Anisotropic stacked epoxy composites with excellent thermal properties

-

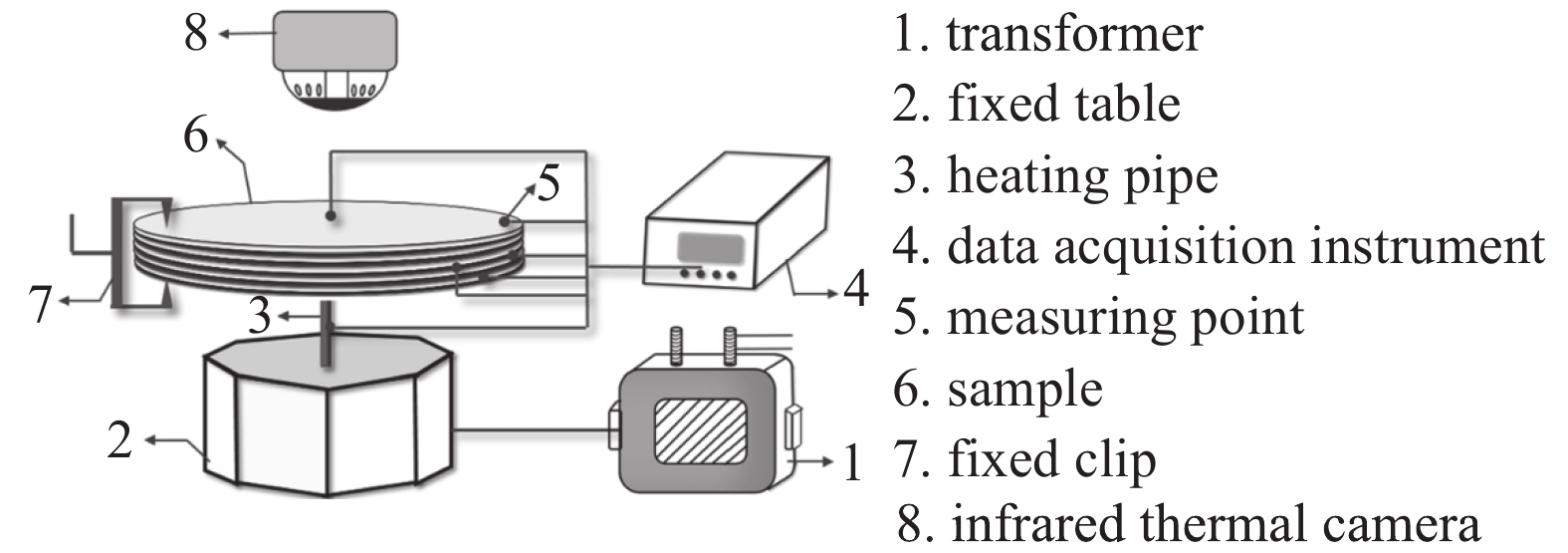

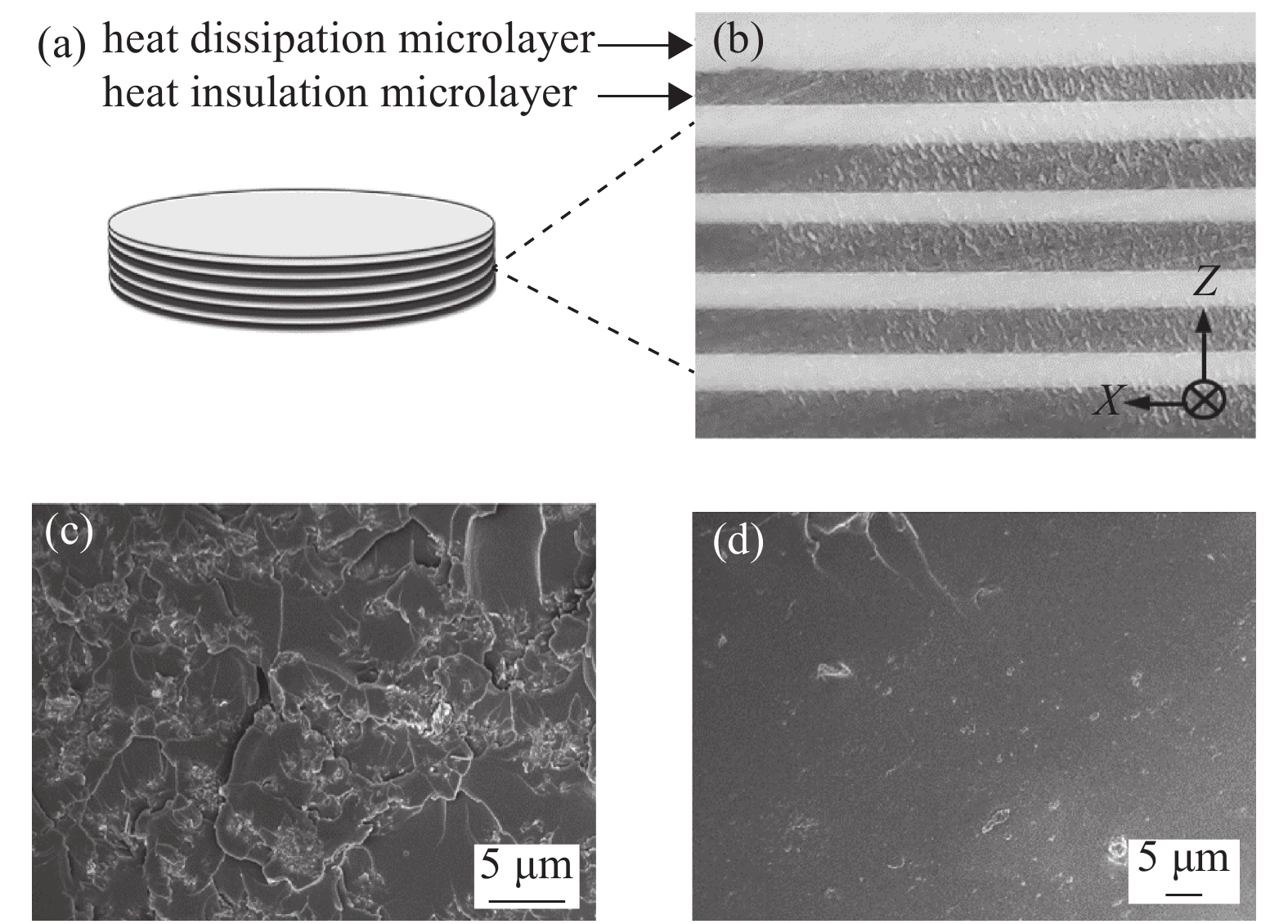

摘要: 基于导热-隔热原理,通过在环氧树脂(Epon)中添加质量分数为5%,15%,25%的六方氮化硼(h-BN)作为填料制备环氧基散热层,质量分数为1%的膨胀蛭石(E-ver)作为填料制备环氧基隔热层,设计了宏观交替堆叠的环氧复合材料,并进行了热防护性能的研究。研究结果表明:具有各向异性结构的复合材料,顶部中心温度较传统材料的温度下降13~16 ℃,热延迟时间大大提升,并随着h-BN含量的增加,热性能得到明显改善。理论分析了该堆叠结构下复合材料“横向散热、纵向抑热”的机理。Abstract: With the rapid development of high-power lasers and electronic technology, higher requirements have been proposed for the structure and material of the heat sink device. Based on the principle of conduction-insulation heat, alternating stack epoxy resin composites with excellent thermal protection were prepared, the hexagonal boron nitride (h-BN: 5%, 15%, 25%) and expanded vermiculite (E-ver: 1%) are used as fillers for heat dissipation layer and thermal insulation layer, respectively. The thermal protection performance experiment was completed. The result shows that the temperature of the top center is 13−16 °C lower than that of the traditional materials, and the thermal delay time is greatly improved. An increase in the h-BN content causes an increase in the thermal protection properties of the composites. The thermal mechanism of the anisotropic stacked composites was explained.

-

图 3 (a)堆叠结构样品模型;(b)复合材料横截面的光学显微镜图(c)h-BN(25%质量分数)散热微层的扫描电镜图;(d)膨胀蛭石(1%质量分数)隔热微层的扫描电镜图

Figure 3. (a) The sample model of stacked composites; (b) The optical microscope image of interfacial morphology; (c) The SEM image of h-BN(25%) filled epoxy resin composites; (d) The SEM image of E-ver (1%) filled epoxy resin composites.

-

[1] 王文, 褚金雷, 高欣, 等. 基于多芯片封装的半导体激光器热特性[J]. 强激光与粒子束, 2014, 26:011015. (Wang Wen, Chu Jinlei, Gao Xin, et al. Thermal characteristics of semiconductor laser based on multi-chip packaging[J]. High Power Laser and Particle Beams, 2014, 26: 011015 [2] 胡慧慧, 李凡, 李立群. 环氧树脂基导热绝缘复合材料的研究进展[J]. 绝缘材料, 2011, 44(5):27-30. (Hu Huihui, Li fan, Li Liqun. Progress in epoxy-based thermal conductive insulating composites[J]. Insulating Materials, 2011, 44(5): 27-30 [3] 陈敏孙, 江厚满, 刘泽金. 玻璃纤维/环氧树脂复合材料热分解动力学参数的确定[J]. 强激光与粒子束, 2010, 22(9):1971-1973. (Chen Minsun, Jiang Houman, Liu Zejin. Determination of thermal decomposition kinetic parameters of glass-fiber/epoxy composite[J]. High Power Laser and Particle Beams, 2010, 22(9): 1971-1973 [4] Mu Mulan, Wan Chaoying, Tony M. Thermal conductivity of 2D nano-structured graphitic materials and their composites with epoxy resins[J]. 2D Materials, 2017, 4(4): 537-545. [5] Zhang Xiaomeng, Zhang Jiajia, Zhang Xianlong, et al. Toward high efficiency thermally conductive and electrically insulating pathways through uniformly dispersed and highly oriented graphites close-packed with SiC[J]. Composites Science and Technology, 2017, 5(150): 217-226. [6] 冷鑫钰, 肖超, 陈璐, 等. 环氧树脂中3D氮化硼复合导热网络的构筑及性能[J]. 高分子材料科学与工程, 2019, 35(3):102-106. (Leng Xinyu, Xiao Chao, Chen Lu, et al. Constructing of 3D mirco-nano boron nitride networks in epoxy resin and characterization[J]. Polymer Materials Science and Engineering, 2019, 35(3): 102-106 [7] 习永广, 彭同江. 膨胀蛭石/石膏复合保温材料的制备与表征[J]. 复合材料学报, 2011, 28(5):156-161. (Xi Yongguang, Peng Tongjiang. Preparation and characterization of expanded vermiculite/gypsum thermal insulation composites[J]. Acta Materiae Compositae Sinica, 2011, 28(5): 156-161 [8] Shukla M, Sharma K. Effect of carbon nanofillers on the mechanical and interfacial properties of epoxy based nanocomposites: A review[J]. Composites Science and Technology, 2019, 61(4): 439-436. [9] Zhao Kang, Li Suishui, Huang Ming, et al. Remarkably anisotropic conductive MWCNTs /polypropylene nanocomposites with alternating microlayers[J]. Chemical Engineering Journal, 2019, 358(4): 924-935. [10] Yang Shuya, Huang Yanfei, Lei Jun, et al. Enhanced thermal conductivity of polyethylene/boron nitride multilayer sheets through annealing[J]. Composites: Part A, 2018, 107(8): 135-143. [11] Jiang Fang, Cui Siqi, Song Na, et al. Hydrogen bond regulated boron nitride network structures for improved thermal conductive property of polyamide-imide composites[J]. ACS Appl Mater Interfaces, 2018, 10(19): 16812-16821. doi: 10.1021/acsami.8b03522 -

下载:

下载: