Development of mechanical property analysis program for space thermionic fuel element

-

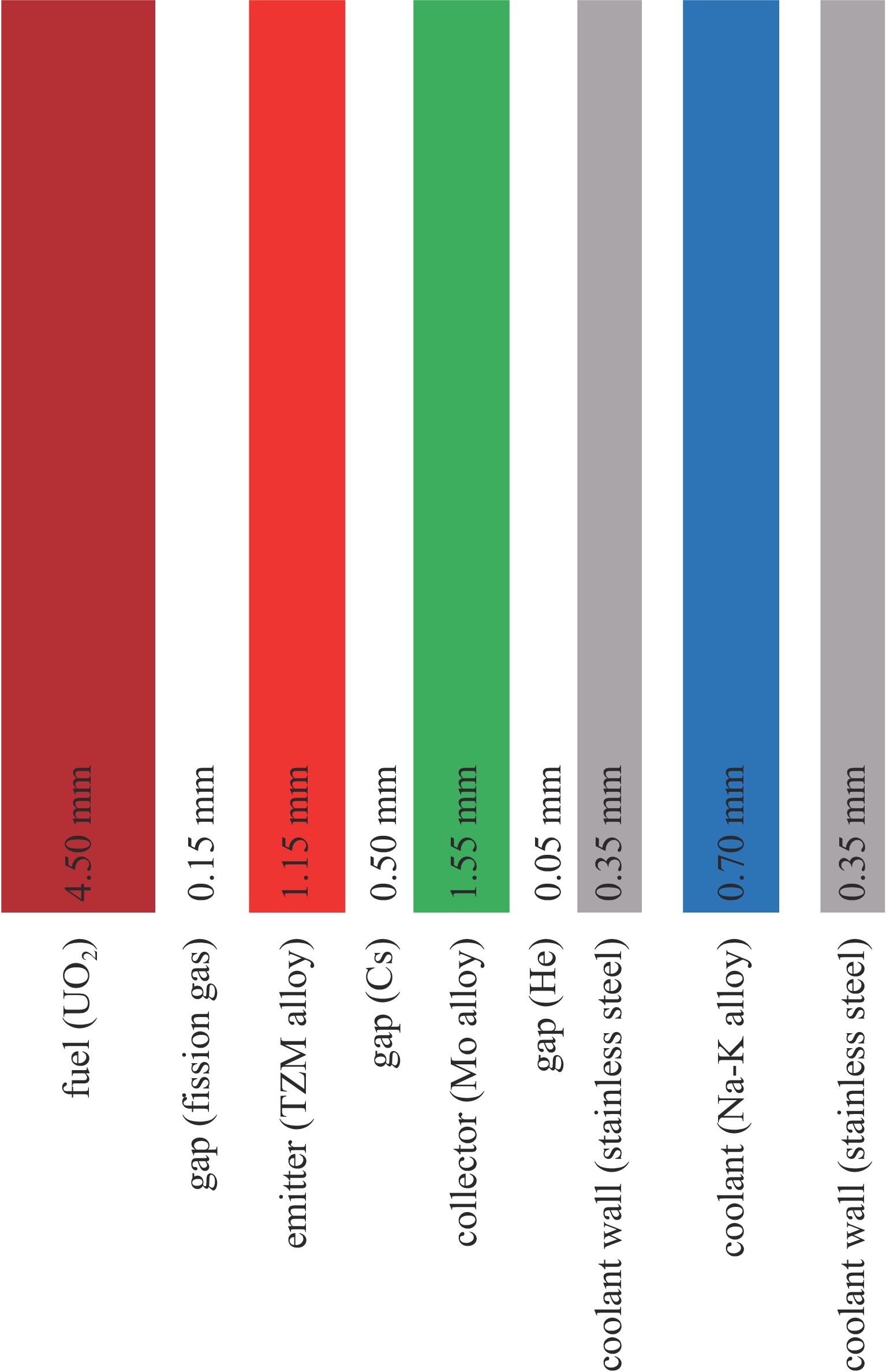

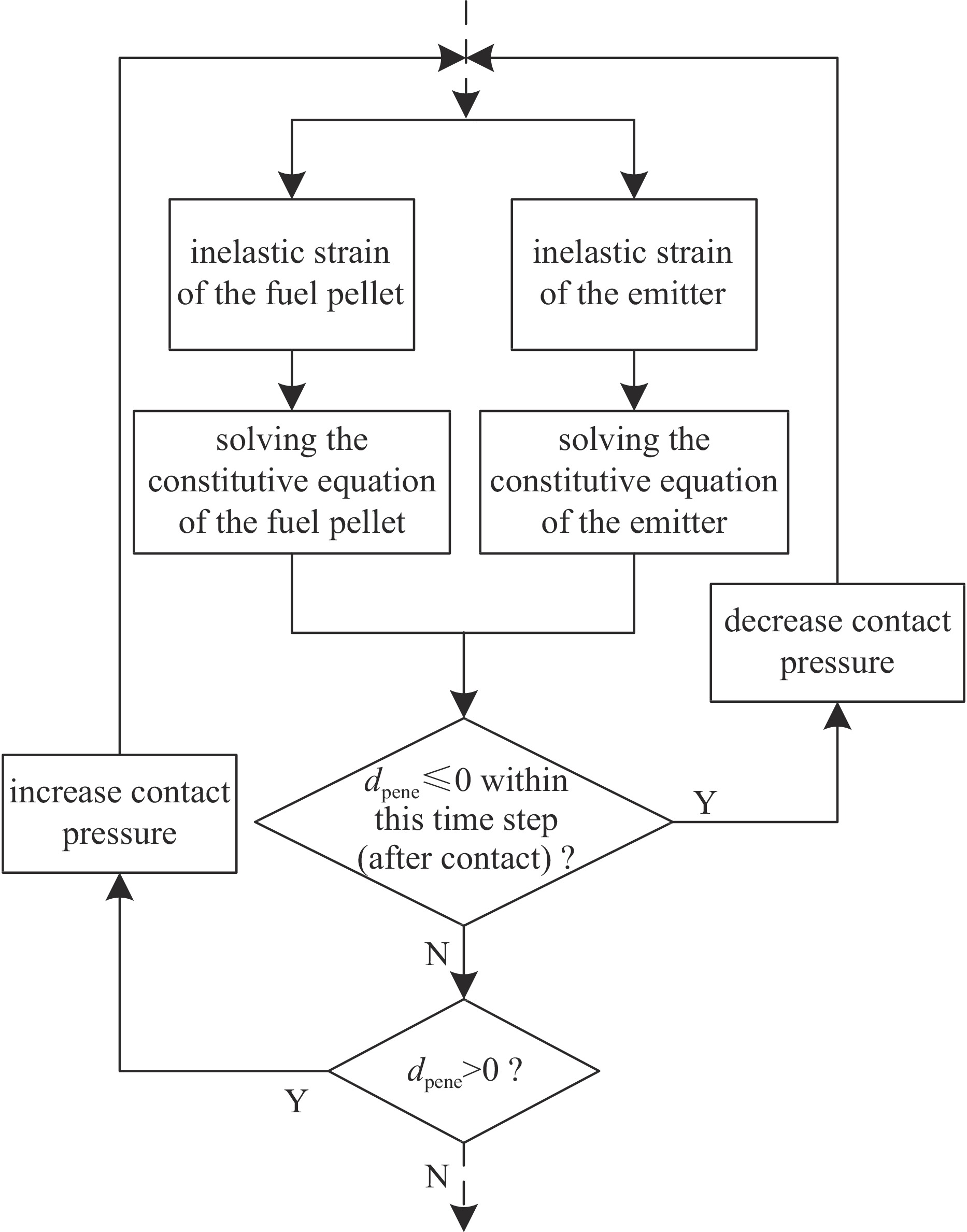

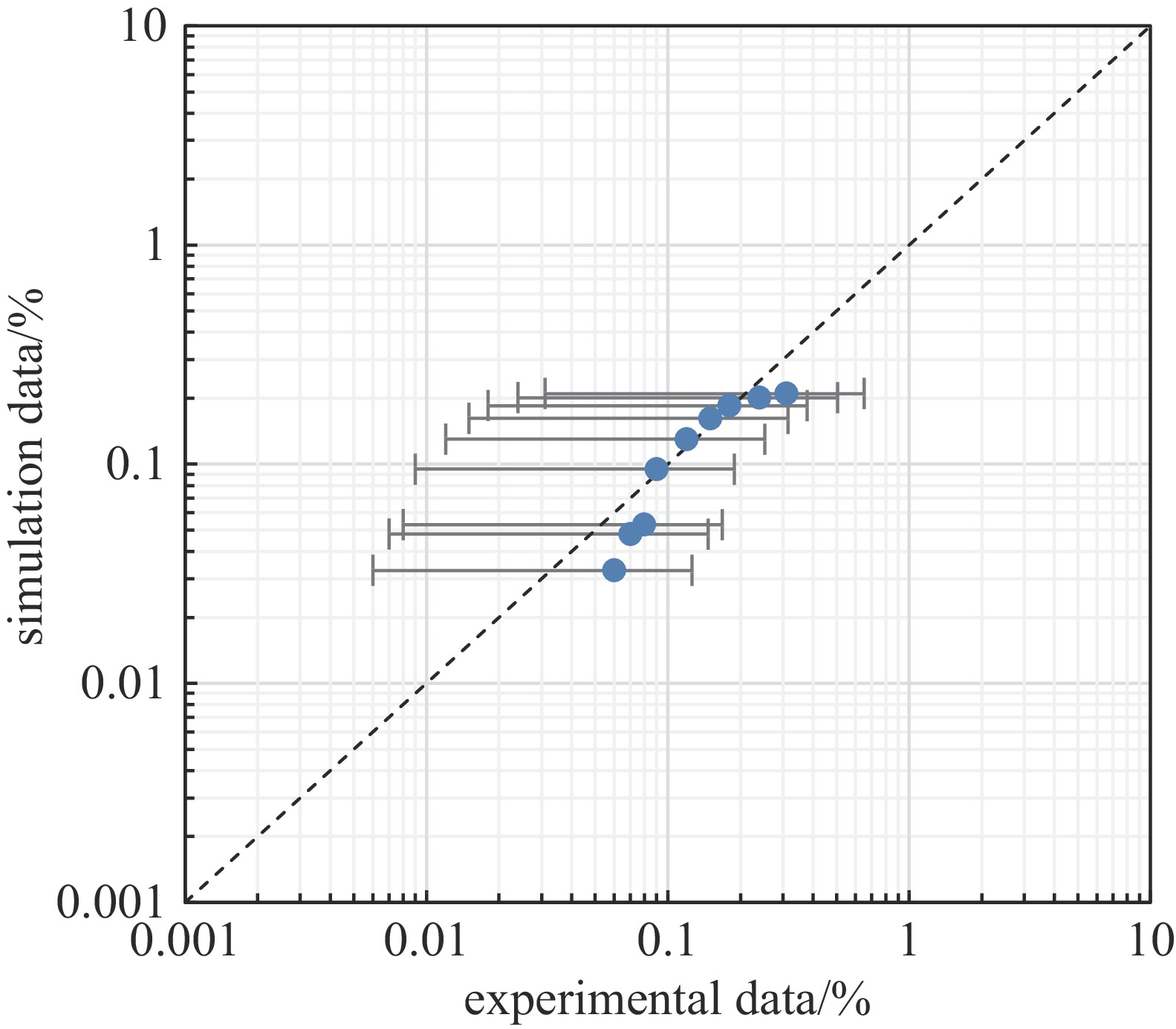

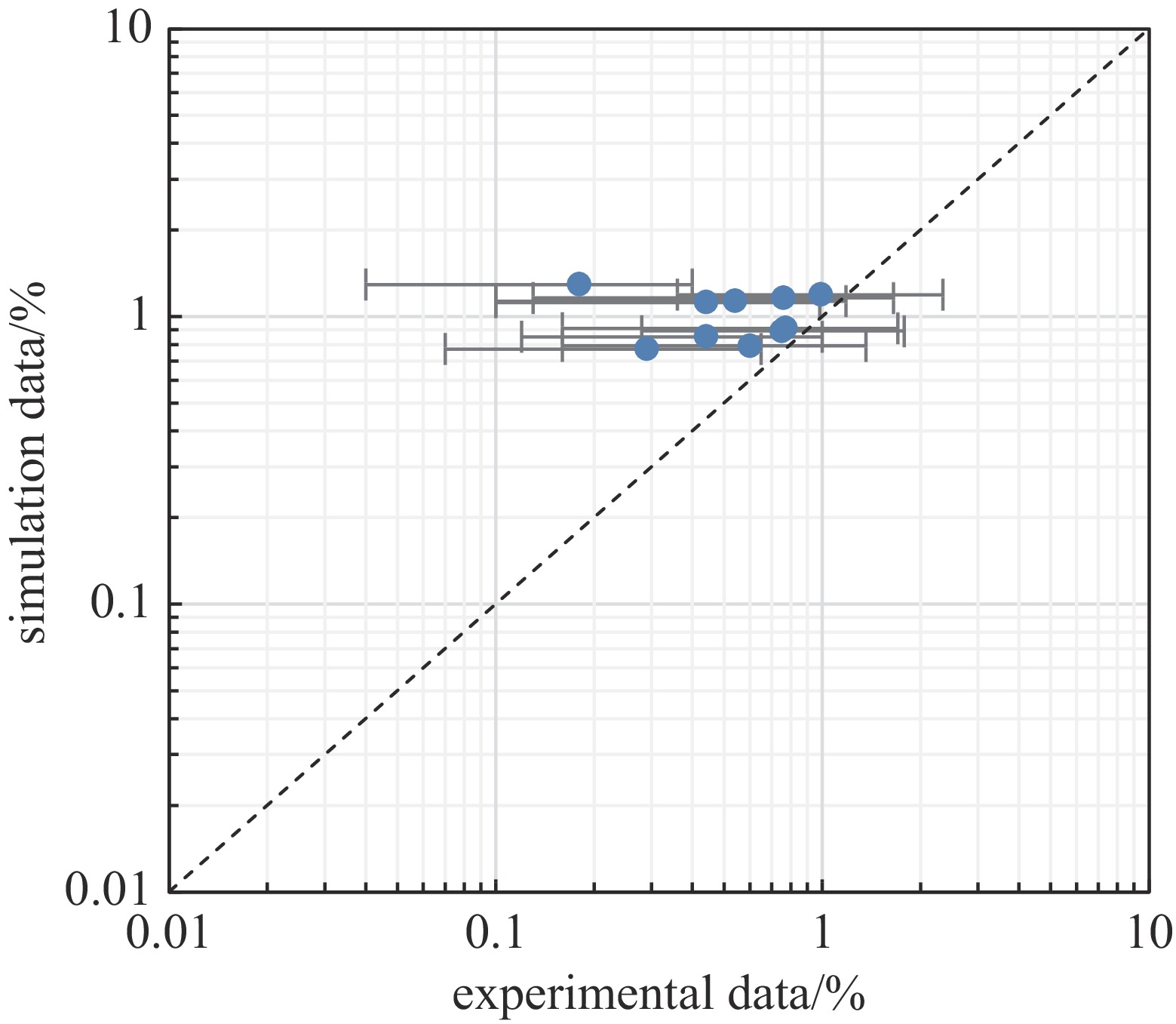

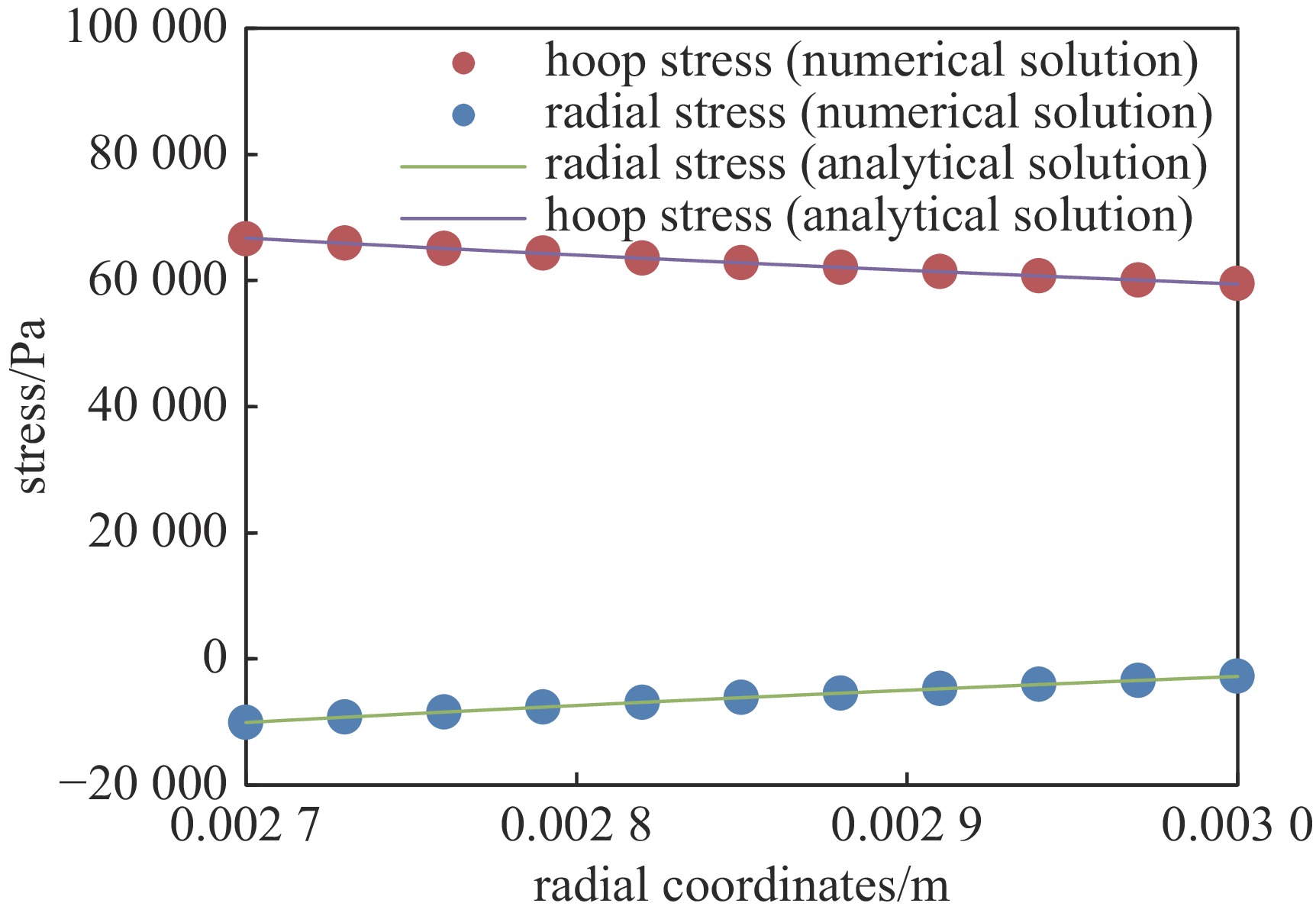

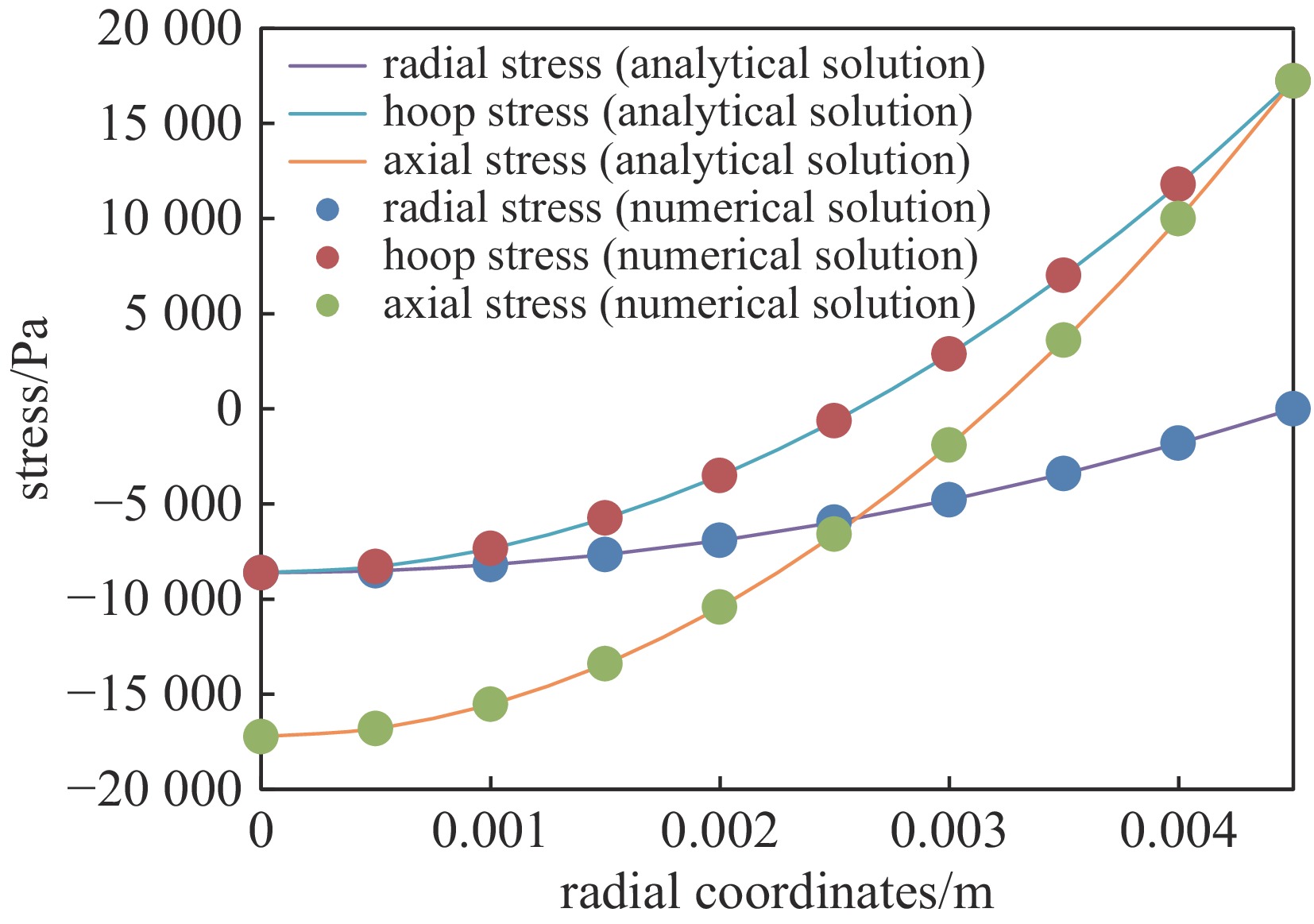

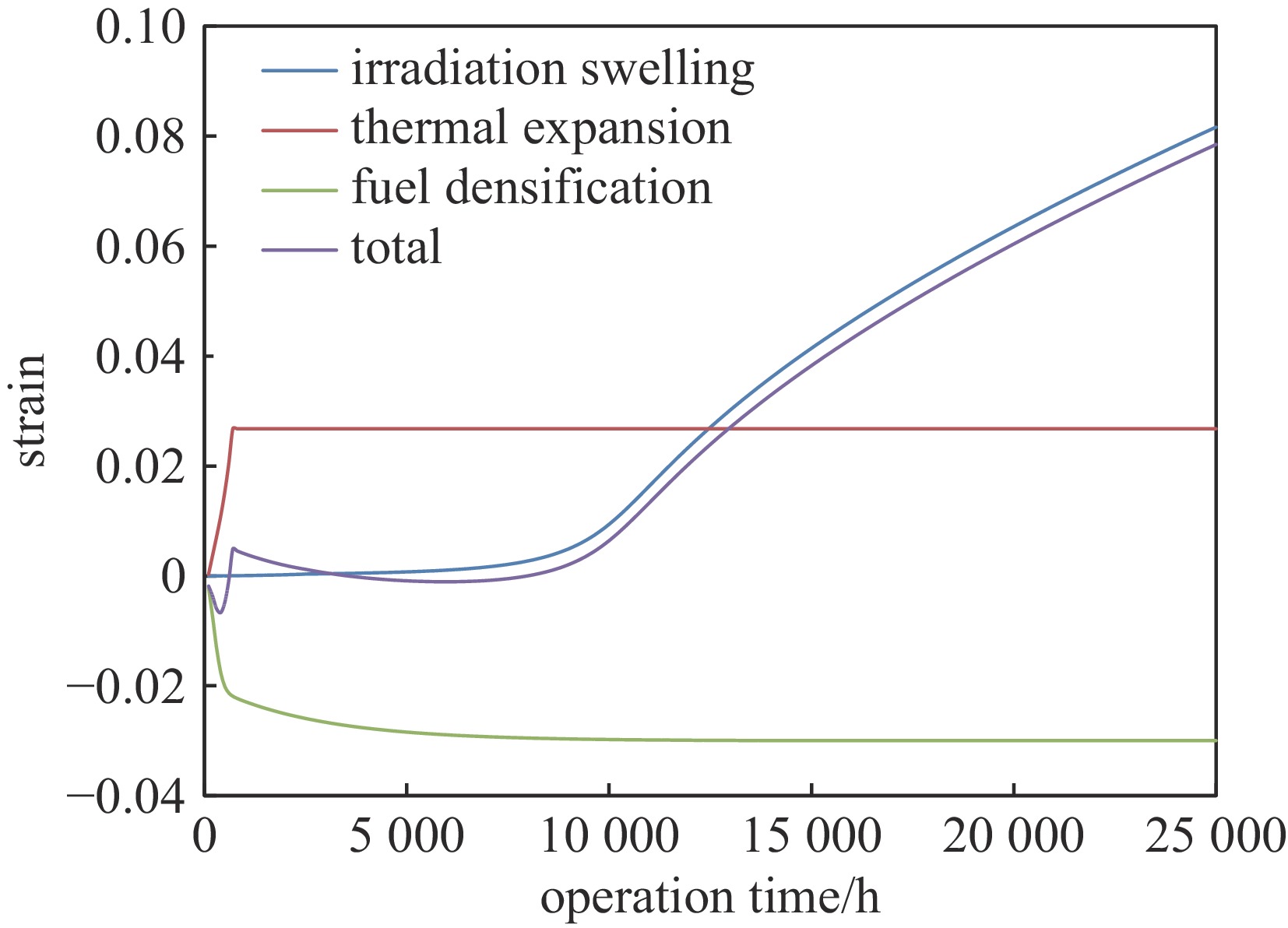

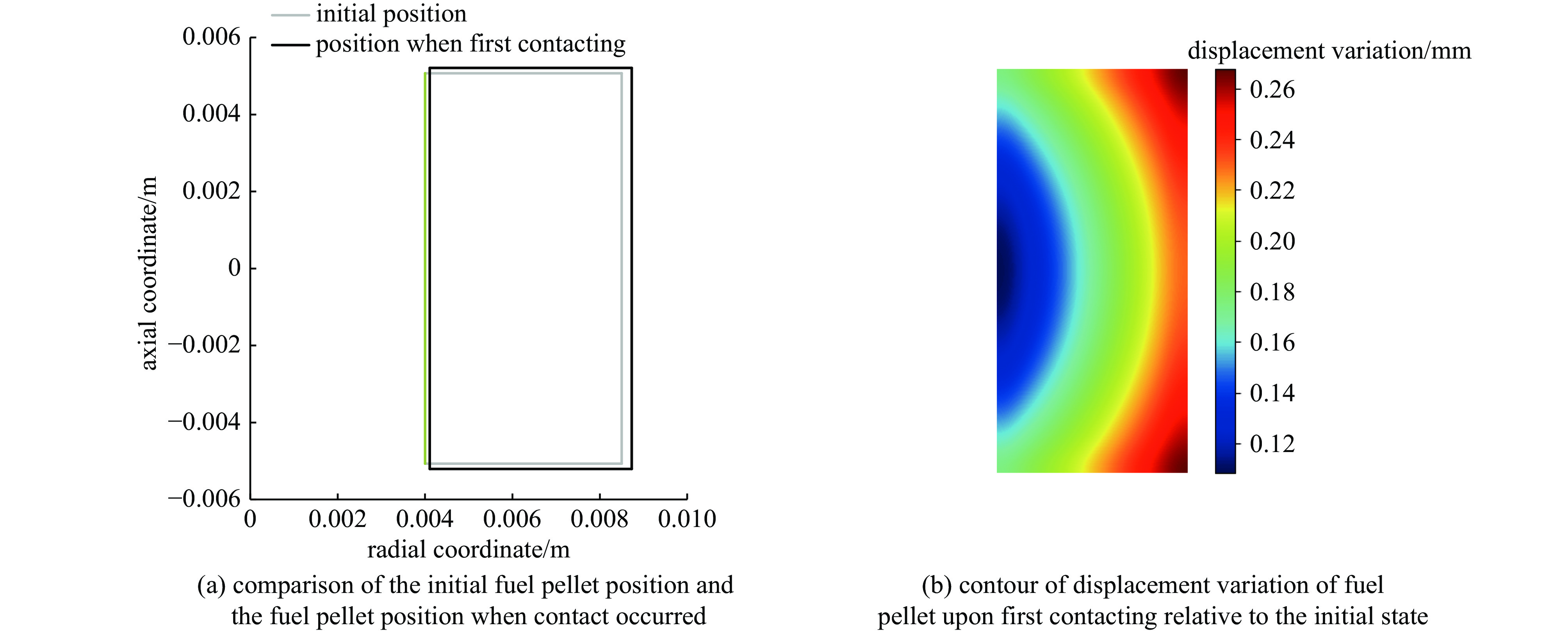

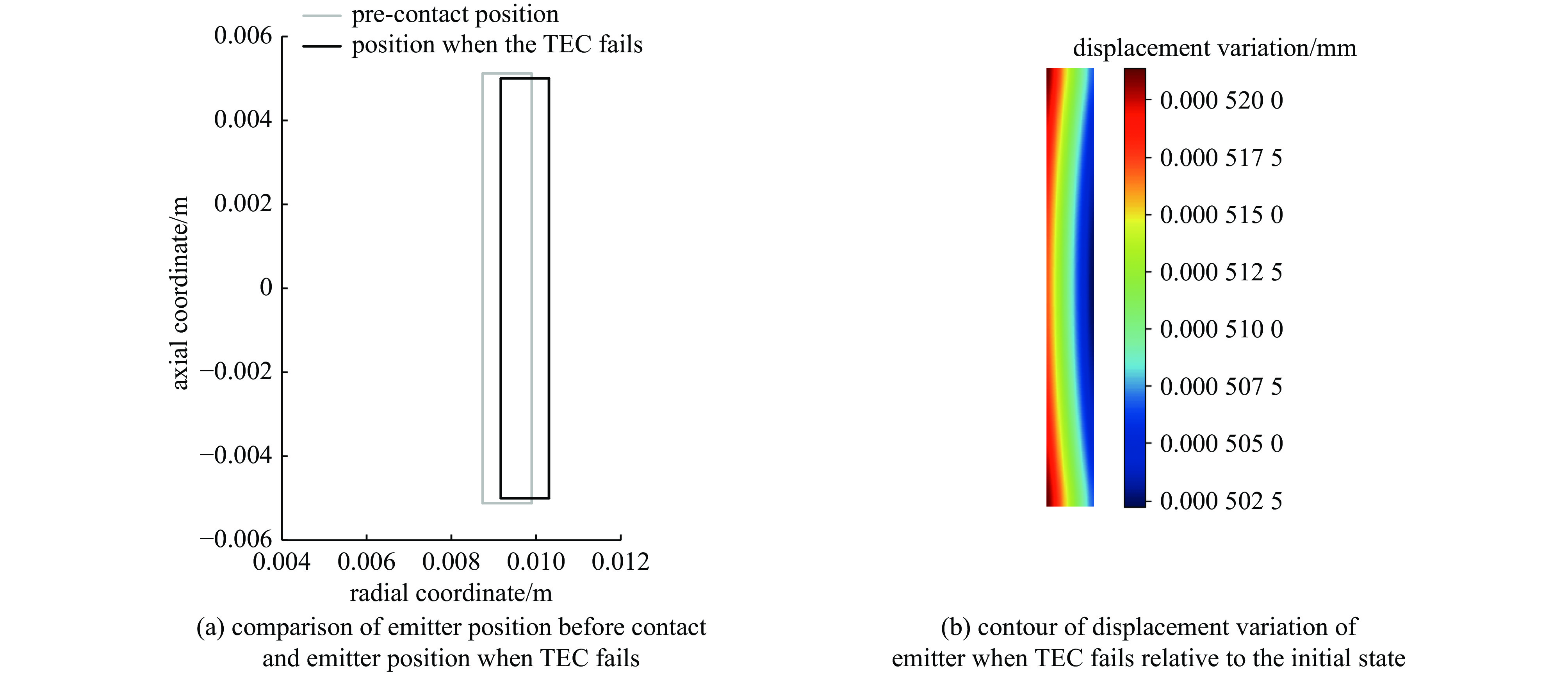

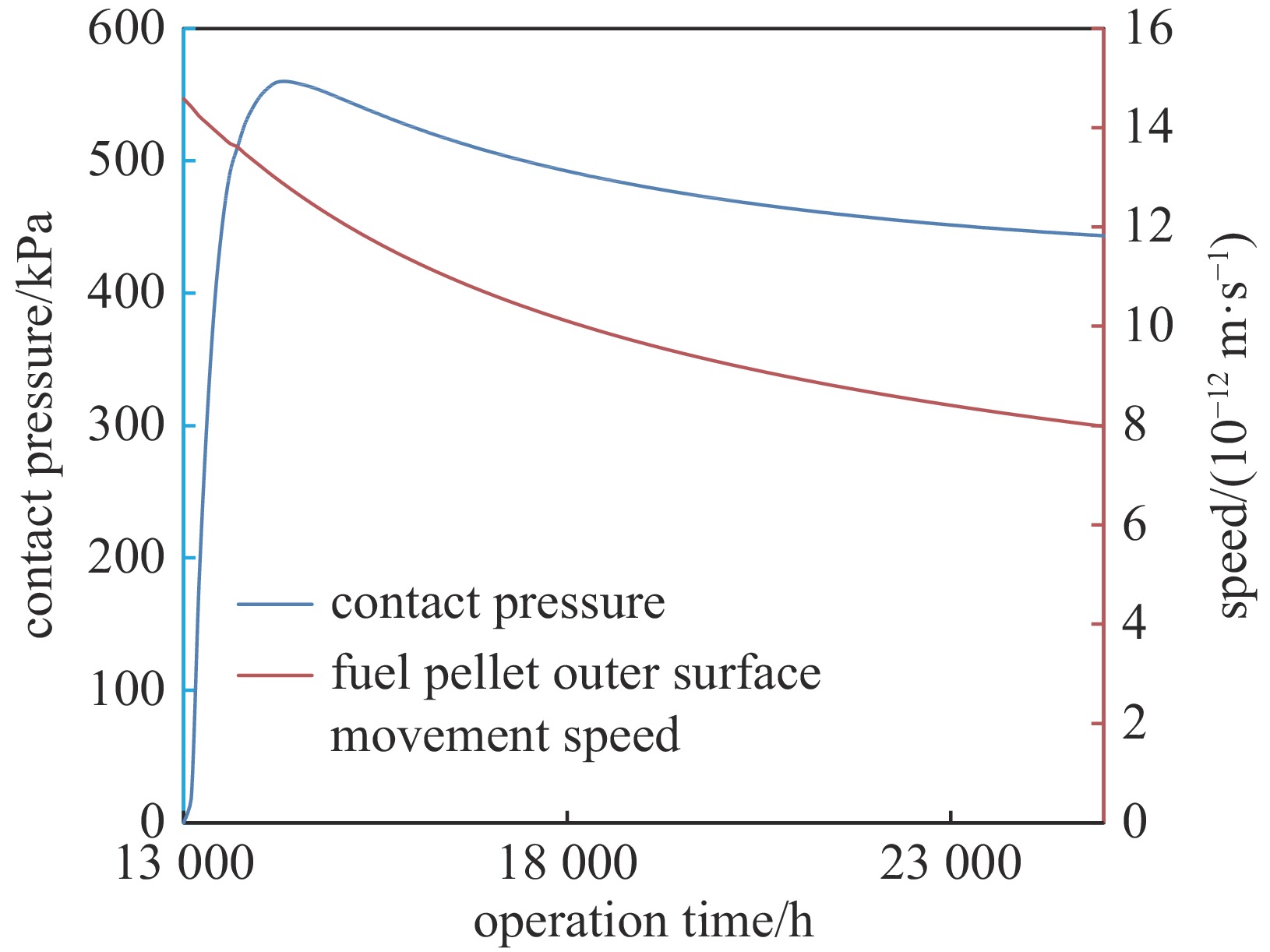

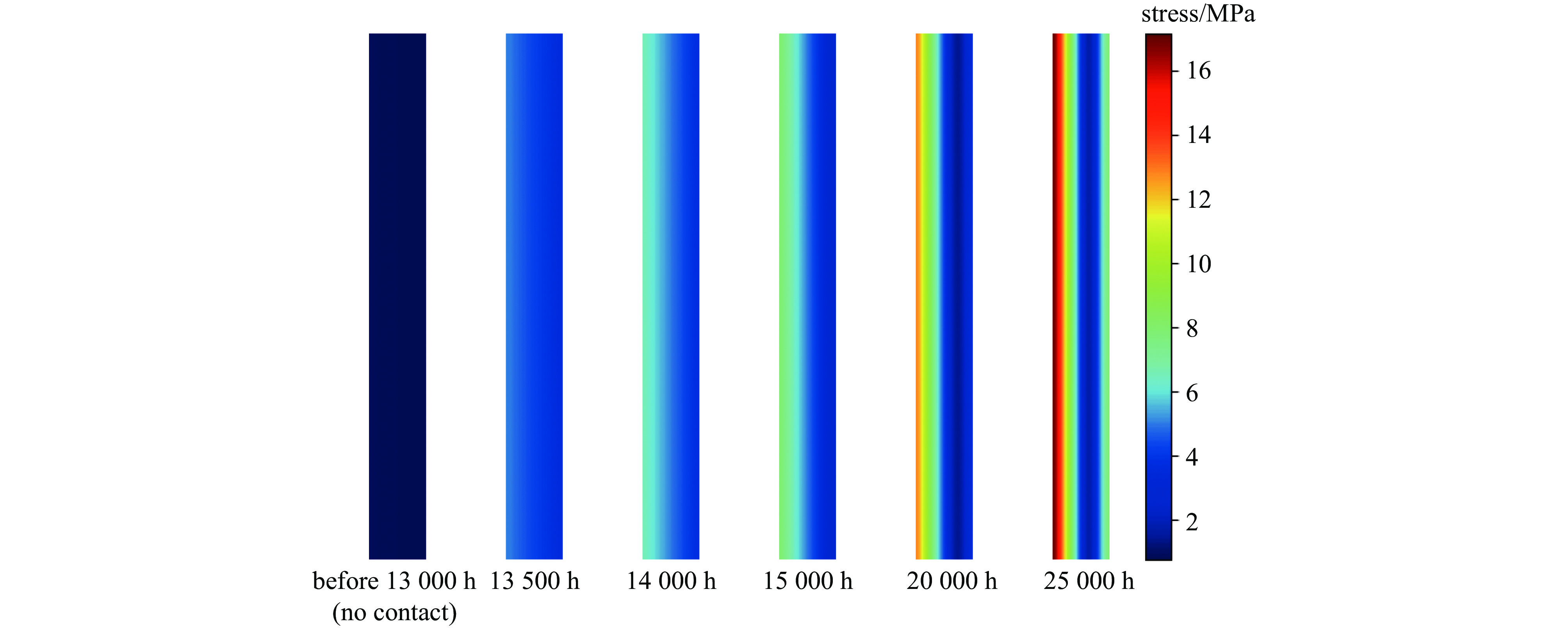

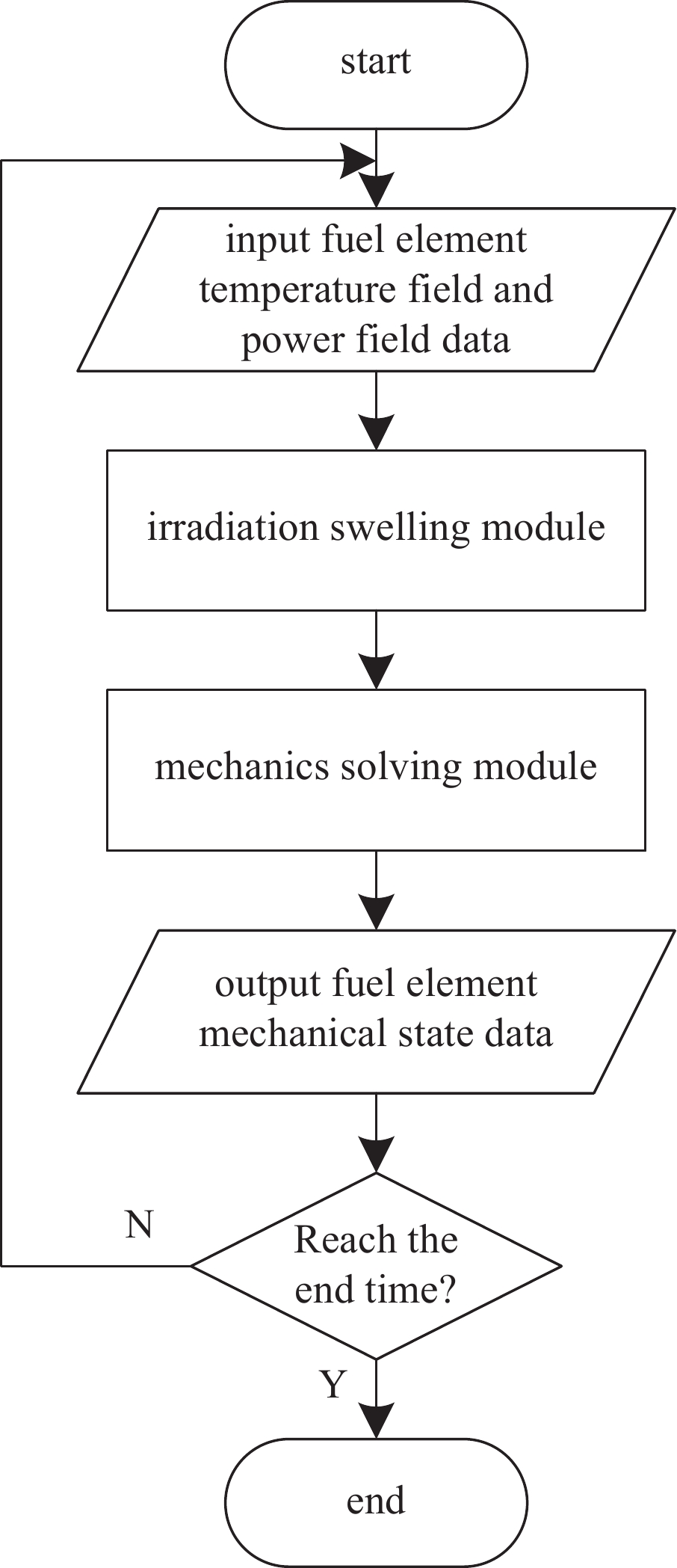

摘要: 为了实现对空间热离子反应堆燃料元件运行期间安全性能的预测,研究开发了一种燃料元件力学性能分析程序,并针对多层圆筒状的TOPAZ-Ⅱ热离子燃料元件开展了应力、应变和几何变形的高精度模拟。程序考虑了核燃料在高温辐照环境下的辐照肿胀,并分析了燃料芯块-发射极在发生接触后的力学响应问题,从而快速且准确地求解燃料芯块和发射极的力学状态,以对空间热离子反应堆运行期间的性能提供准确预测。结果表明:在正常运行情况下,空间热离子反应堆燃料会发生显著的肿胀效应,其造成的变形将导致燃料元件热电转换效率降低、元件失效等安全隐患。Abstract: To predict the safety performance of fuel elements during operation of a space thermionic reactor, this study developed a mechanical performance analysis program for fuel elements, and conducted high-precision simulation of stress, strain, and geometric deformation for the multi-layer cylindrical TOPAZ-II thermionic fuel element. The program takes into account the irradiation swelling of nuclear fuel under high-temperature radiation environment, and analyzes the mechanical response of the fuel pellet-emitter after contact, thereby quickly and accurately solving the mechanical state of the fuel pellet and emitter, to provide accurate prediction of the performance during operation of the space thermionic reactor. The results indicate that in normal operating conditions, the fuel of a space thermionic reactor undergoes significant swelling effects, which causes deformation that can lead to potential safety hazards such as reduced thermal-electric conversion efficiency and component failure.

-

Key words:

- space reactor /

- fuel element /

- irradiation swelling /

- mechanical analysis

-

表 1 模型相关系数

Table 1. Constants of the model

${K_1}/{{\text{K}}^{-{{1}}}}$ ${K_2}$ ${K_3}$ ${E_D}{\text{/J}}$ $9.80 \times {10^{ - 6}}$ $2.61 \times {10^{ - 3}}$ $3.16 \times {10^{ - 1}}$ $1.32 \times {10^{ - 19}}$ 表 2 算例的主要参数

Table 2. Main parameters of the case

elastic

modulus/GPaPoisson’s

ratioouter diameter of

cylinder/mminner diameter of

cylinder/mmexternal surface

pressure/MPainternal surface

pressure/MPa197 0.3 6 5.4 0.101 0.028 -

[1] Cameron G, Reynolds E. Integration of the Topaz 2 space nuclear reactor with the NEPSTP spacecraft[C]//Proceedings of the Intersociety Energy Conversion Engineering Conference. 1994: 3817. [2] Thurman J L. Optimization of steady-state thermal design of space radiators[J]. Journal of Spacecraft and Rockets, 1969, 6(10): 1114-1119. doi: 10.2514/3.29773 [3] Bellucci A, Girolami M, Trucchi D M. Thermionic and thermoelectric energy conversion[M]//Datas A. Ultra-High Temperature Thermal Energy Storage, Transfer and Conversion. Duxford: Woodhead Publishing, 2021: 253-284. [4] Pastore G, Pizzocri D, Rabiti C, et al. An effective numerical algorithm for intra-granular fission gas release during non-equilibrium trapping and resolution[J]. Journal of Nuclear Materials, 2018, 509: 687-699. doi: 10.1016/j.jnucmat.2018.07.030 [5] Olander D R, Wongsawaeng D. Re-solution of fission gas–A review: Part I. Intragranular bubbles[J]. Journal of Nuclear Materials, 2006, 354(1/3): 94-109. [6] Pastore G, Luzzi L, Di Marcello V, et al. Physics-based modelling of fission gas swelling and release in UO2 applied to integral fuel rod analysis[J]. Nuclear Engineering and Design, 2013, 256: 75-86. doi: 10.1016/j.nucengdes.2012.12.002 [7] Hagrman D L, Reymann G A. MATPRO-Version 11: a handbook of materials properties for use in the analysis of light water reactor fuel rod behavior[R]. Idaho Falls: Idaho National Lab. , 1979: 37-44. [8] Luscher W G, Geelhood K J. Material property correlations: comparisons between FRAPCON-3.4, FRAPTRAN 1.4, and MATPRO[R]. Richland: Pacific Northwest National Lab. , 2010: 42-53. [9] 薛守义. 弹塑性力学[M]. 北京: 中国建材工业出版社, 2005: 25-30Xue Shouyi. Theory of elasticity and plasticity[M]. Beijing: China Building Materials Press, 2005: 25-30 [10] Karahan A. Modelling of thermo-mechanical and irradiation behavior of metallic and oxide fuels for sodium fast reactors[D]. Cambridge: Massachusetts Institute of Technology, 2009: 99-103. [11] Deng Yangbin, Wu Yingwei, Gong Cheng, et al. Upgrade of FROBA code and its application in thermal-mechanical analysis of space reactor fuel[J]. Nuclear Engineering and Design, 2018, 332: 297-306. doi: 10.1016/j.nucengdes.2018.03.041 [12] Baker C. The fission gas bubble distribution in uranium dioxide from high temperature irradiated sghwr fuel pins[J]. Journal of Nuclear Materials, 1977, 66(3): 283-291. doi: 10.1016/0022-3115(77)90117-9 [13] White R J. The development of grain-face porosity in irradiated oxide fuel[J]. Journal of Nuclear Materials, 2004, 325(1): 61-77. doi: 10.1016/j.jnucmat.2003.10.008 [14] 朱滨. 弹性力学[M]. 合肥: 中国科学技术大学出版社, 2008: 148-151Zhu Bin. Elasticity[M]. Hefei: University of Science and Technology of China Press, 2008: 148-151 [15] 张系斌. 圆柱筒的应力与变形分析[J]. 工程力学, 2000(s1):456-460Zhang Xibin. Stress and deformation analysis of cylindrical tubes[J]. Engineering Mechanics, 2000(s1): 456-460 [16] Valentini B, Leuprecht C, Plankensteiner A, et al. Finite element analysis of the high-temperature creep deformation of a TZM heavy duty charge carrier[J]. International Journal of Refractory Metals and Hard Materials, 2015, 53: 104-110. doi: 10.1016/j.ijrmhm.2015.05.015 -

下载:

下载: