Investigation on the application of microtube and shell heat exchanger in energy conversion cycle

-

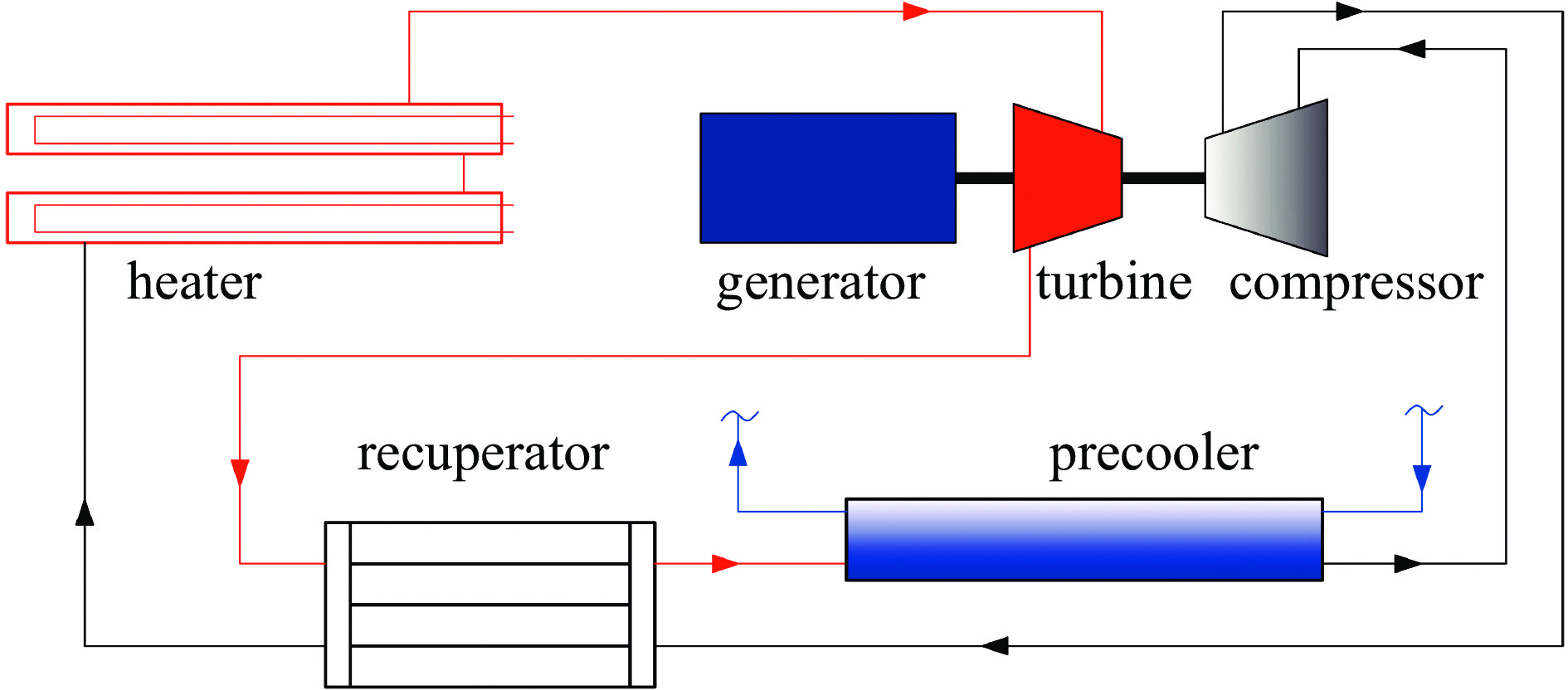

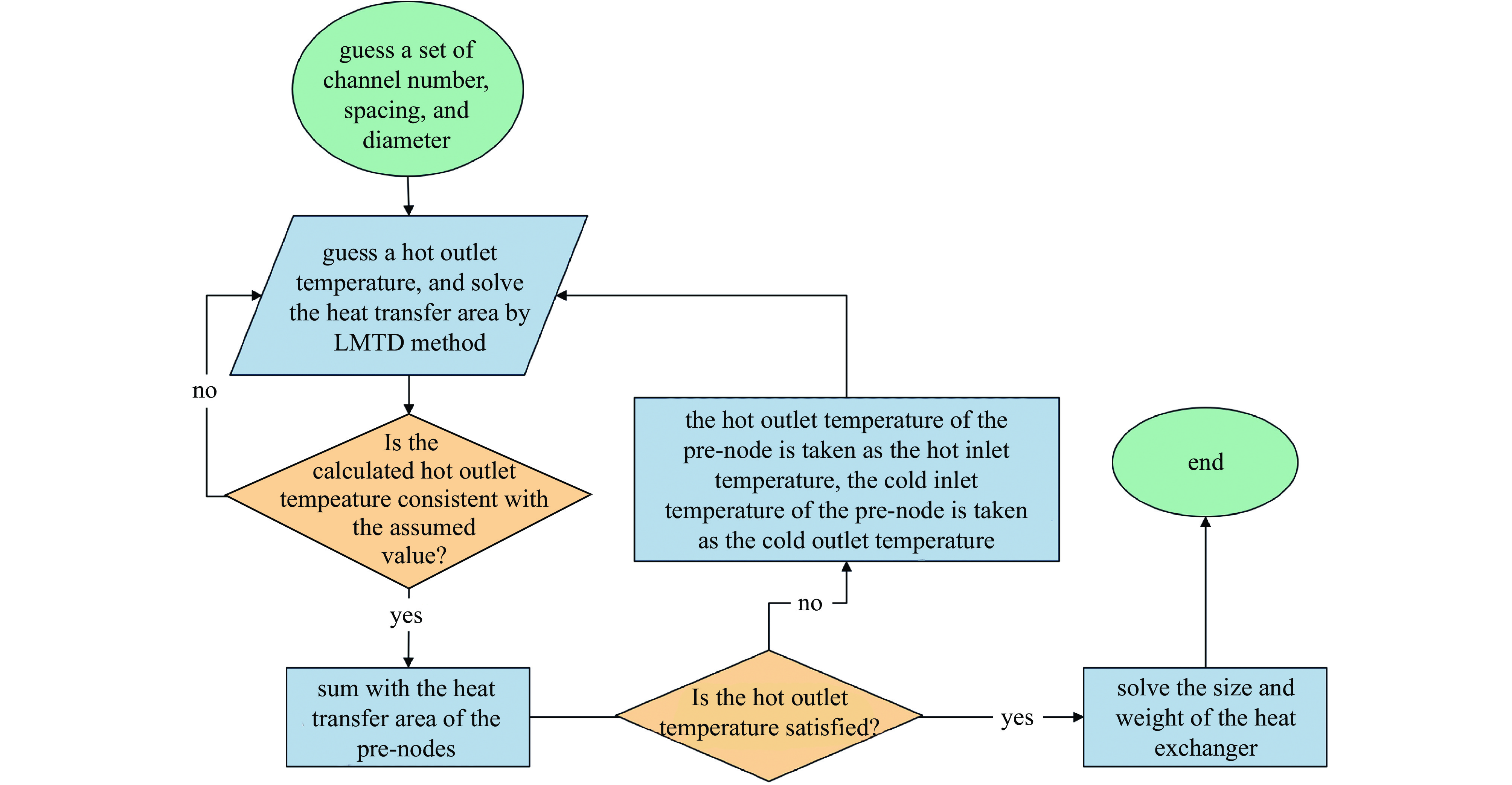

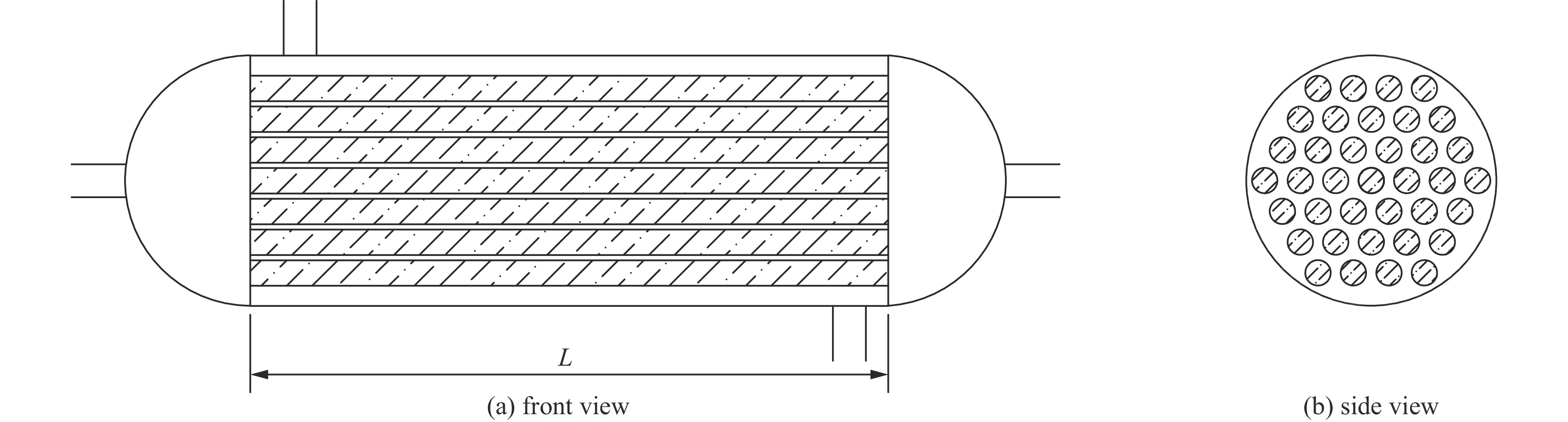

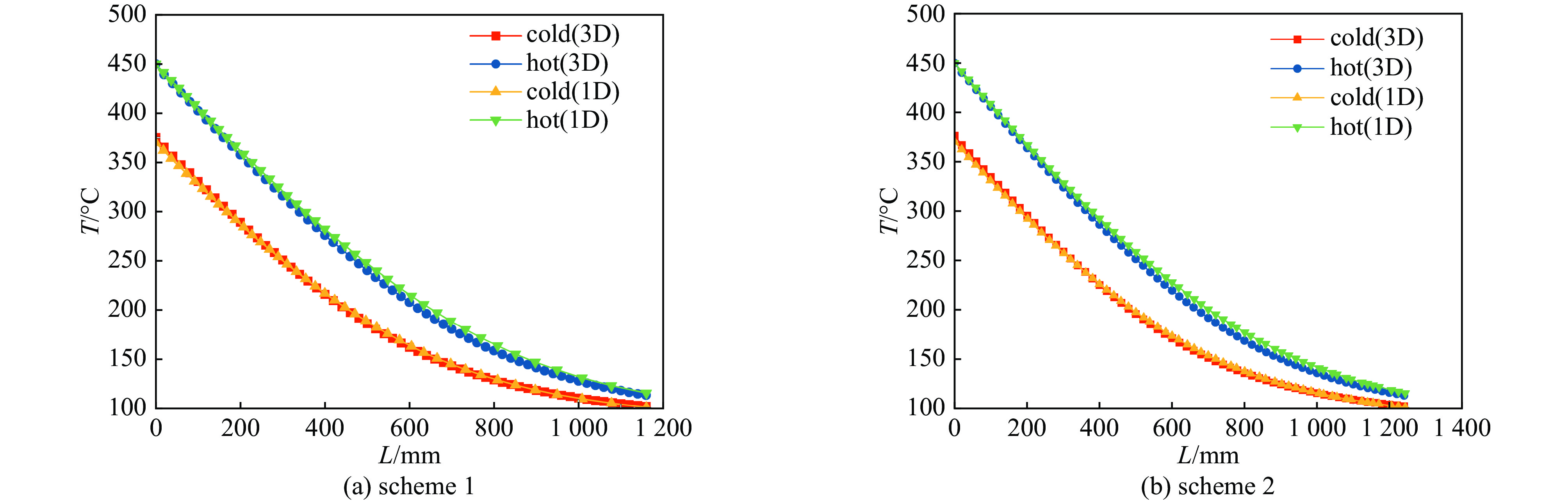

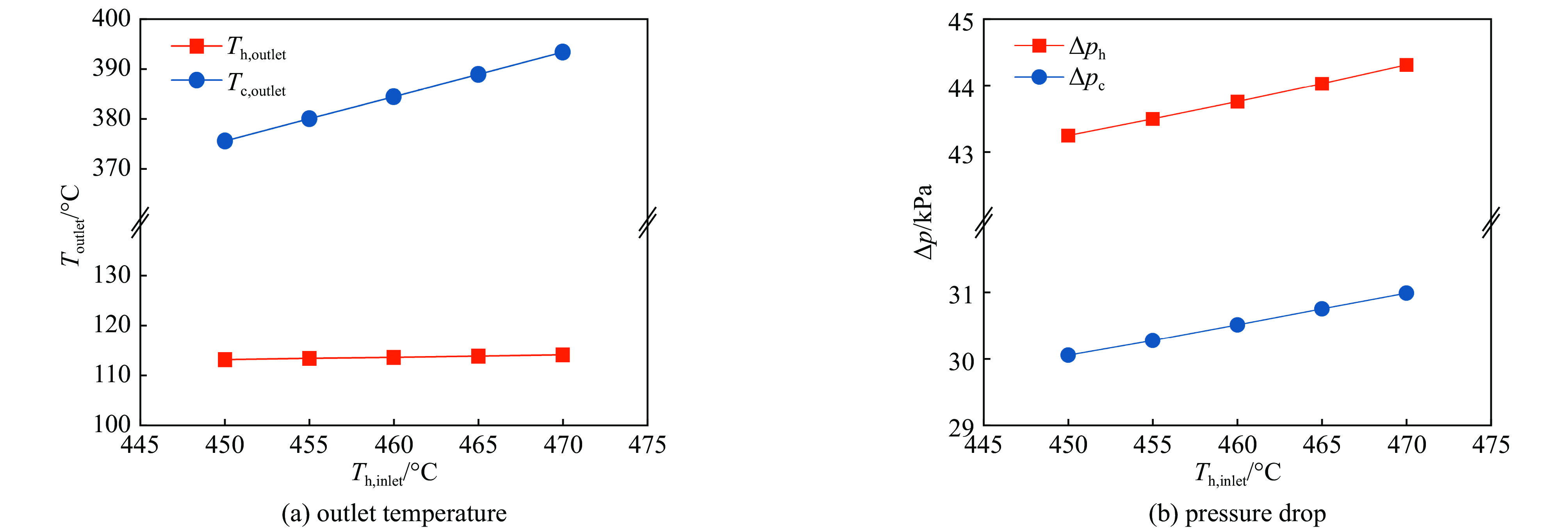

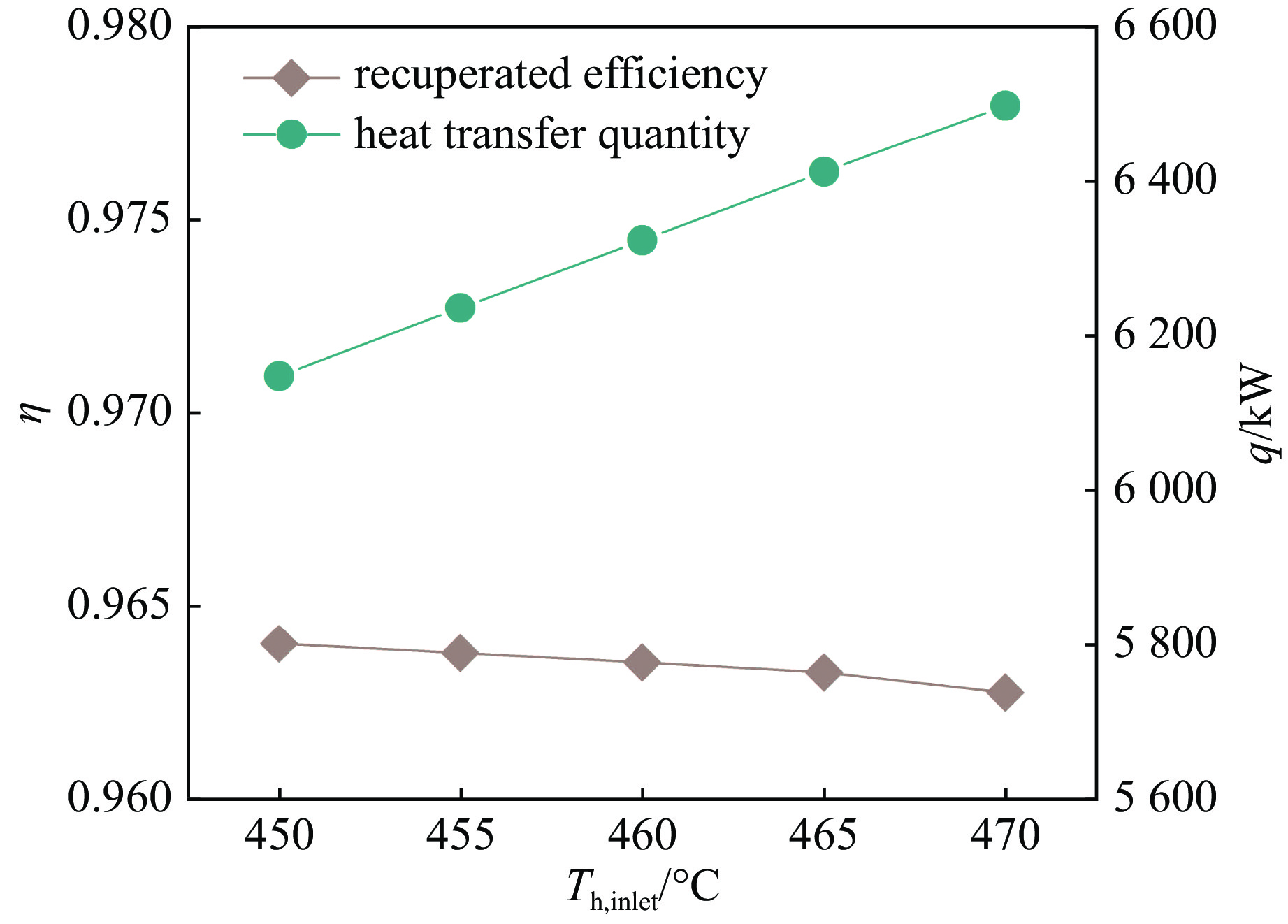

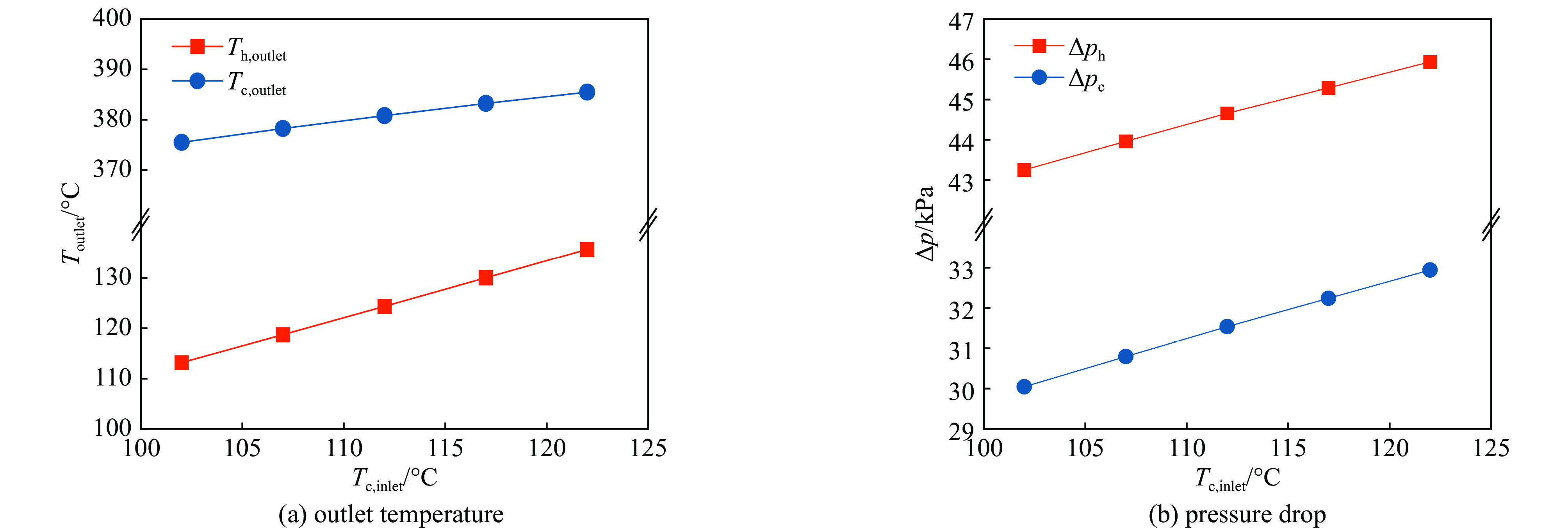

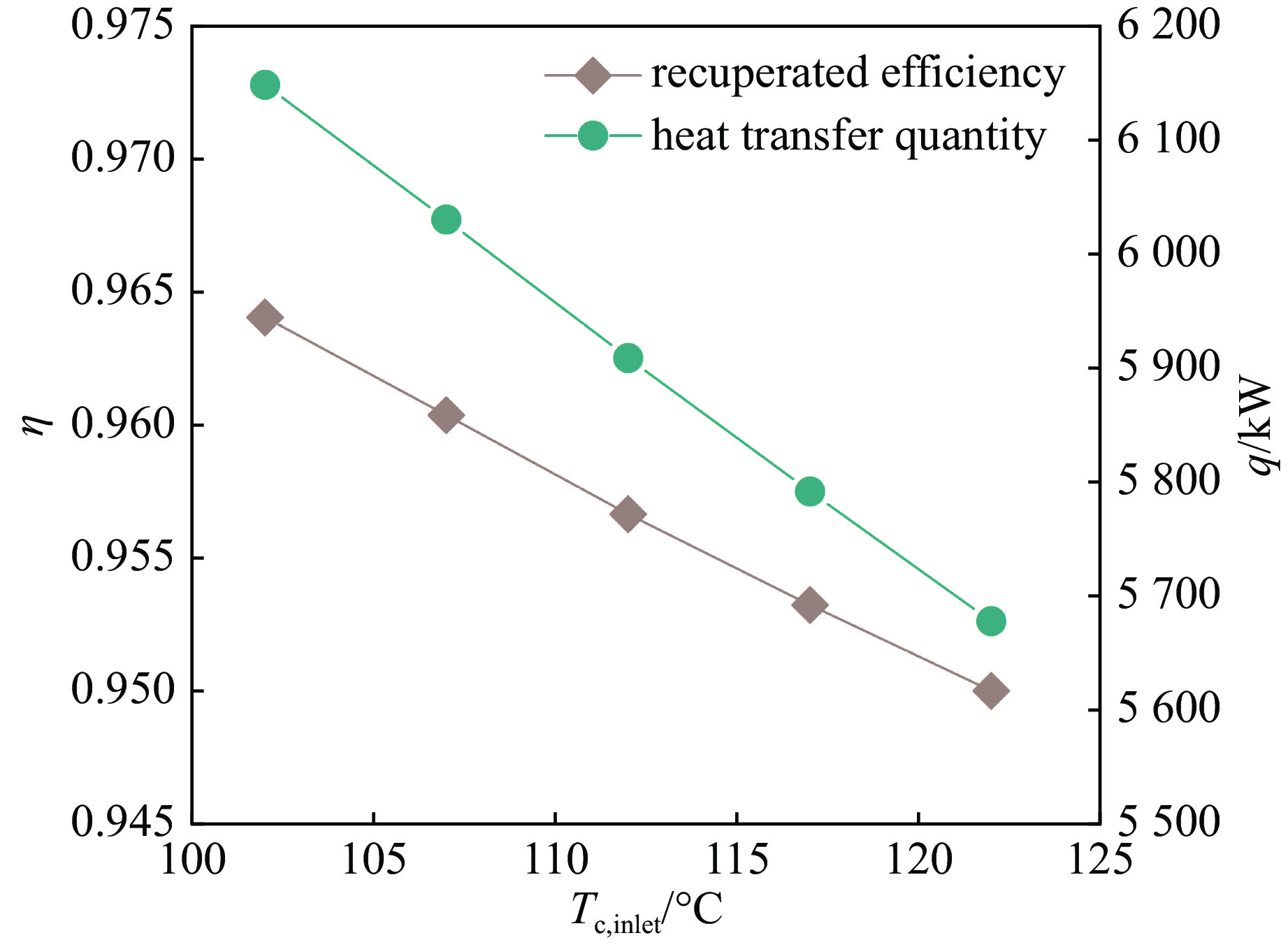

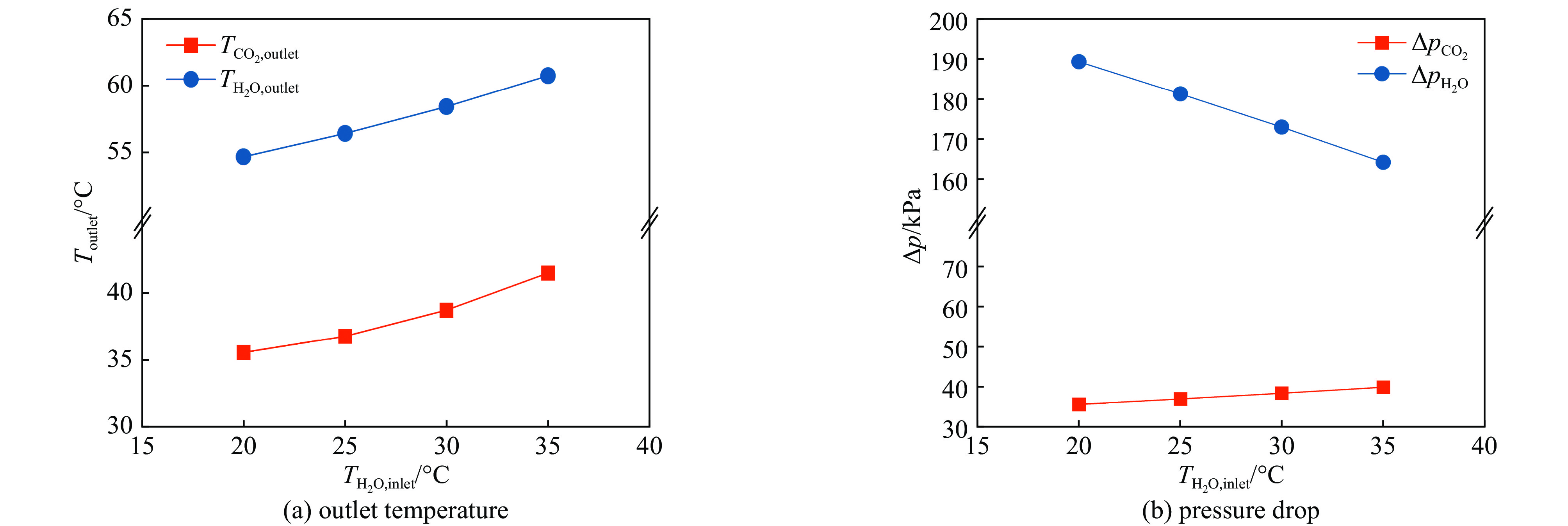

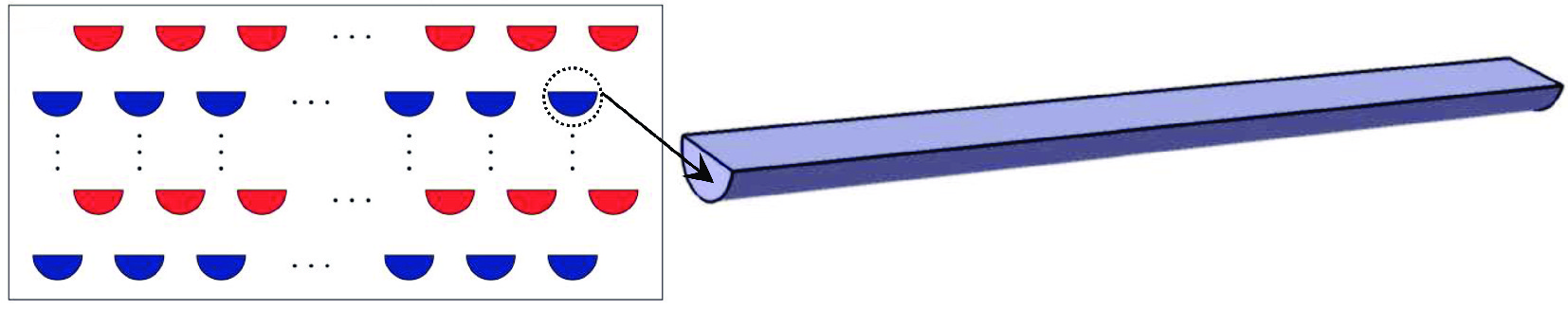

摘要: 目前,超临界二氧化碳(S-CO2)布雷顿循环普遍采用印刷电路板换热器(PCHE)来保证其相对其他能量转换循环的紧凑性优势。PCHE芯体为整体结构,若内部出现泄漏或结垢等问题,很难进行维护与检修。本文提出了一种微管壳式换热器(MSTE),其结构与传统管壳式换热器类似,但其管径缩小至微通道级。由于MSTE的流道横截面积占总截面积之比较PCHE大,在典型的回热器与冷却器设计工况下,相对PCHE而言,采用MSTE可将体积与质量均减小30%以上。灵敏性分析结果显示,采用本文设计的MSTE结构的回热器与冷却器,回热器冷热流道入口温度升高20 ℃左右,压缩机入口温度变化均不超过1 ℃,说明该种结构换热器的换热能力足够支撑能量转换循环的一般工况波动。Abstract: Print circuit heat exchanger (PCHE) is widely used in the present supercritical carbon dioxide (S-CO2) Brayton cycle to support its superiority in compactness when compared with other energy conversion cycles. The maintenance and overhaul of PCHE are hard to be carried out when leakage and fouling appear because of the integral structure of the core. A microtube and shell heat exchanger (MSTE) is proposed in this research. The structure of the MSTE is similar to that of the conventional shell-and-tube heat exchanger except that the tube diameter is reduced to microchannel level. The cross-section area of the flow channel in MSTE takes more counts than that in PCHE, thus the volume and weight of MSTE can be reduced by more than 30% when compared with PCHE under typical design conditions of recuperator and precooler. Sensitivity analysis results show that if the designed recuperator and precooler with MSTE structure are adopted, the inlet temperature of compressor changes less than 1 ℃ when the hot or cold inlet temperature of recuperator increased by about 20 ℃. It can be concluded from the analysis results that the heat transfer capacity of MSTE is sufficient to adjust the general working condition fluctuations of the energy conversion cycle.

-

表 1 换热器设计参数

Table 1. Design parameters of the heat exchangers

component hot outlet pressure/MPa hot inlet temperature/℃ hot outlet temperature/℃ cold outlet pressure/MPa cold inlet temperature/℃ recuperator 8.09 450 118 19.91 102 precooler 8 118 38 0.1 25 表 2 相同设计工况下的MSTE与PCHE对比

Table 2. Comparison between MSTE and PCHE under the same design condition

component volume/m3 relative variation of volume/% weight/kg relative variation of weight /% recuperator precooler recuperator precooler recuperator precooler recuperator precooler PCHE (reference) 0.333 0.167 − − 2150 1080 − − MSTE 0.228 0.111 −31 −34 1380 630 −36 −42 -

[1] Crespi F, Gavagnin G, Sánchez D, et al. Supercritical carbon dioxide cycles for power generation: a review[J]. Applied Energy, 2017, 195: 152-183. doi: 10.1016/j.apenergy.2017.02.048 [2] Liu Yaping, Wang Ying, Huang Diangui. Supercritical CO2 Brayton cycle: a state-of-the-art review[J]. Energy, 2019, 189: 115900. doi: 10.1016/j.energy.2019.115900 [3] Neises T, Turchi C. A comparison of supercritical carbon dioxide power cycle configurations with an emphasis on CSP applications[J]. Energy Procedia, 2014, 49: 1187-1196. doi: 10.1016/j.egypro.2014.03.128 [4] Ahn Y, Bae S J, Kim M, et al. Review of supercritical CO2 power cycle technology and current status of research and development[J]. Nuclear Engineering and Technology, 2015, 47(6): 647-661. doi: 10.1016/j.net.2015.06.009 [5] McCormack D. The application of printed circuit heat exchanger technology in the pebble bed modular reactor demonstration plant[C]//ASME Turbo Expo 2001: Power for Land, Sea, and Air. 2001. [6] Chai Lei, Tassou S A. A review of printed circuit heat exchangers for helium and supercritical CO2 Brayton cycles[J]. Thermal Science and Engineering Progress, 2020, 18: 100543. doi: 10.1016/j.tsep.2020.100543 [7] Chu Wenxiao, Li Xionghui, Ma Ting, et al. Experimental investigation on SCO2-water heat transfer characteristics in a printed circuit heat exchanger with straight channels[J]. International Journal of Heat and Mass Transfer, 2017, 113: 184-194. doi: 10.1016/j.ijheatmasstransfer.2017.05.059 [8] Pandey V, Kumar P, Dutta P. Thermo-hydraulic analysis of compact heat exchanger for a simple recuperated sCO2 Brayton cycle[J]. Renewable and Sustainable Energy Reviews, 2020, 134: 110091. doi: 10.1016/j.rser.2020.110091 [9] Wu Pan, Ma Yunduo, Gao Chuntian, et al. A review of research and development of supercritical carbon dioxide Brayton cycle technology in nuclear engineering applications[J]. Nuclear Engineering and Design, 2020, 368: 110767. doi: 10.1016/j.nucengdes.2020.110767 [10] White M T, Bianchi G, Chai Lei, et al. Review of supercritical CO2 technologies and systems for power generation[J]. Applied Thermal Engineering, 2021, 185: 116447. doi: 10.1016/j.applthermaleng.2020.116447 [11] Kwon J S, Son S, Heo J Y, et al. Compact heat exchangers for supercritical CO2 power cycle application[J]. Energy Conversion and Management, 2020, 209: 112666. doi: 10.1016/j.enconman.2020.112666 [12] Chordia L, Portnoff M A, Green E. High temperature heat exchanger design and fabrication for systems with large pressure differentials[R]. Pittsburgh: Thar Energy LLC, 2017. [13] Chordia L, Green E, Li Danyang, et al. Development of modular, low-cost, high-temperature recuperators for the sCO2 power cycles[C]//2016 University Turbine Systems Research Project Review Meeting. 2016. [14] Deserrann D, Zagarol M, Crai D, et al. Performance testing of a high effectiveness recuperator for high capacity turbo-Brayton cryocoolers[C]//Proceedings of the 19th International Cryocooler Conference. 2016: 447-454. [15] Jiang Yuan, Liese E, Zitney S E, et al. Optimal design of microtube recuperators for an indirect supercritical carbon dioxide recompression closed Brayton cycle[J]. Applied Energy, 2018, 216: 634-648. doi: 10.1016/j.apenergy.2018.02.082 [16] 徐哲, 张明辉, 段天应, 等. 超临界二氧化碳在印刷电路板式换热器内的流动换热特性研究[J]. 原子能科学技术, 2021, 55(5):849-855 doi: 10.7538/yzk.2020.youxian.0411Xu Zhe, Zhang Minghui, Duan Tianying, et al. Flow and heat transfer characteristic study of supercritical CO2 in printed circuit heat exchanger[J]. Atomic Energy Science and Technology, 2021, 55(5): 849-855 doi: 10.7538/yzk.2020.youxian.0411 [17] 张虎忠. 超临界CO2印刷电路板换热器性能研究[D]. 北京: 中国科学院工程热物理研究所, 2020Zhang Huzhong. Study on the thermal-hydraulic performance of printed circuit heat exchanger with supercritical carbon dioxide[D]. Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences, 2020 [18] Dostal V. A supercritical carbon dioxide cycle for next generation nuclear reactors[D]. Cambridge: Massachusetts Institute of Technology, 2004. [19] Son S, Heo J Y, Lee J I. Prediction of inner pinch for supercritical CO2 heat exchanger using artificial neural network and evaluation of its impact on cycle design[J]. Energy Conversion and Management, 2018, 163: 66-73. doi: 10.1016/j.enconman.2018.02.044 [20] Cui Xinying, Xiang Mengru, Guo Jiangfeng, et al. Analysis of coupled heat transfer of supercritical CO2 from the viewpoint of distribution coordination[J]. The Journal of Supercritical Fluids, 2019, 152: 104560. doi: 10.1016/j.supflu.2019.104560 -

下载:

下载: