A theoretical study on intense laser induced damage of monocrystalline silicon by absorption front model

-

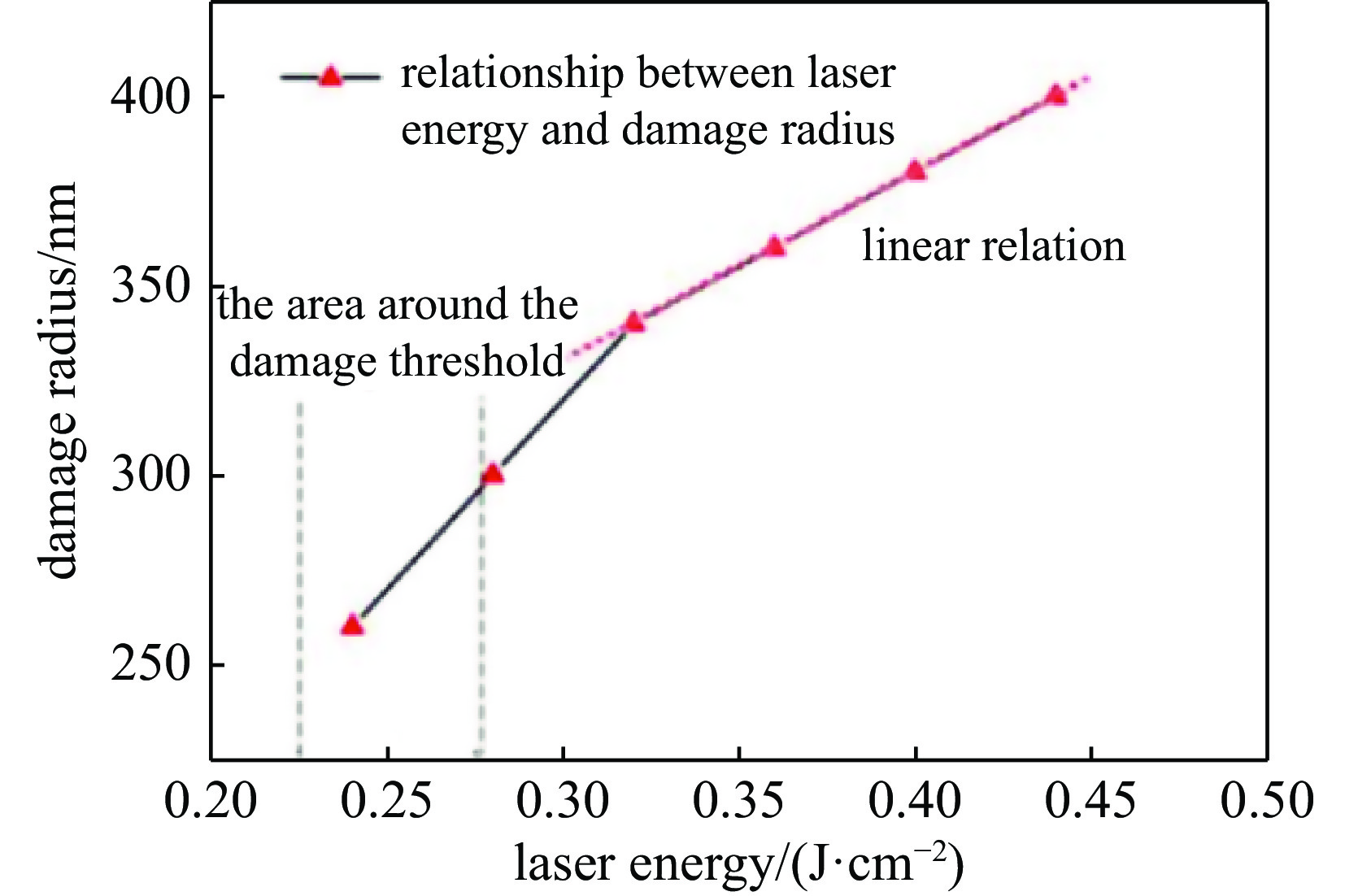

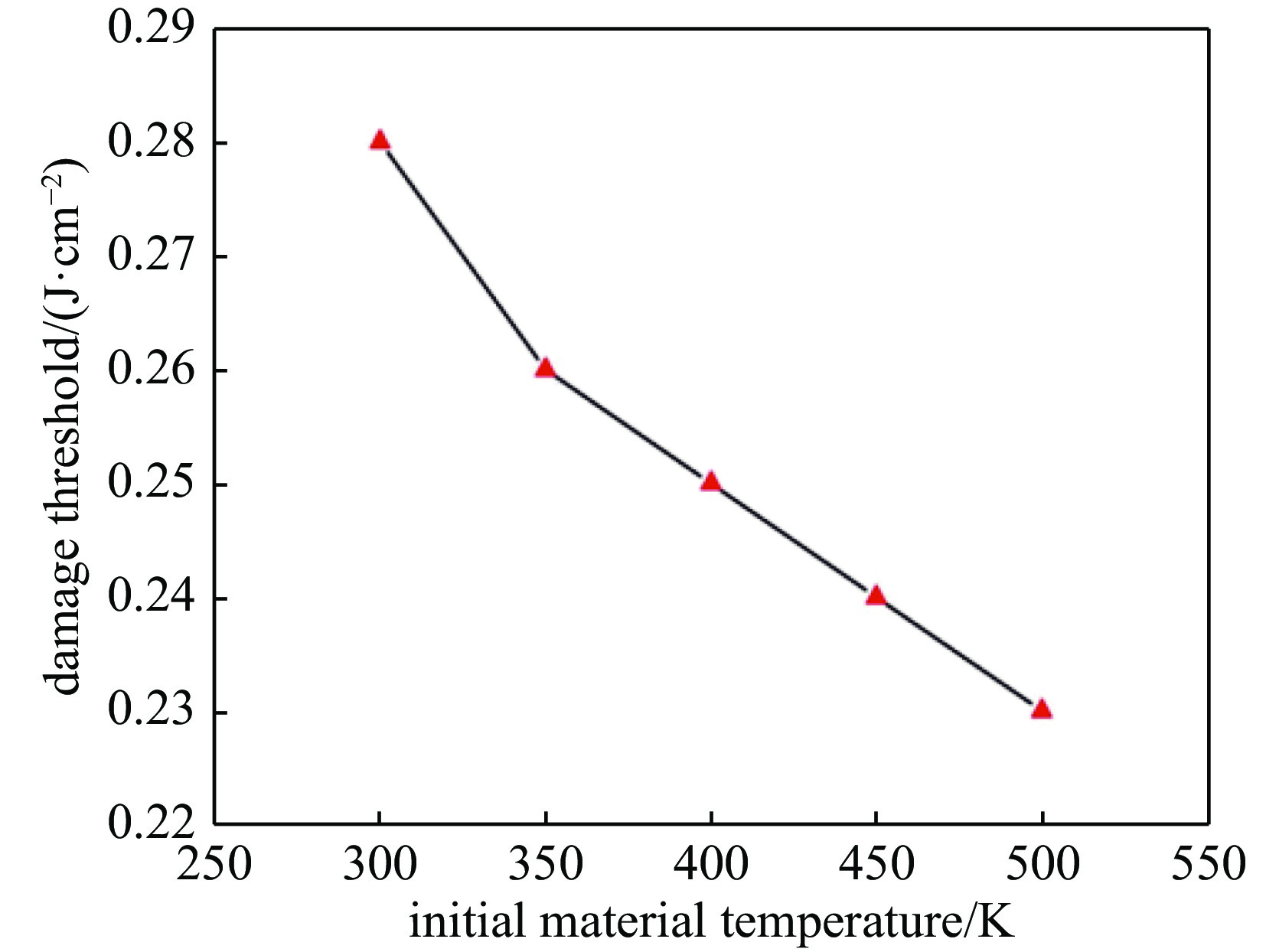

摘要: 改进了描述光学材料强激光损伤的吸收波前模型,在原有模型的基础上引入了杂质缺陷吸收项,并将一维形式推广到了三维。利用改进后的吸收波前模型,数值模拟了红外单晶硅光学材料在波长1064 nm皮秒激光辐照时杂质源(以金属铁为例)附近材料的温度、损伤半径及损伤阈值等变化情况,并分析了光学材料初始温度对损伤阈值的影响规律。数值结果显示:(1)与传统的热传递模型不同,在损伤阈值附近,激光场能量密度从低于损伤到达到(或超出)损伤的微小变化导致温度场的巨大变化;(2)达到损伤能量密度后,杂质附近的最高温度及利用吸收波前表征的材料损伤半径随着辐照能量密度的增加近似线性增长;(3)激光损伤阈值随着材料初始温度的增加而降低。研究结果表明改进后的吸收波前模型可以较好地描述光学材料的杂质缺陷诱导强激光损伤:相比于传统的热超导模型,吸收波前模型可以更合理的表示损伤阈值附近温度场的突变,并可定量分析杂质诱导光学材料的强激光损伤尺寸。另外对单晶硅吸收波前模型的研究还显示提升材料的初始温度可以有效降低材料的强激光损伤阈值,这为提升光电对抗中光电探测器的激光损伤效率提供了一种思路。Abstract: The absorption front model for laser induced damage of optical materials is modified. Different from the original model, the impurity defect absorption term is introduced, and the one-dimensional model is extended to a three-dimensional model. Using the modified absorption front model, temperature distribution near impurity(taking metal iron as an example), damage radius and damage threshold of infrared optical material of monocrystalline silicon are numerically studied, which is irradiated by 1064nm picosecond laser. The influence of initial temperature of the optical material on damage threshold is also studied. Our results show that: (1) Different from the traditional heat thermal transport models, near the damage threshold, a small change of laser field energy density from below to equal to or beyond damage threshold leads to a great change of temperature field in the presently modified absorption front model; (2) The maximum temperature near impurity and damage radius characterized by the absorption front increase approximately linearly with the increase of the irradiation energy density as the laser energy density goes far beyond damage threshold; (3) The laser damage threshold decreases with the increase of the initial temperature of the material. Our results prove that the presently modified absorption front model can better describe the laser damage induced by impurity defects in optical materials. Compared with the traditional thermal transport models, the present absorption front model can represent the sudden change of temperature field near the damage threshold more reasonably, and can quantitatively analyze laser damage size of optical materials induced by impurities. In addition, our results also show that increasing the initial temperature of the material can effectively reduce its laser damage threshold, which provides a way to improve the laser damage efficiency of photodetectors in photoelectric countermeasures.

-

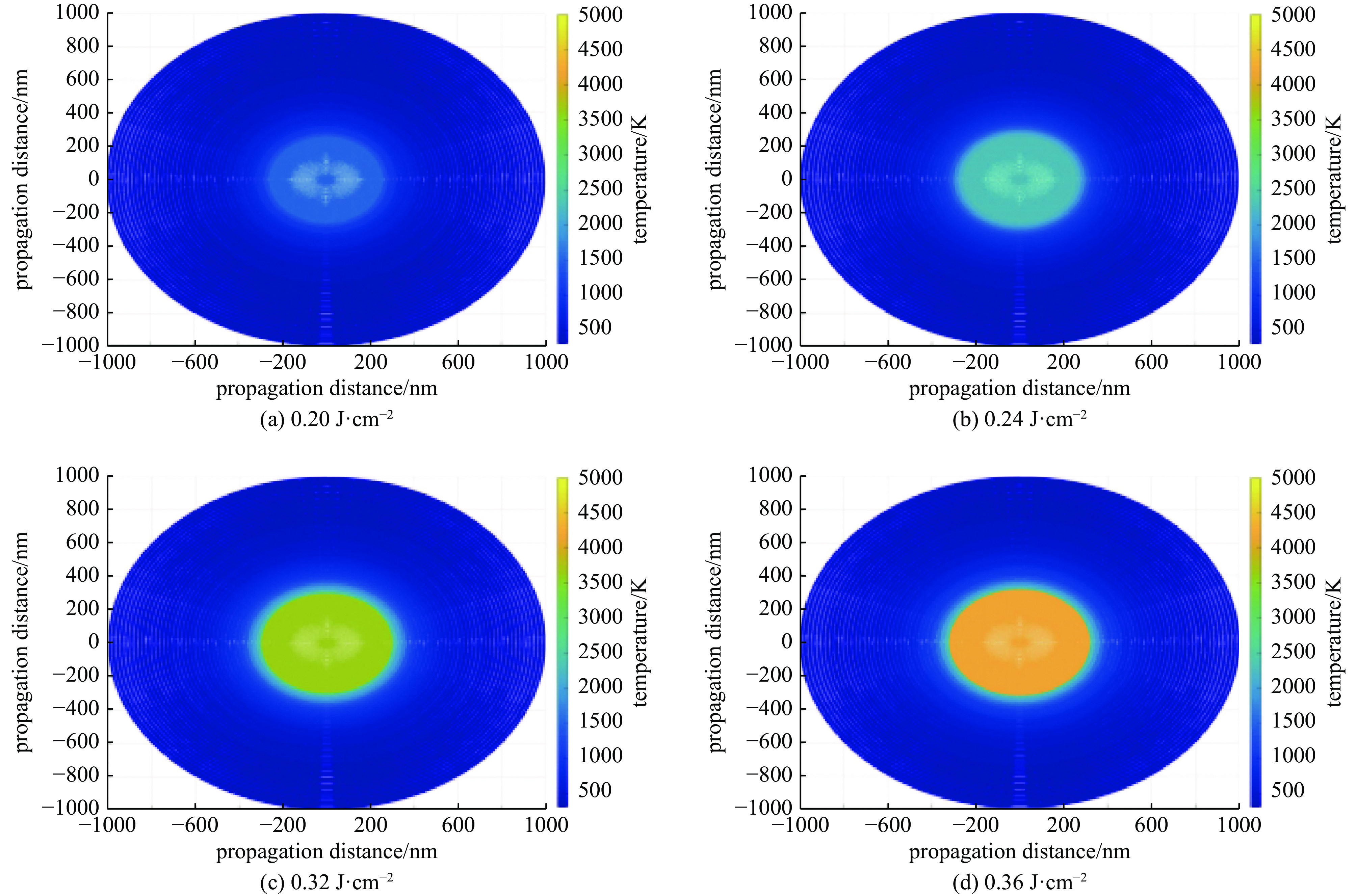

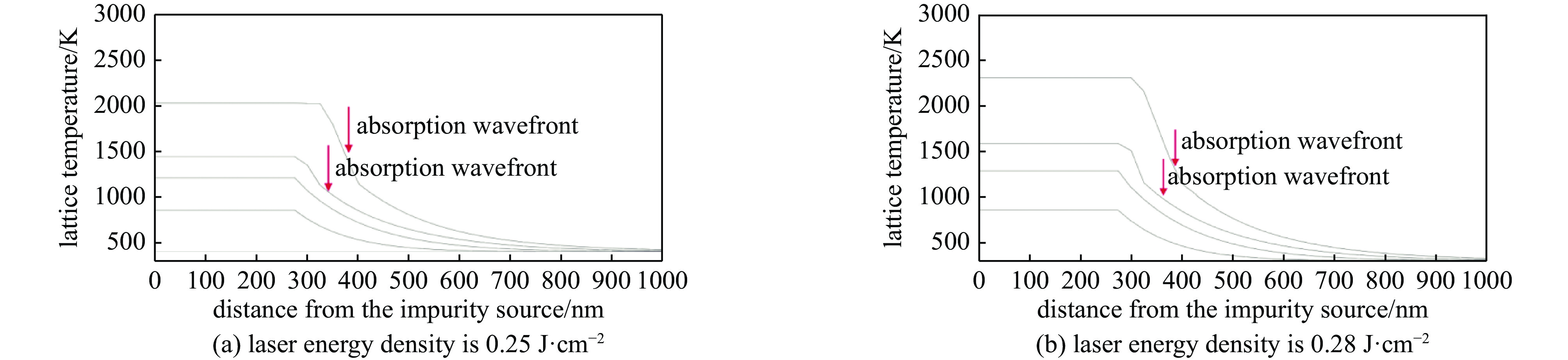

图 2 不同激光能量密度照射后杂质源附近的温度场分布(材料初始温度300 K,激光波长1064 nm、 脉宽400 ps;辐照时间 400 ps)

Figure 2. Temperature fields near impurity source after different laser irradiation at different laser energy densities (material’s initial temperature 300 K, laser wavelength 1064 nm, pulse width 400 ps; irradiation time 400 ps)

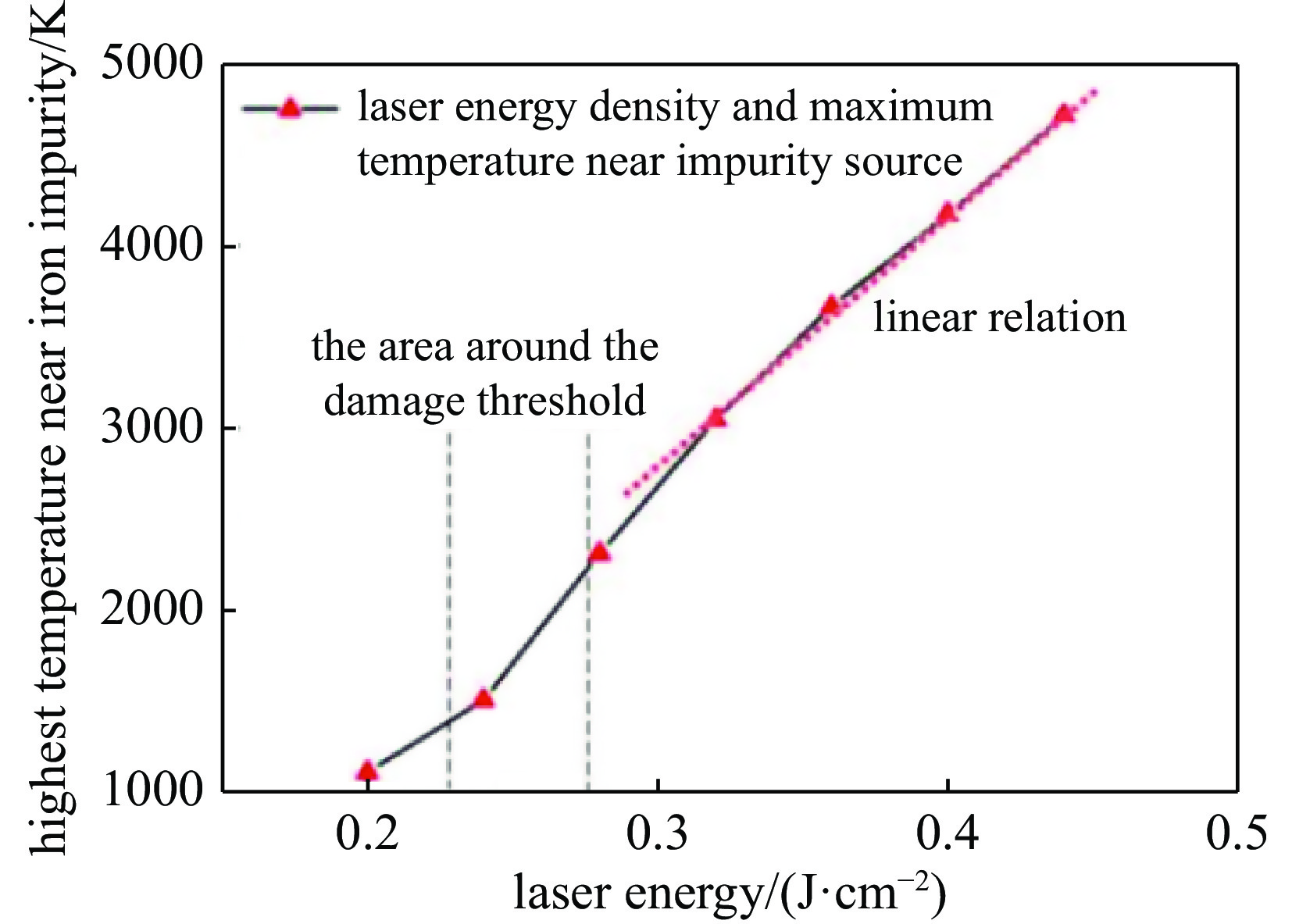

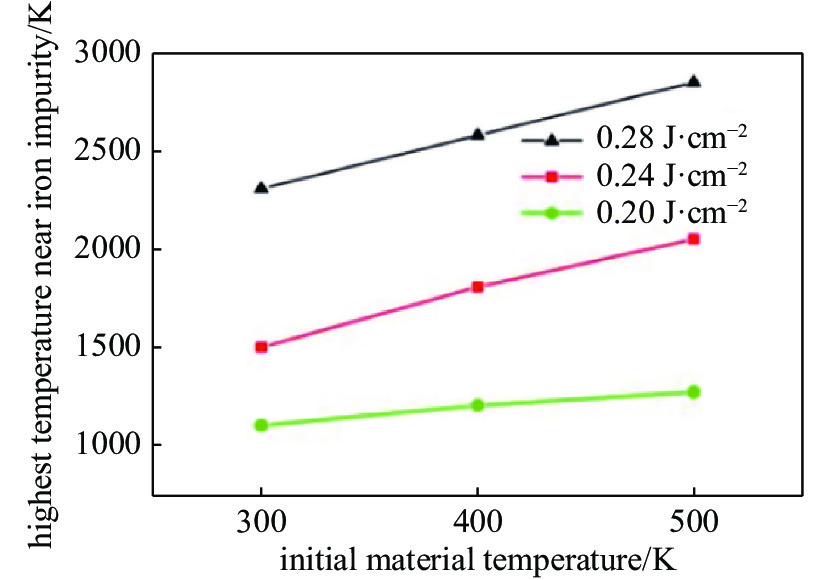

图 3 不同激光能量密度(0.2,0.24,0.28,0.32,0.36,0.40,0.45 J·cm−2)辐照后铁杂质附近的最高温度(材料初始温度300 K,激光波长1064 nm,脉宽400 ps)

Figure 3. Highest temperature near iron impurity after irradiation at different laser energy densities (0.2, 0.24, 0.28, 0.32, 0.36, 0.40, 0.45 J·cm−2) (initial material temperature 300 K, laser wavelength 1064 nm, pulse width 400 ps)

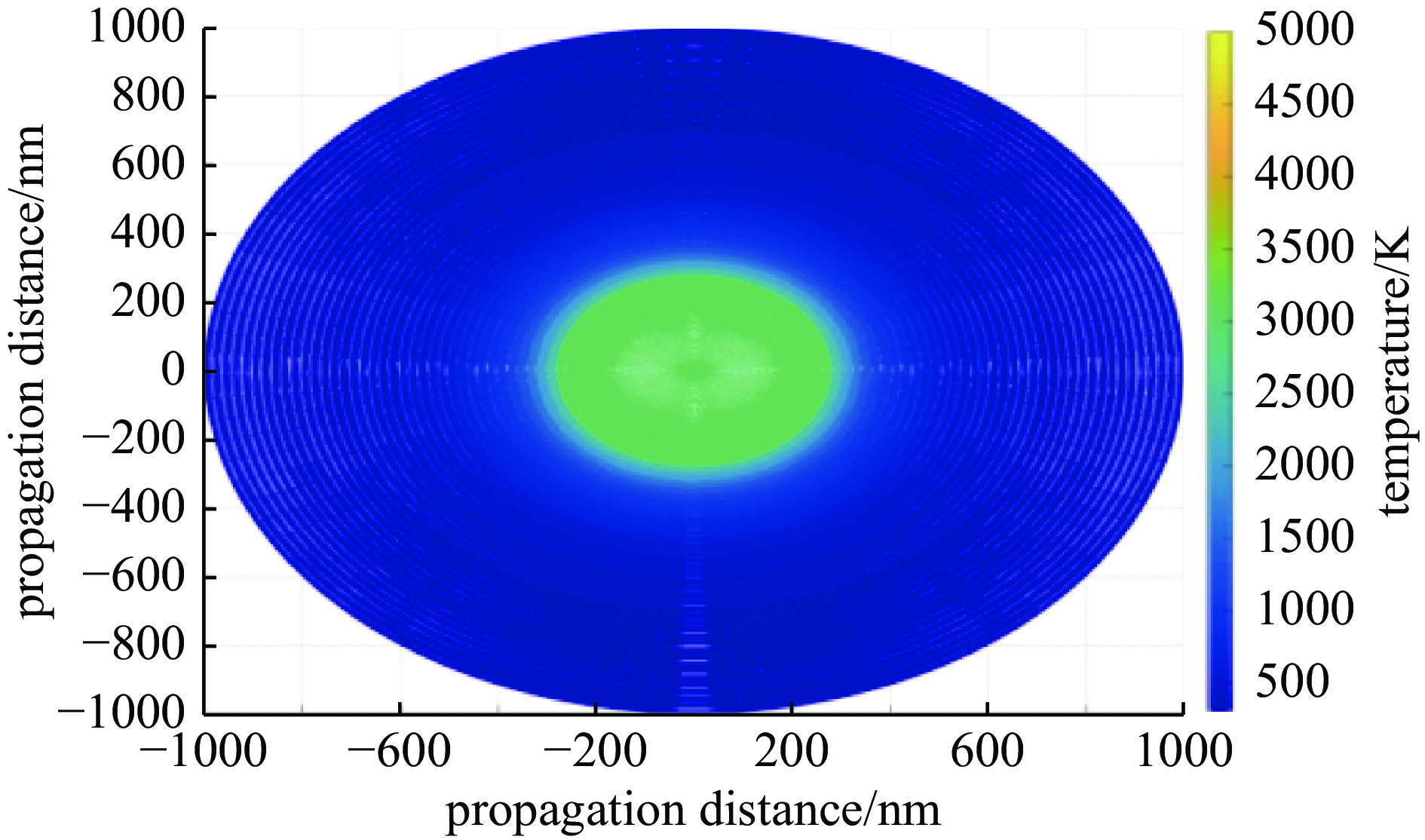

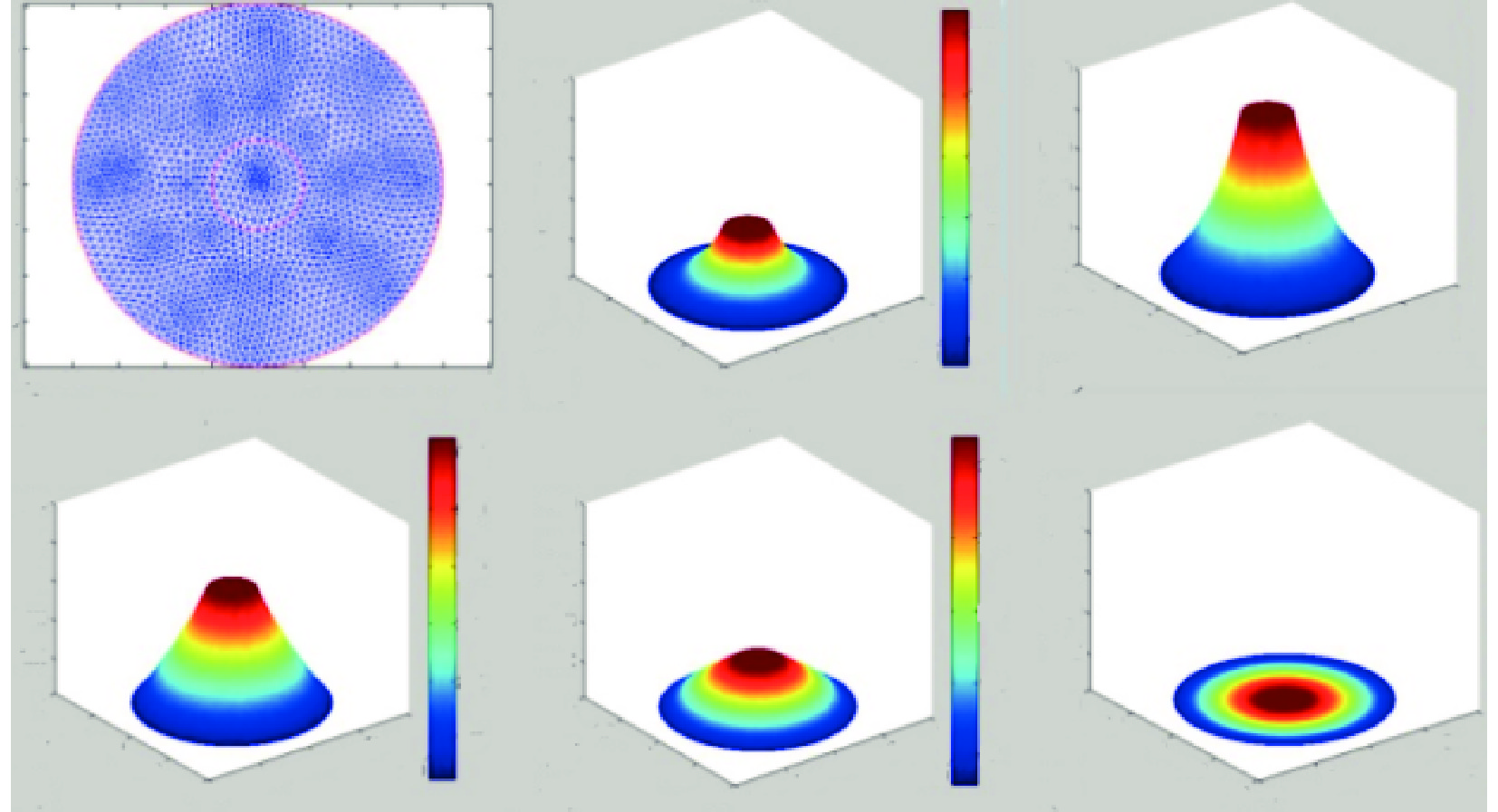

图 4 材料初始温度300 K,激光脉宽400 ps,波长1064 nm, 激光能量为0.28 J·cm−2的激光辐照后,杂质源附近的温度分布(辐照时间400 ps)

Figure 4. Temperature field near impurity source after laser radiation. Here the initial temperature of material is 300 K, laser pulse width is 400 ps, wavelength is 1064 nm, laser energy is 0.28 J·cm−2 (irradiation time 400 ps)

-

[1] 王东, 王非, 白冰, 等. 10.6μm脉冲激光对多晶硅探测器干扰损伤实验[J]. 激光与红外, 2015, 45(9):1084-1087 doi: 10.3969/j.issn.1001-5078.2015.09.016Wang Dong, Wang Fei, Bai Bing, et al. Experiment study on the jamming and damage thresholds of polycrystalline silicon detector irradiated by 10.6 μm pulsed CO2 laser[J]. Laser & Infrared, 2015, 45(9): 1084-1087 doi: 10.3969/j.issn.1001-5078.2015.09.016 [2] 栗兴良, 牛春晖, 马牧燕, 等. 单脉冲激光损伤CCD探测器的有限元仿真[J]. 激光技术, 2016, 40(5):730-733 doi: 10.7510/jgjs.issn.1001-3806.2016.05.023Li Xingliang, Niu Chunhui, Ma Muyan, et al. Finite element simulation of damage characteristics of CCD detectors under single-laser-pulse irradiation[J]. Laser Technology, 2016, 40(5): 730-733 doi: 10.7510/jgjs.issn.1001-3806.2016.05.023 [3] Malik R, Mills B, Price J H V, et al. Determination of the mid-IR femtosecond surface-damage threshold of germanium[J]. Applied Physics A, 2013, 113(1): 127-133. doi: 10.1007/s00339-012-7499-9 [4] Liu Yang, Liu Lisheng, Tang Wei, et al. Experimental study on the damage of optical materials by out of band composite laser[J]. Applied Sciences, 2020, 10: 3578. doi: 10.3390/app10103578 [5] Lee H. Picosecond mid-IR laser induced surface damage on gallium phosphate (GaP) and calcium fluoride(CaF2)[J]. Journal of Mechanical Science and Technology, 2007, 21(7): 1077-1082. doi: 10.1007/BF03027657 [6] Wang X, Zhu D H, Shen Z H, et al. Surface damage morphology investigations of silicon under millisecond laser irradiation[J]. Applied Surface Science, 2010, 257(5): 1583-1588. doi: 10.1016/j.apsusc.2010.08.098 [7] Stuart B C, Feit M D, Herman S, et al. Nanosecond-to-femtosecond laser-induced breakdown in dielectrics[J]. Physical Review B, 1996, 53(4): 1749-1761. doi: 10.1103/PhysRevB.53.1749 [8] 徐娇, 陈丽霞, 游兴海, 等. 表面杂质诱导薄膜元件的热应力损伤[J]. 光学学报, 2017, 37:0614003 doi: 10.3788/AOS201737.0614003Xu Jiao, Chen Lixia, You Xinghai, et al. Thermal stress damage of thin-film components induced by surface impurities[J]. Acta Optica Sinica, 2017, 37: 0614003 doi: 10.3788/AOS201737.0614003 [9] 彭玉峰, 盛朝霞, 张虎, 等. 激光辐照下固体材料的温度分布理论研究[J]. 强激光与粒子束, 2004, 16(10):1225-1228Peng Yufeng, Sheng Zhaoxia, Zhang Hu, et al. Theoretical analyses of temperature distributions of solid materials irradiated by high power laser[J]. High Power Laser and Particle Beams, 2004, 16(10): 1225-1228 [10] 段晓峰, 牛燕雄, 张雏. 半导体材料的激光辐照效应计算和损伤阈值分析[J]. 光学学报, 2004, 24(8):1057-1061Duan Xiaofeng, Niu Yanxiong, Zhang Chu. Calculation of laser irradiation effect and analysis of laser-induced damage threshold in semiconductor[J]. Acta Optica Sinica, 2004, 24(8): 1057-1061 [11] Carr C W, Bude J D, DeMange P. Laser-supported solid-state absorption fronts in silica[J]. Physical Review B, 2010, 82: 184304. doi: 10.1103/PhysRevB.82.184304 [12] Shen N, Bude J D, Carr C W. Model laser damage precursors for high quality optical materials[J]. Optics Express, 2014, 22(3): 3393-3404. doi: 10.1364/OE.22.003393 [13] Ristau D. Laser-induced damage in optical materials[M]. Boca Raton: CRC Press, 2014: 27-30. [14] Bonneau F, Combis P, Rullier J L, et al. Study of UV laser interaction with gold nanoparticles embedded in silica[J]. Applied Physics B, 2002, 75(8): 803-815. doi: 10.1007/s00340-002-1049-7 [15] Stevens-Kalceff M A, Stesmans A, Wong J. Defects induced in fused silica by high fluence ultraviolet laser pulses at 355 nm[J]. Applied Physics Letters, 2002, 80(5): 758-760. doi: 10.1063/1.1446203 [16] Bude J, Miller P E, Shen N, et al. Silica laser damage mechanisms, precursors and their mitigation[C]//Proceedings of SPIE 9237, Laser-Induced Damage in Optical Materials. 2014: 92370S. [17] 项建胜. 基于Mie光散射理论的气泡测量技术研究[D]. 西安: 中国科学院研究生院(西安光学精密机械研究所), 2007: 10-11Xiang Jiansheng. Research on bubble measurement technology based on Mie light scattering theory[D]. Xi'an: University of Chinese Academy of Sciences, 2007: 10-11). [18] Van De Hulst H C. Light scattering by small particles[M]. New York: Dover Publications, 1981: 40-57. [19] Wang M Y, Ge D B, Xu J, et al. FDTD study on back scattering of conducting sphere coated with double negatibe metamaterials[J]. International Journal of Infrared and Millimeter Waves, 2007, 28: 689. doi: 10.1007/s10762-007-9250-8 [20] Endo R K, Fujihara Y, Susa M. Calculation of the density and heat capacity of silicon by molecular dynamics simulation[J]. High Temperatures-High Pressures, 2003, 35/36(5): 505-511. doi: 10.1068/htjr135 [21] Sin E H, Ong C K, Tan H S. Temperature dependence of Interband optical absorption of silicon at 1152, 1064, 750, and 694 nm[J]. Physica Status Solidi (A), 1984, 85(1): 199-204. doi: 10.1002/pssa.2210850124 -

下载:

下载: