Research on temperature control of high power microwave oven based on back propagation neural network PID

-

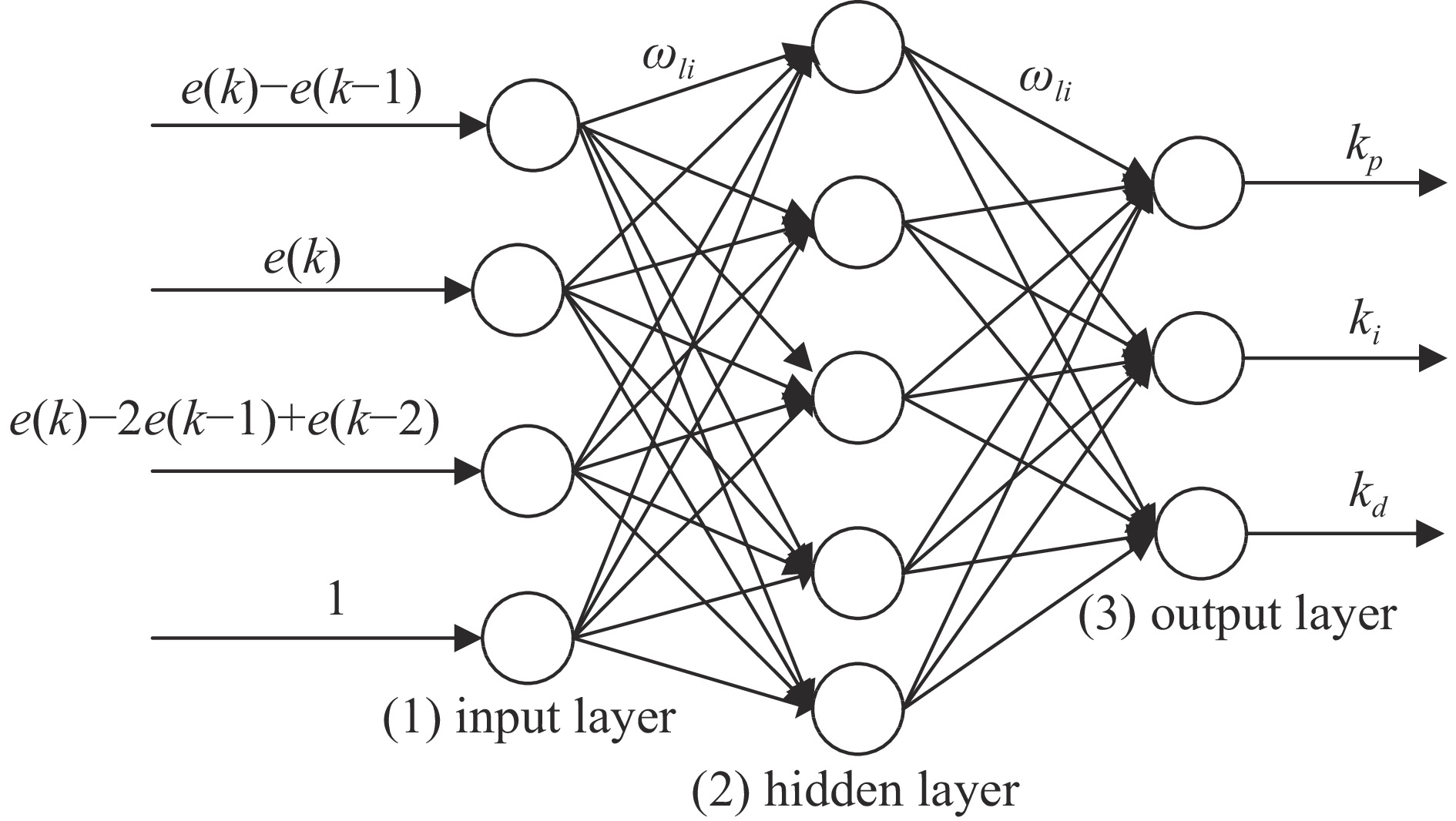

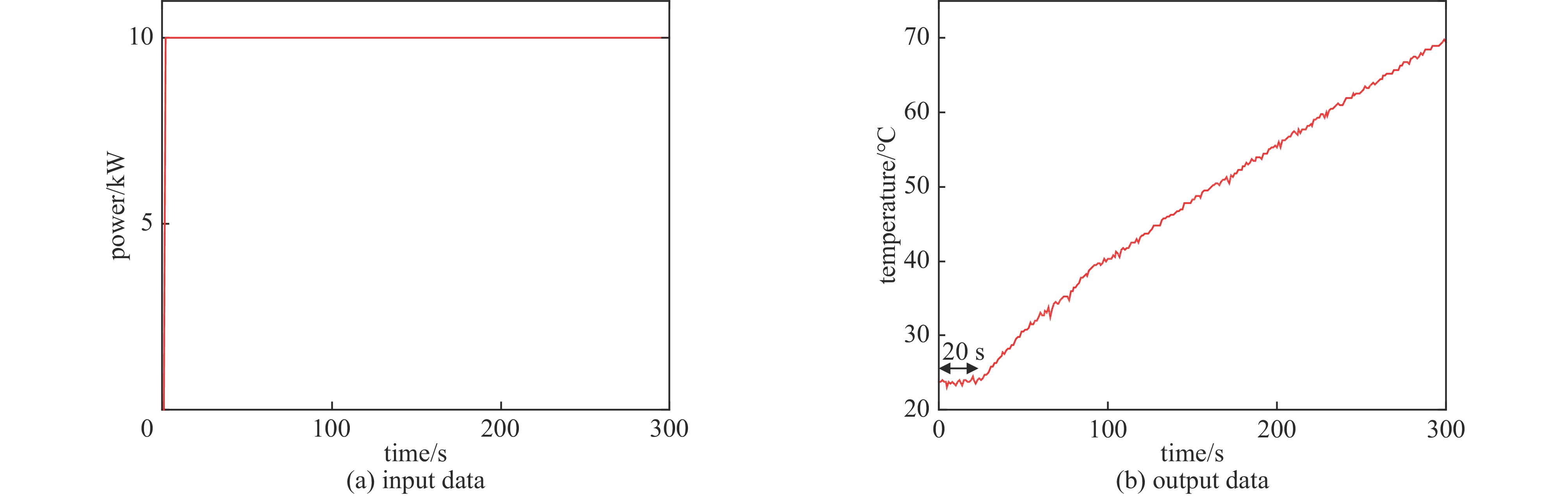

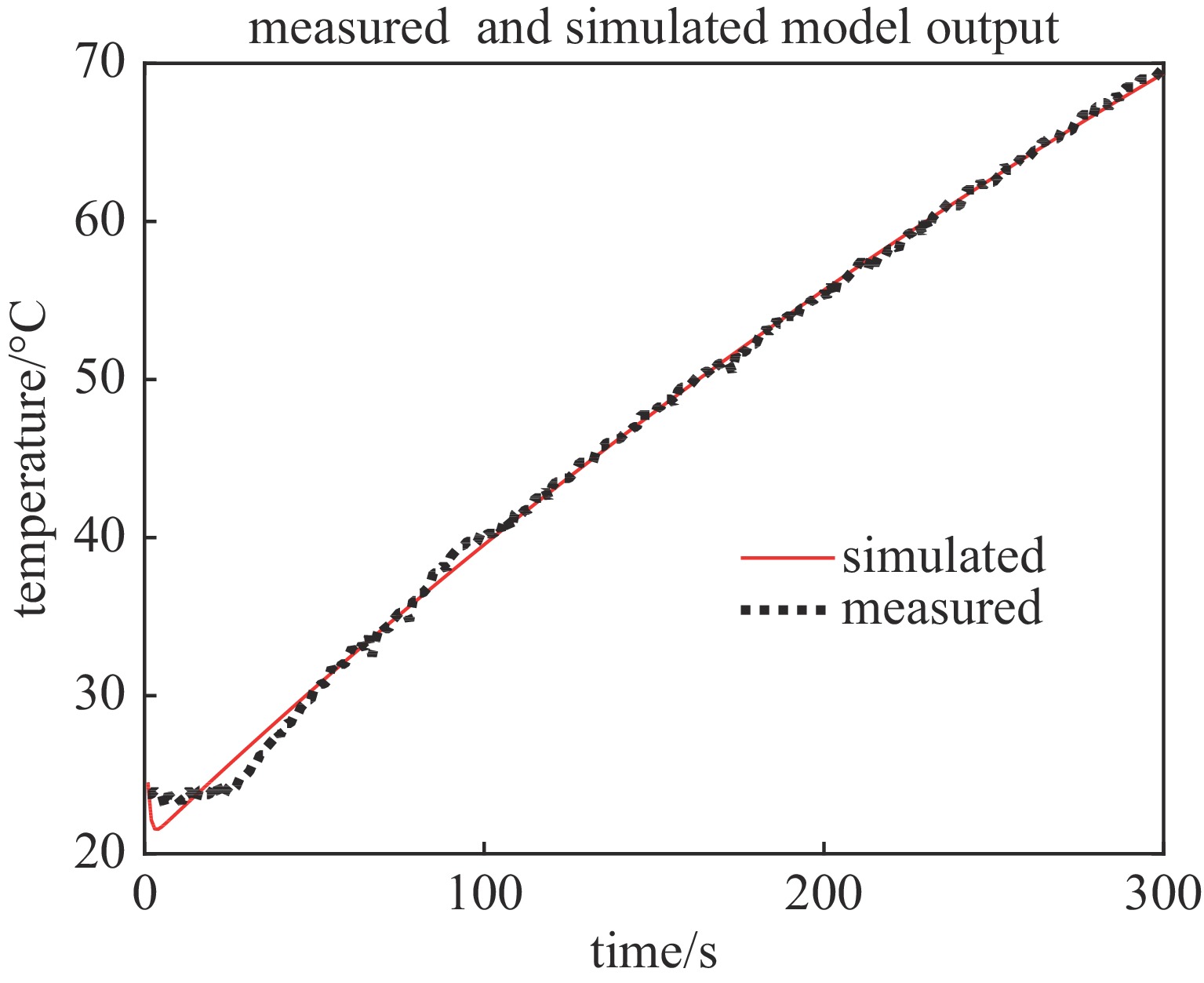

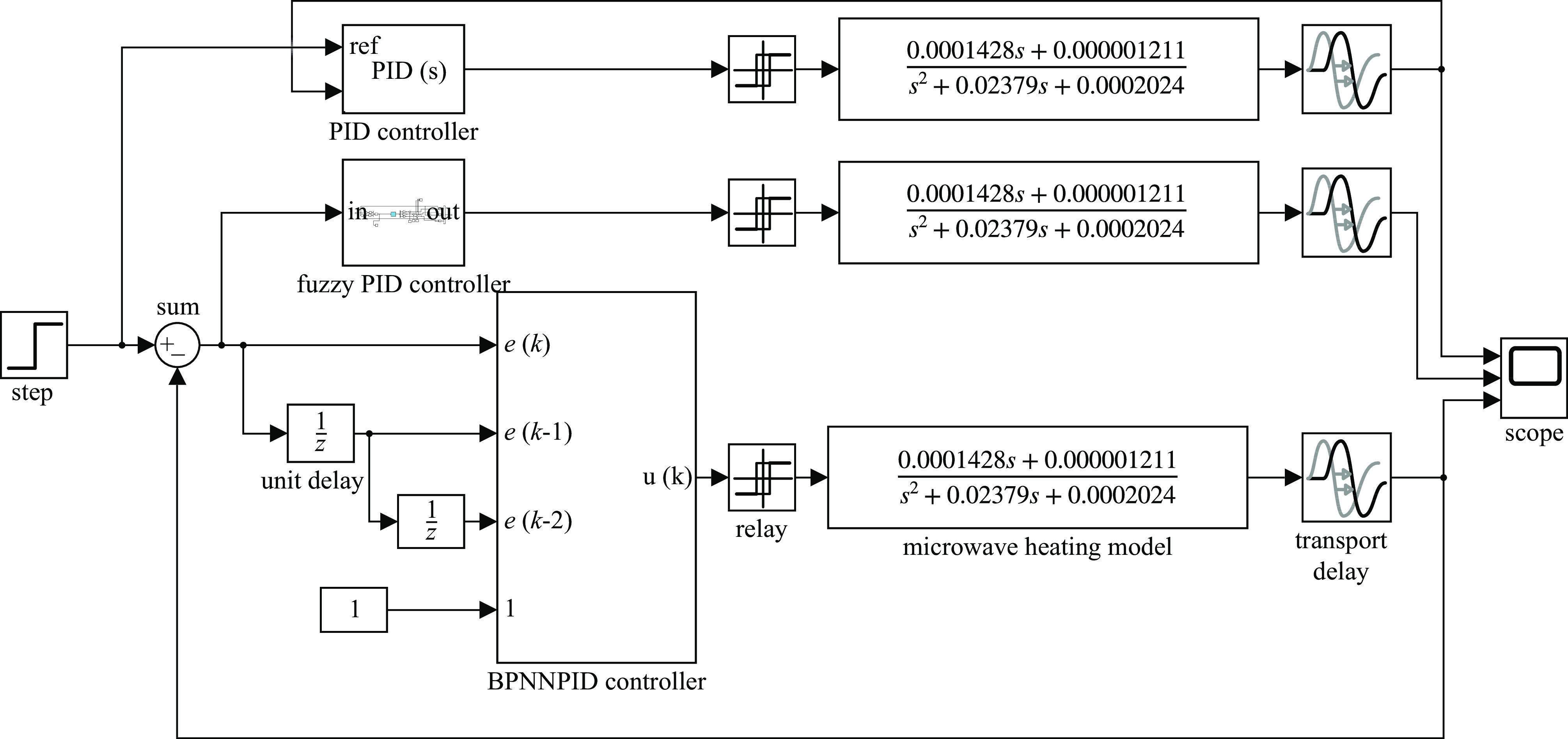

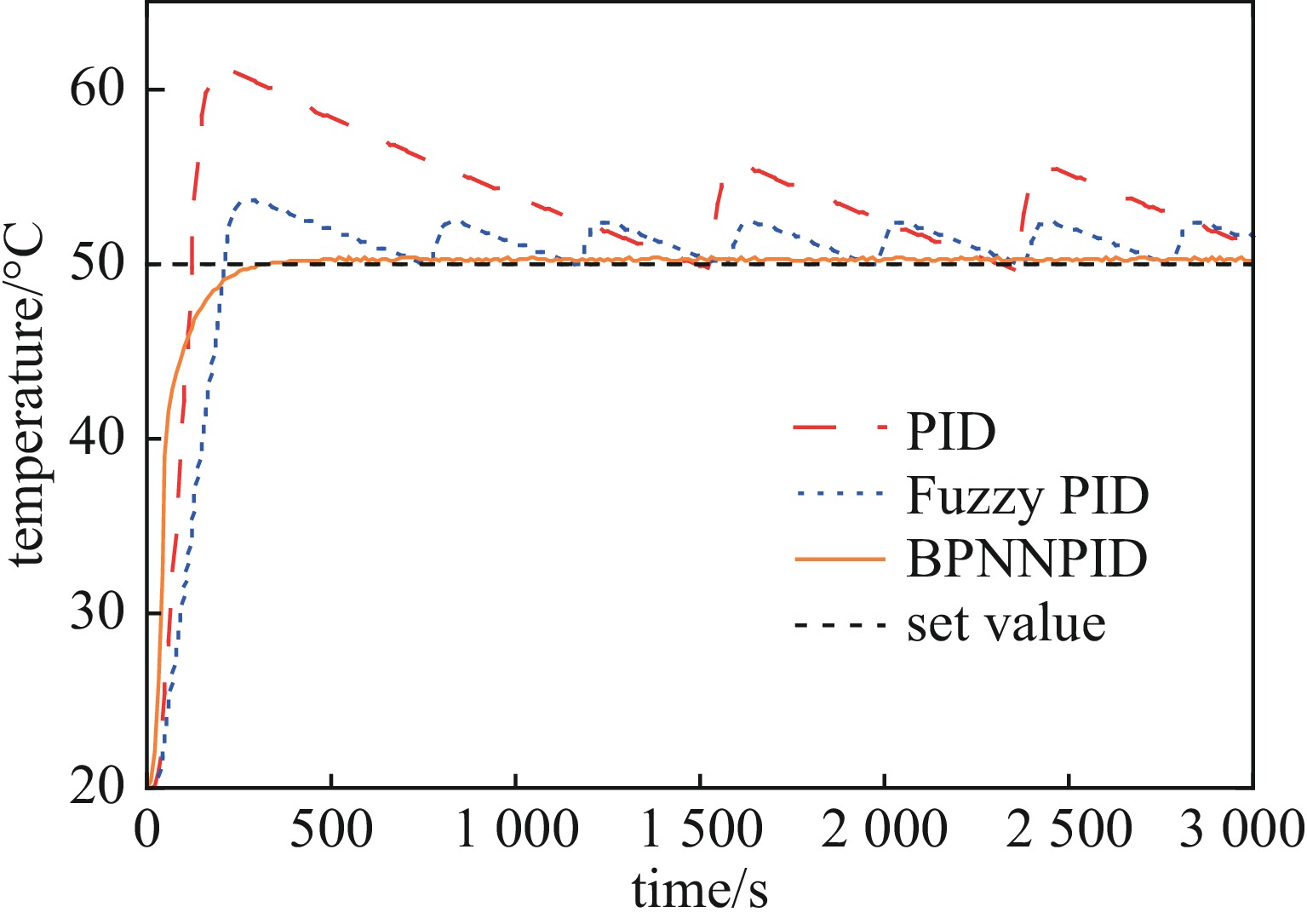

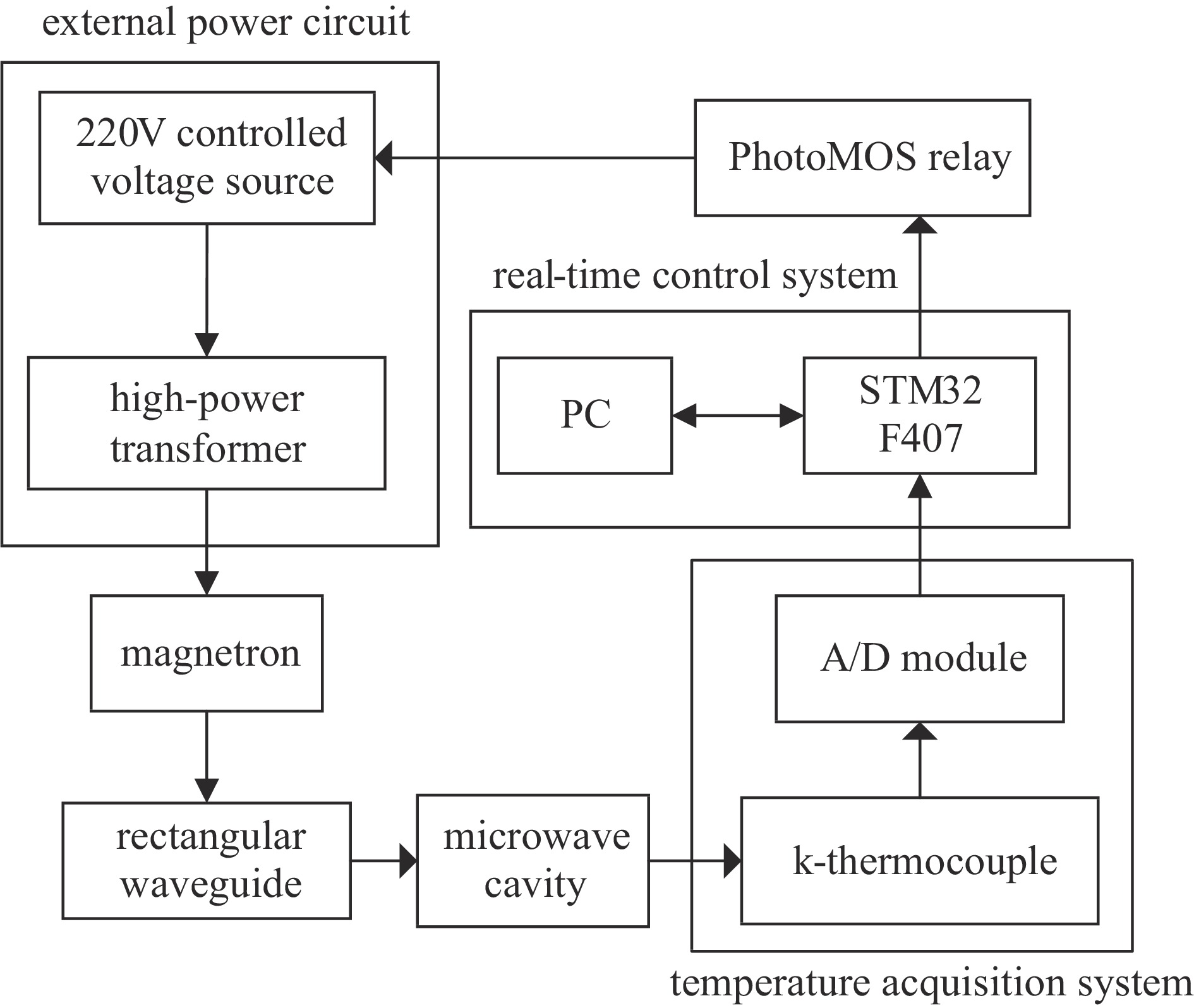

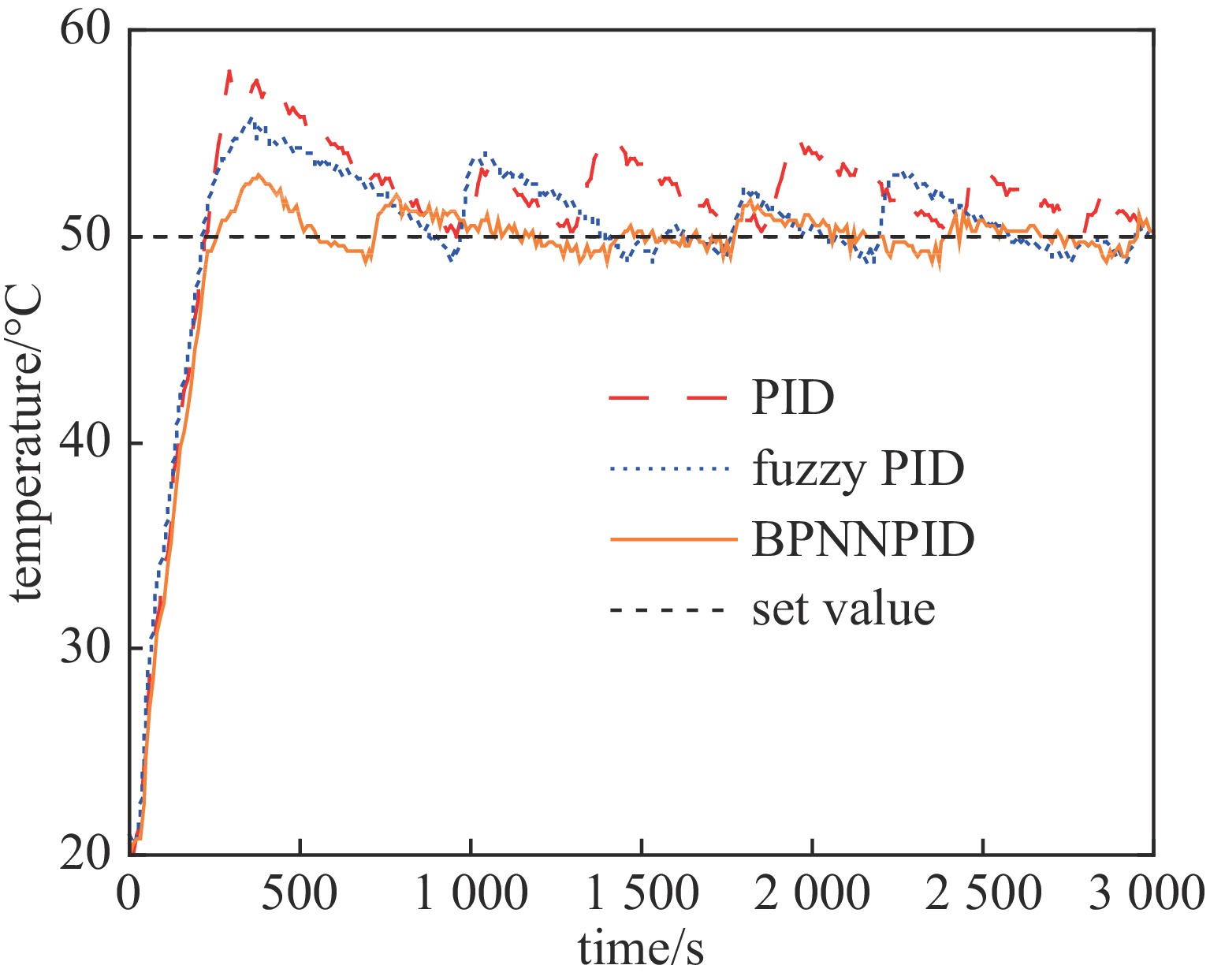

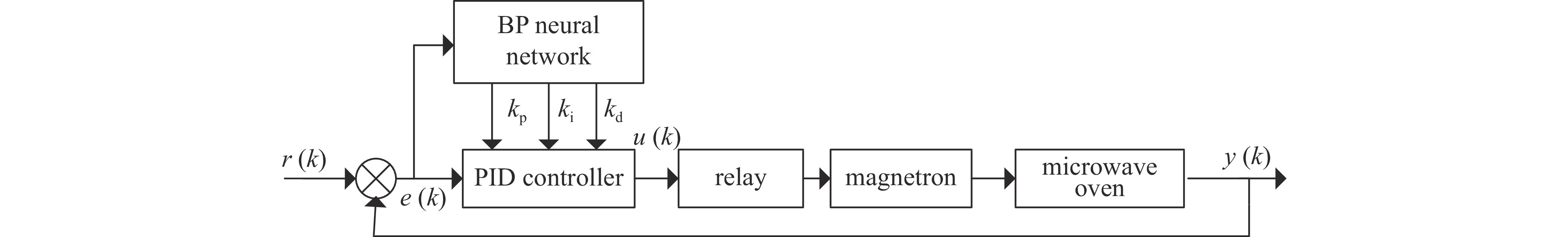

摘要: 针对现有10 kW高功率工业微波炉,采用继电器作为控制执行器,在使用传统控制方法加热时,温度存在较大超调和明显振荡,系统温度稳定性较低,为解决上述问题将反向传播神经网络PID(BPNNPID)控制引入到该装置微波加热温度控制中,并以自来水为加热对象进行仿真对比与实验验证。首先,利用现有输入输出实验数据,建立工业微波炉温度控制模型;其次,运用MATLAB/SIMULINK搭建高功率工业微波炉温度控制系统并进行仿真对比实验;最后,实验验证BPNNPID控制方法在加热5 kg自来水时工业微波炉的温度控制性能,实验结果表明,较常规PID、模糊PID控制,该方法在微波加热过程中对媒质温度控制超调更小且未发生明显温度振荡,有效改善了高功率工业微波炉工作时的系统温度稳定性,有助于提高产品质量和安全性能。Abstract: For the existing 10 kW high-power industrial microwave oven, a relay is used as the control actuator. When using traditional control methods for heating, there is a large overshoot and obvious temperature oscillation, and the system temperature stability is low. To solve the above problems, back propagation neural network PID control is introduced into the microwave heating temperature control of the installation, and simulation comparison and experimental verification are conducted using tap water as the heating object. Firstly, using existing input and output experimental data, establish a temperature control model for industrial microwave ovens; Secondly, use MATLAB/SIMULINK to build a high-power industrial microwave oven temperature control system and conduct simulation comparative experiments; Finally, experimently verify the temperature control performance of the back propagation neural network PID control method in industrial microwave ovens when heating 5 kg of tap water. The experimental results show that this method has smaller overshoot and no significant temperature oscillation compared to conventional PID and fuzzy PID control in the medium temperature control during microwave heating process, effectively improving the system temperature stability during the operation of high-power industrial microwave ovens, and helping to improve product quality and safety performance.

-

Key words:

- high power /

- microwave heating /

- back propagation neural network /

- PID /

- temperature control

-

表 1 各控制方法控制性能对比

Table 1. Comparison of control performance of various control methods

simulated rise

time/smeasured rise

time/ssimulated peak

time/smeasured peak

time/ssimulated

overshoot/%measured

overshoot/%simulated maximum

steady-state error/%measured maximum

steady-state error/%PID 120 230 200 290 22.36 16 11.18 9 fuzzy PID 210 220 270 360 7.28 11.5 4.7 8 BPNNPID 320 260 330 380 0.7 6 0.7 4 -

[1] Ano T, Tsubaki S, Fujii S, et al. Designing local microwave heating of metal nanoparticles/metal oxide substrate composites[J]. The Journal of Physical Chemistry C, 2021, 125(43): 23720-23728. doi: 10.1021/acs.jpcc.1c06650 [2] Li Hangren, Liu Saiyu, Xu Wence, et al. The effect of microwave on the crystallization behavior of CMAS system glass-ceramics[J]. Materials, 2020, 13: 4555. doi: 10.3390/ma13204555 [3] Chen Jin, Gao Lei, Guo Shenghui, et al. Evaluation of the structure and valence state of titanium oxide in titania slag under microwave heating[J]. Materials Letters, 2022, 310: 131475. doi: 10.1016/j.matlet.2021.131475 [4] Lou Yuanzheng, Guan Li, Wang Yanke, et al. Synthesis of (MgCoNiCuZn)O high-entropy oxide composites by microwave heating[J]. Journal of Materials Science:Materials in Electronics, 2023, 34: 132. doi: 10.1007/s10854-022-09596-6 [5] Yang Biao, Xiao Qingyun, Cheng Cheng, et al. Research on temperature uniformity optimization of microwave heating Debye media based on MDADT[J]. International Journal of RF and Microwave Computer-Aided Engineering, 2022, 32: e23538. [6] Yin Shumeng. Effect of metal slots on the heating uniformity of multisource cavity microwave[J]. Frontiers in Energy Research, 2023, 10: 1007566. doi: 10.3389/fenrg.2022.1007566 [7] Gupta N, Midha V, Balakotaiah V, et al. Bifurcation analysis of thermal runaway in microwave heating of ceramics[J]. Journal of the Electrochemical Society, 1999, 146(12): 4659-4665. doi: 10.1149/1.1392690 [8] 黄卡玛, 卢波. 微波加热化学反应中热失控条件的定量研究[J]. 中国科学 E辑:技术科学, 2009, 39(2):266-271Huang Kama, Lu Bo. Quantitative study of thermal runaway conditions in microwave heated chemical reactions[J]. Scientia Sinica (Technologica), 2009, 39(2): 266-271 [9] 周明长. 多馈口微波加热数值仿真及温度控制研究[D]. 绵阳: 西南科技大学, 2020Zhou Mingchang. Study on numerical simulation of microwave heating and temperature control[D]. Mianyang: Southwest University of Science and Technology, 2020 [10] Liu Tong, Liang Shan, Xiong Qingyu, et al. Data-based online optimal temperature tracking control in continuous microwave heating system by adaptive dynamic programming[J]. Neural Processing Letters, 2020, 51(1): 167-191. doi: 10.1007/s11063-019-10081-1 [11] 杨彪, 成宬, 李鑫培, 等. 一种基于预测模型的微波加热过程温度控制策略[J]. 昆明理工大学学报(自然科学版), 2020, 45(5):1-8Yang Biao, Cheng Cheng, Li Xinpei, et al. A temperature control strategy for microwave heating process based on prediction model[J]. Journal of Kunming University of Science and Technology (Natural Science), 2020, 45(5): 1-8 [12] 袁晓峰, 彭金辉, 陈颀, 等. 一种改进的工业微波炉加热控制PID技术[J]. 工业加热, 2015, 44(2):65-68Yuan Xiaofeng, Peng Jinhui, Chen Qi, et al. A improved PID technology used in industrial microwave heating furnace control[J]. Industrial Heating, 2015, 44(2): 65-68 [13] 刘长军, 申东雨. 微波加热陶瓷中热失控现象的分析与控制[J]. 中国科学 E辑: 技术科学, 2008, 38(7): 1097-1105Liu Changjun, Shen Dongyu. Analysis and control of the thermal runaway of ceramic slab under microwave heating[J]. Science in China Series E: Technological Sciences, 2008, 51(12): 2233-2241 [14] 周明长, 李少甫. 基于数值仿真的多馈微波加热温度控制系统[J]. 微波学报, 2019, 35(5):92-96Zhou Mingchang, Li Shaofu. Multi-feed microwave heating temperature control system based on numerical simulation[J]. Journal of Microwaves, 2019, 35(5): 92-96 [15] Yuan Yupeng, Liang Shan, Zhong Jiaqi, et al. Black box system identification dedicated to a microwave heating process[C]//Proceedings of the 27th Chinese Control and Decision Conference. 2015: 4116-4120. [16] 张泽旭. 神经网络控制与MATLAB仿真[M]. 哈尔滨: 哈尔滨工业大学出版社, 2011Zhang Zexu. Neural networks control and MATLAB simulation[M]. Harbin: Harbin Institute of Technology Press, 2011 -

下载:

下载: