Structural optimization design for beam position monitor support of High Energy Photon Source

-

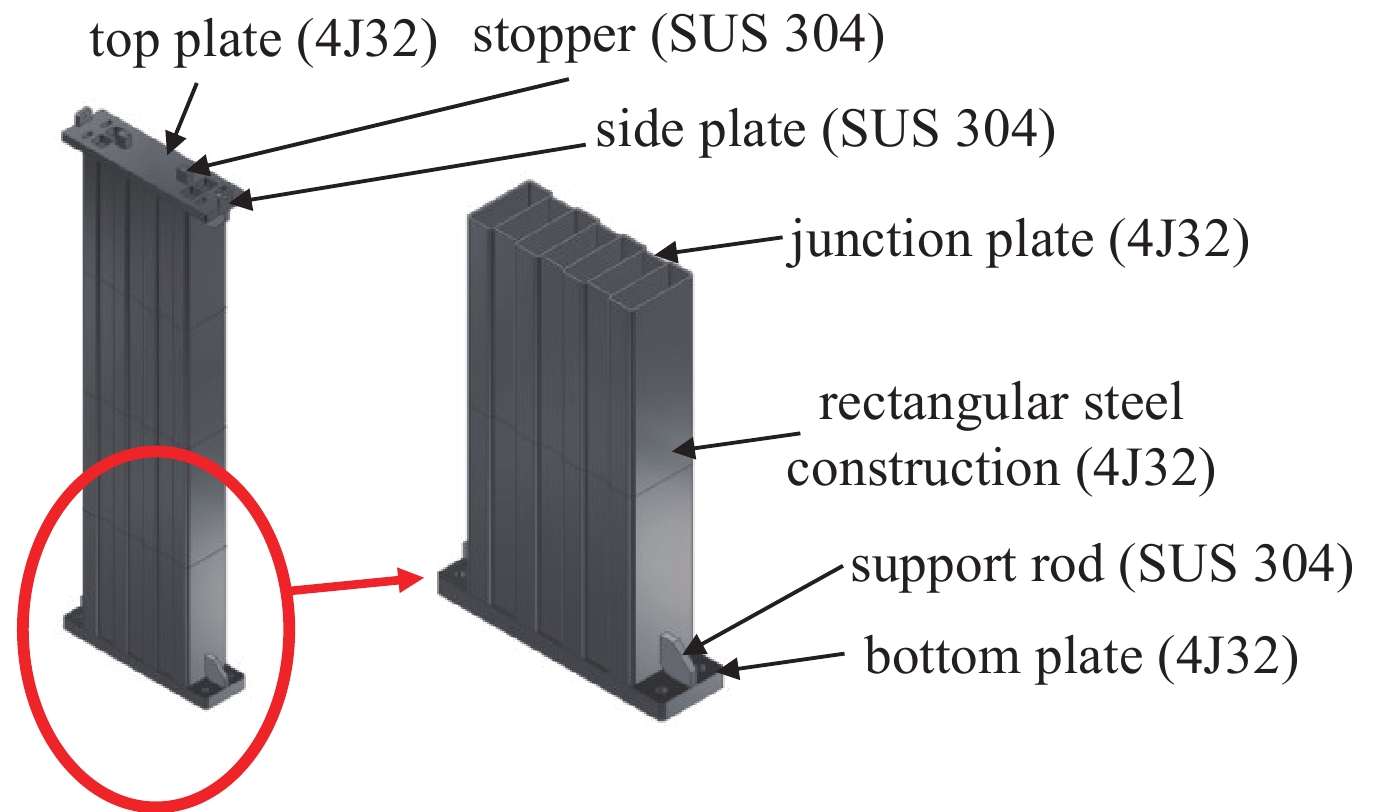

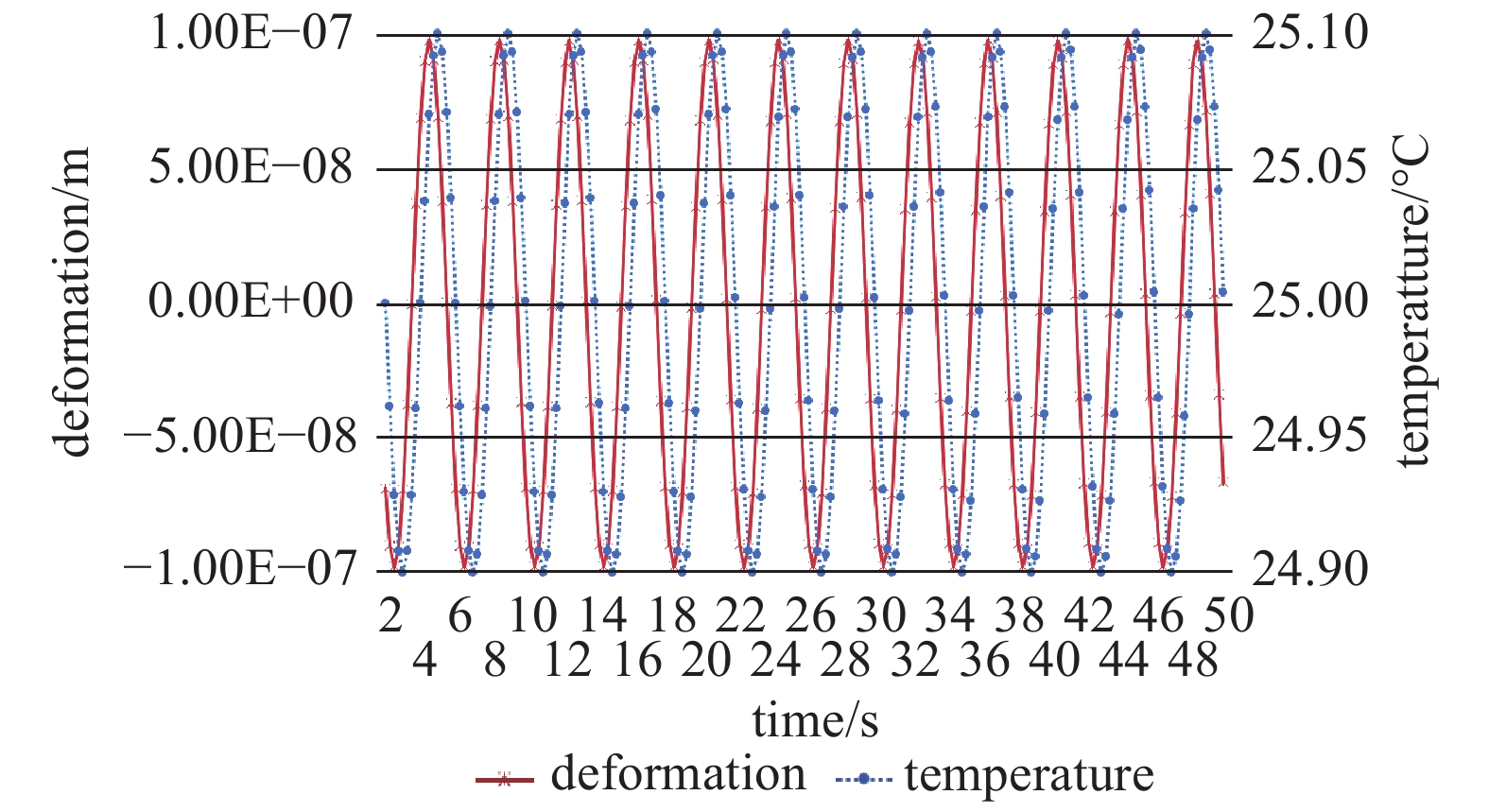

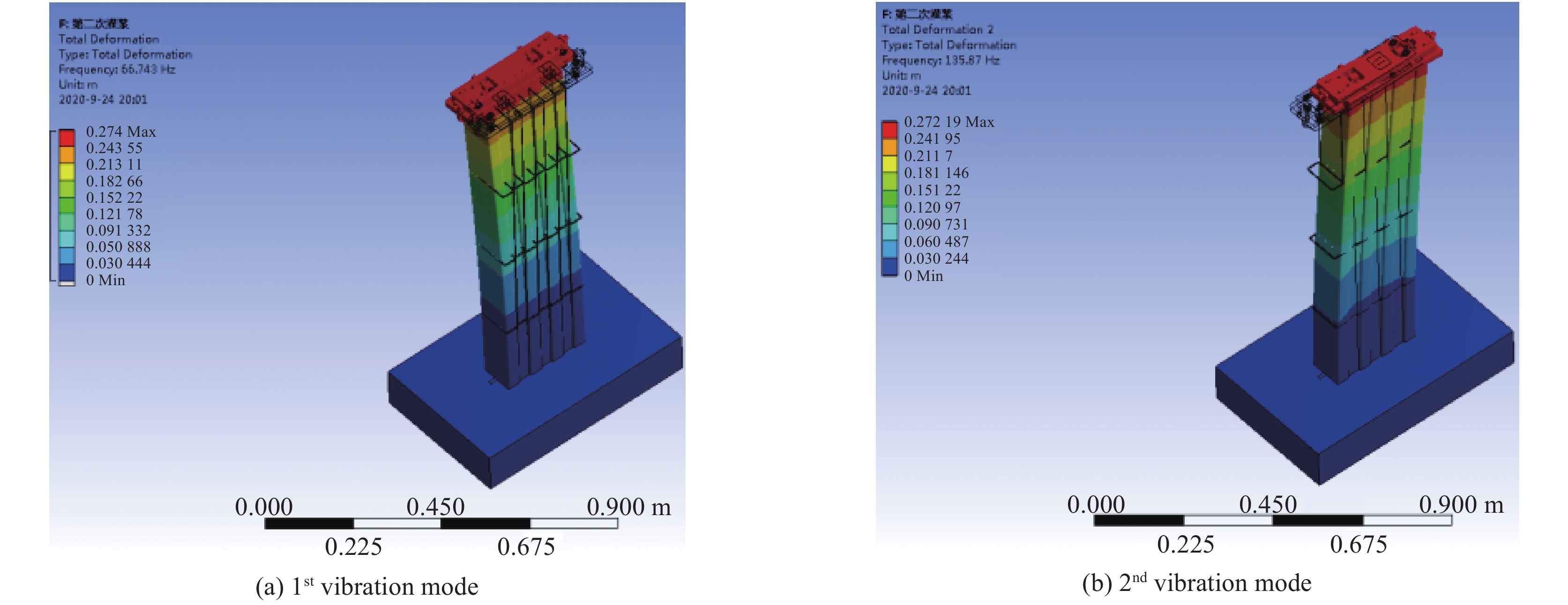

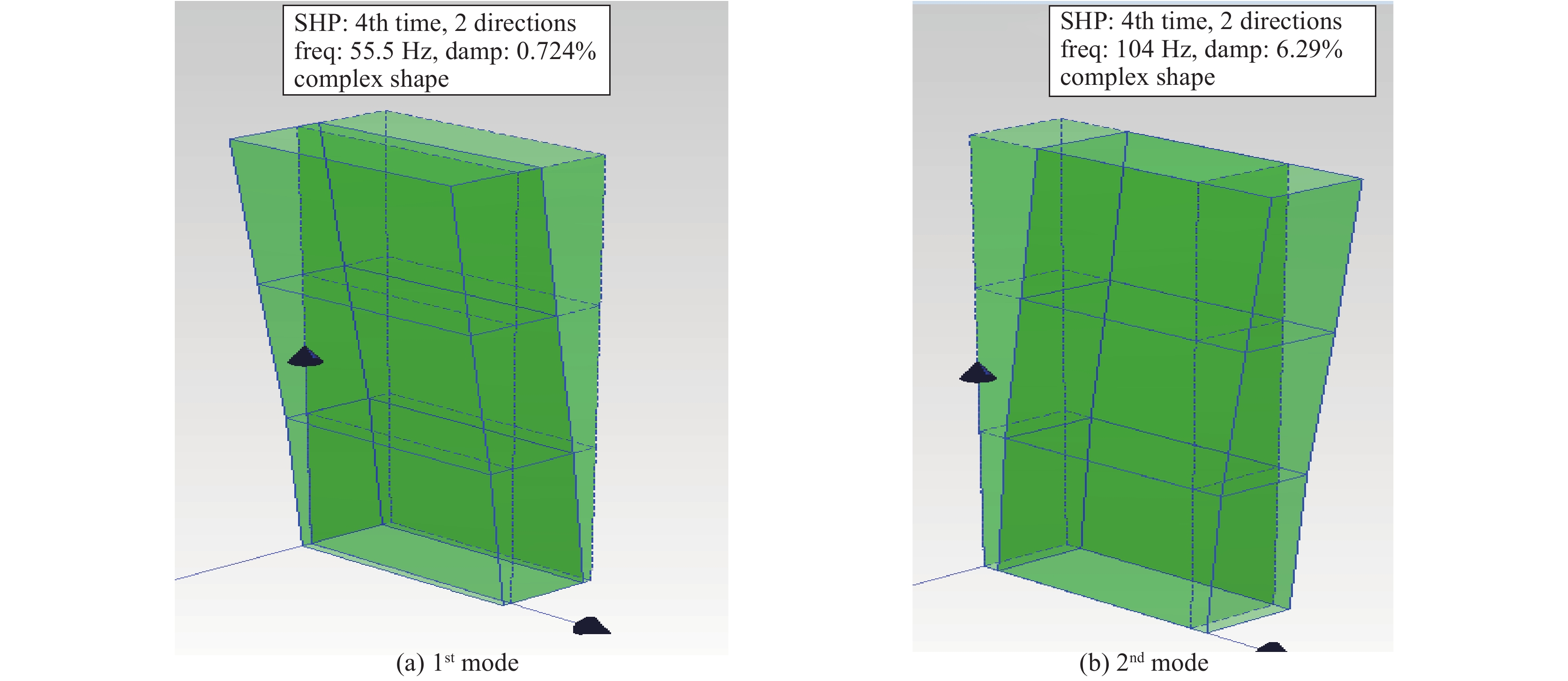

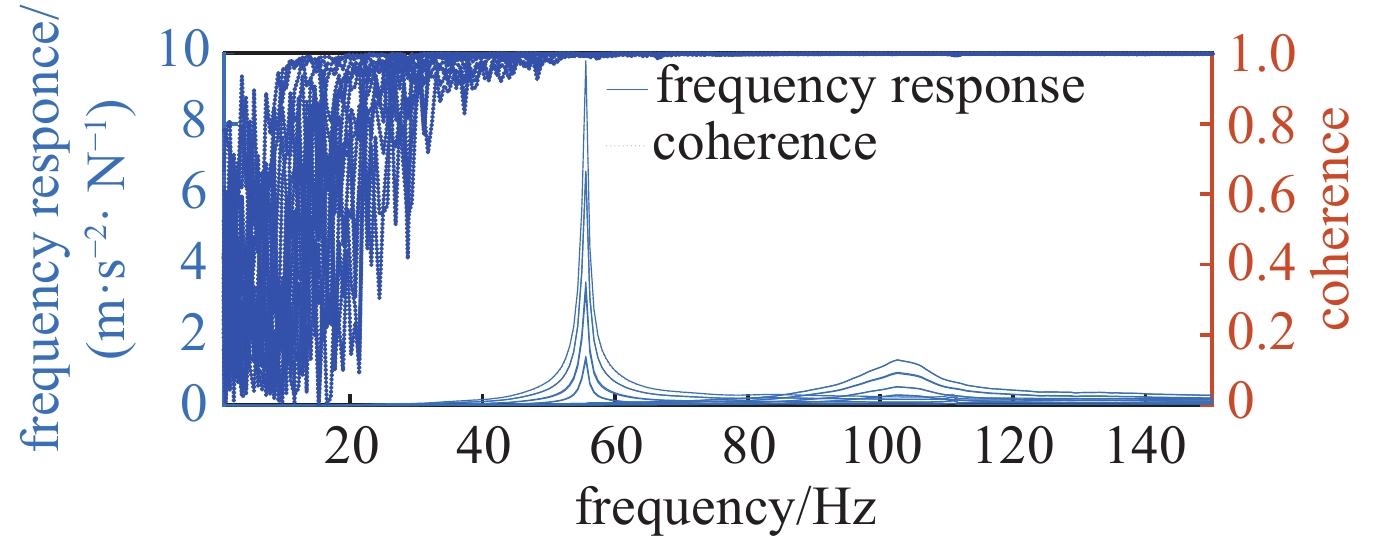

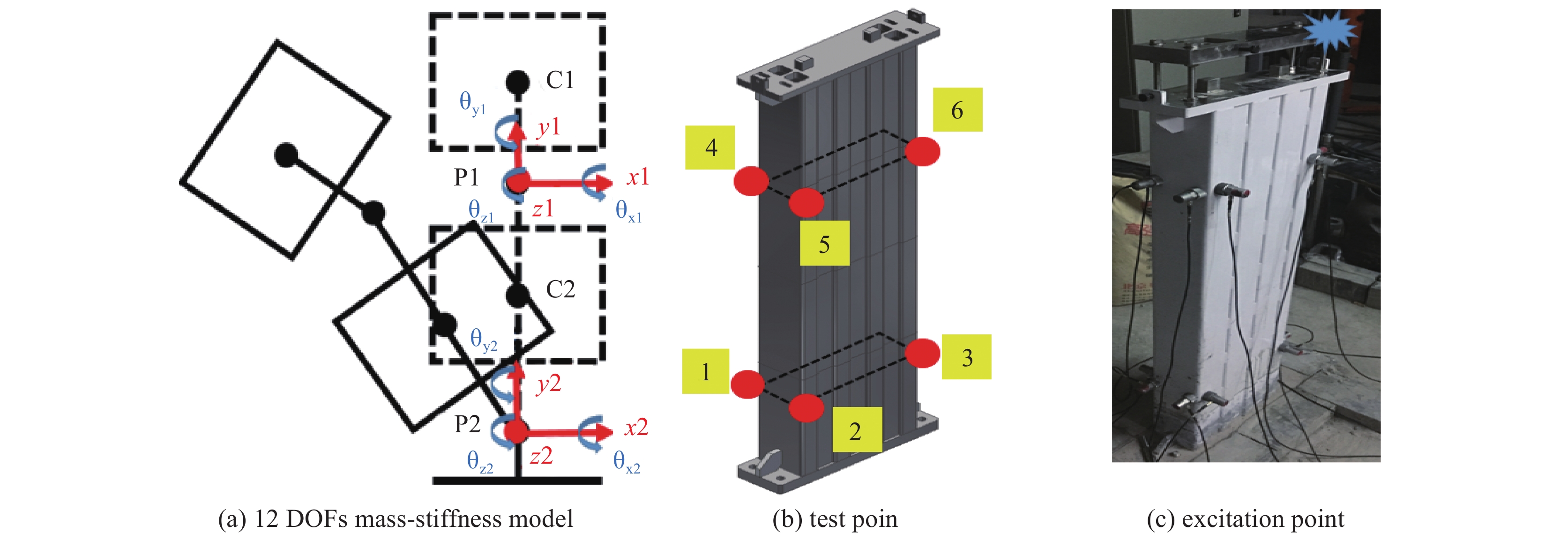

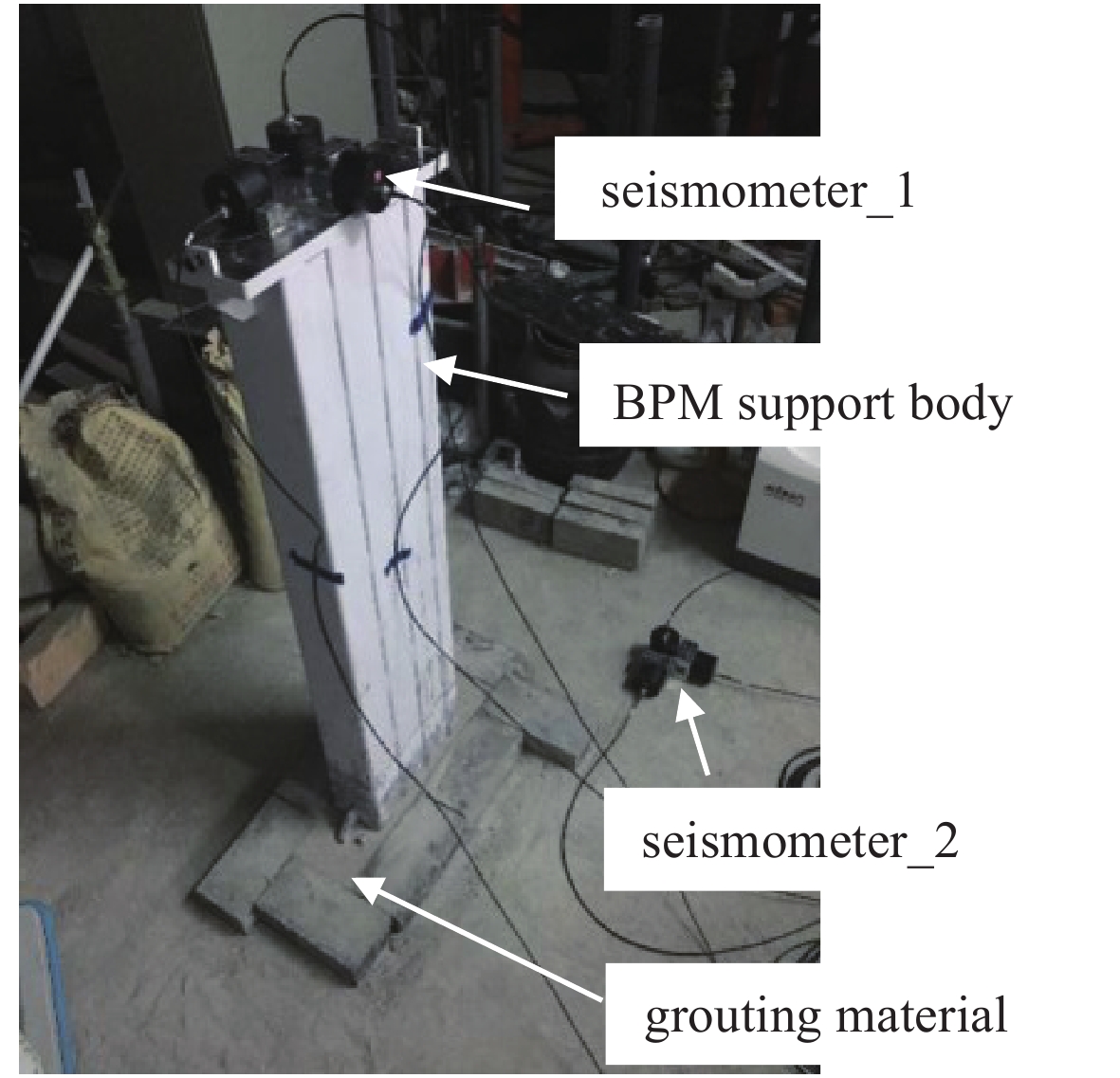

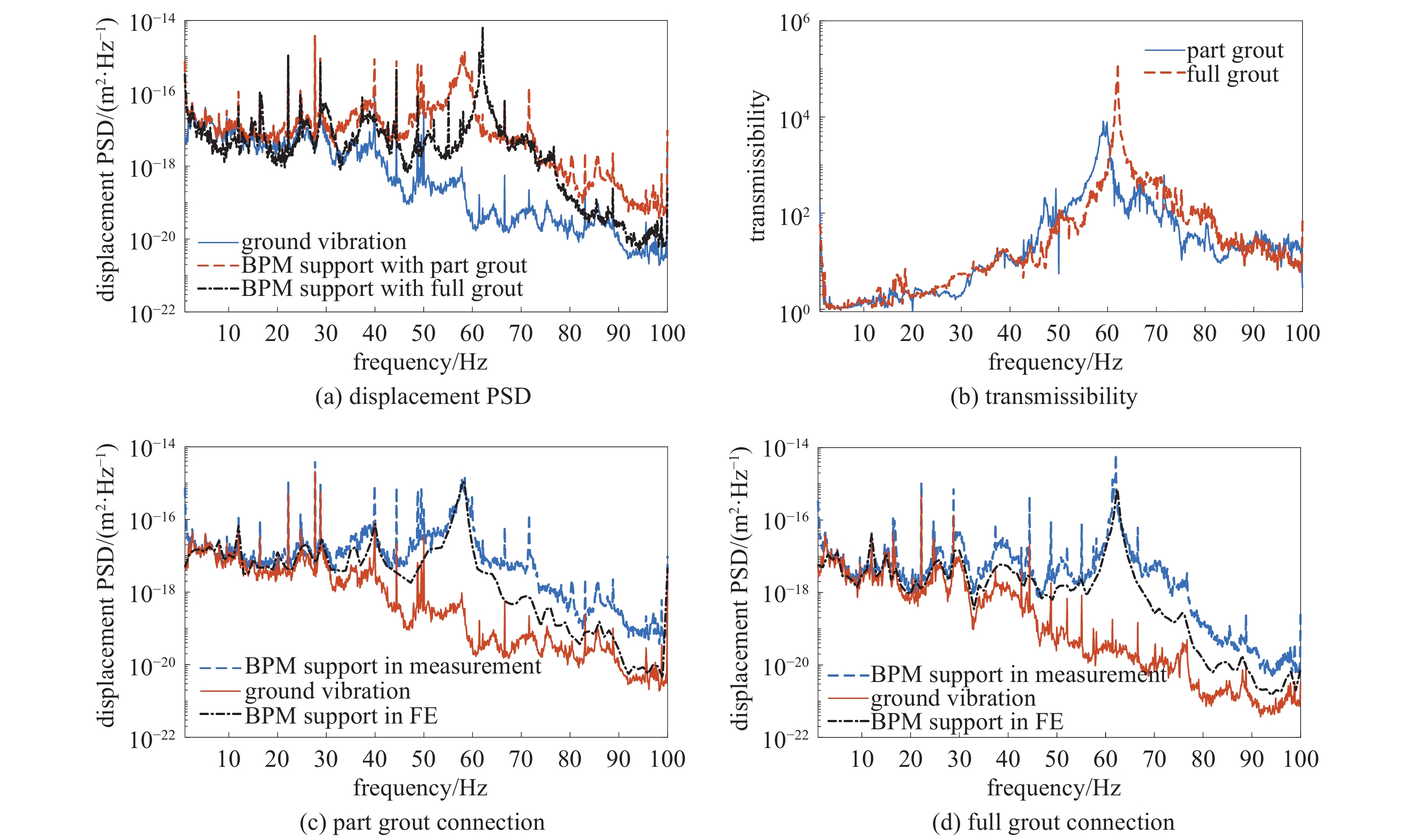

摘要: 从热稳定性和振动稳定性两个角度出发,优化设计得到了超高稳定的刚性支撑架结构;通过ANSYS有限元模态分析,验证了结构的热膨胀变化量和特征频率;采用混凝土二次灌浆方法对支撑架进行地面固定和特征频率测试,结果表明,支撑架结构的特征频率达到61.9 Hz、振动幅值小于30 nm,均满足设计要求。最后采用动态刚度测试方法,得到混凝土二次灌浆层的主要刚度值,进一步验证支撑架结构优化结果的准确性。Abstract: Based on thermal stability and vibration stability, an ultra stability structure of rigid support is designed and optimized. Through the finite element modal analysis of ANSYS, the thermal expansion variation and the characteristic frequency of the support is verified. The support is fixated to the ground by using the method of concrete grouting and then the characteristic frequency is tested. The test results show that the characteristic frequency of the support reaches up to 61.9 Hz and the vibration amplitude is less than 30 nm, both of which meet the design requirements. Finally, the method of dynamic stiffness testing is adopted to obtain the stiffness value of the concrete grouting, and the accuracy of the optimization results of the support is further verified.

-

表 1 材料参数

Table 1. Material parameters

material coefficient of thermal expansion / ℃−1 Poisson’s ratio modulus of elasticity / GPa density / (kg·m3) Invar 4J32 0.63×10−6 0.23 145 8140 SUS 304 1.7×10−5 0.31 193 7750 concrete 1.4×10−5 0.18 30 2300 表 2 主支撑体不同固定方式的仿真结果

Table 2. Simulation results of different fixed modes of BPM support

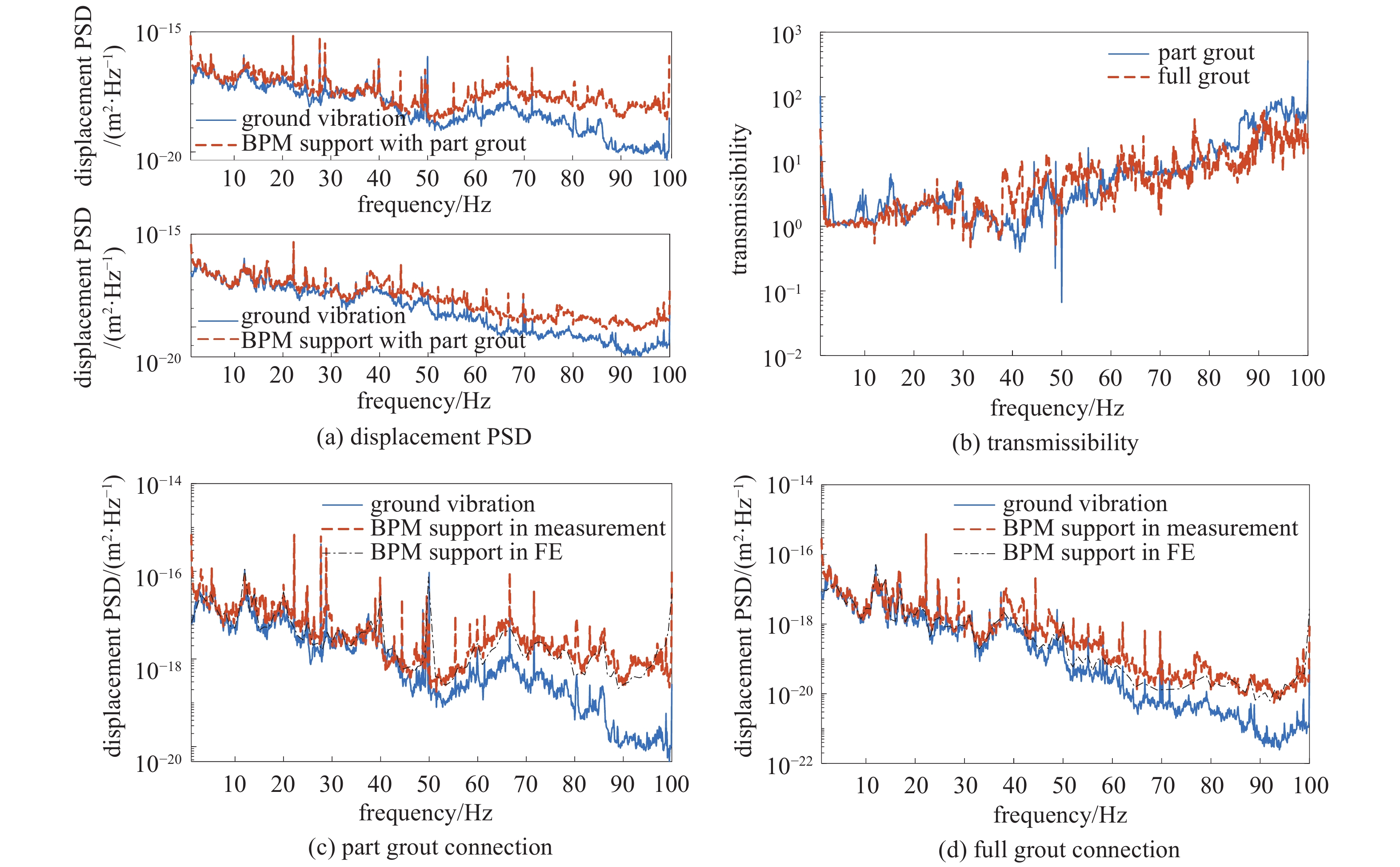

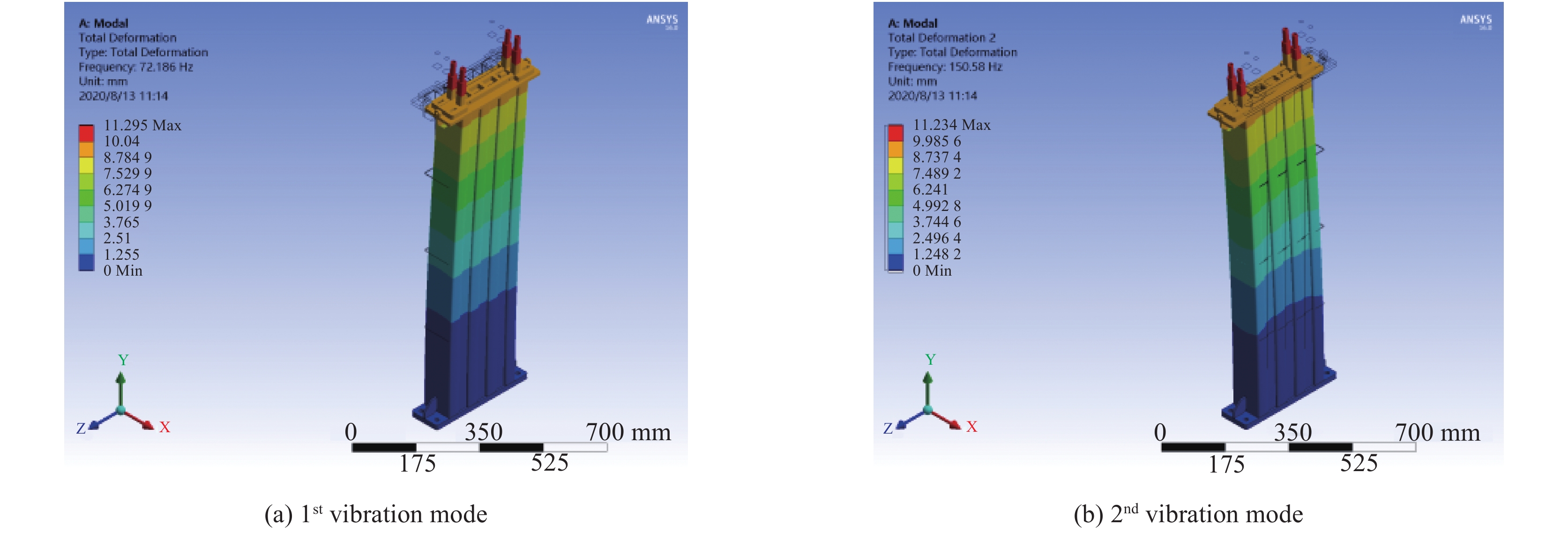

simulation natural frequency / Hz 1st(longitudinal) 2nd(lateral) ground bolt 38.7 107.4 part grout 63.8 132.5 full grout 66.7 135.9 表 3 主支撑体模态测试结果与仿真误差

Table 3. Modal test results and simulation error of BPM support

fixation mode experimental natural frequency / Hz simulation error 1st

(longitudinal)2nd

(lateral)1st

(longitudinal)2nd

(lateral)ground bolt 16.9 48.4 129% 122% part grout 55.5 104 15% 27% full grout 61.8 107 8% 27% 表 4 测试与仿真结果

Table 4. Test and simulation results

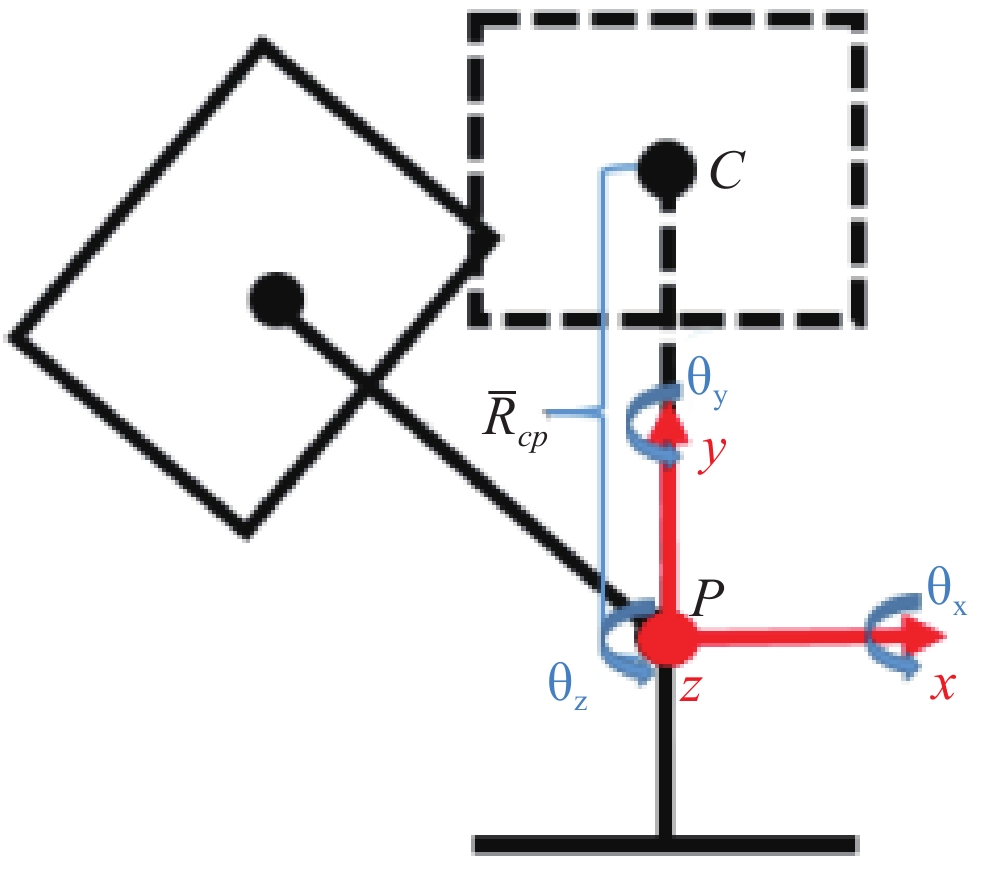

stiffness / N·m·rad−1 simulation natural frequency / Hz simulation error 1st(longitudinal) 2nd(lateral) 1st(longitudinal) 2nd(lateral) 1st(longitudinal) 2nd(lateral) ground bolt 2.3×105 2.2×106 16.8 48.5 0.6% 0.2% part grout 9×106 2.1×107 55.5 103.5 0 0.5% full grout 3.4×107 2.5×107 61.9 107.1 0.2% 0.1% 表 5 主支撑体振动响应测试结果(RMS 1~100 Hz)

Table 5. BPM support vibration response test(RMS 1~100 Hz)

measurement simulation longitudinal lateral longitudinal lateral ground/

nmBPM

support/nmratio ground/

nmBPM

support/nmratio ground/

nmBPM

support/nmratio ground/

nmBPM

support/nmratio full grout 19.5 62.8 3.22 23.7 29.4 1.24 19.5 47.6 2.44 23.7 27.3 1.15 part grout 22.6 82.49 3.65 23.3 29.6 1.27 22.6 59.4 2.63 23.3 27.3 1.17 -

[1] Jiang Xiaoming, Wang Jiuqing, Qin Qing, et al. Chinese high energy photon source and the test facility[J]. Scientia Sinica Physica, Mechanica & Astronomica, 2014, 10: 1075-1094. [2] Bialowons W, Amirikas R, Bertolini A, et al. Measurement of ground motion in various sites[C]//10th European Particle Accelerator Conference. 2006: 147-153. [3] Seryi A, Hendrickson L, Raimondi P, et al. Simulation studies of the NLC with improved ground motion models[C]//20th International Linac Conference. 2000: 1423-1429. [4] Amirikas R, Ehrlichmann H, Bialowons W, et al. Ground motion and comparison of various sites[R]. EUROTeV-023-1, 2005. [5] 王之琢, 曹建社, 王梓豪, 等. 高能光源BPMS独立支架系统设计[J]. 强激光与粒子束, 2019, 31:095101. (Wang Zhizhuo, Cao Jianshe, Wang Zhihao, et al. Independent support system for beam position monitors in HEPS[J]. High Power Laser and Particle Beams, 2019, 31: 095101 doi: 10.11884/HPLPB201931.190072 [6] Liu Renhong, Qu Huamin, Kang Ling, et al. Modal analysis of AC quadrupole magnet system for CSNS/RCS[J]. Chinese Physics C, 2013, 37: 087002. doi: 10.1088/1674-1137/37/8/087002 [7] 王梓豪, 李春华, 王之琢, 等. 基于模态匹配法的接触刚度[J]. 强激光与粒子束, 2019, 31:085101. (Wang Zihao, Li Chunhua, Wang Zhizhuo, et al. Contact stiffness measurement based on modal matching method[J]. High Power Laser and Particle Beams, 2019, 31: 085101 doi: 10.11884/HPLPB201931.190033 [8] Jankovics D, Gohari H, Tayefeh M, et al. Developing topology optimization with additive manufacturing constraints in ANSYS[J]. IFAC Papers OnLine, 2018, 51(11): 1359-1364. doi: 10.1016/j.ifacol.2018.08.340 [9] 李国会, 徐宏来, 向汝建, 等. 金属和玻璃胶合体热膨胀仿真及实验验证[J]. 强激光与粒子束, 2019, 31:121002. (Li Guohui, Xu Honglai, Xiang Rujian, et al. Simulation and experimental verification of thermal expansion of metal and glass cementing bodies[J]. High Power Laser and Particle Beams, 2019, 31: 121002 doi: 10.11884/HPLPB201931.190272 [10] 王柯颖, 范宣华, 陈学前, 等. 基于PANDA平台的光机部件随机振动响应分析[J]. 强激光与粒子束, 2020, 32:011021. (Wang Keying, Fan Xuanhua, Chen Xueqian, et al. Random vibration response analysis of Shenguang laser facility component based on PANDA platform[J]. High Power Laser and Particle Beams, 2020, 32: 011021 doi: 10.11884/HPLPB202032.190269 [11] 陈学前, 沈展鹏, 鄂林仲阳, 等. 基于薄层单元与弹簧单元的滚动直线导轨副动力学建模[J]. 强激光与粒子束, 2020, 32:072001. (Chen Xueqian, Shen Zhanpeng, Elin Zhongyang, et al. Dynamic modeling on a linear rolling guide based on thin layer element and spring element[J]. High Power Laser and Particle Beams, 2020, 32: 072001 -

下载:

下载: