| [1] |

Ninokata H, Efthimiadis A, Todreas N E. Distributed resistance modeling of wire-wrapped rod bundles[J]. Nuclear Engineering and Design, 1987, 104(1): 93-102. doi: 10.1016/0029-5493(87)90306-2

|

| [2] |

Jeong H Y, Ha K S, Chang W P, et al. Modeling of flow blockage in a liquid metal-cooled reactor subassembly with a subchannel analysis code[J]. Nuclear Technology, 2005, 149(1): 71-87. doi: 10.13182/NT05-A3580

|

| [3] |

陈选相, 吴攀, 单建强. 钠冷快堆分析程序ATHAS-LMR的子通道模型[J]. 原子能科学技术, 2012, 46(6):695-700Chen Xuanxiang, Wu Pan, Shan Jianqiang. Subchannel model of analysis code ATHAS-LMR for LMFBR[J]. Atomic Energy Science and Technology, 2012, 46(6): 695-700

|

| [4] |

Lodi F, Grasso G, Mattioli D, et al. ANTEO+: A subchannel code for thermal-hydraulic analysis of liquid metal cooled systems[J]. Nuclear Engineering and Design, 2016, 301: 128-152. doi: 10.1016/j.nucengdes.2016.03.001

|

| [5] |

吴宗芸, 刘天才, 吴明宇. 基于双区域模型的钠冷快堆组件子通道分析程序的开发与验证[J]. 原子能科学技术, 2022, 56(4):672-683Wu Zongyun, Liu Tiancai, Wu Mingyu. Development and validation of subchannel analysis program based on two-region model for sodium cooled fast reactor assembly[J]. Atomic Energy Science and Technology, 2022, 56(4): 672-683

|

| [6] |

Wantland J L. ORRIBLE–A computer program for flow and temperature distribution in 19-ROD LMFBR fuel subassemblies[J]. Nuclear Technology, 1974, 24(2): 168-175. doi: 10.13182/NT74-A31473

|

| [7] |

Rowe D S. COBRA IIIC: digital computer program for steady state and transient thermal-hydraulic analysis of rod bundle nuclear fuel elements[R]. Richland, WA, USA: Battelle Pacific Northwest Labs. , 1973.

|

| [8] |

Sun R L, Zhang D L, Liang Y, et al. Development of a subchannel analysis code for SFR wire-wrapped fuel assemblies[J]. Progress in Nuclear Energy, 2018, 104: 327-341. doi: 10.1016/j.pnucene.2017.12.005

|

| [9] |

Liu X J, Scarpelli N. Development of a sub-channel code for liquid metal cooled fuel assembly[J]. Annals of Nuclear Energy, 2015, 77: 425-435. doi: 10.1016/j.anucene.2014.10.030

|

| [10] |

Mikityuk K. Heat transfer to liquid metal: review of data and correlations for tube bundles[J]. Nuclear Engineering and Design, 2009, 239(4): 680-687. doi: 10.1016/j.nucengdes.2008.12.014

|

| [11] |

Cheng S K, Todreas N E. Hydrodynamic models and correlations for bare and wire-wrapped hexagonal rod bundles—bundle friction factors, subchannel friction factors and mixing parameters[J]. Nuclear Engineering and Design, 1986, 92(2): 227-251. doi: 10.1016/0029-5493(86)90249-9

|

| [12] |

Castellana F S, Adams W T, Casterline J E. Single-phase subchannel mixing in a simulated nuclear fuel assembly[J]. Nuclear Engineering and Design, 1974, 26(2): 242-249. doi: 10.1016/0029-5493(74)90059-4

|

| [13] |

Pramuditya S, Takahashi M. Thermal–hydraulic analysis of wire-wrapped SFR test subassemblies by subchannel analysis method[J]. Annals of Nuclear Energy, 2013, 54: 109-119. doi: 10.1016/j.anucene.2012.11.011

|

| [14] |

Bogoslovskaya G P, Zhukov A V, Sorokin A P. Models and characteristics of interchannel exchange in pin bundles cooled by liquid metal[R]. Vienna, Austria: International Atomic Energy Agency, 2000.

|

| [15] |

Zheng S G. Constitutive correlations for wire-wrapped subchannel analysis under forced and mixed convection conditions[D]. Cambridge: Massachusetts Institute of Technology, 1984.

|

| [16] |

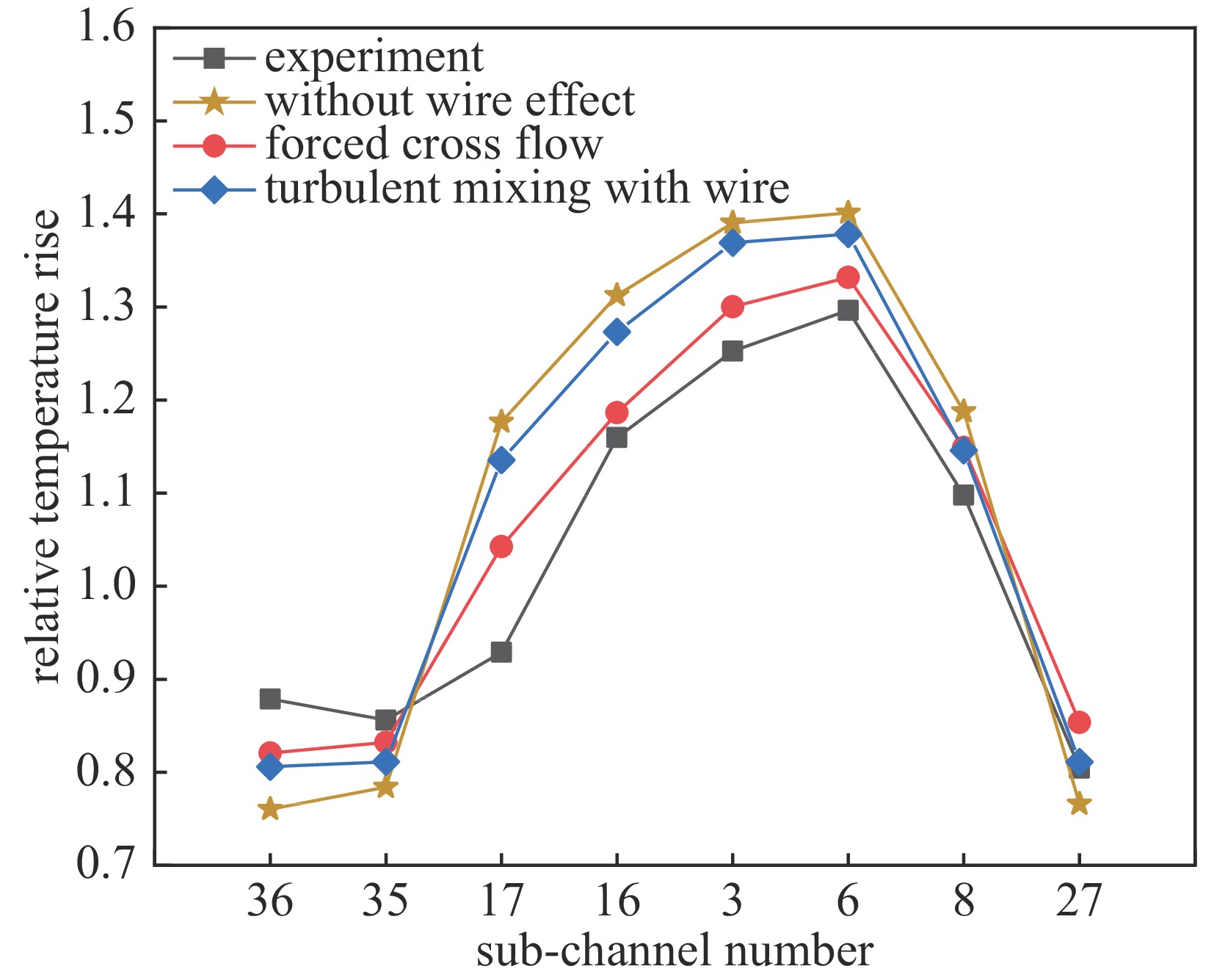

Fontana M H, MacPherson R, Gnadt P, et al. Temperature distribution in a 19-rod simulated LMFBR fuel assembly in a hexagonal duct (fuel failure mockup bundle 2A): Record of experimental data[J]. ORNL-TM-4113, 1973.

|

下载:

下载: