Surface defect detection method for capsule based on micro-CT image

-

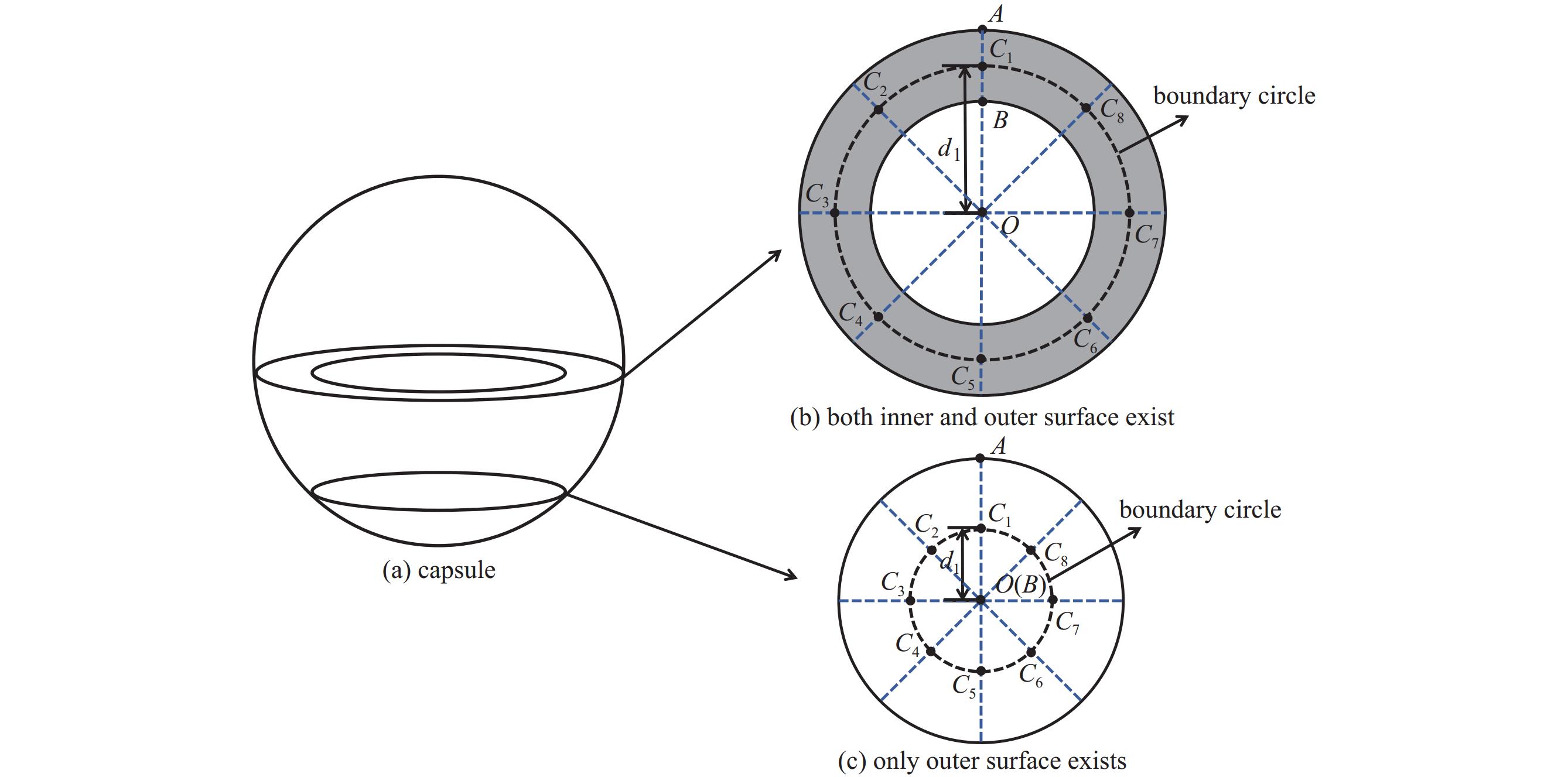

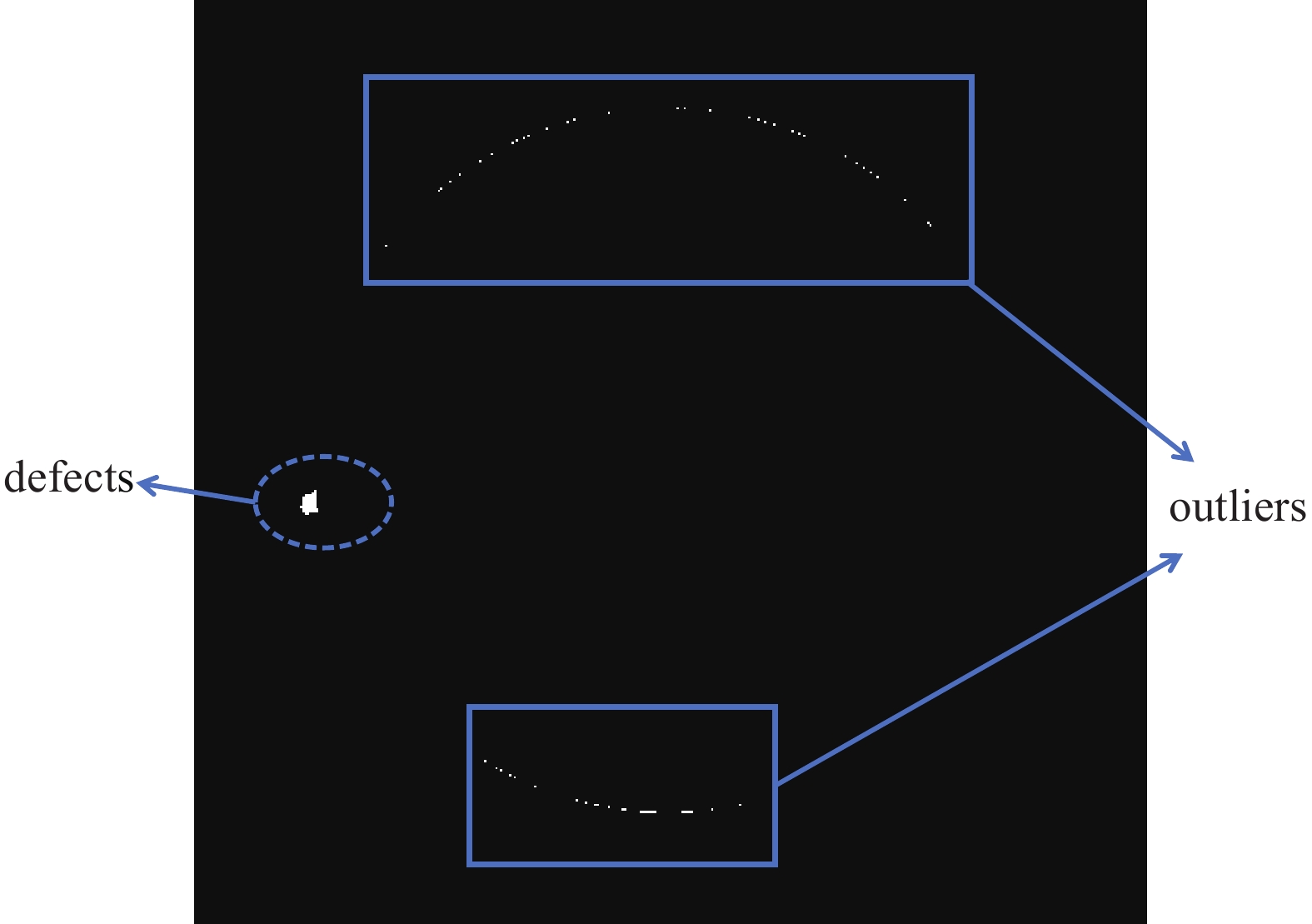

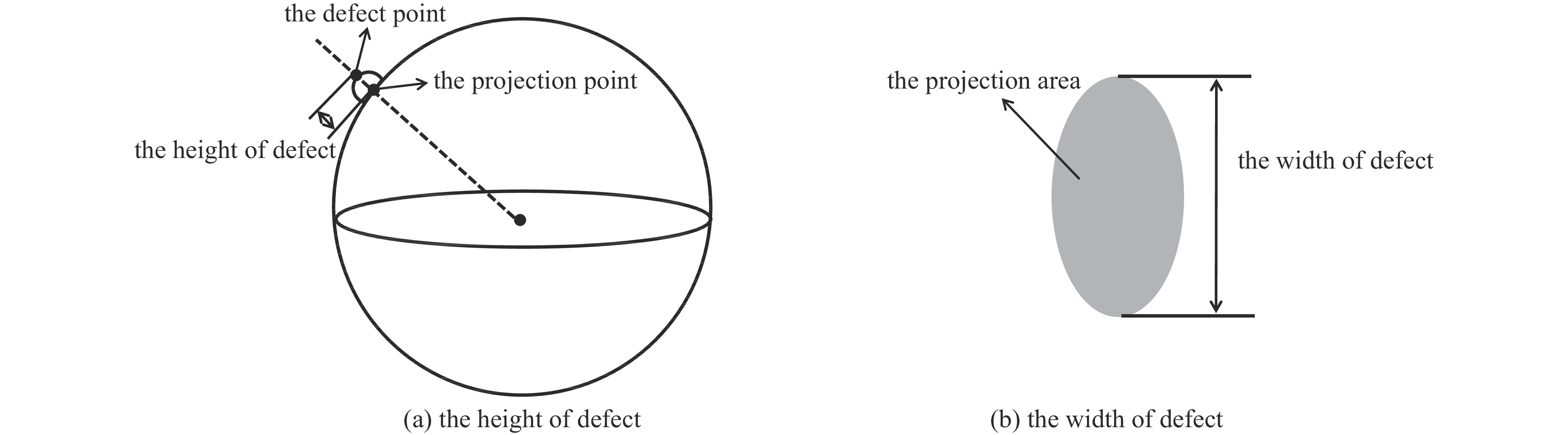

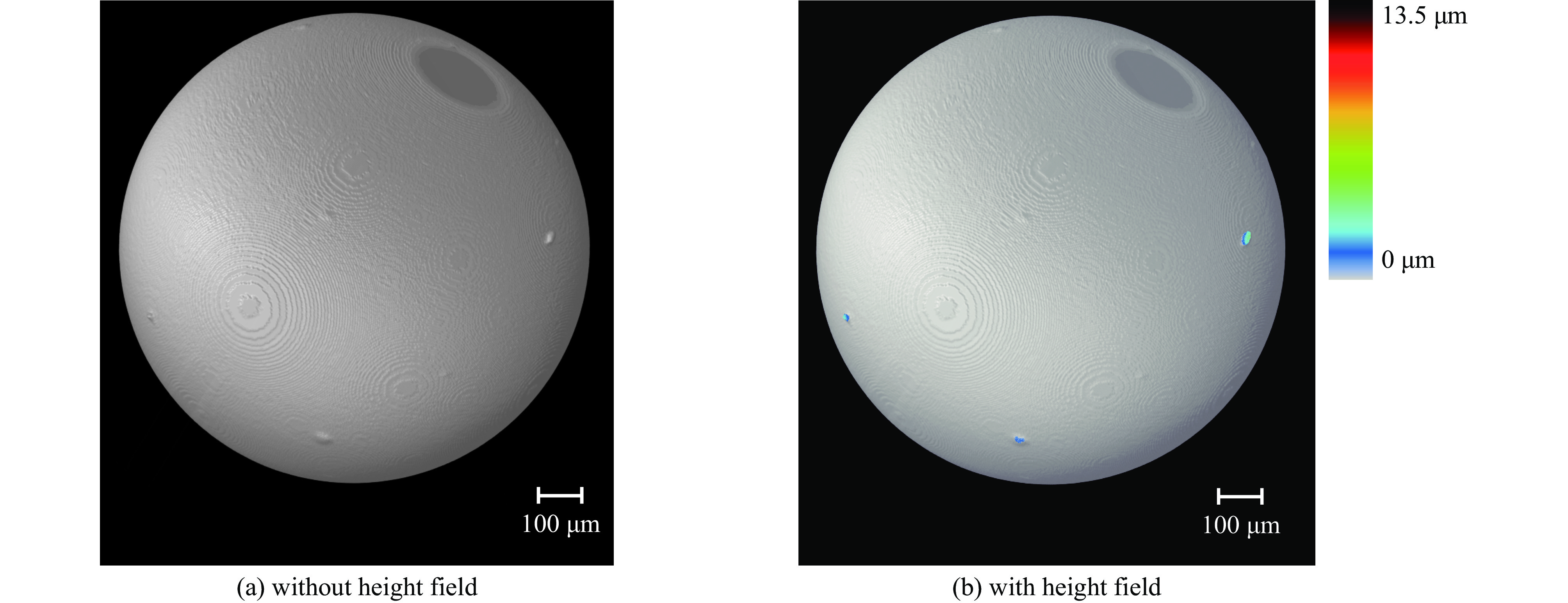

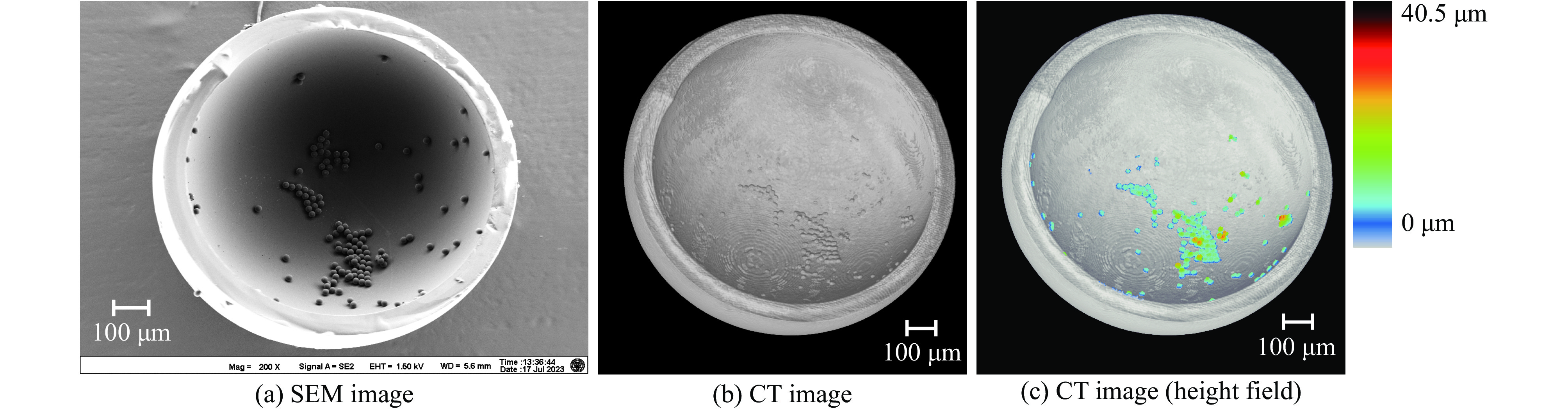

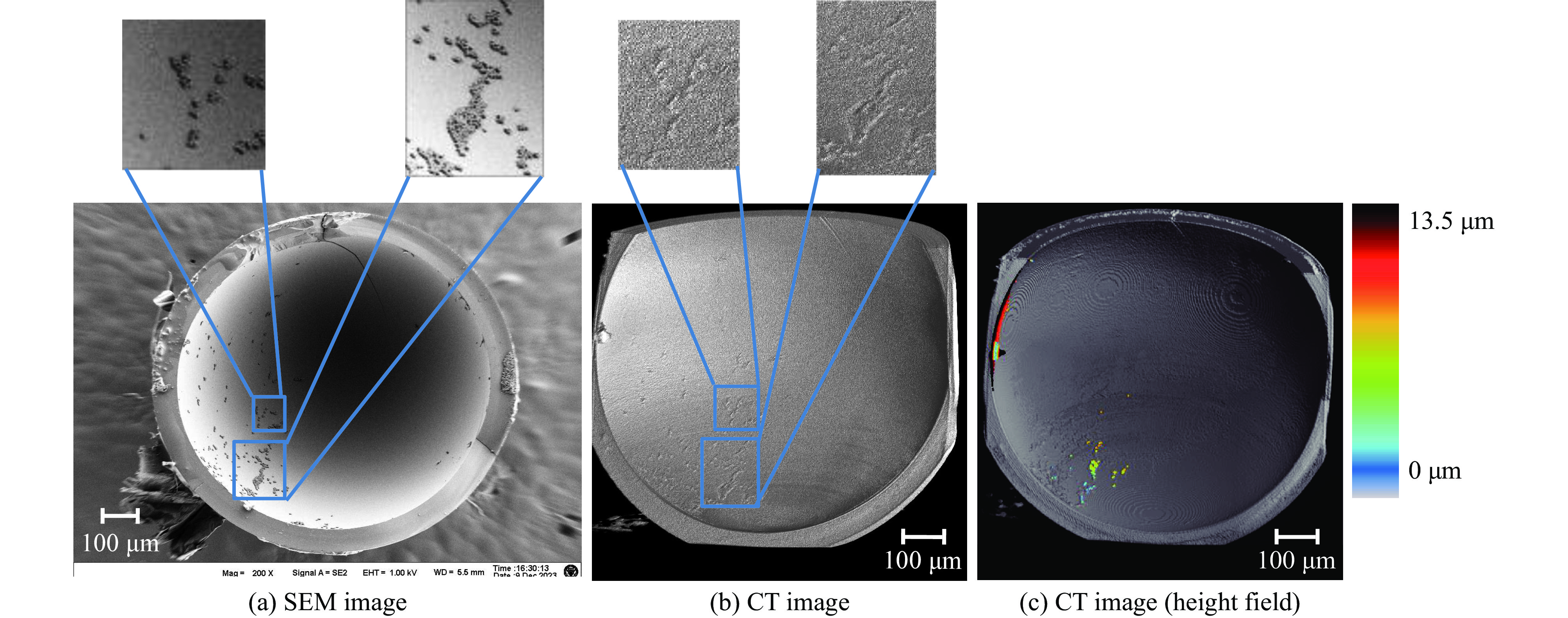

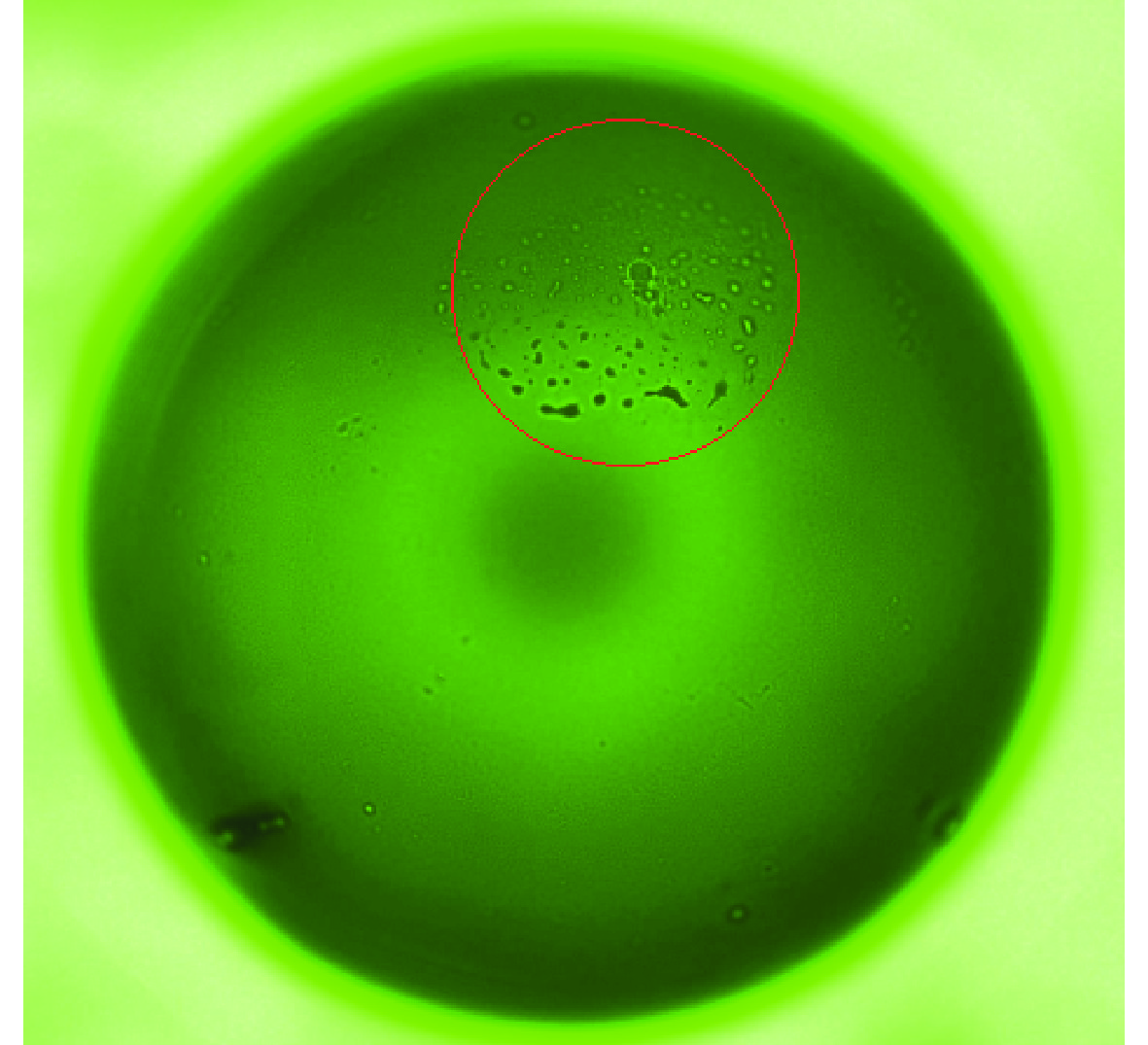

摘要: 靶丸的内外表面缺陷分布对激光惯性约束聚变实验成功率及效率有重要影响,目前观测不透明靶丸的内表面仅有用X射线直接成像技术获取局部二维信息。运用显微CT实现靶丸三维成像,可得到靶丸内外全表面形貌信息;运用边缘检测、理想曲面拟合分割出缺陷区域,通过连通域分析对表面缺陷进行分块,并分别计算各区域的宽度、高度;运用体绘制方法交互绘制出了靶丸三维数据的立体效果,尤其突出了缺陷区域的彩色高度场效果,并通过虚拟切割观察靶丸内表面。基于该方法的靶丸内外表面缺陷观测技术,能识别大多数表面缺陷,且能较为准确地计算出缺陷尺寸参数,未识别出的缺陷通过体绘制可被观察到作为补充,为研究人员提供了良好的辅助分析手段。Abstract: The distribution of defects on the inner and outer surfaces of the capsule has an important impact on the success rate and efficiency of the laser inertial confinement fusion experiment. At present, the only way to observe the inner surface is to use direct X-ray imaging technology to obtain local two-dimensional information, while this paper uses micro-CT to photograph the capsule to non-destructively obtain the full surface morphology information of its inner and outer surfaces. On this basis, a technique is proposed for the observation of defects on the inner and outer surfaces of the capsule. First, the defect area was segmented by edge detection and ideal surface fitting. Then the defects were divided into blocks by connected domain analysis, and the width and height of each area were calculated separately. In addition, a stereoscopic image of the capsule was interactively drawn using a volume rendering method, especially highlighting the colored height field in the defect areas and allowing the inner surface of the capsule to be observed by virtual cutting. This method can identify most surface defects, and can calculate the defect size parameters more accurately. Unidentified defects can be observed as a supplement through volume rendering, providing researchers with a good aid for analysis.

-

表 1 靶丸缺陷参数测量结果

Table 1. Measurement results of capsule defect parameters

height of the

defects/voxelmeasured

height/voxelaverage error of

height/%width of the

defects/voxelmeasured

width/voxelaverage error of

width/%GT

quantitiesmeasured

quantities3 2.65±1.44 11.7 6 6.21±1.13 17.2 12 12 6 6.39±1.33 6.5 12 12.38±0.69 3.1 14 13 10 10.99±1.54 9.9 20 21.01±0.63 5.1 14 14 -

[1] 高莎莎, 吴小军, 何智兵, 等. 激光惯性约束聚变靶制备技术研究进展[J]. 强激光与粒子束, 2020, 32:032001 doi: 10.11884/HPLPB202032.200039Gao Shasha, Wu Xiaojun, He Zhibing, et al. Research progress of fabrication techniques for laser inertial confinement fusion target[J]. High Power Laser and Particle Beams, 2020, 32: 032001 doi: 10.11884/HPLPB202032.200039 [2] Sandras F, Hermerel C, Choux A, et al. Characterization of the microshell surface using holographic measurements[J]. Fusion Science and Technology, 2009, 55(4): 389-398. doi: 10.13182/FST09-A7416 [3] Meng Jie, Zhao Xuesen, Tang Xing, et al. Surface characterization of ICF capsule by AFM-based profilometer[J]. High Power Laser Science and Engineering, 2017, 5: 03000e21. [4] McEachern R L, Moore C E, Wallace R J. The design, performance, and application of an atomic force microscope-based profilometer[J]. Journal of Vacuum Science & Technology A, 1995, 13(3): 983-989. [5] 唐兴, 王琦, 马小军, 等. 靶丸内表面轮廓的白光共焦光谱测量技术[J]. 中国光学, 2020, 13(2):266-272 doi: 10.3788/co.20201302.0266Tang Xing, Wang Qi, Ma Xiaojun, et al. Determination of the inner-surface profile of a capsule using chromatic confocal spectroscopy[J]. Chinese Optics, 2020, 13(2): 266-272 doi: 10.3788/co.20201302.0266 [6] Patterson B M, Obrey K A D, Havrilla G J, et al. Nondestructive investigations of a copper- and argon-doped sputtered beryllium capsule using X-rays in three dimensions[J]. Fusion Science and Technology, 2009, 55(4): 417-423. doi: 10.13182/FST09-A7420 [7] Sain J D, Brown W D, Martz H E, et al. Analysis procedures for double-shell target concentricity and wall thickness[R]. Livermore: Lawrence Livermore National Laboratory, 2006. [8] Nora R, Clark D, Masse L, et al. Modeling the interactions of multiple voids in inertial confinement fusions implosions[C]//APS Division of Plasma Physics Meeting. 2021. [9] Ferris A L, Kuettner L, Loomis E, et al. CT analysis of double shell targets[C]//APS Division of Plasma Physics Meeting. 2020. [10] 赵学森, 高党忠, 马小军, 等. X射线法ICF靶丸几何参数批处理及壁厚分布计算[J]. 原子能科学技术, 2012, 46(4):487-492Zhao Xuesen, Gao Dangzhong, Ma Xiaojun, et al. Batch processing of geometric parameters and wall thickness distribution calculation of ICF capsule by X-ray imaging method[J]. Atomic Energy Science and Technology, 2012, 46(4): 487-492 [11] 王琦, 高党忠, 马小军, 等. 惯性约束聚变靶丸高精度X射线数字成像[J]. 光学 精密工程, 2020, 28(2):324-333 doi: 10.3788/OPE.20202802.0324Wang Qi, Gao Dangzhong, Ma Xiaojun, et al. High precision X-ray digital imaging of inertial confinement fusion capsules[J]. Optics and Precision Engineering, 2020, 28(2): 324-333 doi: 10.3788/OPE.20202802.0324 [12] Gonzalez R C. Digital image processing[M]. 3rd ed. Upper Saddle River: Pearson/Prentice Hall, 2008: 741-747. [13] Yagüe-Fabra J A, Ontiveros S, Jiménez R, et al. A 3D edge detection technique for surface extraction in computed tomography for dimensional metrology applications[J]. CIRP Annals, 2013, 62(1): 531-534. doi: 10.1016/j.cirp.2013.03.016 [14] Pirillo F. Study on segmentation techniques for geometric measurements in industrial computed tomography[D]. Milan: Polytechnic University of Milan, 2022: 37-40. [15] Engel K, Hadwiger M, Kniss J M, et al. Real-time volume graphics[C]//ACM SIGGRAPH 2004 Course Notes. 2004: 29-es. [16] Max N. Optical models for direct volume rendering[J]. IEEE Transactions on Visualization and Computer Graphics, 1995, 1(2): 99-108. doi: 10.1109/2945.468400 [17] Phong B T. Illumination for computer generated pictures[J]. Communications of the ACM, 1975, 18(6): 311-317. doi: 10.1145/360825.360839 -

下载:

下载: