Simulation and verification of 3D temperature model for high power microwave heating

-

摘要:

微波加热不均匀性一直以来都是从事微波加热控制方向研究人员心目中的热点问题。根据微波加热装置的物理结构建立了炉内各层表面的温度静态差分模型结合实验以求得微波加热的实际功率。再基于传热学的有限差分法建立三维空间中的温度分布模型,利用MATLAB以及COMSOL仿真对比验证了模型的有效性。假定微波均匀加热求得被加热介质的平衡温度与不均匀加热时的温度进行比对以找出微波加热过程中介质的部分温升平衡点,最后互相比对找出最优点为控制对象进行专家PID(proportion-integral-derivative)微波加热。实验结果表明,该方法能较为精确地测量出被加热介质任何时刻的平衡温度,使得微波加热在工业生产上有着更加广泛的应用。

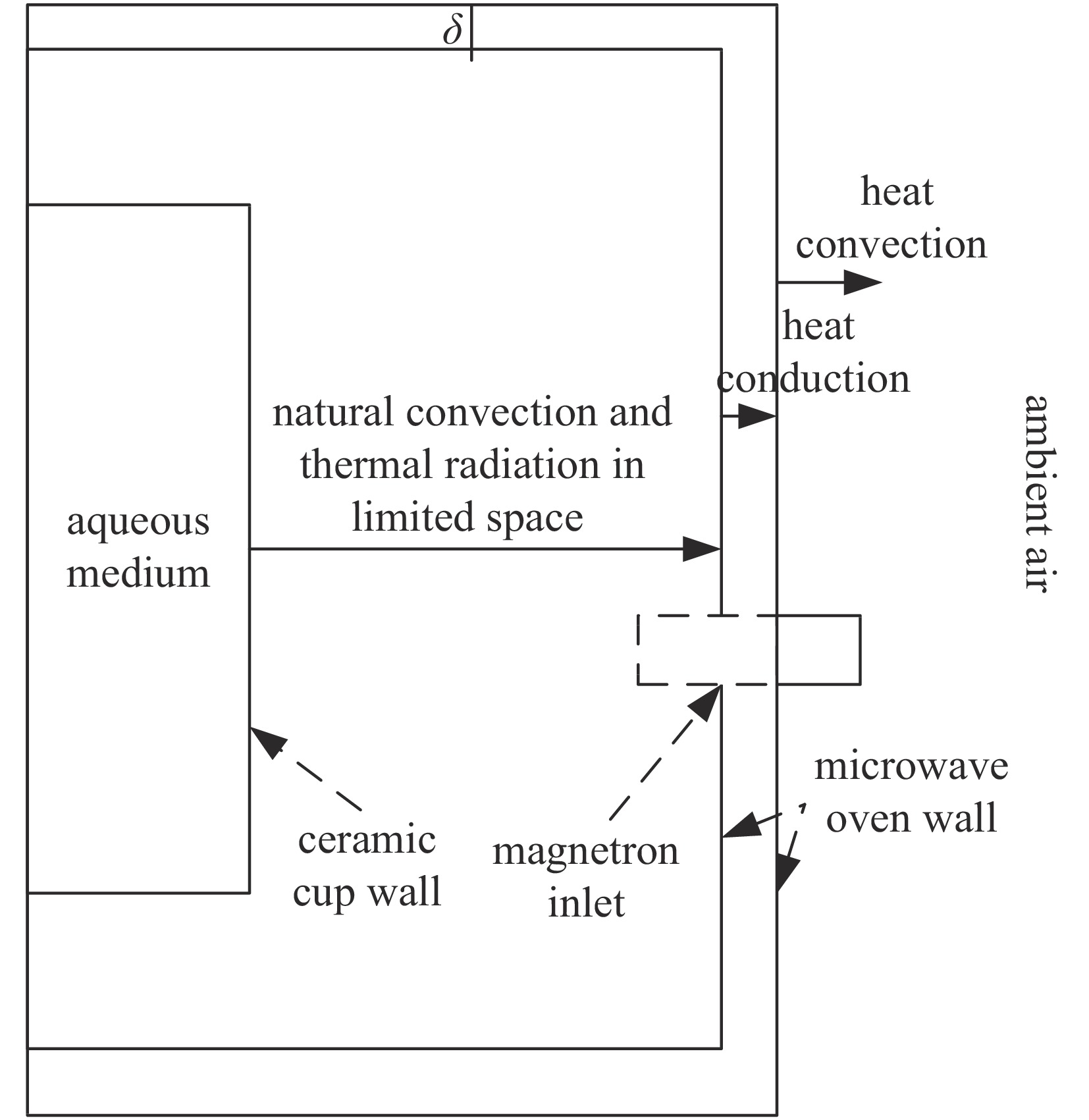

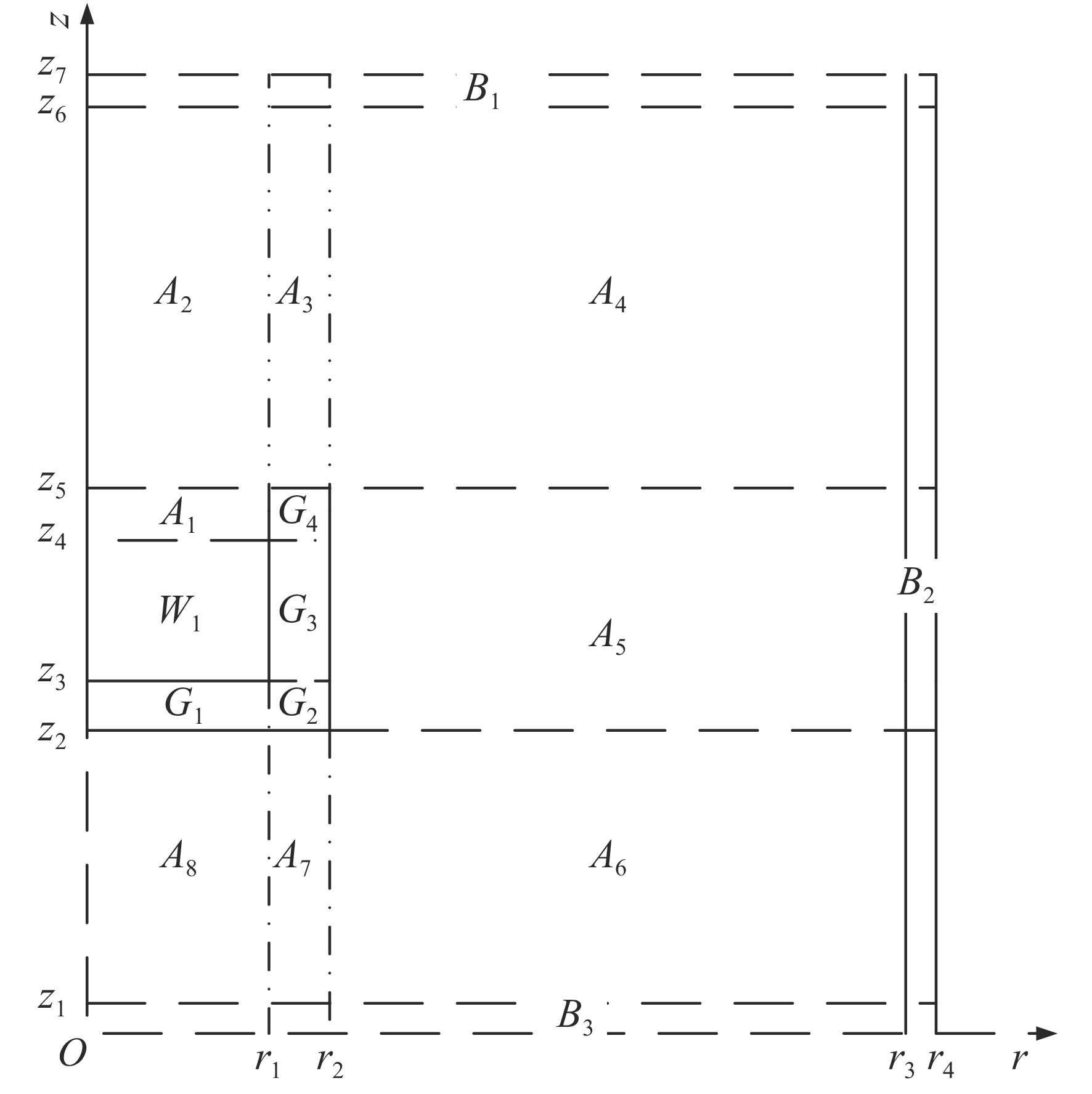

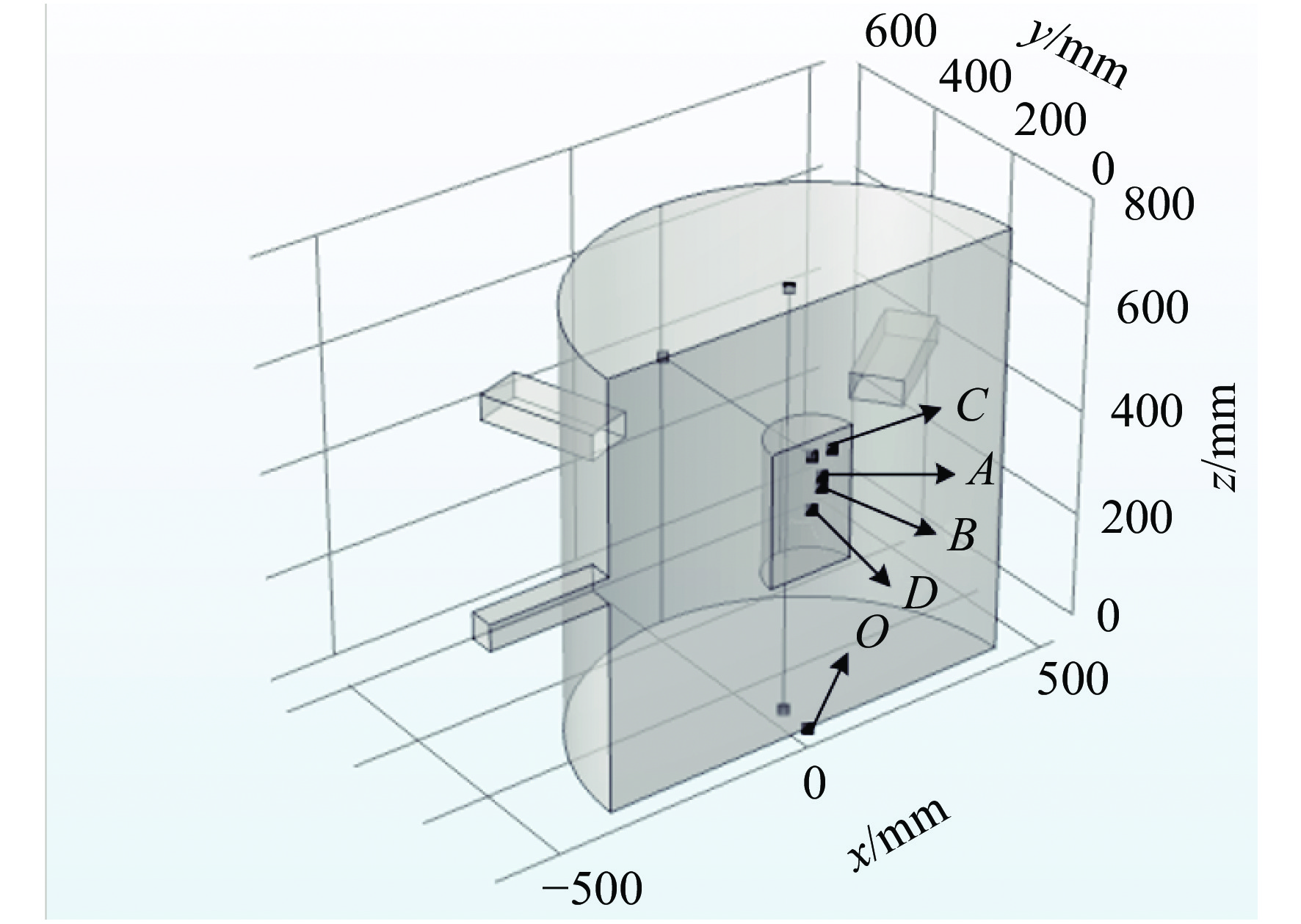

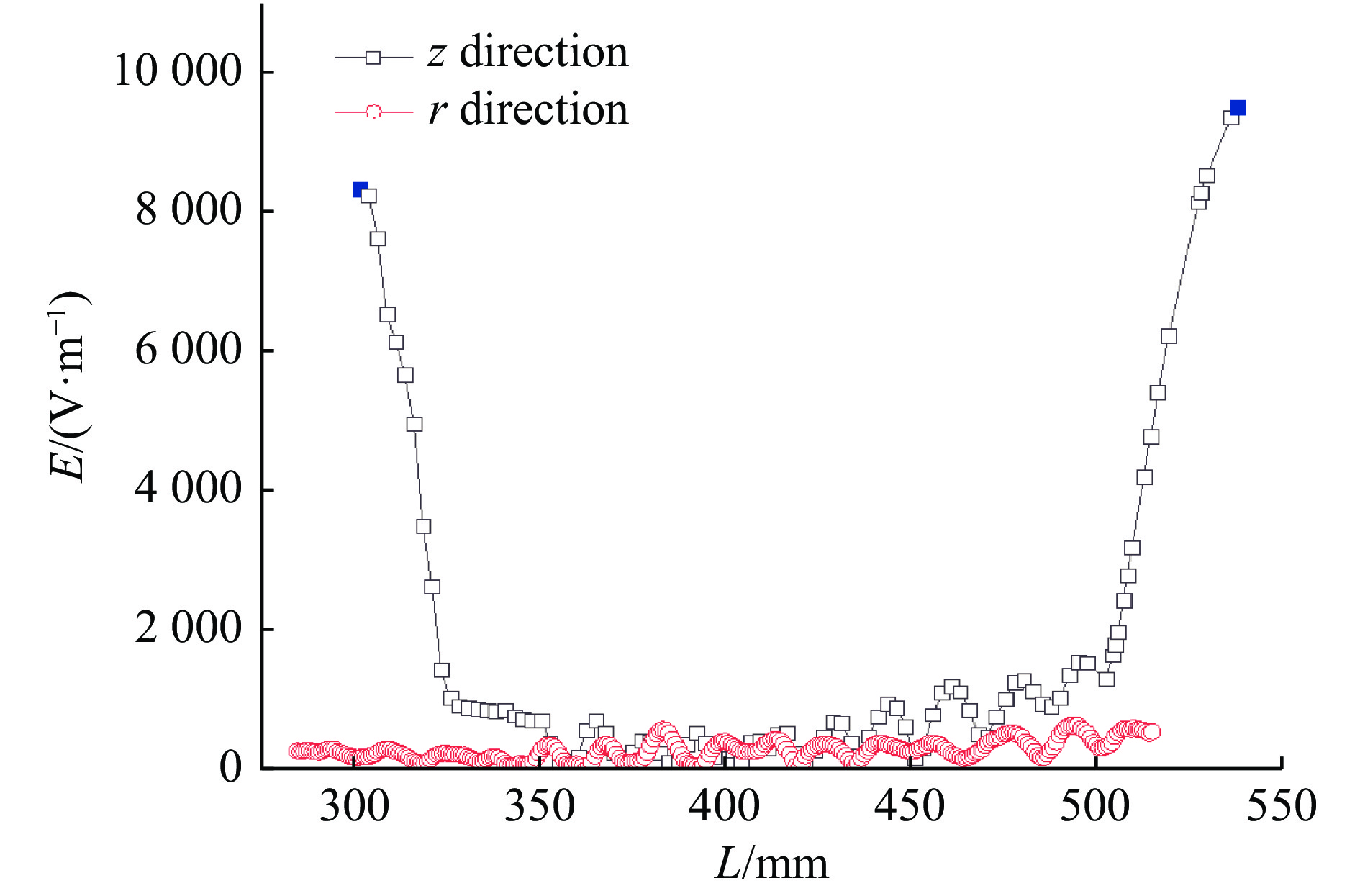

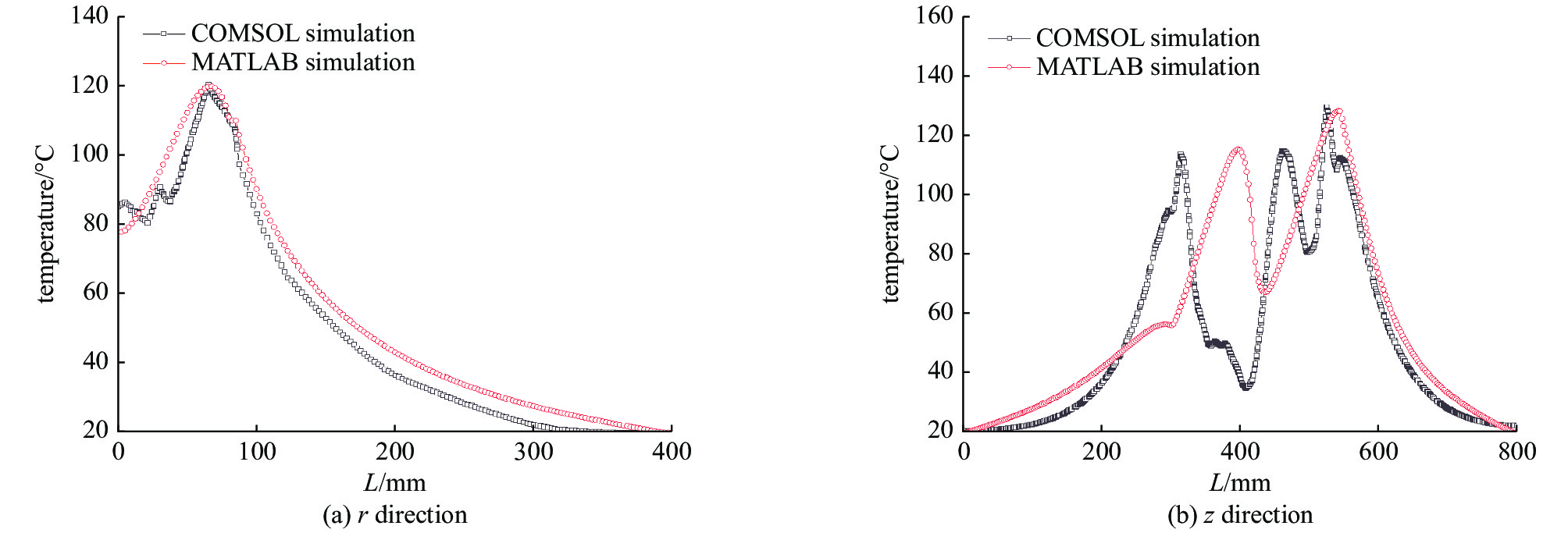

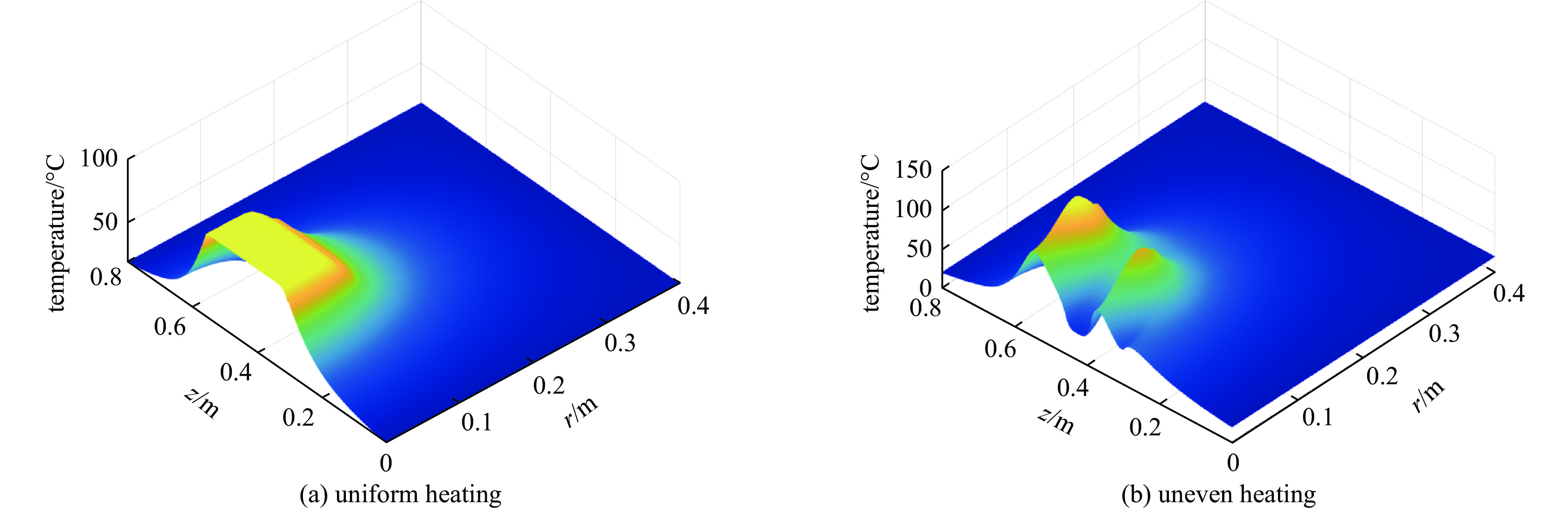

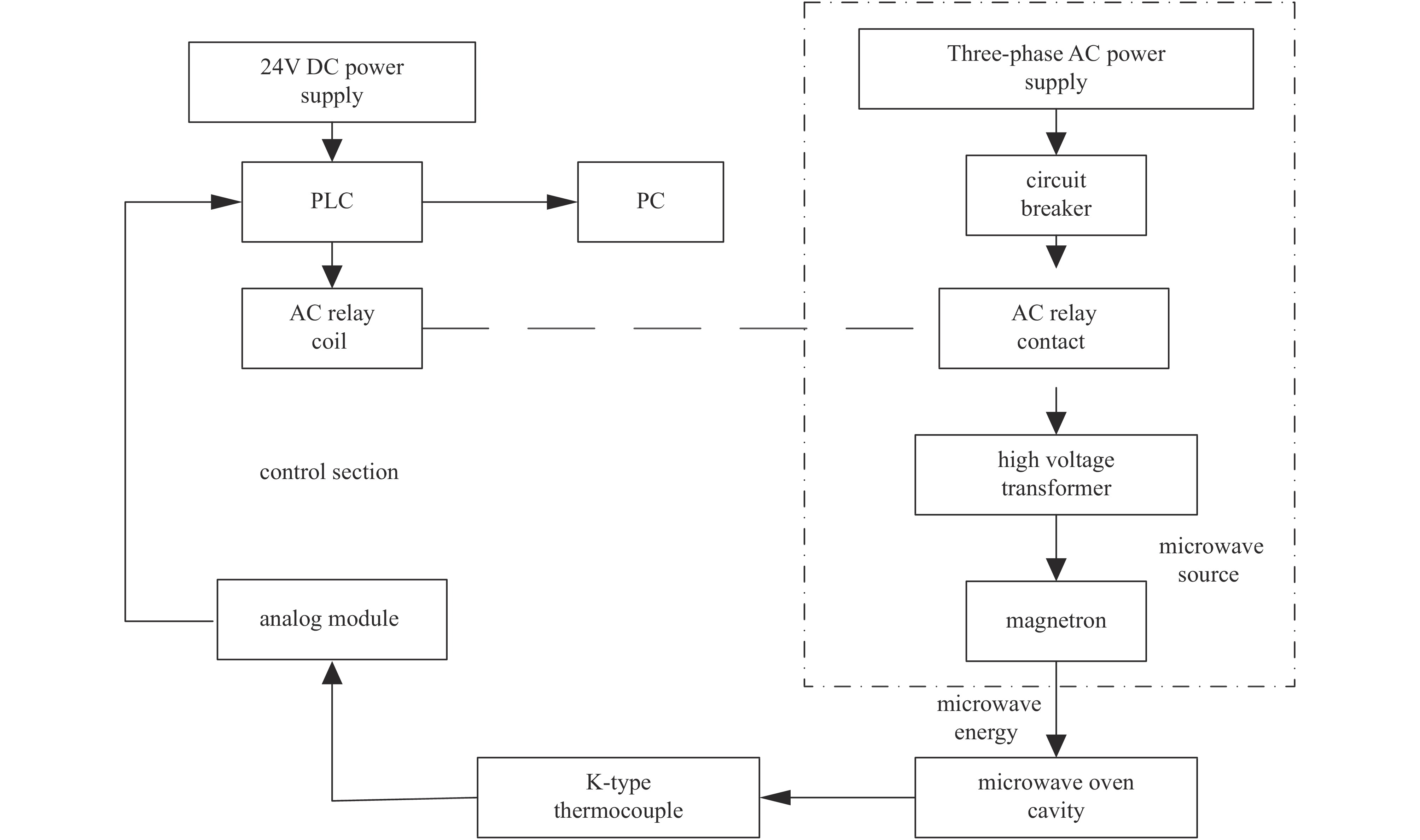

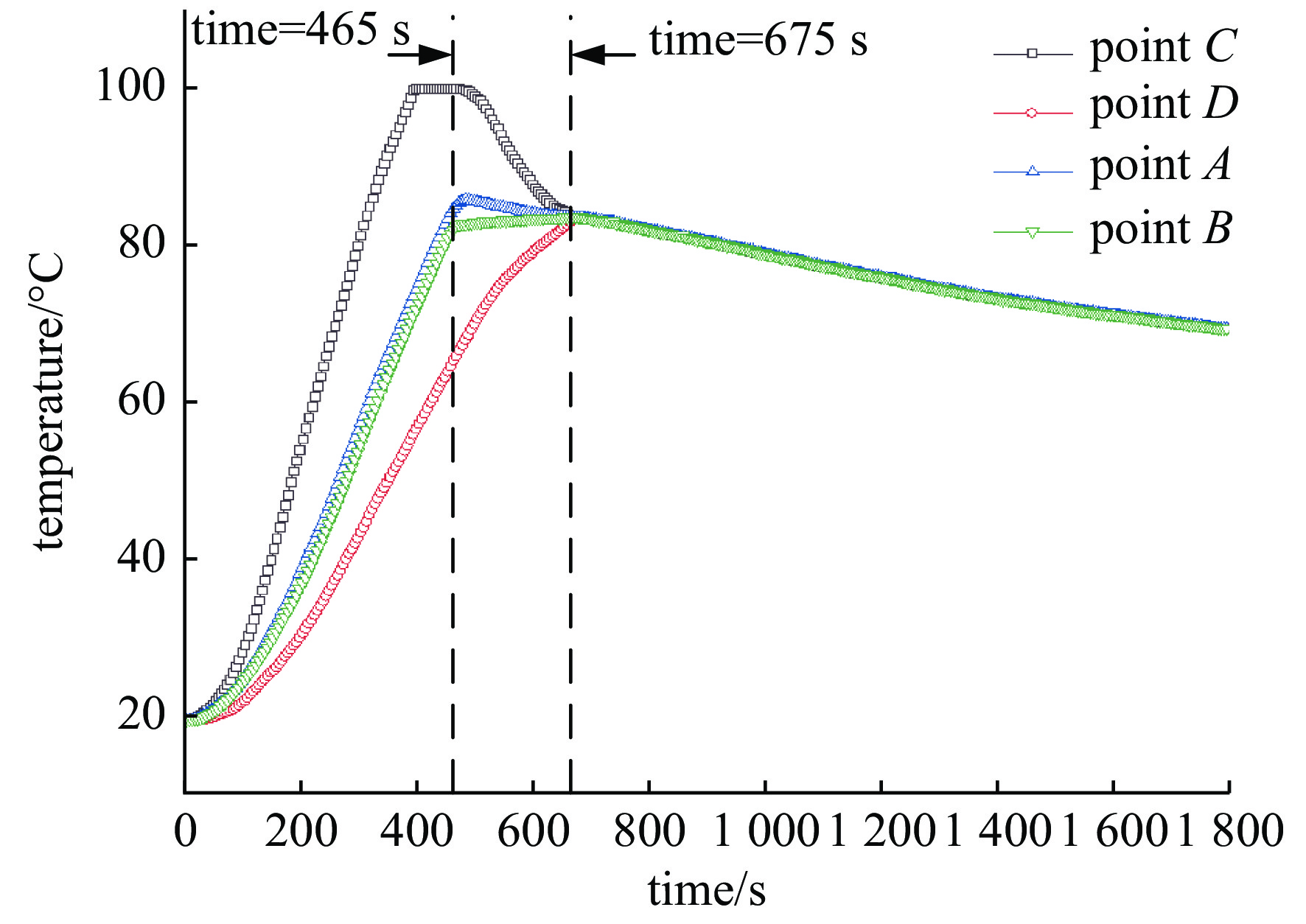

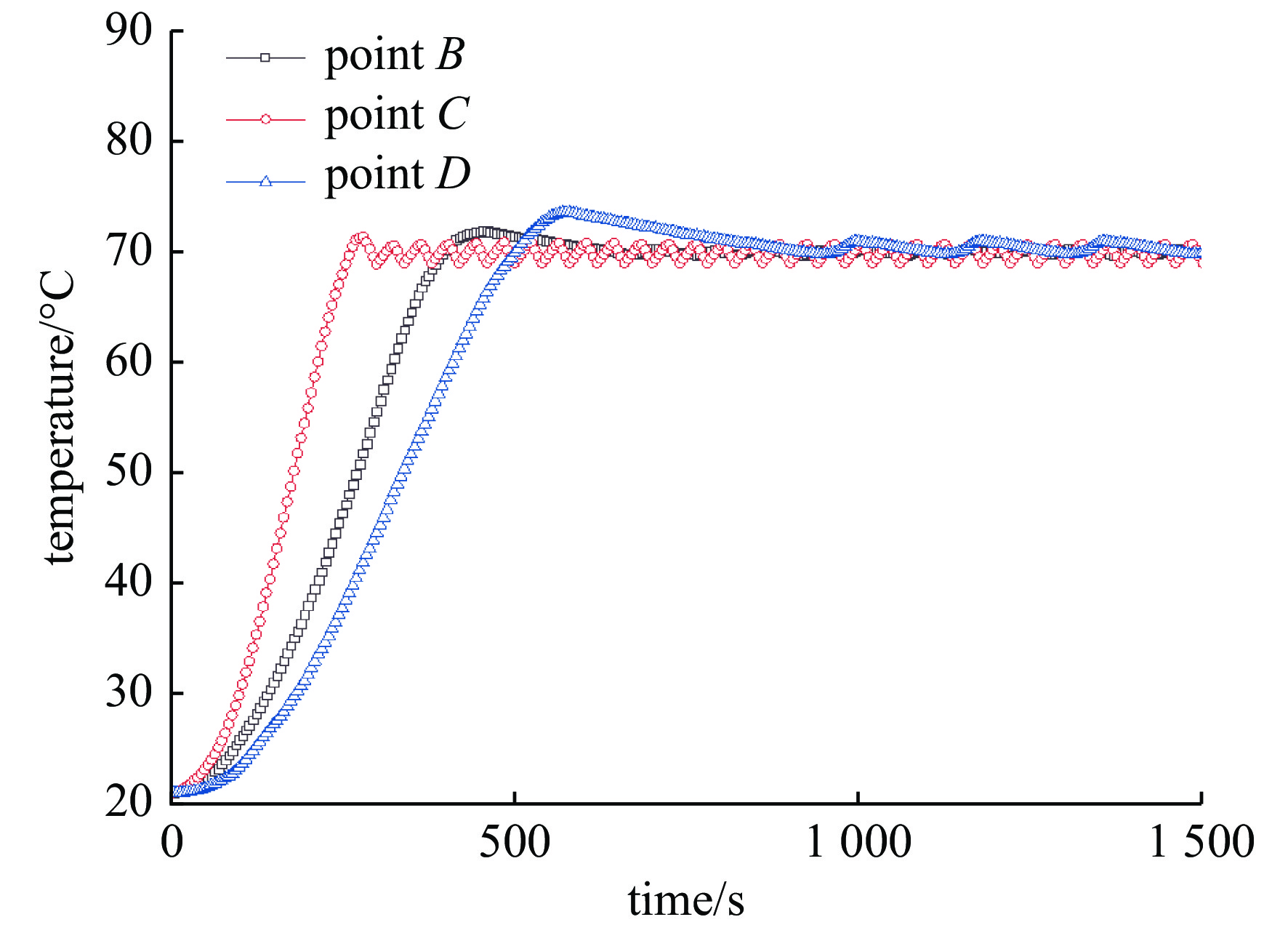

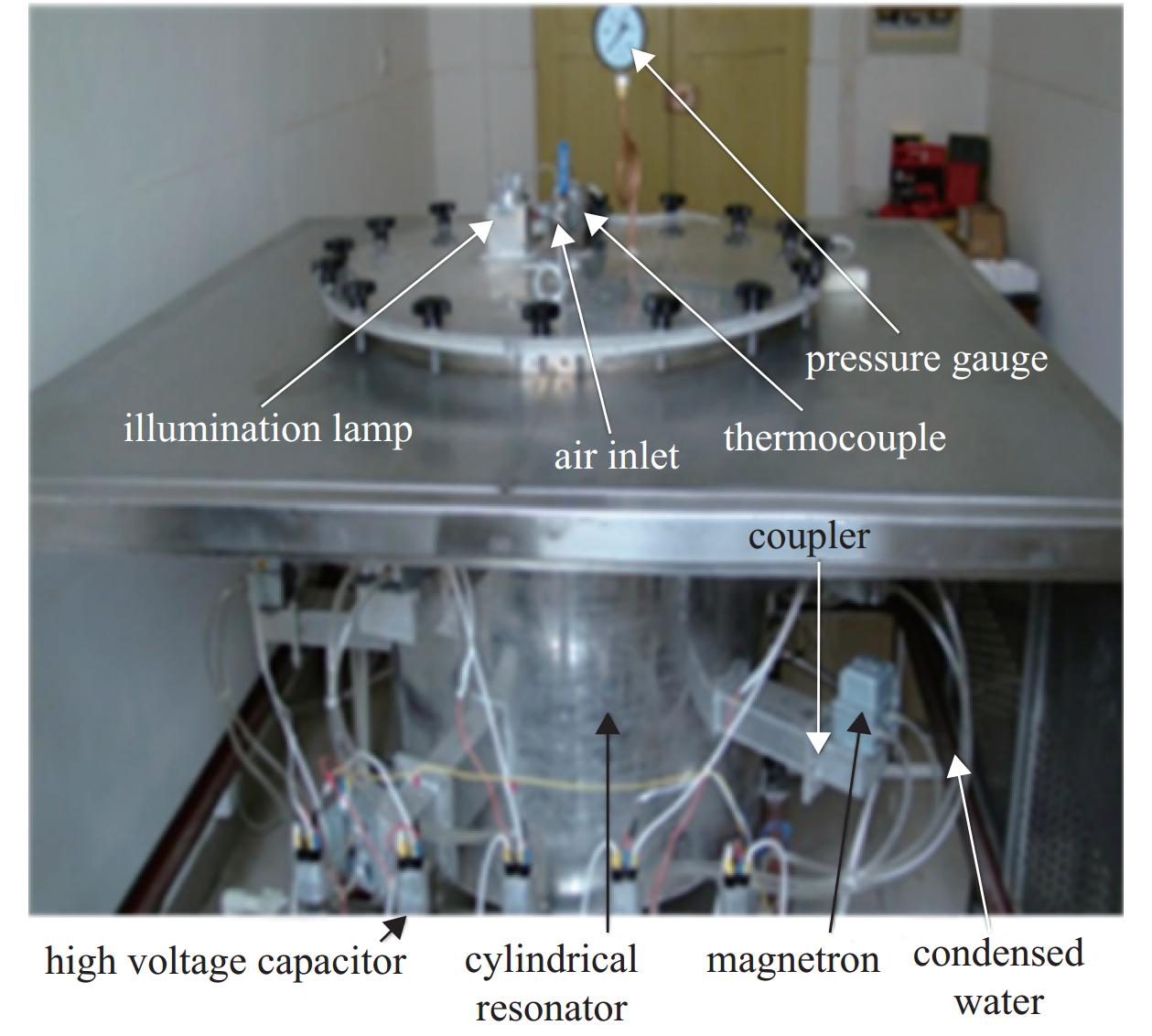

Abstract:Microwave heating inhomogeneity has always been a hot issue in microwave heating control research. According to the physical structure of the microwave heating device, the static difference model of the surface temperature of each layer in the furnace is established, and the actual power of microwave heating is obtained by combining with experiments. Based on the finite difference method of heat transfer, the temperature distribution model in 3D space is established, and the effectiveness of the model is verified by MATLAB and COMSOL simulations. The equilibrium temperature of the heated medium obtained by uniformly heating the microwave is compared with the temperature distribution during uneven heating, the partial temperature rise equilibrium points of the medium during the microwave heating process are identified. Finally, comparison is carried out to find out the best point for the control object for expert PID (proportion-integral-derivative) microwave heating. The experimental results show that this method can accurately measure the equilibrium temperature of liquid heated medium at any time, and can make microwave heating more widely used in industrial production.

-

Table 1. Material parameter values of each layer

material $ \rho /\left( {{\rm{kg}}\cdot {{\rm{m}}^{-3}}} \right) $ $ c/\left({\rm{J}}\cdot{\rm{kg}}^{-1}\cdot {{\text{℃}}}^{-1}\right) $ $ \lambda /\left({\rm{W}}\cdot{\rm{m}}^{-1}\cdot {{\text{℃}}}^{-1}\right) $ W 1000 4200 0.59 G 2600 850 2 A 1.18 1005 0.028 B 7930 1260 16.2 Table 2. Empirical rule table of incremental expert PID control

No. if then 1 u>1.00 all five magnetrons run 2 1.00≥u>0.75 four magnetrons run randomly 3 0.75≥u>0.50 three magnetrons run randomly 4 0.50≥u>0.25 two magnetrons run randomly 5 0.25≥u>0.00 one magnetron run randomly 6 u≤0.00 all magnetrons stop running -

[1] Li Hangren, Liu Saiyu, Xu Wence, et al. The effect of microwave on the crystallization behavior of CMAS system glass-ceramics[J]. Materials, 2020, 13: 4555. doi: 10.3390/ma13204555 [2] Zhong Jiaqi, Liang Shan. A data-driven based spatiotemporal model reduction for microwave heating process with the mixed boundary conditions[J]. Processes, 2021, 9: 827. doi: 10.3390/pr9050827 [3] Chan T V C T, Reader H C. Computational design of a multiplex magnetron cavity[C]//Proceedings of IEEE AFRICON’96. 1996: 523-527. [4] Jeni K, Yapa M, Rattanadecho P. Design and analysis of the commercialized drier processing using a combined unsymmetrical double-feed microwave and vacuum system (case study: tea leaves)[J]. Chemical Engineering and Processing:Process Intensification, 2010, 49 (4) : 389-395. doi: 10.1016/j.cep.2010.03.003 [5] Wang Shunmin, Hu Zhichao, Han Yongbin, et al. Effects of magnetron arrangement and power combination of microwave on drying uniformity of carrot[J]. Drying Technology, 2013, 31 (11) : 1206-1211. doi: 10.1080/07373937.2013.783590 [6] Zhou Mingchang. Study on numerical simulation of microwave heating and temperature control[D]. Mianyang: Southwest University of Science and Technology, 2020. [7] Dai Chengjun. The design and development of the microwave activation equipment on the industry[D]. Mianyang: Southwest University of Science and Technology, 2012. [8] Yang Biao, Wang Shili, Guo Linjia, et al. Numerical calculation of temperature uniformity in microwave heating based on moving mesh[J]. Control and Decision, 2019, 34 (1) : 113-120. [9] Zhong Jiaqi, Liang Shan, Xiong Qingyu. H∞ guaranteed cost temperature tracking control for microwave heating Debye media process[J]. Acta Automatica Sinica, 2018, 44 (8) : 1518-1527. [10] Zheng Hongfei. Fundamentals of thermodynamics and heat transfer[M]. Beijing: Science Press, 2016. [11] Liu Yanfeng, Liang Xiujun, Gao Zhengyang, et al. Heat transfer[M]. Beijing: China Electric Power Press, 2021. [12] Zhou Mingchang, Li Shaofu. Multi-feed microwave heating temperature control system based on numerical simulation[J]. Journal of Microwaves, 2019, 35 (5) : 92-96. -

下载:

下载: