Microstructure characterization and thermionic emission performance of barium-tungsten cathode

-

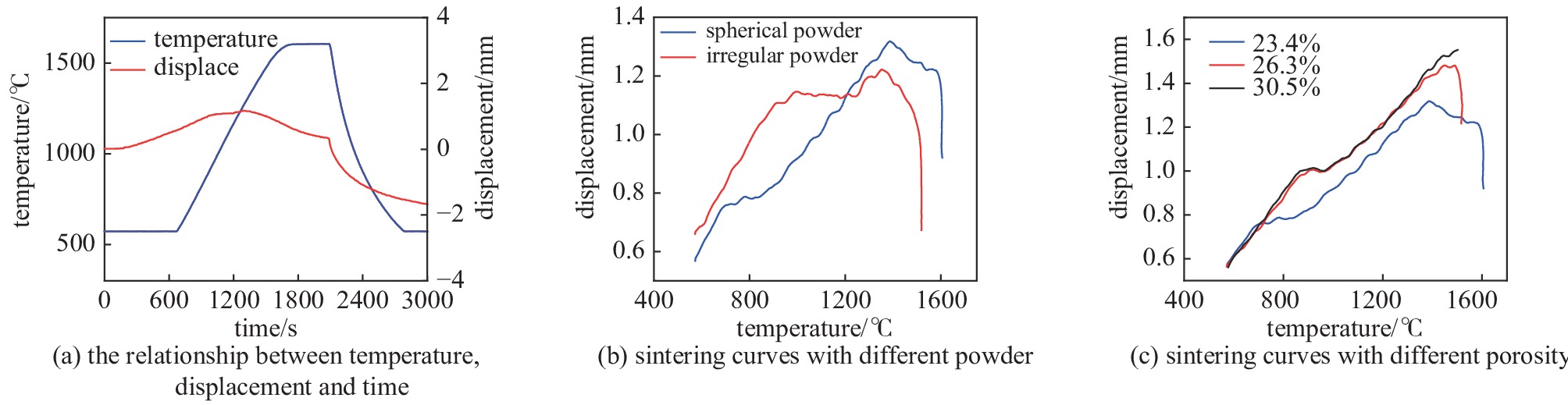

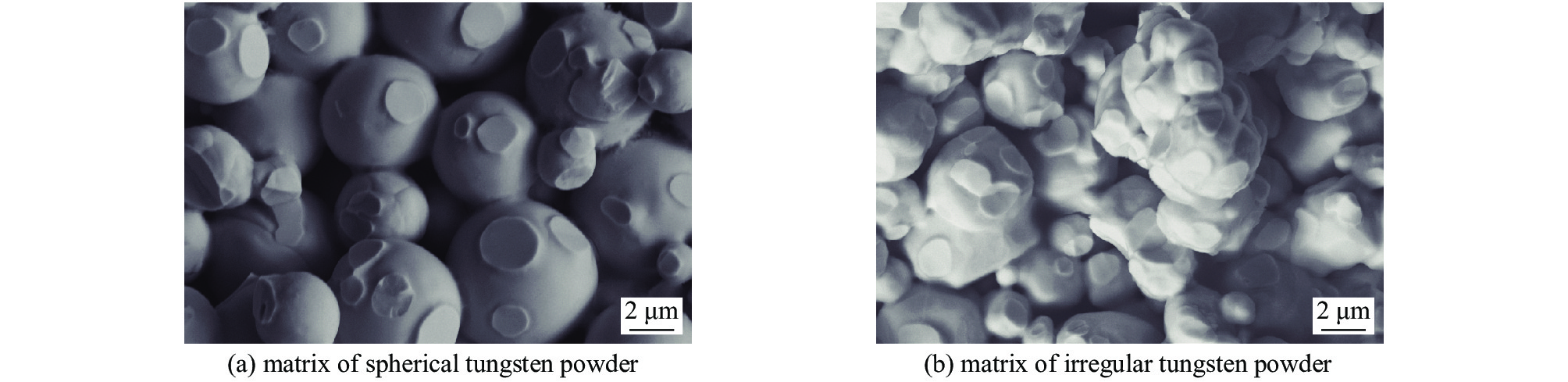

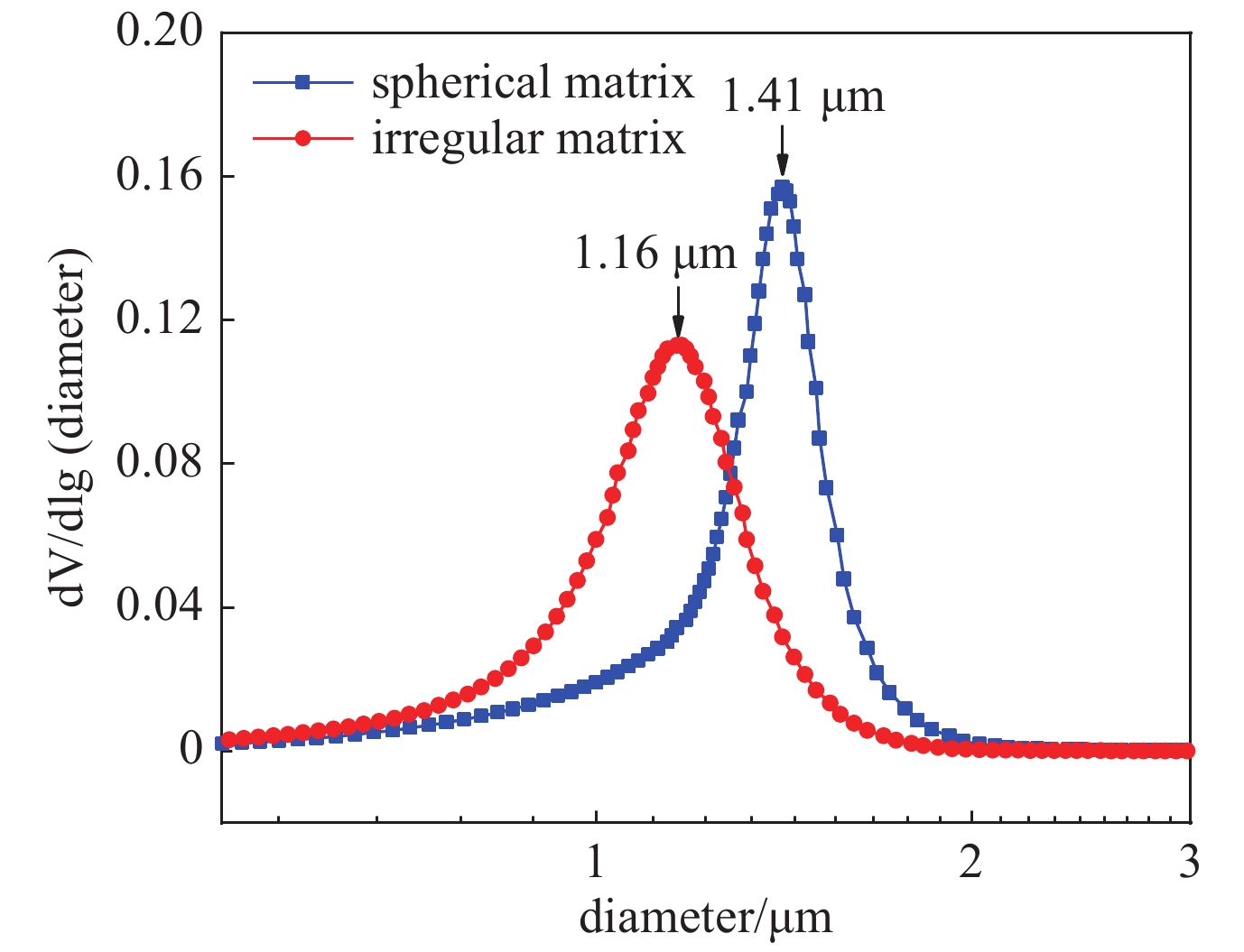

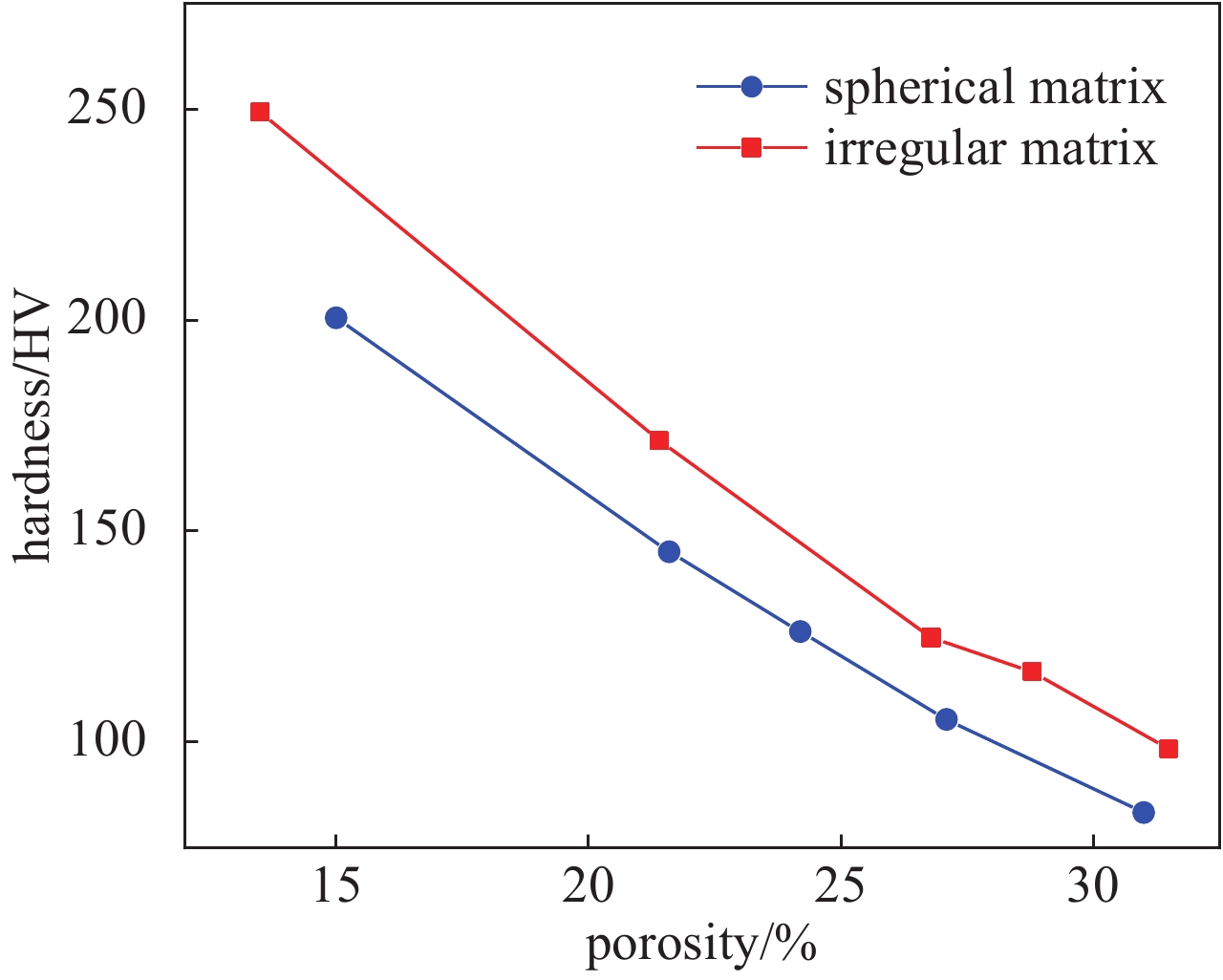

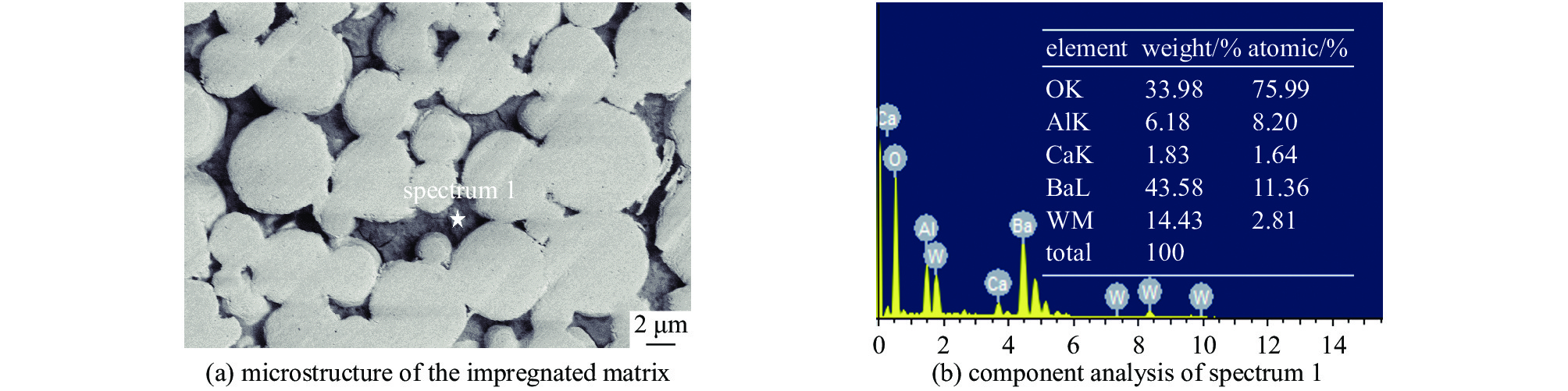

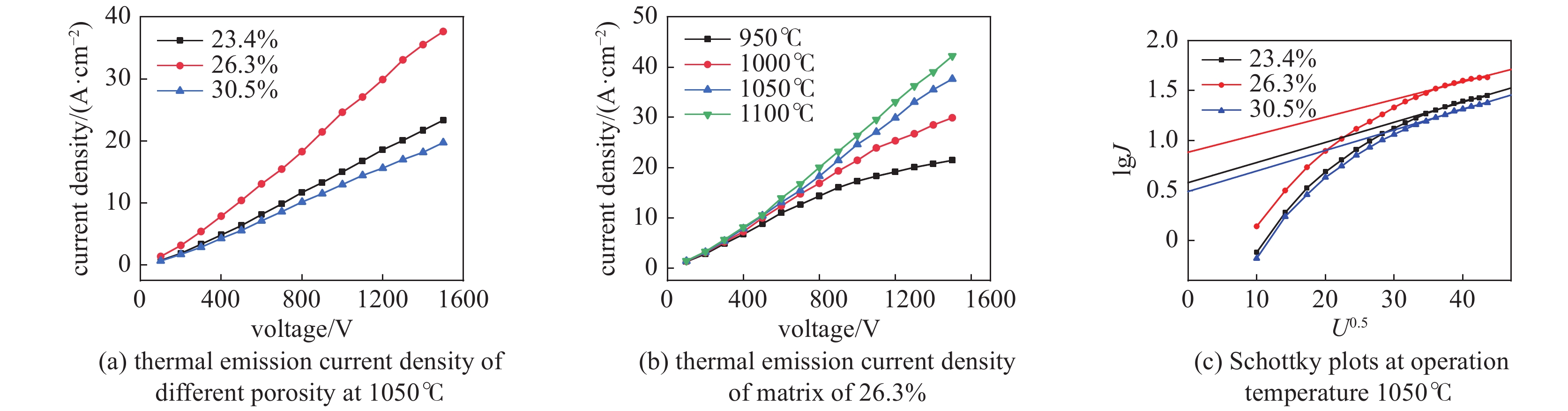

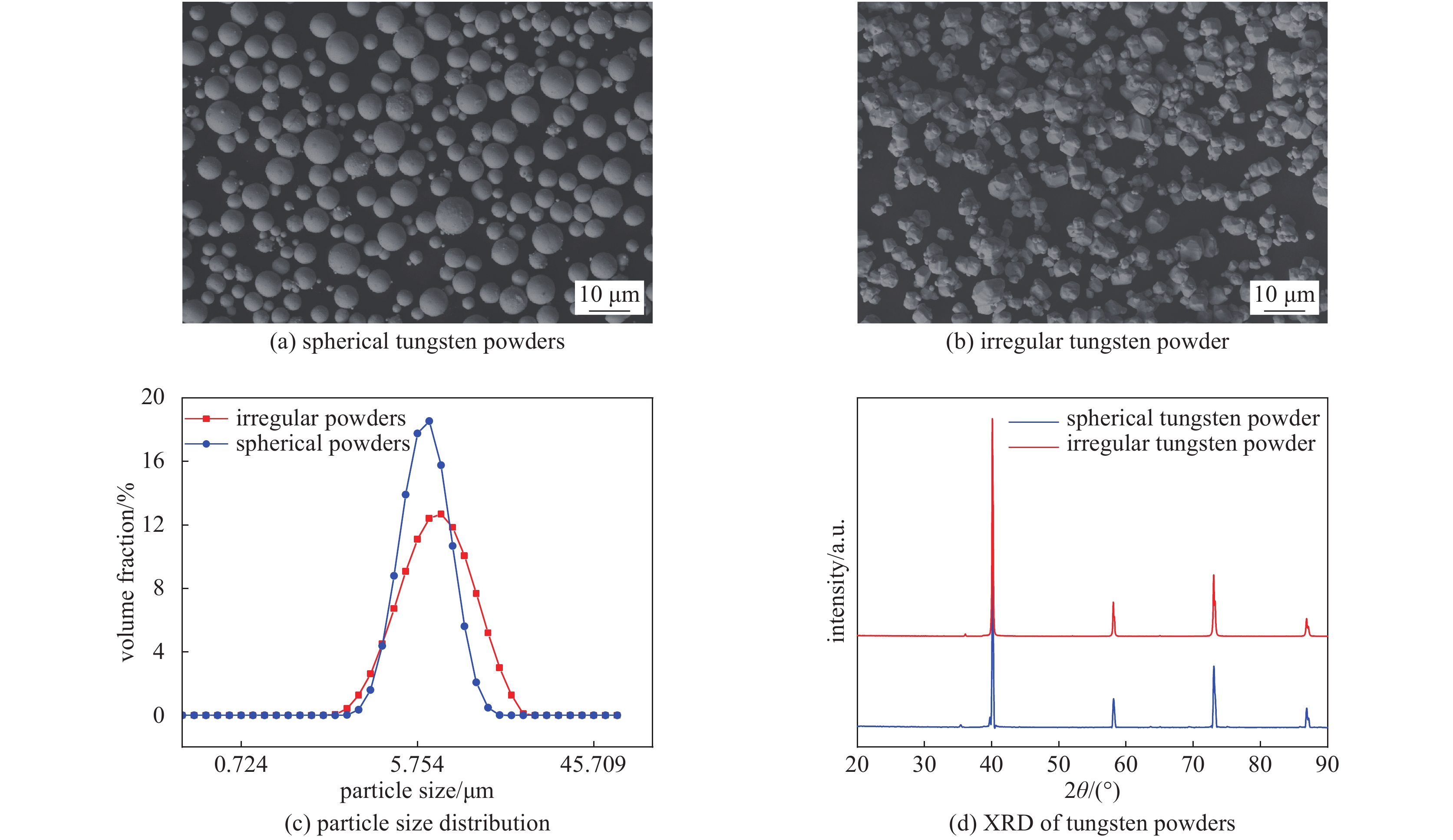

摘要: 利用正交试验探讨了放电等离子技术工艺参数(温度、压力、保温时间)对钡-钨(Ba-W)阴极中的W的孔隙度的影响规律,获得了孔隙率在23%~30%内变化时所需要的最佳工艺参数。在此基础上,制备出了具有不同孔隙度的球形W基体和普通不规则的W基体。研究表明:球形多孔W颗粒间堆积、排列有序,无闭孔,孔径分布集中而均匀,在26.3%的孔隙度下中值孔径为1.41 μm;机械性能方面,球形钨粉基体维氏硬度低于传统普通不规则钨多孔体。在脉宽10 μs、频率1000 Hz的条件下,阴极脉冲发射电流密度随着孔隙度的增大,先增大后减小。当基体孔隙度为26.3%时,阴极电流发射密度最大,在1050 ℃,偏离点发射电流密度可达24.62 A/cm2,零场发射电流密度为7.62 A/cm2,功函数为1.95 eV。Abstract: The effect of the parameters (sintering temperature, pressure, holding time) of spark plasma sintering technique on the W porosity of Ba-W cathode was studied by orthogonal method. When the W porosity varied in the range of 23%−30%, the corresponding process parameters were obtained. On this basis, the spherical and traditional irregular W matrix with different porosity were sintered. The results show that the spherical porous W particles were packed and arranged orderly, and the pore size distribution was concentrated and uniform. When the porosity of spherical W was 26.3%, the size of the median pore was 1.41 μm. The vickers hardness of spherical tungsten matrix was lower than that of conventional irregular tungsten matrix. Under the condition of pulse width 10 μs and frequency 1000 Hz, the impulse current density of Ba-W cathode increased at first and then decreased with the increase in porosity. The maximum current density belonged to the Ba-W cathode with the matrix porosity of 26.3%. At 1050 ℃, the off-point emission current density of Ba-W cathode reached 24.62 A/cm2, the corresponding zero-field current density and workfunction were 7.62 A/cm2 and 1.95 eV, respectively.

-

表 1 参数因素水平

Table 1. Parametric factor level

level temperature/℃ holding time/min pressure/MPa 1 1500 1 15 2 1600 2 20 3 1700 3 25 表 2 正交试验方案及结果

Table 2. Orthogonal experimental results

number A B C error porosity/% 1 1500 1 15 1 28.34 2 1500 2 20 2 25.33 3 1500 3 25 3 21.00 4 1600 2 15 3 22.05 5 1600 3 20 1 19.56 6 1600 1 25 2 21.97 7 1700 3 15 2 19.46 8 1700 1 20 3 18.15 9 1700 2 25 1 15.97 表 3 正交试验极差分析

Table 3. Orthogonal experiment range analysis

A B C error K 74.67 68.46 69.85 63.87 63.58 63.35 63.04 66.76 53.58 60.02 58.94 61.20 R 21.09 8.44 10.91 5.56 表 4 正交试验方差分析,各因素偏方差和(SA)、自由度(f )与置信度(α)

Table 4. Orthogonal experiment variance analysis,sum of variance(SA),degree of freedom(f ) and confidence (α) of each factor

source SA f F α degree temperature(A) 74.20 2 14.39 0.1 high holding Time(B) 12.05 2 2.34 0.25 low pressure(C) 20.25 2 3.93 0.25 middle error 5.16 2 SUM 111.66 8 表 5 不同温度与孔隙度阴极偏离点电流密度

Table 5. Cathode deviation point values of different temperature and porosity

temperature/℃ Jdev with different spherical matrix cathode/(A·cm−2) 23.4% 26.3% 30.5% 900 8.42 10.27 8.60 1000 10.66 14.77 11.43 1050 12.37 24.62 13.00 1100 13.95 33.07 14.56 表 6 1050 ℃下各阴极J0与Φ

Table 6. J0 and Φ values of three cathodes after activated at 1050 ℃

activated temperature/℃ J0/(A·cm−2) Φ/eV 23.4% 26.3% 30.5% 23.4% 26.3% 30.5% 1050 3.79 7.62 3.10 2.03 1.95 2.05 -

[1] Thomas R E, Gibson J W, Haas G A, et al. Thermionic sources for high-brightness electron beams[J]. IEEE Transactions on Electron Devices, 1990, 37(3): 850-861. doi: 10.1109/16.47802 [2] 林祖伦, 王小菊. 阴极电子学[M]. 北京: 国防工业出版社, 2013.Lin Zulun, Wang Xiaoju. Cathode electronics[M]. Beijing: National Defense Industry Press, 2013 [3] Kirkwood D M, Gross S J, Balk T J, et al. Frontiers in thermionic cathode research[J]. IEEE Transactions on Electron Devices, 2018, 65(6): 2061-2071. doi: 10.1109/TED.2018.2804484 [4] 李鹤. 扩散式钡钨阴极性能研究[D]. 成都: 电子科技大学, 2015.Li He. Study on performance of impregnated dispenser cathode[D]. Chengdu: University of Electronic Science and Technology of China, 2015 [5] Wang Xiaoxia, Chen Xiaoqian, Zhang Shuai, et al. The work function of the ammonium perrhenate impregnated W matrix Ba-W cathode[C]//Proceedings of the 2019 International Vacuum Electronics Conference (IVEC). 2019. [6] Li Jinglin, Zhao Weihua, Wei Jianjun, et al. Effect of BaO on the phase composition and properties of aluminates for Ba-W cathodes[J]. Ceramics International, 2019, 45(4): 4308-4315. doi: 10.1016/j.ceramint.2018.11.105 [7] Shang Jihua, Yang Xinyu, Wang Ziyu, et al. Influence of the surface tungsten distribution on the emission properties of barium tungsten cathode[J]. IEEE Transactions on Electron Devices, 2020, 67(6): 2580-2584. doi: 10.1109/TED.2020.2986034 [8] Li Jinglin, Wei Jianjun, Feng Yongbao, et al. Effect of CaO on phase composition and properties of aluminates for barium tungsten cathode[J]. Materials, 2018, 11(8): 1380. doi: 10.3390/ma11081380 [9] Gӓrtner G, Geittner P, Lydtin H, et al. Emission properties of top-layer scandate cathodes prepared by LAD[J]. Applied Surface Science, 1997, 111: 11-17. doi: 10.1016/S0169-4332(96)00698-8 [10] Hu Mingwei, Wang Xiaoxia, Qi Shikai. Preparation, performance, and work function model of impregnated tungstate cathodes[J]. IEEE Transactions on Electron Devices, 2019, 66(8): 3592-3598. doi: 10.1109/TED.2019.2922707 [11] Wu Zhaohao. The relations of impregnated cathode properties to the tungsten matrix structure[J]. Journal of Electronics (China), 1987, 4(4): 273-281. doi: 10.1007/BF02779035 [12] Melnikova I P, Vorozheikin V G, Usanov D A. Correlation of emission capability and longevity of dispenser cathodes with characteristics of tungsten powders[J]. Applied Surface Science, 2003, 215(1/4): 59-64. [13] Singh A K, Ravi M, Bisht M S, et al. Study and development of active sintered controlled porosity dispenser cathode[J]. IEEE Transactions on Electron Devices, 2015, 62(11): 3837-3843. doi: 10.1109/TED.2015.2478970 [14] 胡可, 邱振涛, 杨新宇, 等. 等离子体球化处理和放电等离子烧结制备的钡钨阴极多孔钨基体[J]. 稀有金属材料与工程, 2019, 48(2):608-613. (Hu Ke, Qiu Zhentao, Yang Xinyu, et al. Porous tungsten matrix for Ba-W cathode prepared by plasma spheroidization process and spark plasma sintering[J]. Rare Metal Materials and Engineering, 2019, 48(2): 608-613 [15] Bao Jixiu, Wan Baofei. The tungsten powder study of the dispenser cathode[J]. Applied Surface Science, 2006, 252(16): 5873-5876. doi: 10.1016/j.apsusc.2005.08.012 [16] Skorokhod V V, Get’Man O I, Zuev A E, et al. Correlation between the particle size, pore size, and porous structure of sintered tungsten[J]. Soviet Powder Metallurgy and Metal Ceramics, 1988, 27(12): 941-947. [17] Deng Shenghua, Yuan Tiechui, Li Ruidi, et al. Spark plasma sintering of pure tungsten powder: densification kinetics and grain growth[J]. Powder Technology, 2017, 310: 264-271. doi: 10.1016/j.powtec.2017.01.050 [18] Qin Junhua, Chen Qing, Yang Chunyan, et al. Research process on property and application of metal porous materials[J]. Journal of Alloys and Compounds, 2016, 654: 39-44. doi: 10.1016/j.jallcom.2015.09.148 [19] Dudina D V, Bokhonov B B, Olevsky E A. Fabrication of porous materials by spark plasma sintering: a review[J]. Materials, 2019, 12(3): 541-569. doi: 10.3390/ma12030541 [20] Li Baoqiang, Sun Zhiqiang, Jin Huacheng, et al. Fabrication of homogeneous tungsten porous matrix using spherical tungsten powders prepared by thermal plasma spheroidization process[J]. International Journal of Refractory Metals and Hard Materials, 2016, 59: 105-113. doi: 10.1016/j.ijrmhm.2016.06.002 [21] 刘瑞江, 张业旺, 闻崇炜, 等. 正交试验设计和分析方法研究[J]. 实验技术与管理, 2010, 27(9):52-55. (Liu Ruijiang, Zhang Yewang, Wen Chongwei, et al. Study on the design and analysis methods of orthogonal experiment[J]. Experimental Technology and Management, 2010, 27(9): 52-55 doi: 10.3969/j.issn.1002-4956.2010.09.016 [22] 何学良. 扩散式钡钨阴极用钨基体材料的研究[D]. 北京: 北京有色金属研究总院, 2018.He Xueliang. Study on tungsten matrix material for diffusion barium tungsten cathode[D]. Beijing: General Research Institute for Nonferrous Metals, 2018 [23] Yin Shengyin, Zhang Zhaochuan, Peng Zhen, et al. A new impregnated dispenser cathode[J]. IEEE Transactions on Electron Devices, 2013, 60(12): 4258-4262. doi: 10.1109/TED.2013.2287729 -

下载:

下载: