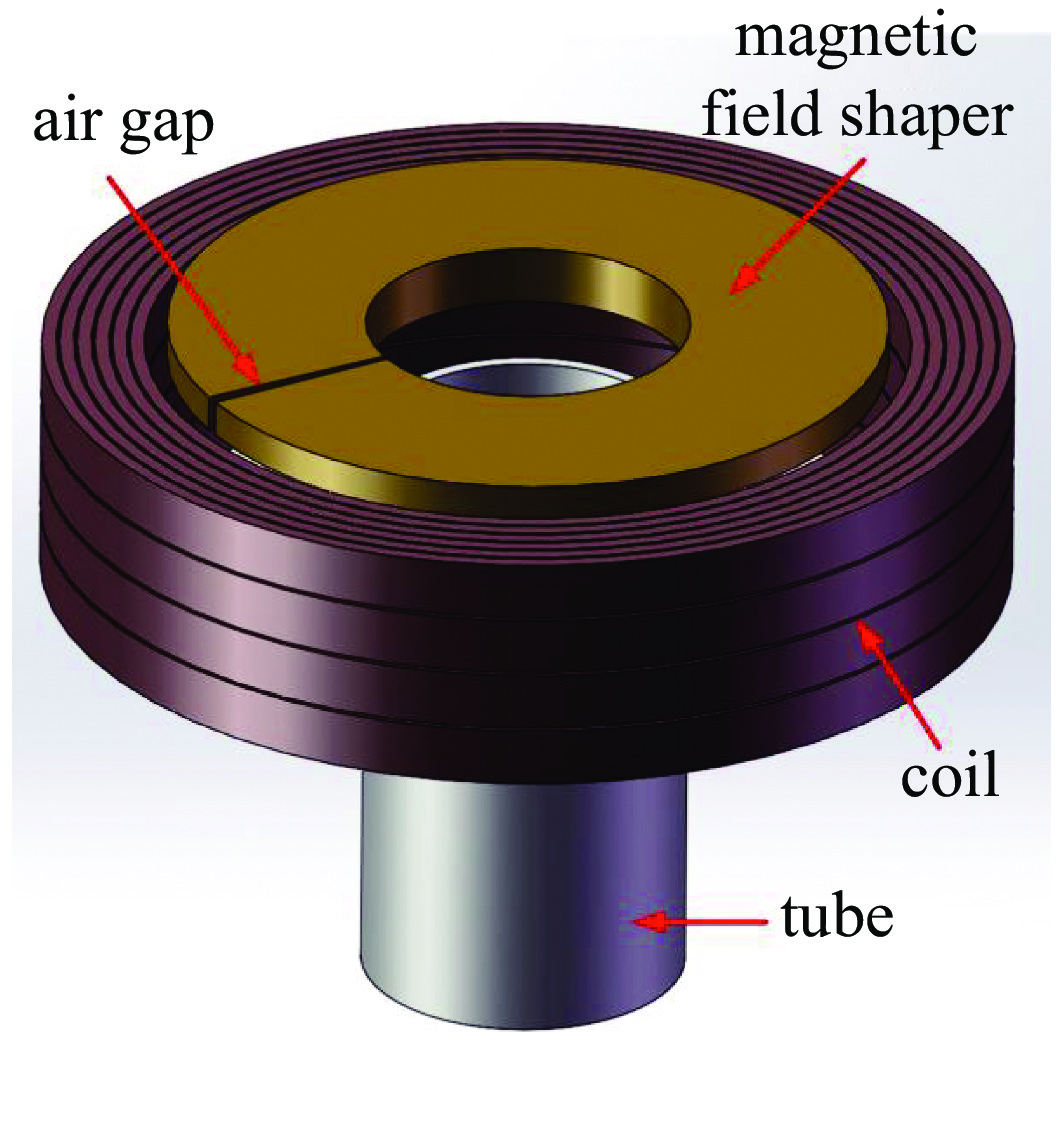

摘要: 针对微小铝合金管件电磁翻边工艺,现有方法将驱动线圈置于管件端部外侧,利用双频电流法产生吸引式电磁力实现翻边。然而其翻边能力不强,基于此提出一种带集磁器的吸引式电磁力翻边方法。在现有方法基础上引入集磁器,利用其能够改变磁场位形的特点,优化电磁力分布并增大轴向电磁力,达到增强翻边效果的目的。为验证该方法的可行性,通过搭建管件翻边过程的电磁-结构全耦合有限元仿真模型,对比引入不同集磁器后的翻边效果,同时分析了不同工况对电磁力分布、电磁力密度以及磁场和涡流的影响。得出阶梯型集磁器效果最佳,结果表明,该方法下管件翻边角度从38°增大到90°。进一步分析表明,其磁通密度径向分量和涡流密度环向分量分别增大到164%和135%,作用在管件上的电磁力分布改变,峰值时刻轴向电磁力体密度明显加强,增大到211%。该方法进一步完善了对微小铝合金管件的电磁翻边成形,对拓展电磁成形技术在铝合金管件翻边上的应用具有一定意义。Abstract: Aiming at the electromagnetic flanging process for small aluminum alloy tube fittings, the driving coil is placed on the outside of the end of the tube, and the dual-frequency discharge current method is used to generate the attractive electromagnetic force to realize flanging in the existing method. However, its flanging ability is not strong, under this background, an attractive electromagnetic force flanging method with a magnetic field shaper is proposed. On the basis of the existing method, a magnetic field shaper is introduced, which can change the magnetic field configuration, optimize the electromagnetic force distribution and increase the axial electromagnetic force, so as to achieve the purpose of enhancing the flanging effect. To verify the feasibility of this method, firstly, the electromagnetic-structural fully coupled finite element simulation model of the tube flanging process was built, and the flanging effects after introducing different magnetic field shaper were compared, and it is concluded that the stepped magnetic field shaper has the best effect. The flanging process were analyzed under the working conditions with stepped magnetic field shaper and without magnetic field shaper. The results show that the flanging angle of the tube fittings is increased from 38° to 90° compared with the case without the magnetic field shaper. Further analysis shows that the radial component of the magnetic flux density and the annular component of the eddy current density increase to 164% and 135%, respectively. The distribution of the electromagnetic force acting on the pipe fittings changes, and the density of the axial electromagnetic force increases significantly at the peak time, increasing to 211%. The method further improves the electromagnetic flanging forming of small aluminum alloy tube fittings, and it has a certain significance for expanding the application of electromagnetic forming technology in aluminum alloy tube flanging.

-

表 1 材料参数及其几何结构参数

Table 1. Material parameters and geometric structure parameters of the model

object parameter value AA1060 aluminum alloy tube fitting material parameters density/(kg·m−3) 2710 conductance/(S·m−1) 3.76×107 relative magnetic permeability 1 relative dielectric constant 1 Poisson's ratio 0.33 initial yield stress/MPa 98 material parameters of coil and magnetic field shaper (copper) density/(kg·m−3) 8930 conductance/(S·m−1) 5.99×107 relative magnetic permeability 1 relative dielectric constant 1 geometric dimensions of the tube fitting the height of the tube fitting/mm 40 width of the tube fitting/mm 1 inner diameter of the tube fitting/mm 10 outer diameter of the tube fitting/mm 11 geometric dimensions of the coil height of a single turn coil/mm 4 width of a single turn coil/mm 1 inner diameter of the coil/mm 26 outer diameter of the coil/mm 32 the number of turns of the coil 4×6 geometric dimensions of the magnetic field shaper height of the magnetic field shaper/mm 4 inner diameter of the magnetic field shaper/mm 11 outer diameter of the magnetic field shaper/mm 24.5 表 2 脉冲电源系统参数

Table 2. Pulse power system parameters

parameter slow discharge system fast discharge system symbol value symbol/unit value capacitance ${C_{\rm{S}}}$/μF 3200 ${C_{\rm{F}}}$/μF 200 initial discharge voltage ${U_{\rm{S}}}$/kV 8 ${U_{\rm{F}}}$/kV 6.75 equivalent resistance ${R_{\rm{S}}}$/Ω 0.10 ${R_{\rm{F}}}$/Ω 0.09 freewheeling diode ${R_{{\rm{DS}}}}$/Ω 0.02 $ {R_{{\rm{DF}}}} $/Ω 0.02 equivalent inductance ${L_{\rm{S}}}$/mH 0.60 ${L_{\rm{F}}}$/μH 5 表 3 不同工况下的A点位移及管件翻边角度

Table 3. Displacement of point A and flange angle of tube fittings under different working conditions

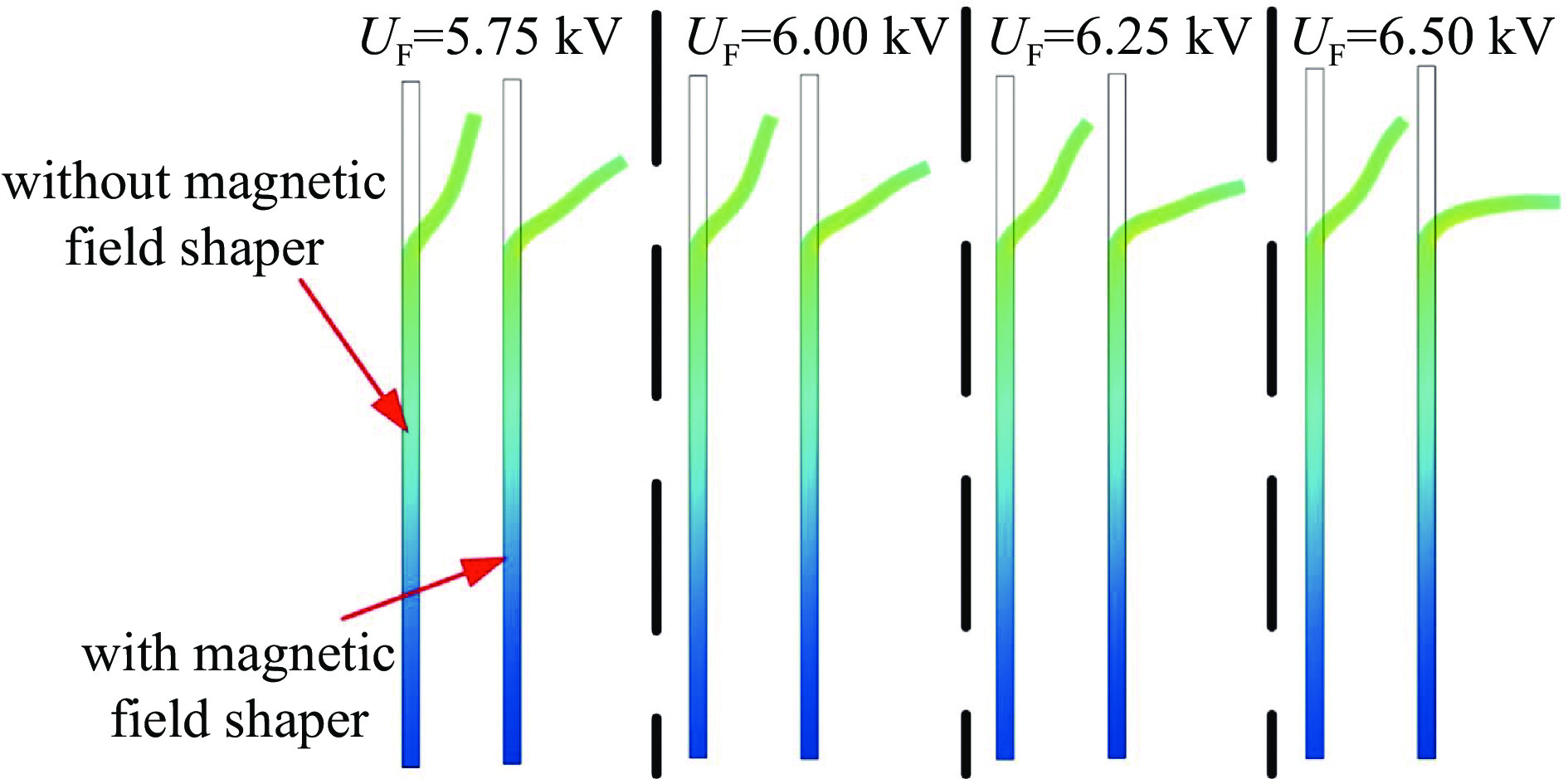

working condition Dz/mm Dr/mm θ/(°) without magnetic field shaper 2.94 5.52 38 with flat magnetic field shaper 6.27 7.88 64 with stepped magnetic field shaper 7.60 8.20 90 with trapezoid magnetic field shaper 5.85 7.65 68 表 4 不同初始放电电压时两种工况下的翻边角度

Table 4. Flanging angles under two working conditions at different initial discharge voltages

initial

discharge

voltage/kVflanging angle

without magnetic

field shaper/(°)flanging angle

with magnetic

field shaper/(°)5.75 25 51 6.00 30 56 6.25 34 64 6.50 36 73 -

[1] 邱立, 田茜, 吴伟业, 等. 基于磁场变换器的双向加载式管件电磁翻边成形效果研究[J]. 精密成形工程, 2022, 14(3):17-24Qiu Li, Tian Xi, Wu Weiye, et al. Electromagnetic flanging forming effect of bidirectional loading tube fittings based on magnetic field shaper[J]. Journal of Netshape Forming Engineering, 2022, 14(3): 17-24 [2] 张无名, 邱立, 张望, 等. 放电时序对双向加载式管件电磁翻边的影响[J]. 精密成形工程, 2021, 13(5):84-91Zhang Wuming, Qiu Li, Zhang Wang, et al. Influence of discharge timing on electromagnetic flanging of tube with bidirectional loading[J]. Journal of Netshape Forming Engineering, 2021, 13(5): 84-91 [3] 熊奇, 唐红涛, 王沐雪, 等. 2011年以来电磁成形研究进展[J]. 高电压技术, 2019, 45(4):1171-1181Xiong Qi, Tang Hongtao, Wang Muxue, et al. Research progress of electromagnetic forming technique since 2011[J]. High Voltage Engineering, 2019, 45(4): 1171-1181 [4] Qiu Li, Yu Yijie, Xiong Qi, et al. Analysis of electromagnetic force and deformation behavior in electromagnetic tube expansion with concave coil based on finite element method[J]. IEEE Transactions on Applied Superconductivity, 2018, 28(3): 1-5. [5] 熊奇, 杨猛, 周丽君, 等. 双线圈吸引式板件电磁成形过程中的涡流竞争问题[J]. 电工技术学报, 2021, 36(10):2007-2017Xiong Qi, Yang Meng, Zhou Lijun, et al. Eddy currents competition in electromagnetic forming process of plates by double-coil attraction[J]. Transactions of China Electrotechnical Society, 2021, 36(10): 2007-2017 [6] 邱立, 余一杰, 聂小鹏, 等. 管件电磁胀形过程中的材料变形性能问题与电磁力加载方案[J]. 电工技术学报, 2019, 34(2):212-218Qiu Li, Yu Yijie, Nie Xiaopeng, et al. Study on material deformation performance and electromagnetic force loading in electromagnetic tube expansion process[J]. Transactions of China Electrotechnical Society, 2019, 34(2): 212-218 [7] 杨澍. 管件磁脉冲侧翻边工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2011: 6-8Yang Shu. Research on technologies of tube magnetic pulse flanging[D]. Harbin: Harbin Institute of Technology, 2011: 6-8 [8] 白雪山, 尹延广, 赵天章. 航空5A02铝合金T型三通管翻边电磁成形[J]. 塑性工程学报, 2021, 28(4):24-29Bai Xueshan, Yin Yanguang, Zhao Tianzhang. Electromagnetic flanging of 5A02 aluminum alloy T-shaped tube for aviation[J]. Journal of Plasticity Engineering, 2021, 28(4): 24-29 [9] 欧航, 安浩, 孙式进, 等. 5182铝合金椭圆孔电磁翻边数值模拟研究[J]. 精密成形工程, 2021, 13(4):9-15Ou Hang, An Hao, Sun Shijin, et al. Numerical simulation study on oblique hole-flanging with 5182 aluminum alloy produced by electromagnetic forming (EMF)[J]. Journal of Netshape Forming Engineering, 2021, 13(4): 9-15 [10] 李彦涛. 基于径向—轴向电磁力加载式管件电磁翻边成形研究[D]. 宜昌: 三峡大学, 2020: 30-37Li Yantao. Research on electromagnetic tube flanging with radial-axial electromagnetic force loading[D]. Yichang: China Three Gorges University, 2020: 30-37 [11] 张望, 王于東, 李彦涛, 等. 基于双向电磁力加载的管件电磁翻边理论与实验[J]. 电工技术学报, 2021, 36(14):2904-2911Zhang Wang, Wang Yudong, Li Yantao, et al. Theory and experiment of tube electromagnetic flanging based on bidirectional electromagnetic force loading[J]. Transactions of China Electrotechnical Society, 2021, 36(14): 2904-2911 [12] Xiong Qi, Tang Hongtao, Deng Changzhen, et al. Electromagnetic attraction-based bulge forming in small tubes: fundamentals and simulations[J]. IEEE Transactions on Applied Superconductivity, 2018, 28: 0600505. [13] Xiong Qi, Tang Hongtao, Wang Muxue, et al. Design and implementation of tube bulging by an attractive electromagnetic force[J]. Journal of Materials Processing Technology, 2019, 273: 116240. doi: 10.1016/j.jmatprotec.2019.05.021 [14] Xiong Qi, Huang Hao, Xia Liangyu, et al. A research based on advance dual-coil electromagnetic forming method on flanging of small-size tubes[J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(9): 4087-4094. [15] Xiong Qi, Gao Dun, Li Zhe, et al. Electromagnetic attraction bulging of small aluminum alloy tube based on a field shaper[J]. The International Journal of Advanced Manufacturing Technology, 2021, 117(1): 511-521. [16] Xiong Qi, Li Zhe, Tang Jianhua, et al. A flexible and economical method for electromagnetic flanging of tubes with field shapers[J]. The International Journal of Advanced Manufacturing Technology, 2021, 116(3/4): 1169-1177. [17] 熊奇, 李青山, 李哲, 等. 集磁器对电磁成形驱动线圈发热影响及机理[J]. 电工技术学报, 2020, 38(2):285-296Xiong Qi, Li Qingshan, Li Zhe, et al. Influence and mechanism of field shaper on heating of electromagnetic forming drive coil[J]. Transactions of China Electrotechnical Society, 2020, 38(2): 285-296 [18] Xiong Qi, Song Xianqi, Yang Meng, et al. Future trends in magnetic source device design for magnetic targeted drug delivery system[J]. International Journal of Applied Electromagnetics and Mechanics, 2021, 67(3): 261-277. doi: 10.3233/JAE-210021 [19] 邱立, 何晨骏, 张望. 双管件电磁约束成形的电磁分布与均匀性变形研究[J]. 电测与仪表, 2021, 58(11):128-135Qiu Li, He Chenjun, Zhang Wang. Study on electromagnetic force distribution and axial uniform deformation of dual-tube electromagnetic constraint forming[J]. Electrical Measurement & Instrumentation, 2021, 58(11): 128-135 [20] 张重远, 芮皓然, 刘贺晨, 等. 高压单芯电缆单相接地故障护套过电压特性仿真分析[J]. 电测与仪表, 2018, 55(11):115-119Zhang Zhongyuan, Rui Haoran, Liu Hechen, et al. Simulation analysis of sheath overvoltage characteristic for single-phase ground fault in high voltage single-core cable[J]. Electrical Measurement & Instrumentation, 2018, 55(11): 115-119 [21] 唐红涛. 基于吸引式电磁力的金属管件电磁胀形设计与实现[D]. 宜昌: 三峡大学, 2019: 16-17Tang Hongtao. Design and implementation of tube bulging by an attractive electromagnetic force[D]. Yichang: China Three Gorges University, 2019: 16-17 [22] Cao Quanliang, Lai Zhipeng, Xiong Qi, et al. Electromagnetic attractive forming of sheet metals by means of a dual-frequency discharge current: design and implementation[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(1): 309-316. [23] 黄浩. 基于集磁器的板材电磁成形校形研究[D]. 宜昌: 三峡大学, 2019: 24-25Huang Hao. Research on electromagnetic calibration of the sheet metal based on the field shaper[D]. Yichang: China Three Gorges University, 2019: 24-25 [24] 黎镇浩, 曹全梁, 赖智鹏, 等. 电流丝法在电磁成形线圈电流和工件电磁力计算中的应用[J]. 电工技术学报, 2018, 33(18):4181-4190Li Zhenhao, Cao Quanliang, Lai Zhipeng, et al. Application of current filament method on the calculation of current and force in electromagnetic forming[J]. Transactions of China Electrotechnical Society, 2018, 33(18): 4181-4190 [25] Cao Quanliang, Han Xiaotao, Lai Zhipeng, et al. Analysis and reduction of coil temperature rise in electromagnetic forming[J]. Journal of Materials Processing Technology, 2015, 225: 185-194. doi: 10.1016/j.jmatprotec.2015.02.006 [26] Du Limeng, Xia Liangyu, Li Xian, et al. Adjustable current waveform via altering the damping coefficient: a new way to reduce Joule heating in electromagnetic forming coils[J]. Journal of Materials Processing Technology, 2021, 293: 117086. doi: 10.1016/j.jmatprotec.2021.117086 [27] 杨猛. 基于双线圈的吸引式板件电磁成形规律研究[D]. 宜昌: 三峡大学, 2021: 21-22Yang Meng. Research on electromagnetic forming law of attracting sheet metal based on dual-coil[D]. Yichang: China Three Gorges University, 2021: 21-22 [28] Xiong Qi, Yang Meng, Liu Xin, et al. A dual-coil method for electromagnetic attraction forming of sheet metals[J]. IEEE Access, 2020, 8: 92708-92717. doi: 10.1109/ACCESS.2020.2994212 -

下载:

下载: