Analysis of thermal safety impact of airflow on the process of femtosecond laser processing explosive charge

-

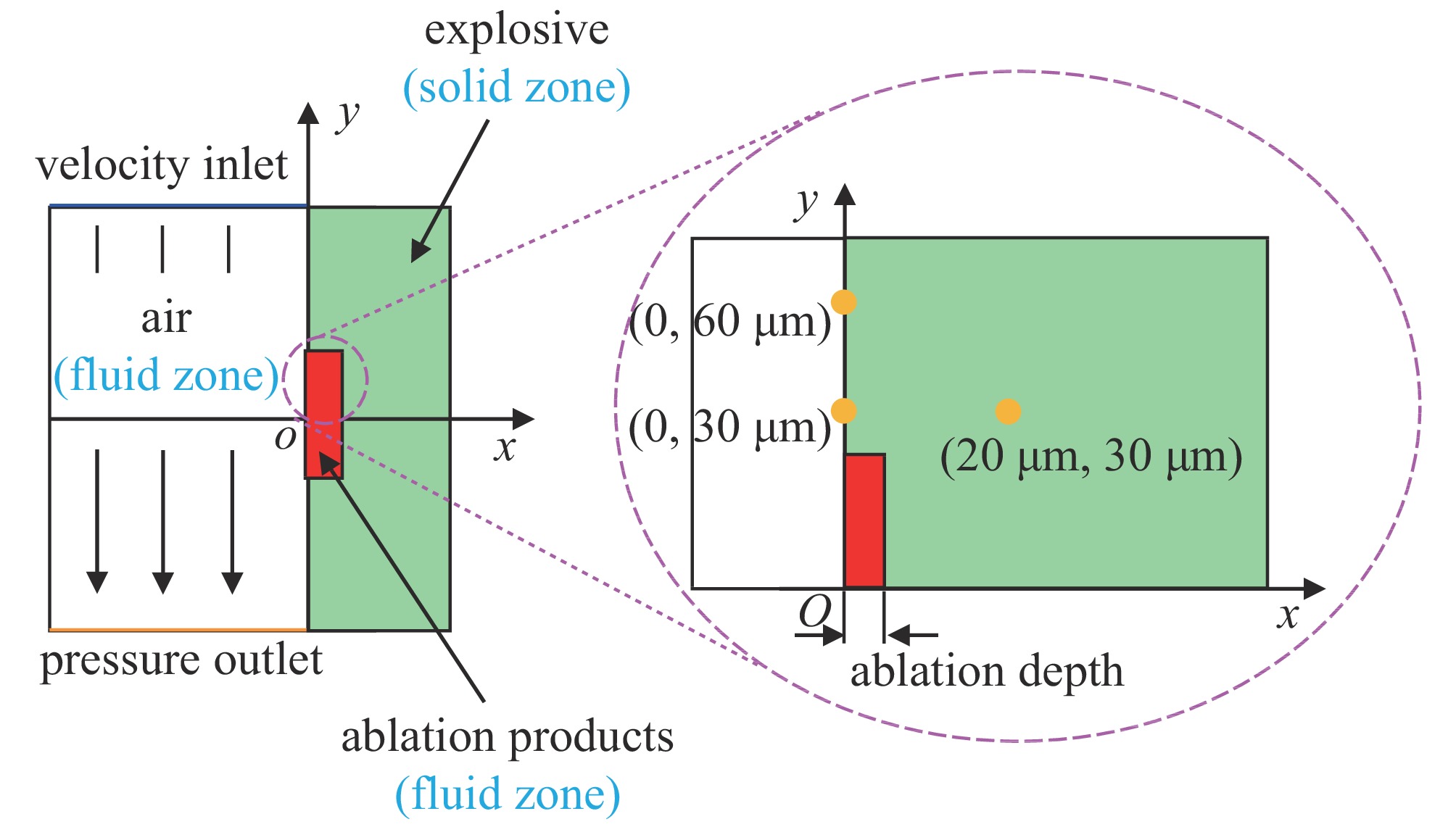

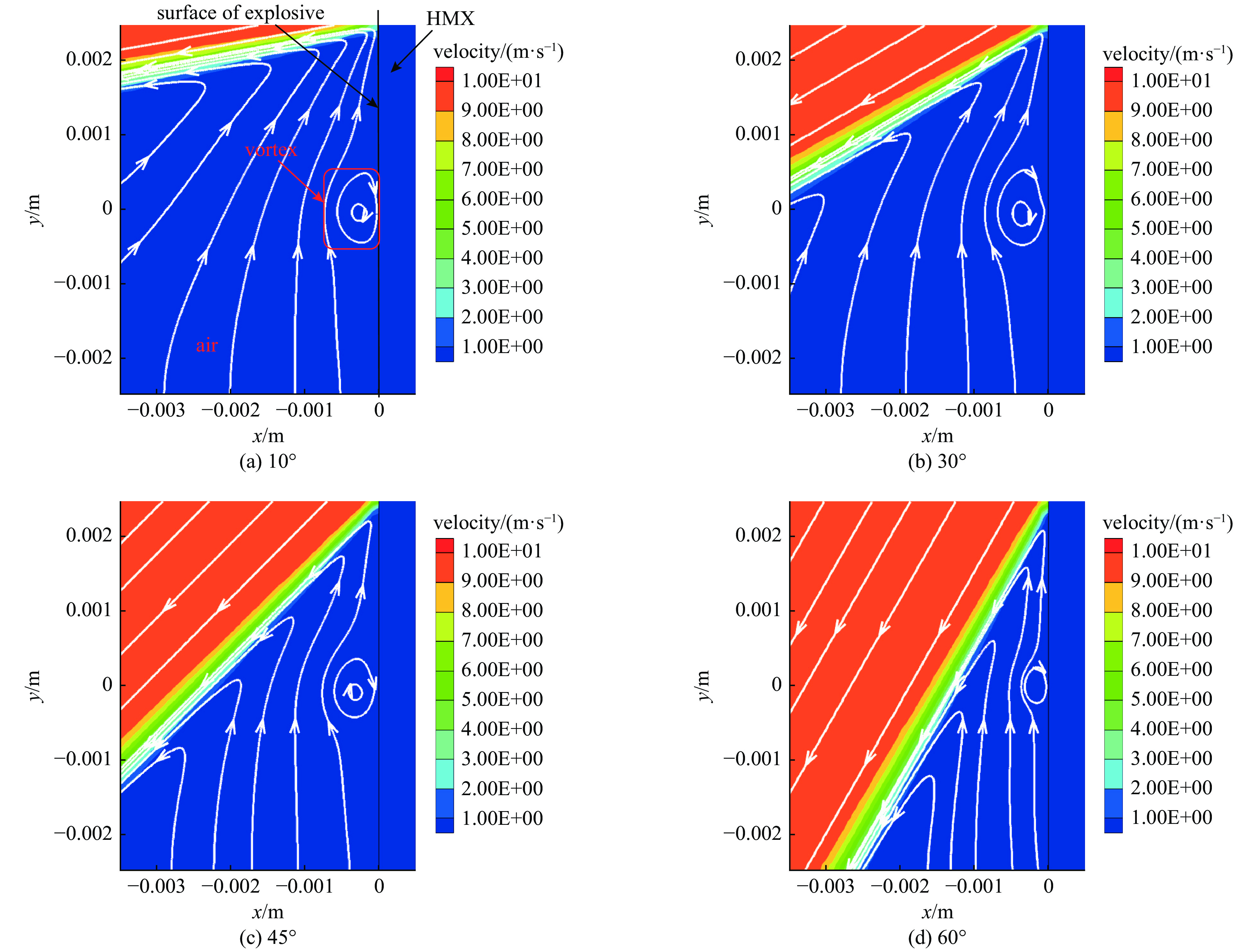

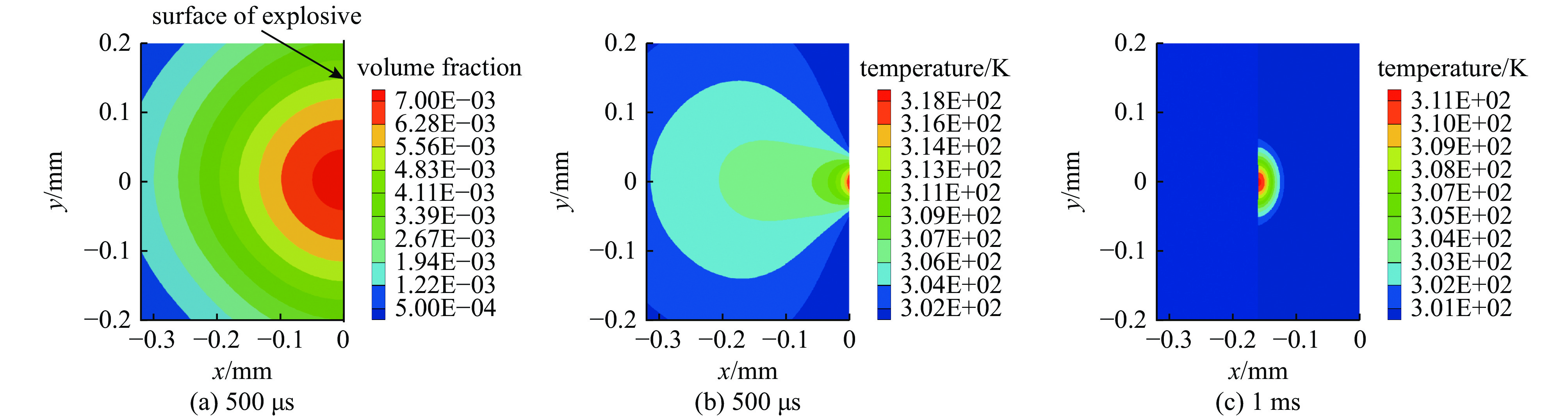

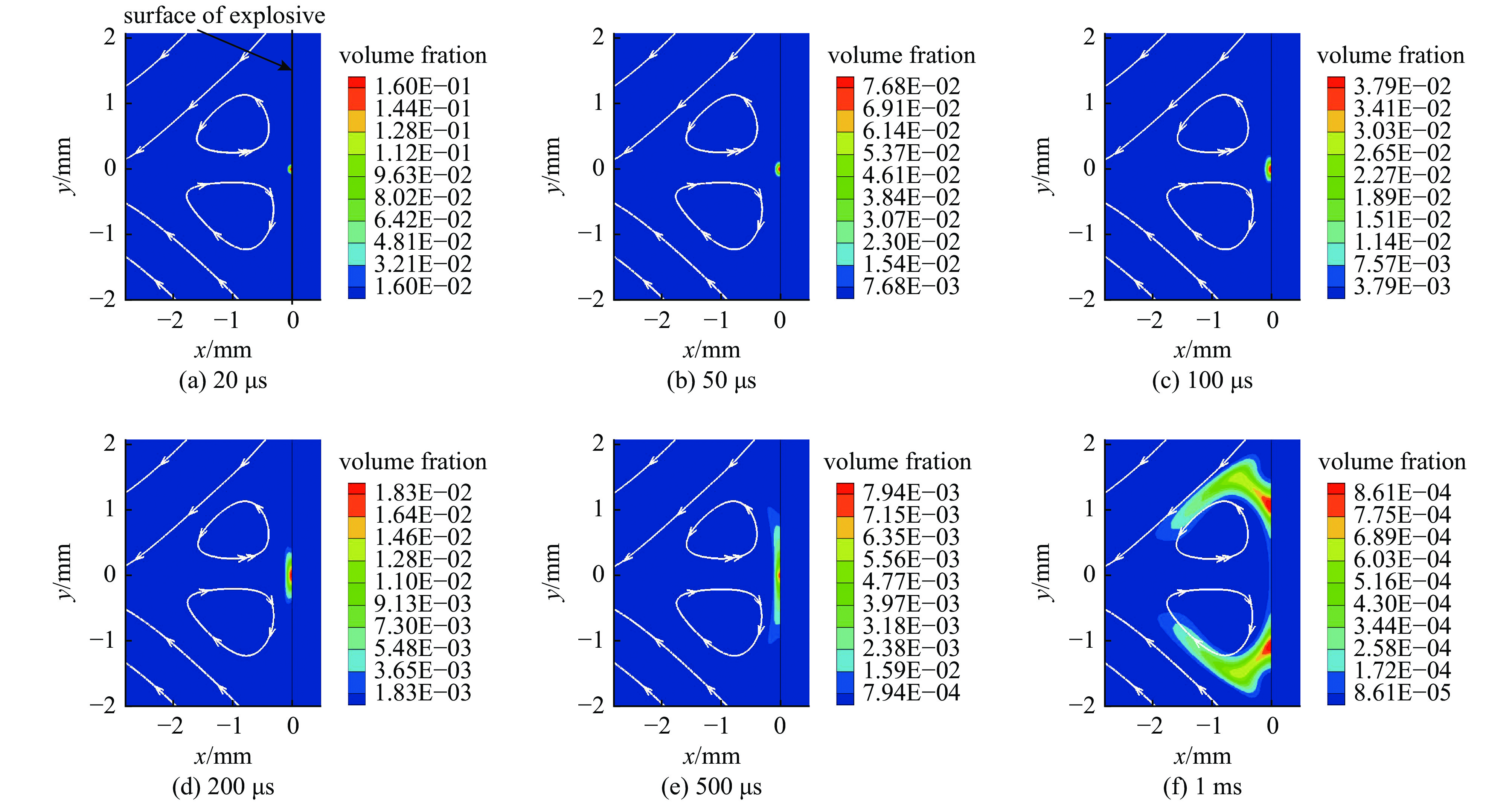

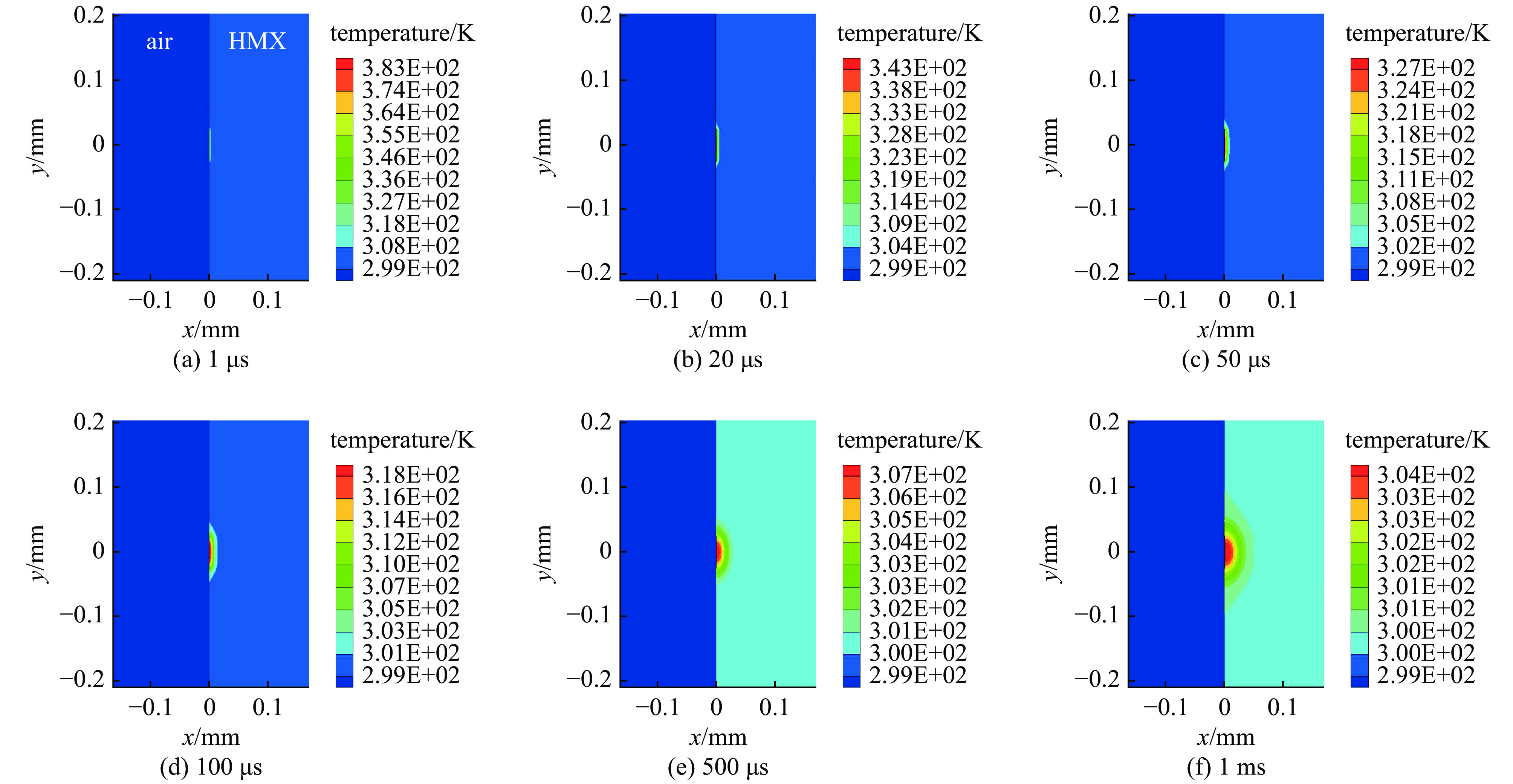

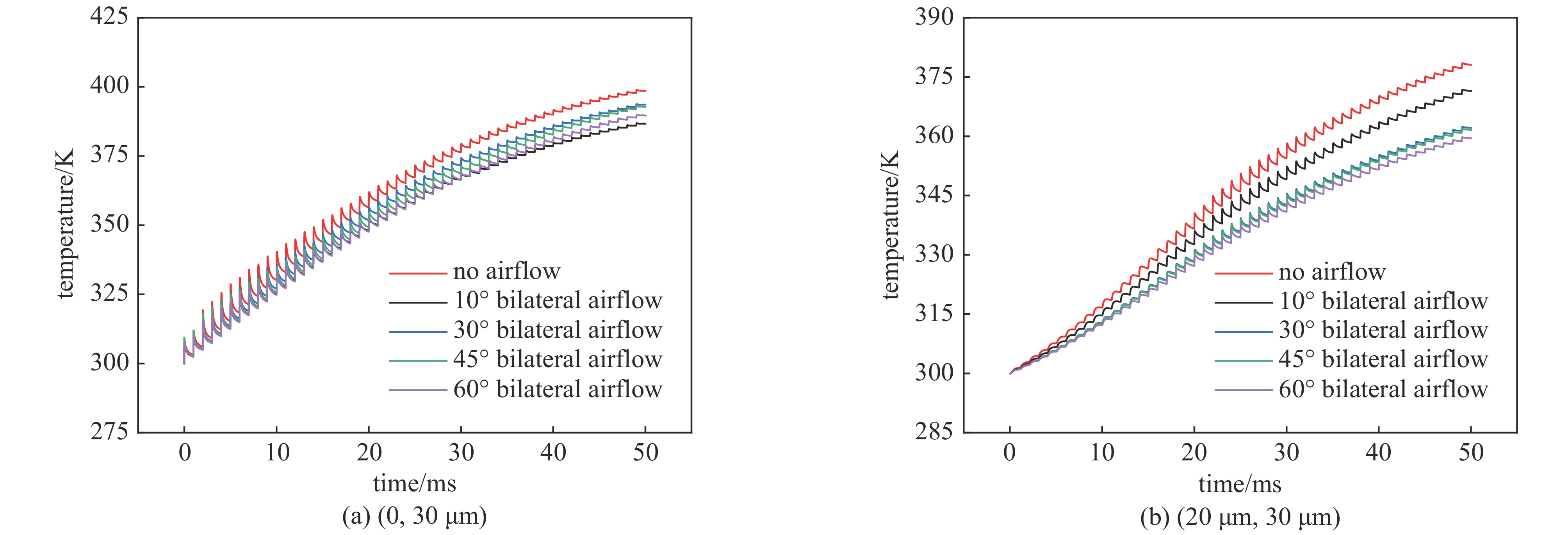

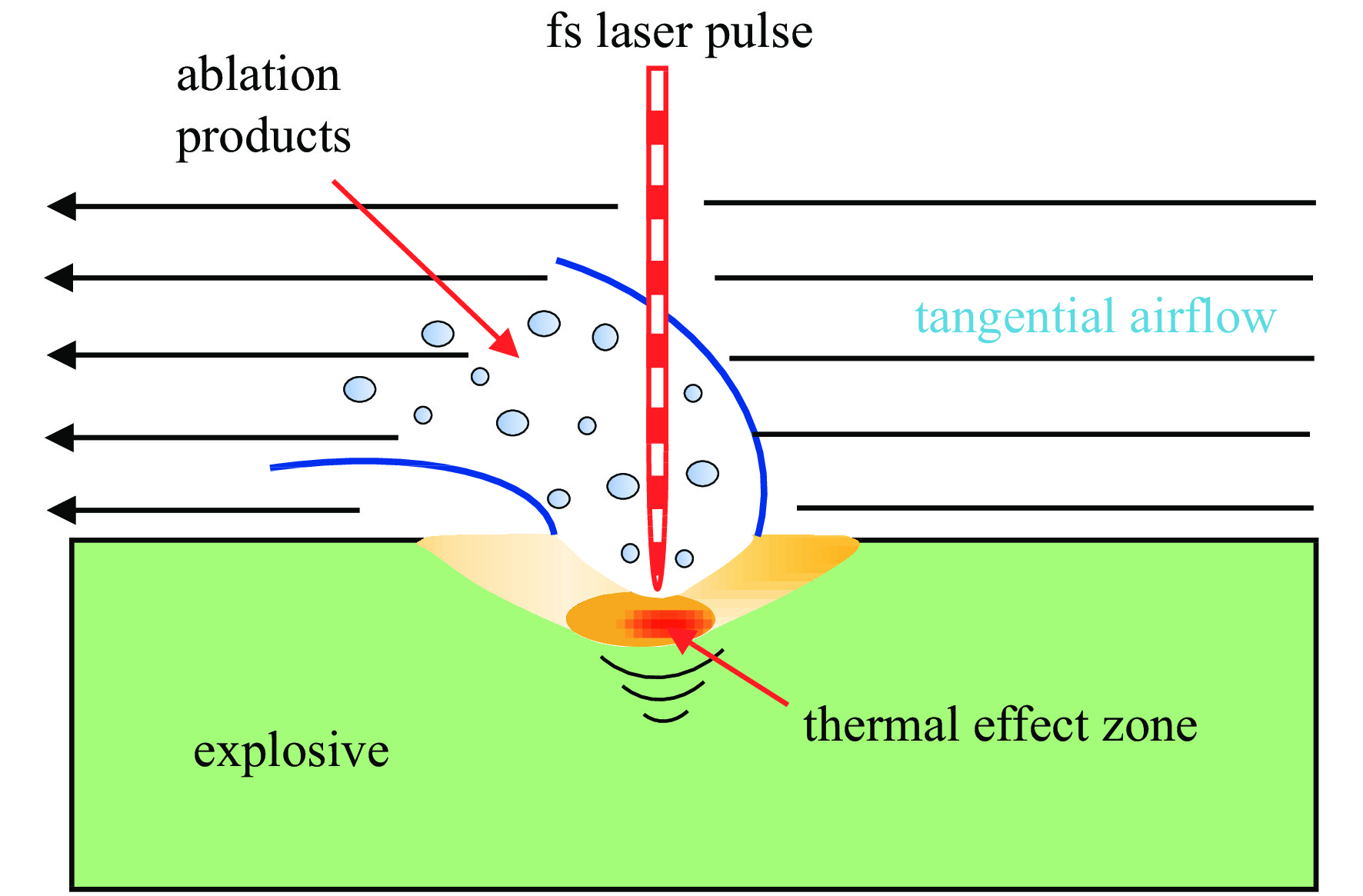

摘要: 由于炸药具有热传导系数小、对温度极其敏感的特点,在使用多脉冲飞秒激光对其进行持续加工时,极有可能在炸药内形成热累积,从而导致点火、燃烧等危险事件的发生。为了降低激光加工材料过程中的热效应,人们普遍采取在材料加工表面施加气流的方法。为了研究加载气流条件下,炸药装药在飞秒激光作用下产生的烧蚀产物的运动规律以及炸药装药内部的温度变化,建立了加载气流条件下飞秒激光加工炸药装药过程的二维流固耦合计算模型,对在单侧、双侧不同入射角度的亚音速气流作用下,飞秒激光加工奥克托今(HMX)炸药装药的过程进行了数值模拟计算。计算结果表明:单侧气流会在炸药加工表面形成漩涡流,导致烧蚀气体产物在炸药表面做旋转运动,加重了烧蚀产物对炸药的热影响;双侧气流会在远离炸药加工表面的地方形成较大的漩涡流,从而使烧蚀气体产物迅速离开炸药加工表面,有效降低了炸药的温度,提高了飞秒激光加工炸药装药过程的安全性。Abstract: Due to the low thermal conductivity and high sensitivity to temperature of explosive, it is highly possible to form heat accumulation inside the explosive during the continuous processing of multi-pulse femtosecond lasers, leading to dangerous events such as ignition and combustion. To reduce the thermal effects during laser processing of materials, applying airflow is a common choice. To study the motion law of ablation products generated by explosive under the action of femtosecond laser and the temperature changes in explosive under the action of airflow, a two-dimensional fluid-solid coupling calculation model of femtosecond laser processing explosive under the action of airflow is established. Numerical simulation calculations are conducted on the process of processing cyclotetramethylene-tetranitramine (HMX) explosive using femtosecond laser under the action of subsonic airflow with different incidence angles on one or both sides. The calculation results show that a unilateral airflow will form a vortex flow on the surface of the explosive, causing the ablation products to rotate on the surface of the explosive, exacerbating the thermal effect of the ablation products on the explosive; The bilateral airflow will form a large vortex flow far from the surface of the explosive, causing the ablation products to leave the surface of the explosive quickly, effectively reducing the temperature of the explosive and improving the safety in the process of femtosecond laser processing explosive.

-

Key words:

- femtosecond laser /

- explosive /

- numerical simulation /

- airflow /

- thermal safety

-

表 1 HMX的多步热分解反应动力学参数

Table 1. Kinetic parameters of multi-step thermal decomposition reaction of HMX

explosive reaction step E/(kJ·mol−1) Z/s−1 Q/(kJ·kg−1) HMX 1 204 7.99×1020 −42 2 221 1.41×1021 −252 3 186 2.61×1016 559 4 143 1.60×1012 5620 表 2 HMX的物性参数

Table 2. Physical properties of HMX

density/

(kg·m−3)specific thermal

capacity/(J·kg−1·K−1)thermal conductivity/

(W·m−1·K−1)absorption

coefficient/m−1reflection

coefficientthermal diffusion

coefficient/(m2·s−1)1 905 1050 0.345 1.434×106 0.090 1.72×10−7 -

[1] 王文亭, 胡冰, 王明伟. 飞秒激光精细加工含能材料[J]. 物理学报, 2013, 62:060601 doi: 10.7498/aps.62.060601Wang Wenting, Hu Bing, Wang Mingwei. Femtosecond laser fine machining of energetic materials[J]. Acta Physica Sinica, 2013, 62: 060601 doi: 10.7498/aps.62.060601 [2] 李全俊, 王国辉, 雷林, 等. 废旧弹药拆分技术现状与发展[J]. 兵工自动化, 2018, 37(5):93-96Li Quanjun, Wang Guohui, Lei Lin, et al. Present situation and development of waste ammunition decomposition technology[J]. Ordnance Industry Automation, 2018, 37(5): 93-96 [3] Roos E V, Benterou J J, Lee R S, et al. Femtosecond laser interaction with energetic materials[C]//Proceedings of SPIE 4760, High-Power Laser Ablation IV. 2002: 415-423. [4] Roeske F, Benterou J, Lee R, et al. Cutting and machining energetic materials with a femtosecond laser[J]. Propellants, Explosives, Pyrotechnics, 2003, 28(2): 53-57. doi: 10.1002/prep.200390008 [5] Boley C D, Cutter K P, Fochs S N, et al. Interaction of a high-power laser beam with metal sheets[J]. Journal of Applied Physics, 2010, 107: 043106. doi: 10.1063/1.3284204 [6] 李君神. 切向气流环境中激光辐照下薄铝板响应初步研究[D]. 长沙: 国防科学技术大学, 2012Li Junshen. Preliminary research on the response of thin aluminum plate subjected to laser irradiation and tangential gas flow[D]. Changsha: National University of Defense Technology, 2012 [7] 张永强, 陶彦辉, 张黎. 亚声速切向气流对激光辐照TA15钛合金热响应的影响[J]. 应用激光, 2014, 34(1):32-35 doi: 10.3788/AL20143401.0032Zhang Yongqiang, Tao Yanhui, Zhang Li. Effect of subsonic tangential flow on the thermal response of TA15 Ti alloy irradiated by laser[J]. Applied Laser, 2014, 34(1): 32-35 doi: 10.3788/AL20143401.0032 [8] 蒙文, 张文杰, 李云霞, 等. 切向气流作用下激光辐照对尼龙材料的热烧蚀规律[J]. 光学 精密工程, 2017, 25(2):351-357 doi: 10.3788/OPE.20172502.0351Meng Wen, Zhang Wenjie, Li Yunxia, et al. Thermal ablation law of laser irradiation on nylon materials under tangential airflow[J]. Optics and Precision Engineering, 2017, 25(2): 351-357 doi: 10.3788/OPE.20172502.0351 [9] Yamamoto R, Parker J, Boley C D, et al. Laser-material interaction studies utilizing the solid-state heat capacity laser[R]. Livermore: Lawrence Livermore National Laboratory, 2007. [10] Boley C D, Fochs S N, Rubenchik A M. Lethality effects of a high-power solid-state laser[R]. Livermore: Lawrence Livermore National Laboratory, 2007. [11] Boley C D, Fochs S N, Rubenchik A M. Large-spot material interactions with a high-power solid-state laser beam[R]. Livermore: Lawrence Livermore National Laboratory, 2008. [12] 张健, 黄晨光. 外部流场对激光加热运动目标影响的数值模拟[J]. 强激光与粒子束, 2007, 19(11):1817-1821Zhang Jian, Huang Chenguang. Numerical simulation of airflow effect on moving body under laser irradiation[J]. High Power Laser and Particle Beams, 2007, 19(11): 1817-1821 [13] 陈敏孙, 江厚满, 刘泽金. 切向气流对激光辐照树脂基复合材料的影响[J]. 强激光与粒子束, 2010, 22(12):2848-2852 doi: 10.3788/HPLPB20102212.2848Chen Minsun, Jiang Houman, Liu Zejin. Effect of tangential airflow on resin composite irradiated by laser[J]. High Power Laser and Particle Beams, 2010, 22(12): 2848-2852 doi: 10.3788/HPLPB20102212.2848 [14] 胡鹏, 陈发良. 高速气流中激光加热平板数值模拟与分析[J]. 强激光与粒子束, 2011, 23(7):1935-1939 doi: 10.3788/HPLPB20112307.1935Hu Peng, Chen Faliang. Numerical simulation of plane target in airflow under laser irradiation[J]. High Power Laser and Particle Beams, 2011, 23(7): 1935-1939 doi: 10.3788/HPLPB20112307.1935 [15] 赵晓利, 孙振旭, 安亦然, 等. 高超声速气动热的耦合计算方法研究[J]. 科学技术与工程, 2010, 10(22):5450-5455,5461Zhao Xiaoli, Sun Zhenxu, An Yiran, et al. Coupled flow-thermal analysis approach for hypersonic aerodynamic heating[J]. Science Technology and Engineering, 2010, 10(22): 5450-5455,5461 [16] 李鹏飞, 吴颂平. 二维圆柱在高超声速气流中的耦合传热计算[J]. 导弹与航天运载技术, 2010(6):34-37Li Pengfei, Wu Songping. Coupling calculation of heat conduction in 2D column in hypersonic flows[J]. Missiles and Space Vehicles, 2010(6): 34-37 [17] 刘嘉锡, 伍俊英, 杨利军, 等. 单脉冲飞秒激光烧蚀炸药过程的热效应研究[J]. 强激光与粒子束, 2020, 32:071007 doi: 10.11884/HPLPB202032.200061Liu Jiaxi, Wu Junying, Yang Lijun, et al. Analysis of thermal effect on explosives of single-pulse femtosecond laser ablation[J]. High Power Laser and Particle Beams, 2020, 32: 071007 doi: 10.11884/HPLPB202032.200061 [18] 刘嘉锡. 飞秒激光烧蚀炸药过程的热力响应机理和作用规律研究[D]. 北京: 北京理工大学, 2022Liu Jiaxi. Thermodynamic mechanism and action law of femtosecond laser ablation of explosive[D]. Beijing: Beijing Institute of Technology, 2022 [19] 张金龙, 郭子如, 杜明燃, 等. RDX的爆炸产物组成和爆热的计算与分析[J]. 煤矿爆破, 2019, 37(4):24-27Zhang Jinlong, Guo Ziru, Du Mingran, et al. Calculation and analysis of explosive product composition and heat of RDX[J]. Coal Mine Blasting, 2019, 37(4): 24-27 [20] Tarver C M, Tran T D. Thermal decomposition models for HMX-based plastic bonded explosives[J]. Combustion and Flame, 2004, 137(1/2): 50-62. [21] 陈朗, 马欣. 炸药热安全性理论与分析方法[M]. 北京: 国防工业出版社, 2015Chen Lang, Ma Xin. Theory and analysis method of thermal safety of explosive[M]. Beijing: National Defense Industry Press, 2015 [22] 杨利军. 飞秒激光烧蚀炸药的作用机理研究[D]. 北京: 北京理工大学, 2021Yang Lijun. Mechanism of femtosecond laser ablation of explosive[D]. Beijing: Beijing Institute of Technology, 2021 -

下载:

下载: