Experimental study on the influences of high-speed airflow on the laser ablation behaviors of C/SiC composites

-

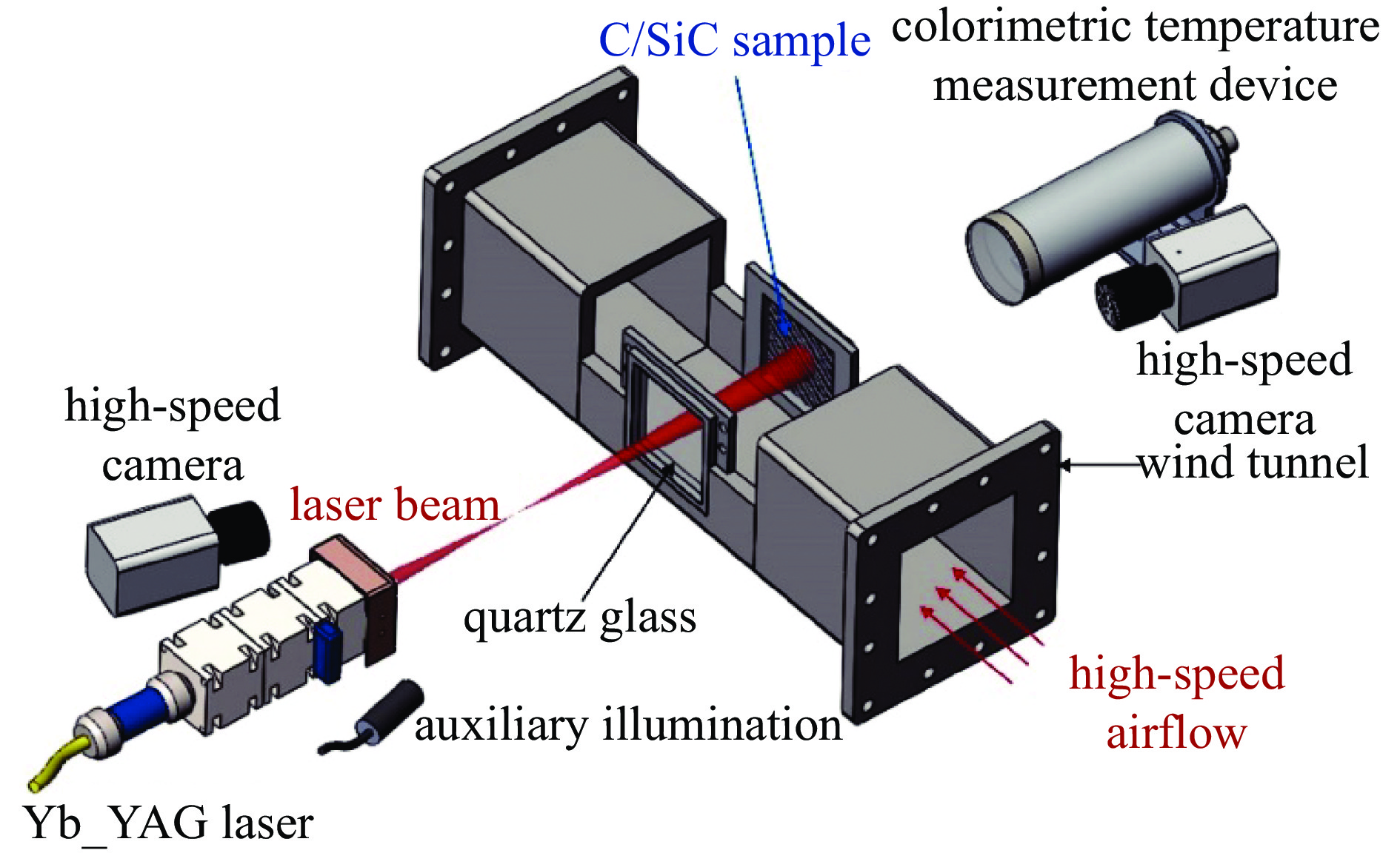

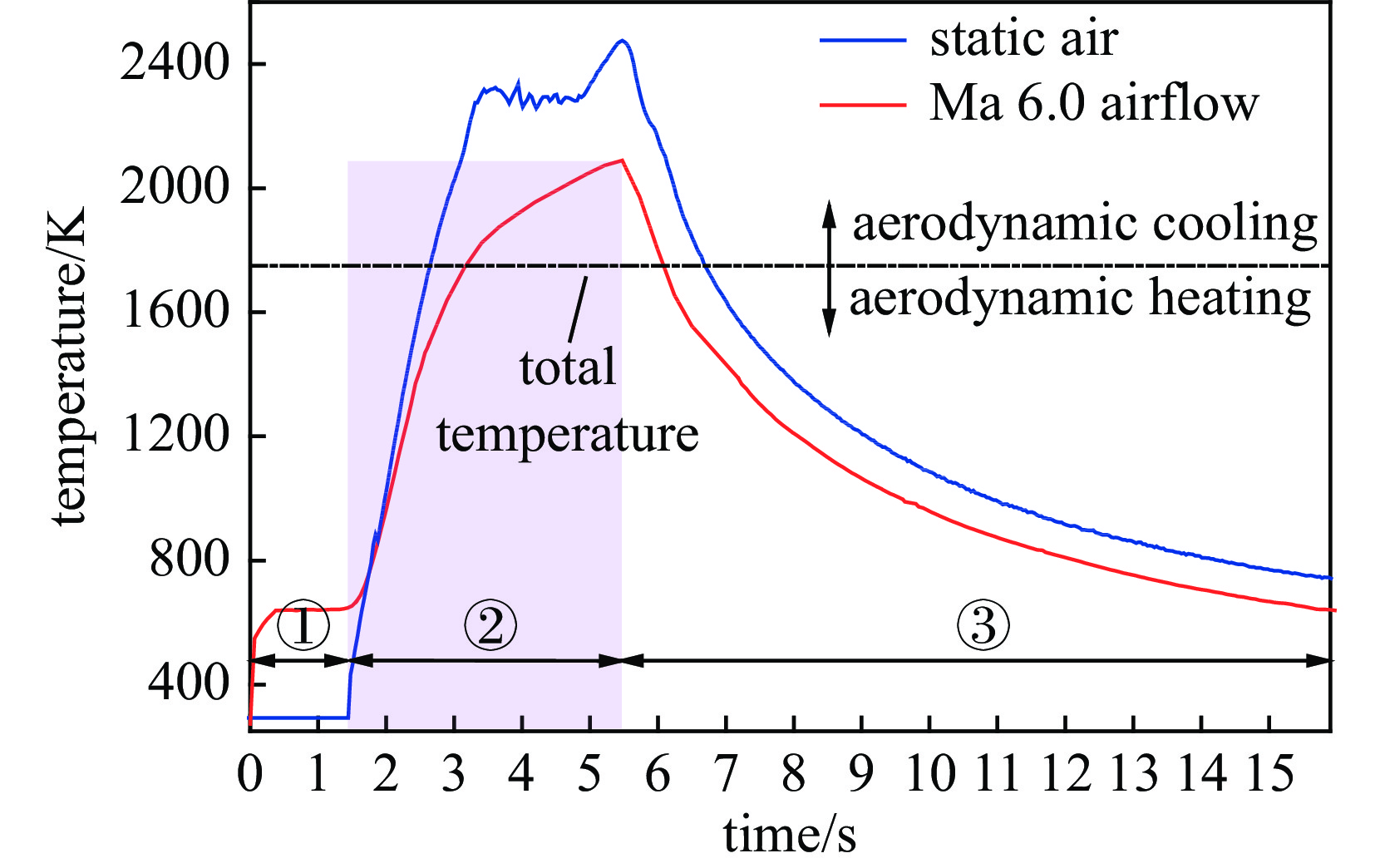

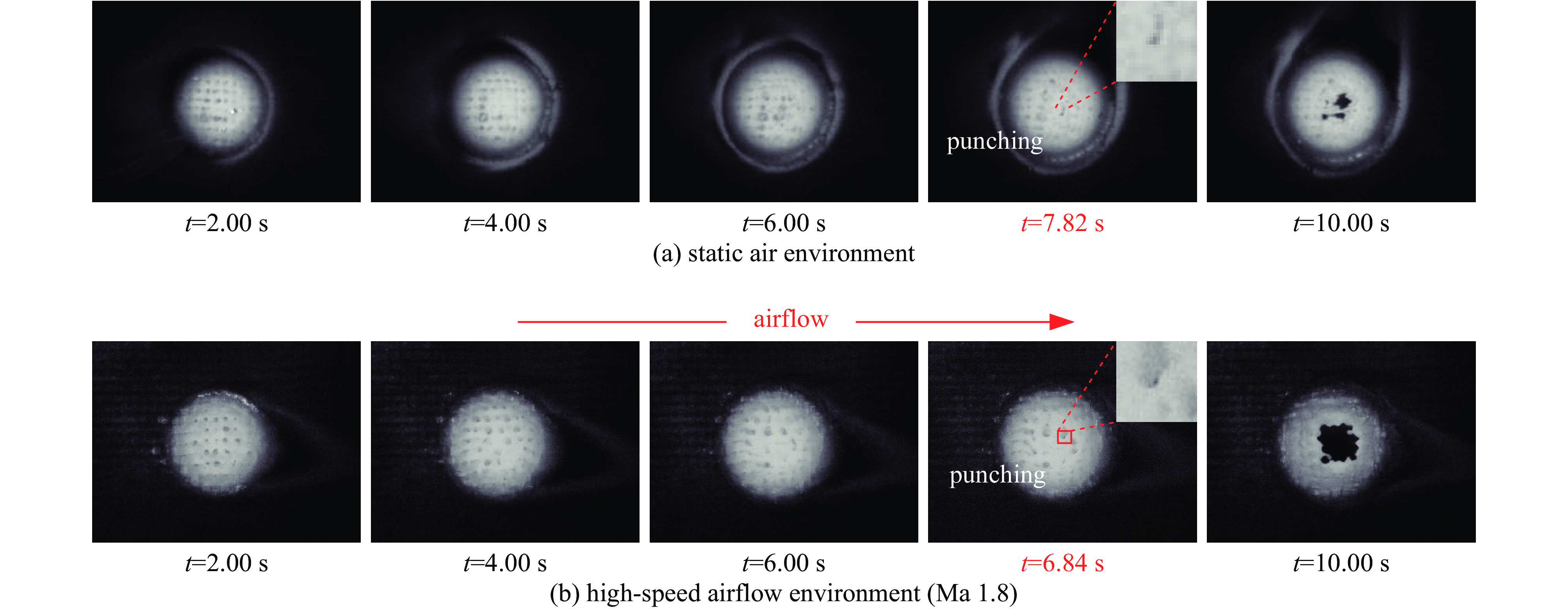

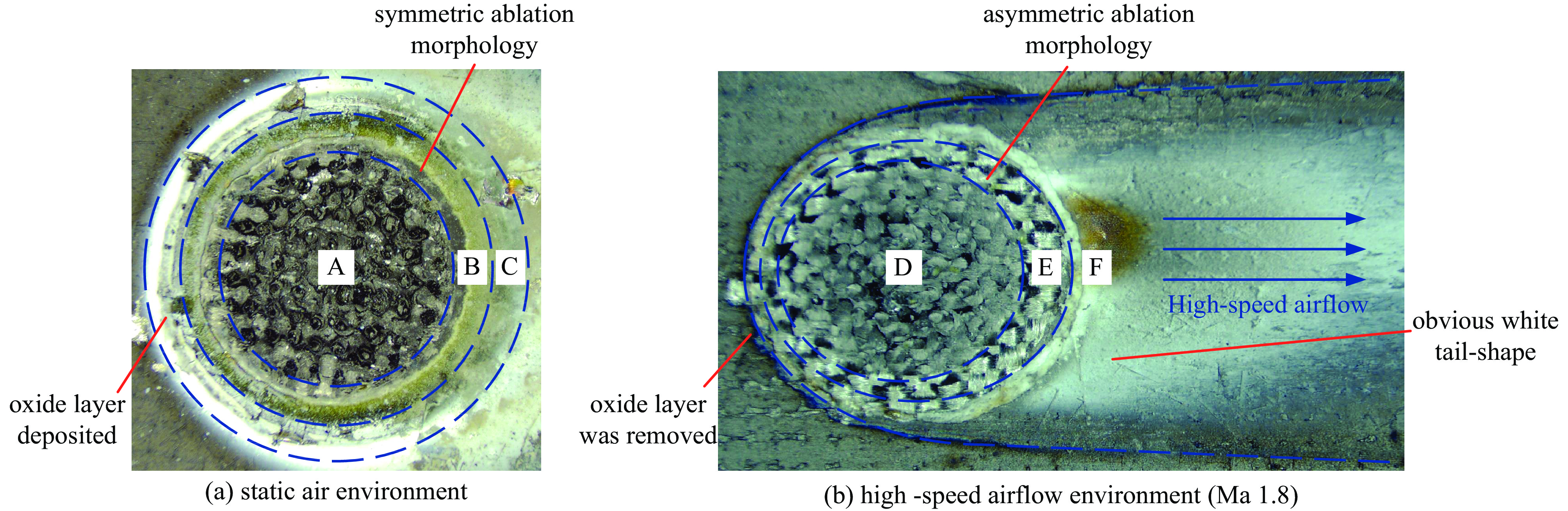

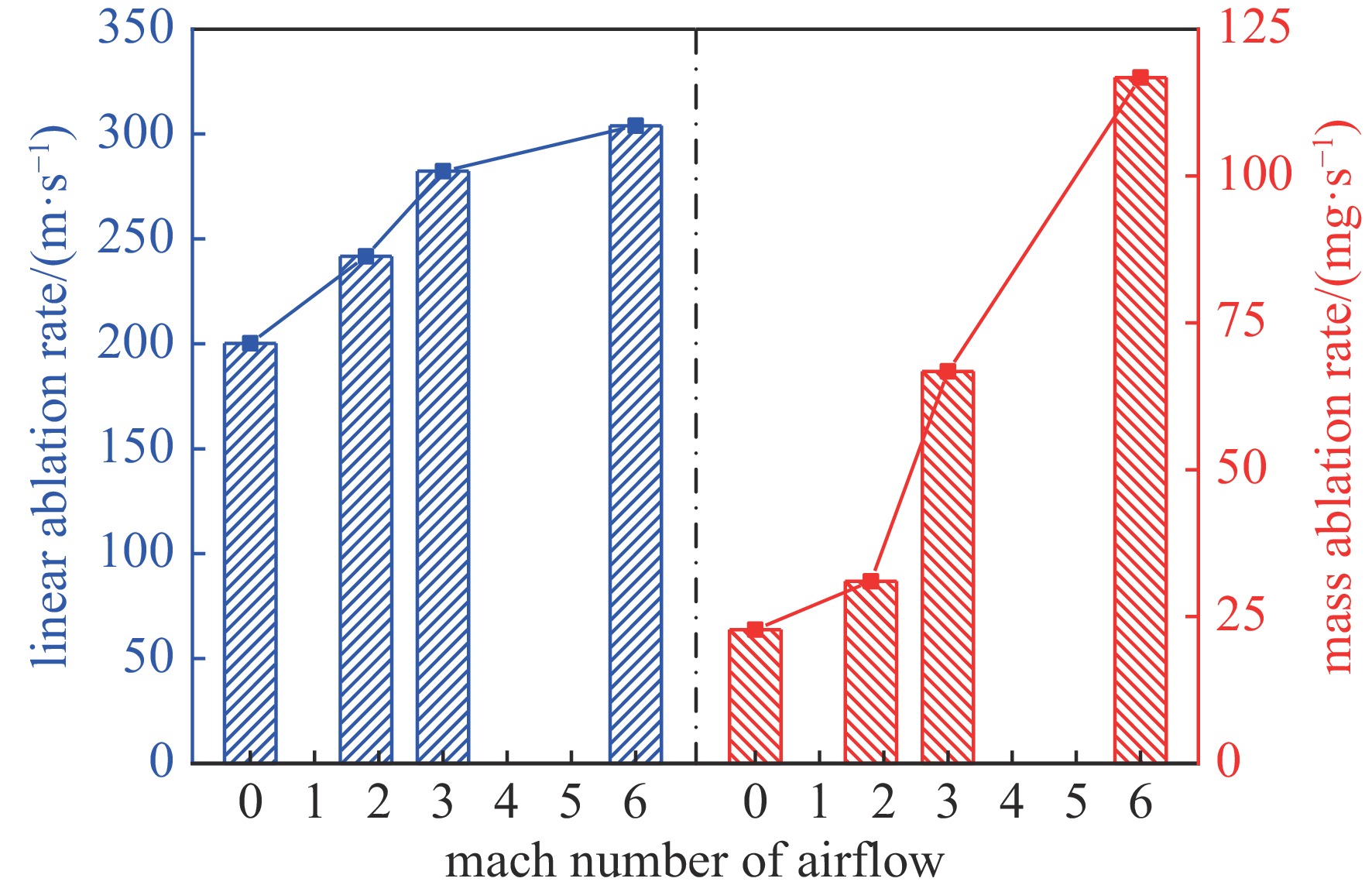

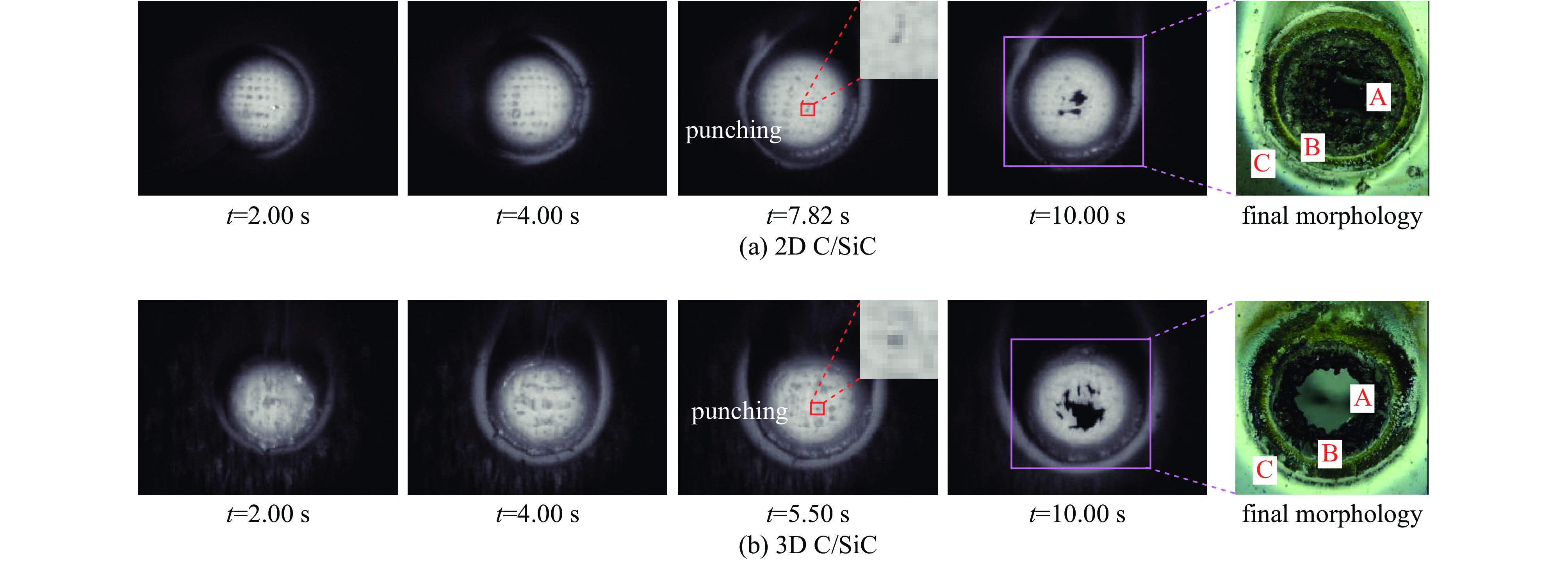

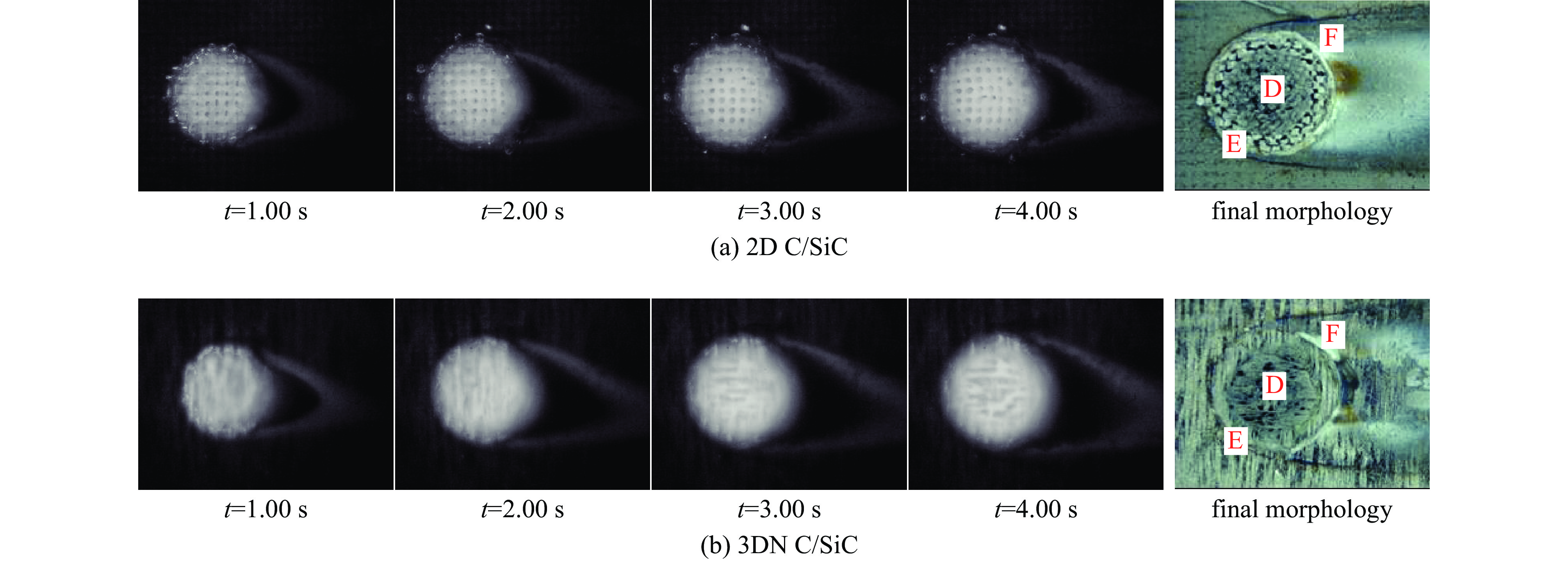

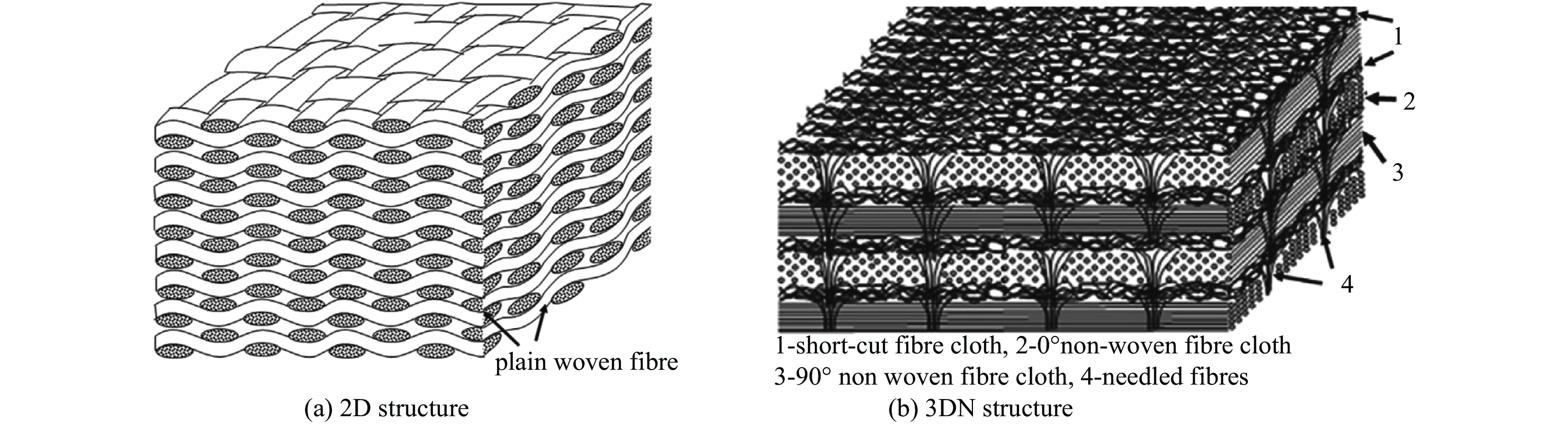

摘要: 为了明确高速气流对C/SiC复合材料激光烧蚀行为的影响机制,开展了不同环境下强激光对C/SiC复合材料的烧蚀对比实验研究。利用激光器与高速风洞联合实验平台,完成了静态以及Ma 1.8,Ma 3.0,Ma 6.0气流环境下2D与3DN C/SiC复合材料激光烧蚀实验。结果表明,与静态环境相比,高速气流对C/SiC复合材料的激光烧蚀行为产生了显著的影响,气流的冲刷使得烧蚀坑呈现出更宽、更深、更光滑的变化趋势。随着气流速度的增长,线烧蚀速率与质量烧蚀速率逐渐增大,主要原因为当地静压降低引起的升华速率增大,以及动压增大引起的剥蚀速率增大。此外,通过实验对比了不同构型对C/SiC激光烧蚀行为的影响。结果表明:2D C/SiC复合材料由于厚度方向更低的导热能力、更低的孔隙率等原因,其在不同环境条件下抗烧蚀能力均强于3DN C/SiC复合材料。Abstract: To investigate the effects of the high-speed airflow on the laser ablation characteristics of C/SiC composites, comparative study of laser ablation experiments under different environment conditions, including static air, Mach 1.8, Mach 3.0, Mach 6.0, were conducted by utilizing the joint experiment system integrating the laser and wind tunnel device. Experimental results show that, compared with the static air condition, the high-speed airflow had a remarkable impact on the laser ablation characteristics of C/SiC composites. The “washing effects” induced by the high-speed airflow made the ablation pit wider, deeper, smoother. Meanwhile, the linear ablation rate and mass ablation rate enlarged with the increasing airflow velocity, which was mainly due to the increased sublimation rate and erosion rate caused by the decreased local static pressure and increased dynamic pressure, respectively. Besides, the contrast experimental study of 2D and 3DN C/SiC composites were conducted to investigate the influences of braided structure of C/SiC composites. Results show thatdue to the factors suchas lower heat conduction capacity along the thickness direction, the lower porosity, the ablation resistance performance of 2D C/SiC composites was superior to that of 3D C/SiC.

-

Key words:

- C/SiC composite /

- laser irradiation /

- high-speed airflow /

- ablation behaviors

-

表 1 实验工况列表

Table 1. Parameters of the test conditions

environmental conditions total temperature/K total pressure/kPa velocity/(m·s−1) irradiation time/s static 300 101 0 4~10 Ma 1.8 363 323 535 4~10 Ma 3.0 815 1850 891 4~10 Ma 6.0 1784 4257 1787 4~10 -

[1] 孙承纬, 陆启生, 范正修, 等. 强激光辐照效应[M]. 北京: 国防工业出版社, 2002: 1-151Sun Chengwei, Lu Qisheng, Fan Zhengxiu, et al. High power laser irradiation effects[M]. Beijing: National Defense Industry Press, 2002: 1-151 [2] 张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨[J]. 复合材料学报, 2007, 24(2):1-6 doi: 10.3321/j.issn:1000-3851.2007.02.001Zhang Litong, Cheng Laifei. Discussion on strategies of sustainable development of continuous fiber reinforced ceramic matrix composites[J]. Acta Materiae Compositae Sinica, 2007, 24(2): 1-6 doi: 10.3321/j.issn:1000-3851.2007.02.001 [3] 朱则刚. 陶瓷基复合材料展现发展价值开发应用新蓝海[J]. 现代技术陶瓷, 2013, 34(2):20-25 doi: 10.3969/j.issn.1005-1198.2013.02.005Zhu Zegang. Ceramic matrix composites show new blue ocean in exploiting and applicating the development value[J]. Advanced Ceramics, 2013, 34(2): 20-25 doi: 10.3969/j.issn.1005-1198.2013.02.005 [4] Schmidt S, Beyer S, Knabe H, et al. Advanced ceramic matrix composite materials for current and future propulsion technology applications[J]. Acta Astronautica, 2004, 55(3): 409-420. [5] Zhang Litong, Cheng Laifei, Luan Xingang, et al. Environmental performance testing system for thermostructure materials applied in aeroengines[J]. Key Engineering Materials, 2006, 313: 183-190. doi: 10.4028/www.scientific.net/KEM.313.183 [6] Su Meng, Cheng Laifei, Luan Xingang, et al. Laser ablation behaviors of C/SiC composites in air[J]. Acta Materiae Compositae Sinica, 2013, 30(6): 37-47. [7] Liu Qiaomu, Zhang Litong, Jiang Fengrui, et al. Laser ablation behaviors of SiC–ZrC coated carbon/carbon composites[J]. Surface and Coatings Technology, 2011, 205(17/18): 4299-4303. [8] Dang Xiaolin, Yin Xiaowei, Fan Xiaomeng, et al. Microstructural evolution of carbon fiber reinforced SiC-based matrix composites during laser ablation process[J]. Journal of Materials Science & Technology, 2019, 35(12): 2919-2925. [9] Tong Yonggang, Bai Shuxin, Zhang Hong, et al. Laser ablation behavior and mechanism of C/SiC composite[J]. Ceramics International, 2013, 39(6): 6813-6820. doi: 10.1016/j.ceramint.2013.02.012 [10] Wang Yang, Chen Zhaofeng, Yu Shengjie. Ablation behavior and mechanism analysis of C/SiC composites[J]. Journal of Materials Research and Technology, 2016, 5(2): 170-182. doi: 10.1016/j.jmrt.2015.10.004 [11] Chen Zhaofeng, Fang Dan, Miao Yunliang, et al. Comparison of morphology and microstructure of ablation centre of C/SiC composites by oxy-acetylene torch at 2900 and 3550 ℃[J]. Corrosion Science, 2008, 50(12): 3378-3381. doi: 10.1016/j.corsci.2008.07.019 [12] 段刘阳, 罗磊, 王一光. 超高温陶瓷基复合材料的改性和烧蚀行为[J]. 中国材料进展, 2015, 34(10):762-769 doi: 10.7502/j.issn.1674-3962.2015.10.03Duan Liuyang, Luo Lei, Wang Yiguang. Modification and ablation behaviors of ultrahigh temperature ceramic matrix composites[J]. Materials China, 2015, 34(10): 762-769 doi: 10.7502/j.issn.1674-3962.2015.10.03 [13] Fang Dan, Chen Zhaofeng, Song Yingdong, et al. Morphology and microstructure of 2.5 dimension C/SiC composites ablated by oxyacetylene torch[J]. Ceramics International, 2009, 35(3): 1249-1253. doi: 10.1016/j.ceramint.2008.06.008 [14] 宋宏伟, 黄晨光. 激光辐照诱导的热与力学效应[J]. 力学进展, 2016, 46(1):435-477 doi: 10.6052/1000-0992-15-025Song Hongwei, Huang Chenguang. Progress in thermal-mechanical effects induced by laser[J]. Advances in Mechanics, 2016, 46(1): 435-477 doi: 10.6052/1000-0992-15-025 [15] 张检民, 马志亮, 冯国斌, 等. 切向空气流速度对玻璃纤维增强树脂基复合材料激光烧蚀热的影响[J]. 中国激光, 2015, 42:0306004 doi: 10.3788/CJL201542.0306004Zhang Jianmin, Ma Zhiliang, Feng Guobin, et al. Influence of tangential airflows velocity on ablation heat of laser irradiated glass fiber reinforced resin composites[J]. Chinese Journal of Lasers, 2015, 42: 0306004 doi: 10.3788/CJL201542.0306004 [16] 陈敏孙, 江厚满, 焦路光, 等. 切向气流作用下玻璃纤维复合材料的激光辐照效应[J]. 强激光与粒子束, 2013, 25(5):1075-1080 doi: 10.3788/HPLPB20132505.1075Chen Minsun, Jiang Houman, Jiao Luguang, et al. Laser irradiation effects on glass fiber composite subjected to tangential gas flow[J]. High Power Laser and Particle Beams, 2013, 25(5): 1075-1080 doi: 10.3788/HPLPB20132505.1075 [17] 张文杰, 蒙文, 李云霞, 等. 切向气流对激光辐照效应影响的研究进展[J]. 激光与光电子学进展, 2016, 53:041403Zhang Wenjie, Meng Wen, Li Yunxia, et al. Research progress of tangential airflow impacting on laser irradiation[J]. Laser & Optoelectronics Progress, 2016, 53: 041403 [18] 黄亿辉, 宋宏伟, 黄晨光. 超声速气流下强激光辐照靶体失效数值模拟[J]. 强激光与粒子束, 2013, 25(9):2229-2234 doi: 10.3788/HPLPB20132509.2229Huang Yihui, Song Hongwei, Huang Chenguang. Numerical simulation of failure of target irradiated by high-power laser subjected to supersonic airflow[J]. High Power Laser and Particle Beams, 2013, 25(9): 2229-2234 doi: 10.3788/HPLPB20132509.2229 [19] Xu Huajie, Zhang Litong, Cheng Laifei. The yarn size dependence of tensile and in-plane shear properties of three-dimensional needled textile reinforced ceramic matrix composites[J]. Materials & Design, 2015, 67: 428-435. [20] Wang Fuyuan, Cheng Laifei, Zhang Qing, et al. Effect of surface morphology and densification on the infrared emissivity of C/SiC composites[J]. Applied Surface Science, 2014, 313: 670-676. doi: 10.1016/j.apsusc.2014.06.044 [21] Wang Jiangtao, Ma Yuzhao, Liu Yuwen, et al. Experimental investigation on laser ablation of C/SiC composites subjected to supersonic airflow[J]. Optics & Laser Technology, 2019, 113: 399-406. [22] Wang Zhe, Wang Jiangtao, Song Hongwei, et al. Laser ablation behavior of C/SiC composites subjected to transverse hypersonic airflow[J]. Corrosion Science, 2021, 183: 109345. doi: 10.1016/j.corsci.2021.109345 [23] Dimitrienko Y I. Thermomechanics of composite structures under high temperatures[M]. Dordrecht: Springer, 2016. -

下载:

下载: