Irradiation damage distribution characteristics of DKDP in large-aperture high-energy laser

-

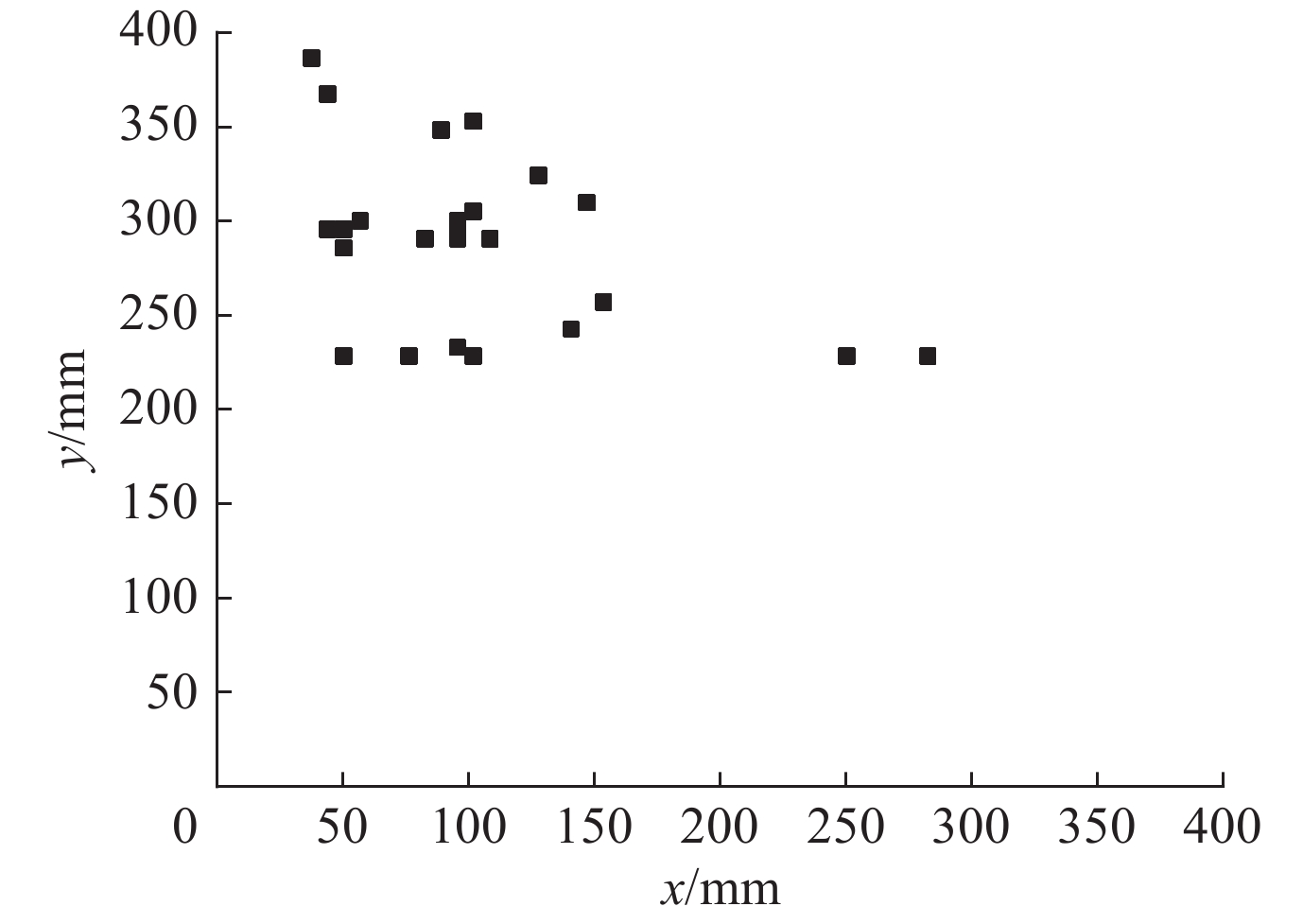

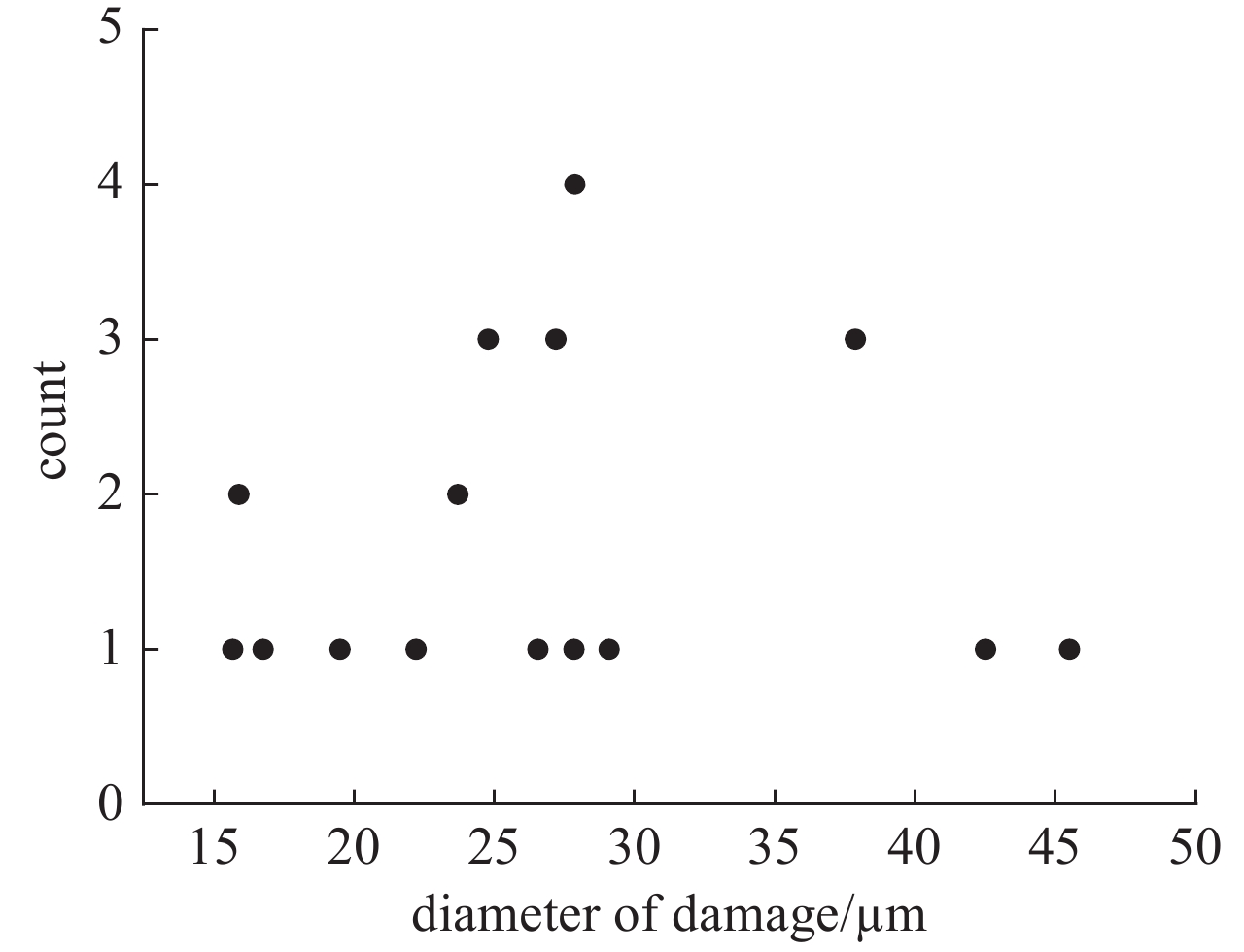

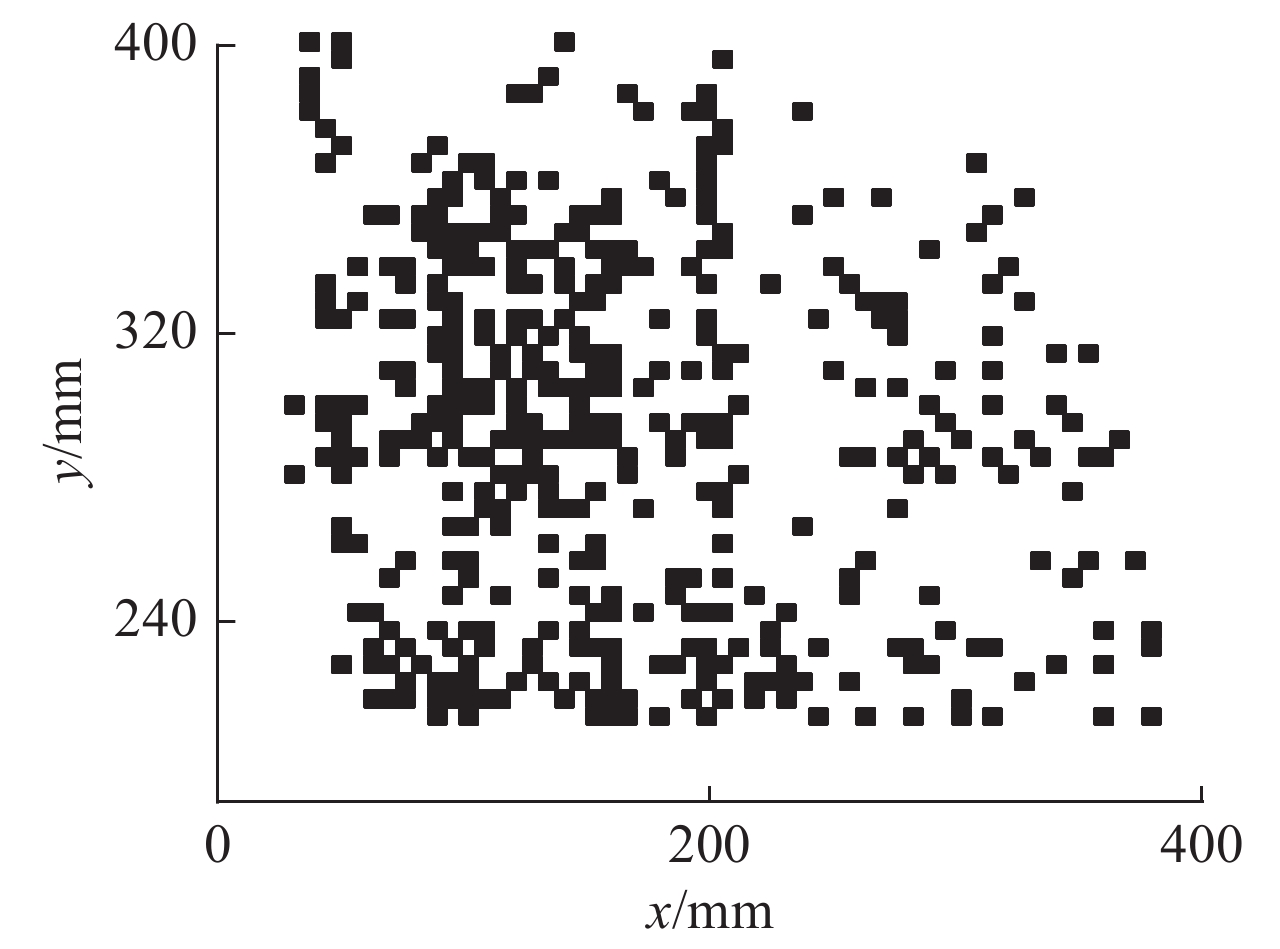

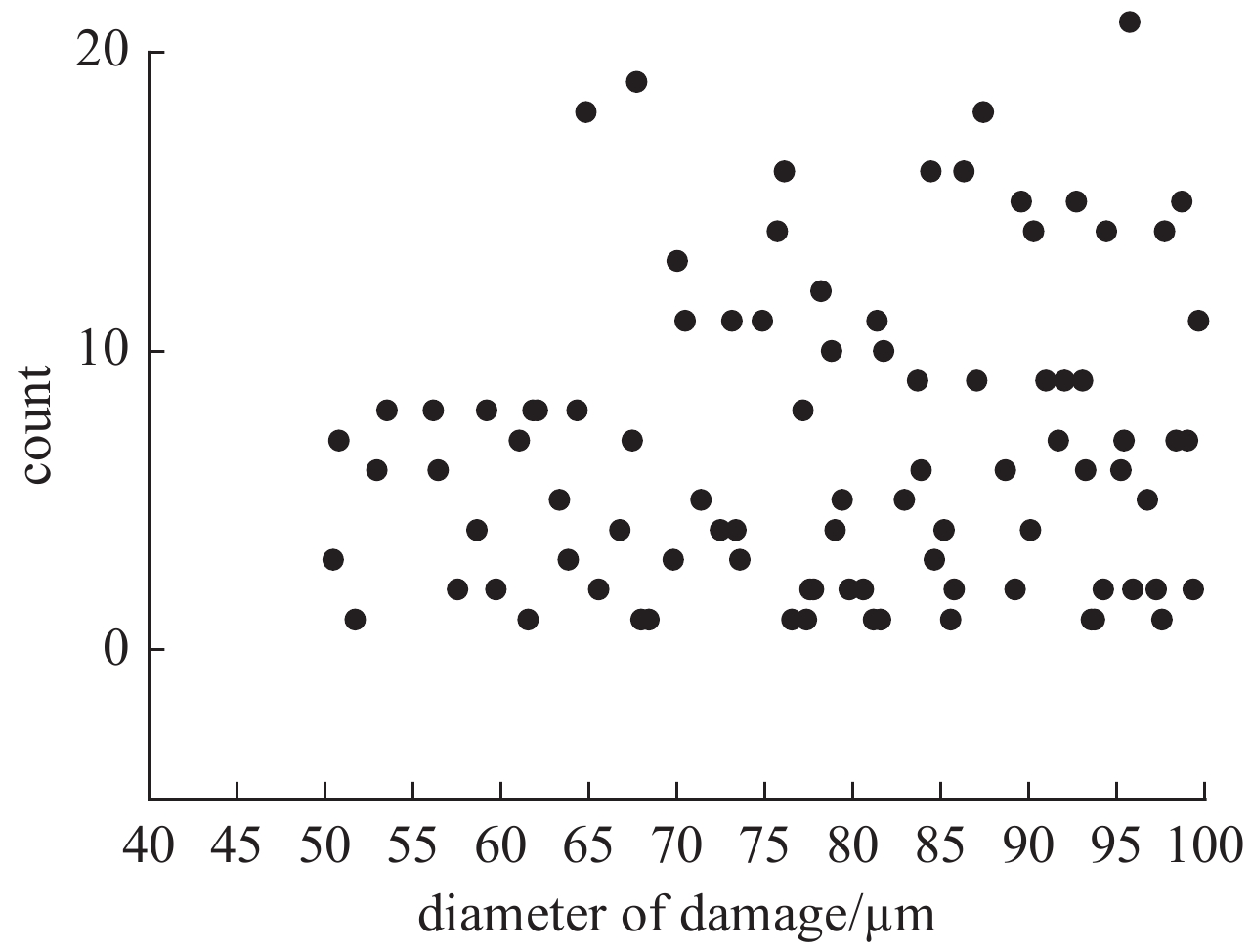

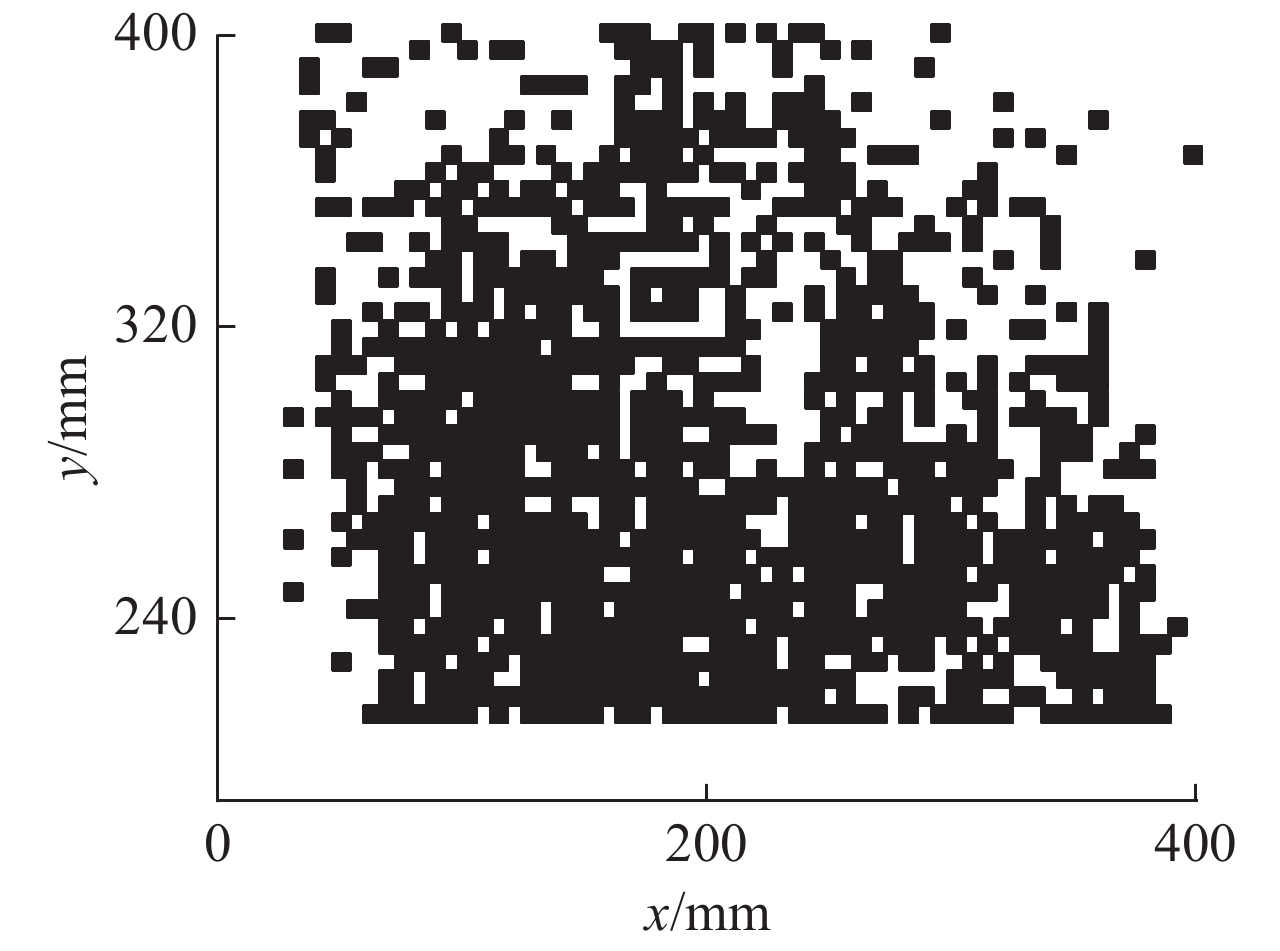

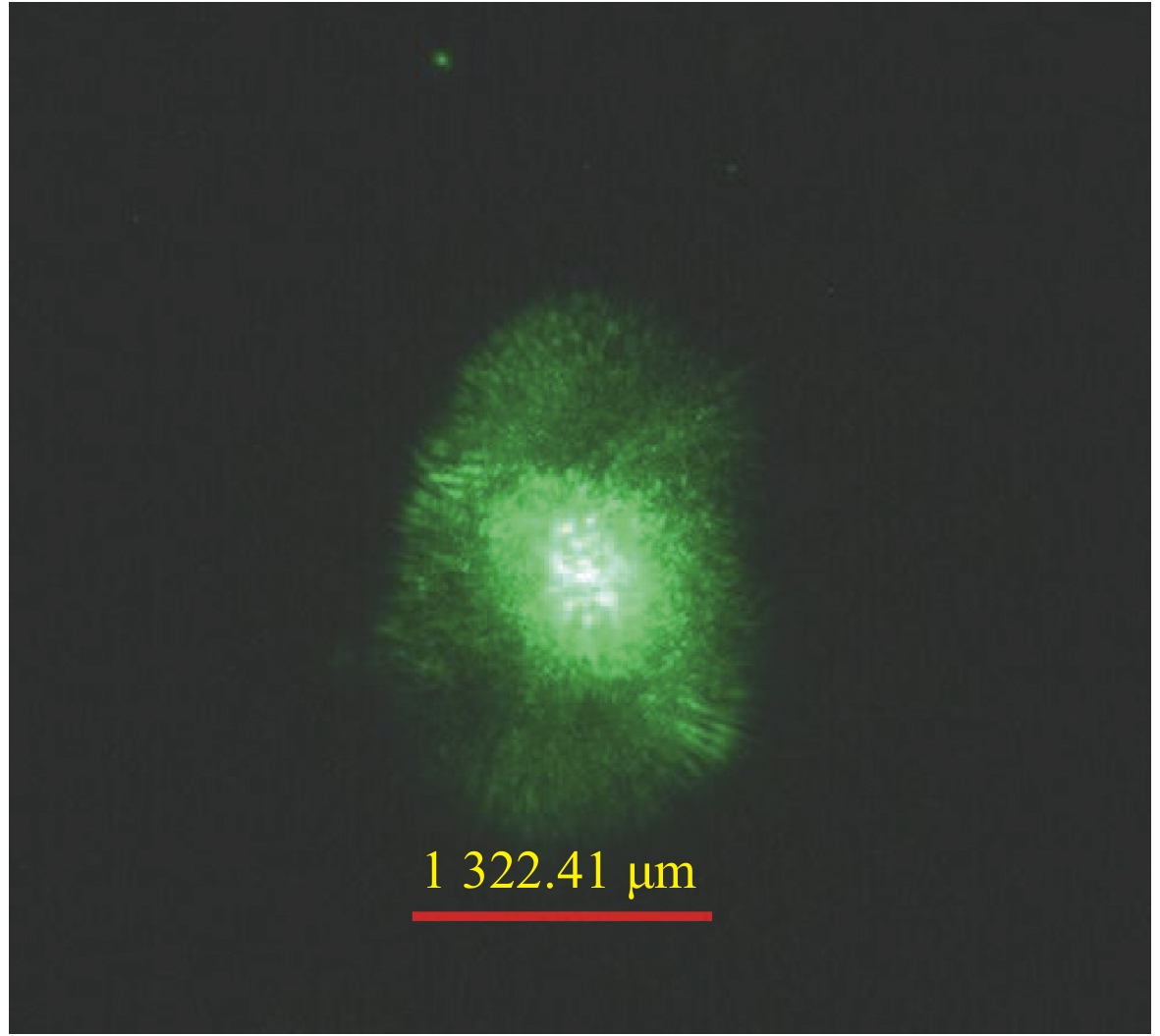

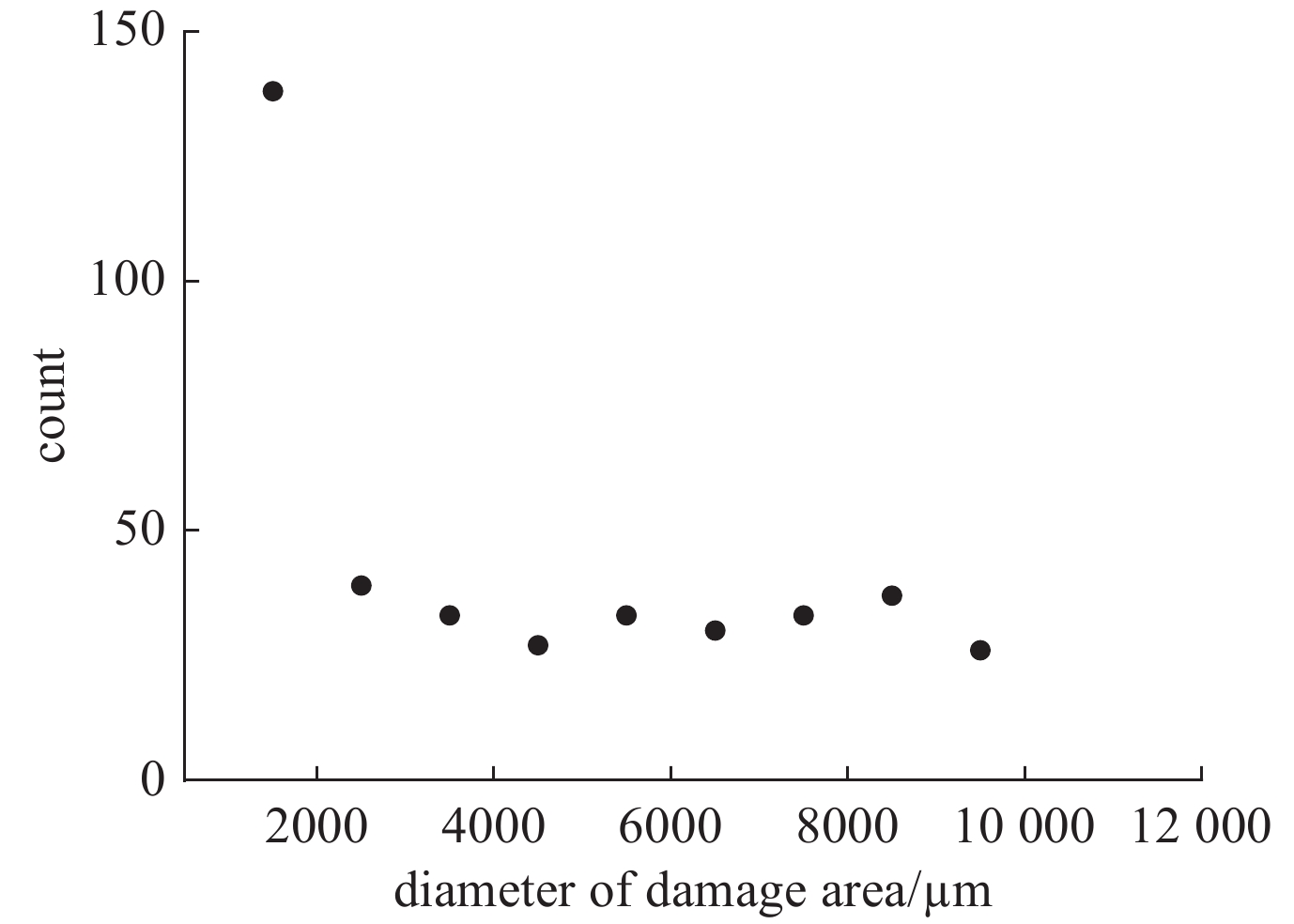

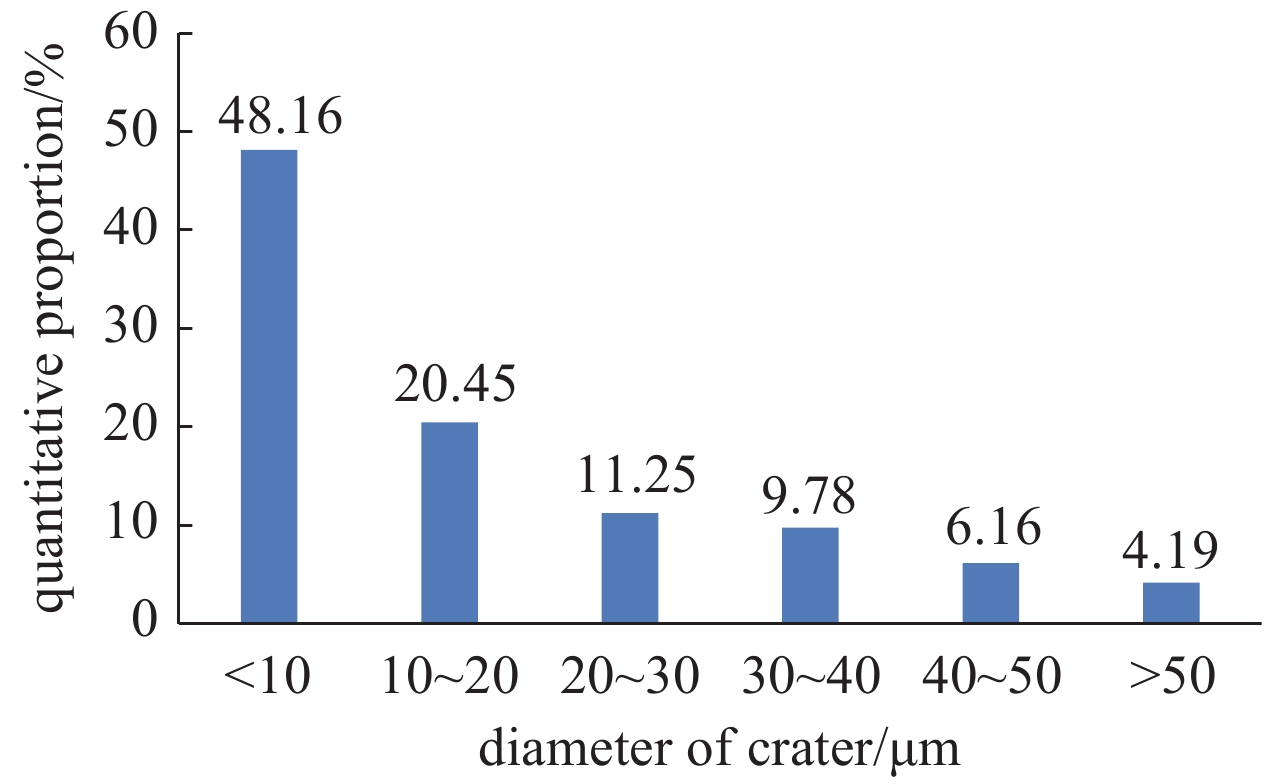

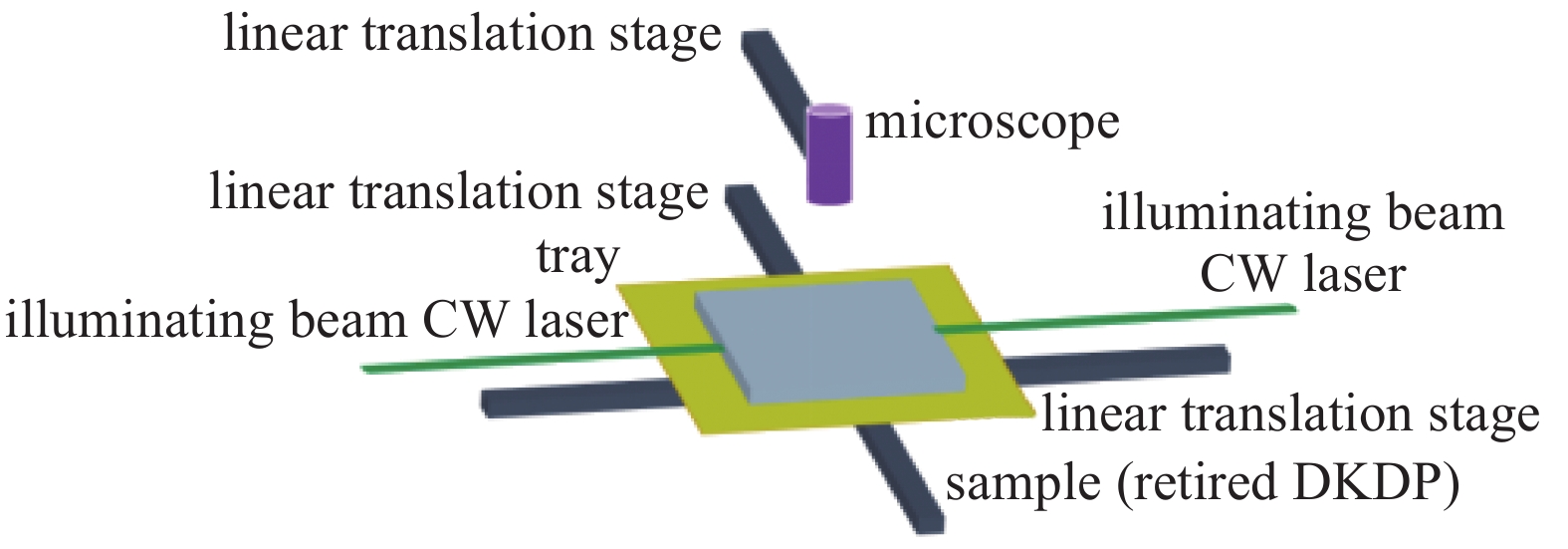

摘要: 大口径高能激光装置是各强国积极研究的重点项目。对装置内大口径光学元件损伤特性进行有效评估具有非常重要的意义,在此研究大尺寸光学元件表面损伤。通过分段拍摄、图像拼合、损伤点记录、统计与归纳等工作发现,不同尺寸损伤点的分布特性差异较大。结合统计学方法与类似实验对比、理论计算等方式对损伤点分布与样品辐照环境特性变化的关系进行分析。结果显示,损伤点的位置分布与辐照光束的能量密度关联紧密;系统光束(351 nm)在低于6 J/cm2时能量分布均匀,高于6.7 J/cm2时呈现较为明显的高斯分布状态。可以为大口径高能辐照环境的元件损伤特性评估提供有价值的参考,对大口径紫外激光器的日常运行与维护具有极其重要的工程意义。Abstract: To establish the effective evaluation about damage properties of large-aperture and high-energy optic components, we studied the statistics of the surface damage of the DKDP component. We analysed and summarized various kinds of damage distributing in surface of the optic component by step-by-step shooting, merging images and counting damage pits. We investigated correlation distribution of damage types and irradiation conditions using statistics of surface damage data, theoretical calculation and demonstration of similar experiment. It is found that positions of damage pits are closely relevant to distribution of energy density of laser beam (3ω). When the energy density exceeds 6.7 J/cm2, the distribution of energy density of the laser beam can be Gaussian. On the contrary, when energy density is less than 6.7 J/cm2, the distribution of energy density of the laser beam can be uniform. Our study could provide a valuable reference for evaluating characteristics of damage to optical component working under irradiation in large-aperture high-energy laser. It is also reterable in operating and maintaining large-aperture high-energy laser facility.

-

Key words:

- DKDP /

- laser induced damage /

- distribution /

- large-aperture /

- high-energy laser

-

表 1 不同类型损伤统计结果(DKDP)

Table 1. Statistical result of different types of damages (DKDP)

diameter of crater D/μm count of craters quantitative proportion/% area of damage/mm2 area proportion/% <50 26 0.70 0.04 ≈0.000 02 50~100 617 16.58 3.20 <0.002 100~1 000 2675 71.89 221.76 0.001 2 >1 000 403 10.83 8335.01 0.045 1 total 3721 8560.01 0.046 3 表 2 损伤统计结果(KDP)

Table 2. Statistical result of damages result (KDP)

diameter of crater/μm count of craters quantitative proportion/% <10 4087 48.16 10~20 1736 20.45 20~30 955 11.25 30~40 830 9.78 40~50 523 6.16 >50 356 4.19 total 8487 表 3 对比损伤统计结果(DKDP)

Table 3. Contrast statistics of result(DKDP)

diameter of crater/μm count of craters quantitative proportion/% <5 0(out of resolution) 0.00 5~10 0 0.00 10~20 5 0.13 20~30 16 0.43 30~40 3 0.08 40~50 2 0.05 >50 3695 99.30 total 3721 -

[1] Melninkaitis A, Sinkevicius M, Lipinskas T, et al. Characterization of the KDP crystals used in large-aperture doublers and triplers[C]//Proceedings of SPIE 5647, Laser-Induced Damage in Optical Materials: 2004. 2005: 298-305. [2] Han Wei, Wang Fang, Zhou Lidan, et al. Suppression of transverse stimulated Raman scattering with laser-induced damage array in a large-aperture potassium dihydrogen phosphate crystal[J]. Optics Express, 2013, 21(25): 30481-30491. doi: 10.1364/OE.21.030481 [3] Negres R A, Raman R N, Bude J D, et al. Dynamics of transient absorption in bulk DKDP crystals following laser energy deposition[J]. Optics Express, 2012, 20(18): 20447-20458. doi: 10.1364/OE.20.020447 [4] Zheng Yinbo, Zhou Xinda, Ba Rongsheng, et al. Microscopic characterization of bulk damage resistance of DKDP nonlinear crystals[J]. Optics & Laser Technology, 2020, 121: 105672. doi: 10.1016/j.optlastec.2019.105672 [5] Han Wei, Huang Wanqing, Wang Fang, et al. Laser-induced damage on large-aperture fused silica gratings[J]. Chinese Physics B, 2010, 19: 106105. doi: 10.1088/1674-1056/19/10/106105 [6] Lamaignère L, Dupuy G, Bourgeade A, et al. Large beam damage experiments in fused silica optics at 351nm[C]//Proceedings of SPIE 9238, Pacific Rim Laser Damage 2014: Optical Materials for High-Power Lasers. 2014: 92380C. [7] Burnham A K, Hackel L, Wegner P, et al. Improving 351-nm damage performance of large-aperture fused silica and DKDP optics[R]. UCRL-JC-144298, 2002. [8] 彭恩鸿. KDP晶体加工微纳缺陷对激光损伤影响和微修复新方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2019Peng Enhong. Study on the effect of machining micro/nano defects on laser damage and novel micro-repairing method of KDP crystal[D]. Harbin: Harbin Institute of Technology, 2019 [9] DeMange P, Negres R A, Carr C W, et al. A multi-dimensional investigation of laser conditioning in KDP and DKDP crystals[R]. UCRL-CONF-216863, 2005. [10] 徐子媛, 王岳亮, 赵元安, 等. 不同脉冲宽度355 nm波长激光诱导DKDP晶体损伤特性[J]. 强激光与粒子束, 2019, 31:091004. (Xu Ziyuan, Wang Yueliang, Zhao Yuan’an, et al. Laser damage behaviors of DKDP crystals dominated by laser pulse duration[J]. High Power Laser and Particle Beams, 2019, 31: 091004 doi: 10.11884/HPLPB201931.190164 [11] Hu Guohang, ZhaoYuan’an, Sun Shaotao, et al. Characteristics of 355 nm laser damage in KDP and DKDP crystals[J]. Chinese Physics Letters, 2009, 26: 097802. doi: 10.1088/0256-307X/26/9/097802 [12] Carr C W, Feit M D, Muyco J J, et al. Effect on scattering of complex morphology of DKDP bulk damage sites[C]//Proceedings of SPIE 5647, Laser-Induced Damage in Optical Materials: 2004. 2005: 532-539. [13] Cao Zhiqiang, Ju Xin, Yan Chunyan, et al. Synchrotron micro-XRF study of metal inclusions distribution in potassium dihydrogen phosphate (KDP) induced by ultraviolet laser pulses[J]. Optical Materials Express, 2015, 5(10): 2201-2208. doi: 10.1364/OME.5.002201 [14] Guillet F, Bertussi B, Surmin A, et al. Effect of strain on laser damage and its relation with precursor defects in KDP/DKDP[C]//Proceedings of SPIE 8190, Laser-Induced Damage in Optical Materials: 2011. 2011: 819027. [15] Tian Ye, Han Wei, Cao Huabao, et al. Characteristics of laser-induced surface damage on large-aperture KDP crystals at 351 nm[J]. Chinese Physics Letters, 2015, 32: 027801. doi: 10.1088/0256-307X/32/2/027801 [16] Han Wei, Zhou Lidan, Xiang Yong, et al. Characteristics of laser-induced surface and bulk damage of large-aperture deuterated potassium dihydrogen phosphate at 351 nm[J]. Chinese Physics Letters, 2016, 33: 027803. doi: 10.1088/0256-307X/33/2/027803 [17] Hunt J T. National Ignition Facility performance review 1998[R]. UCRL-ID-138120-98, 1999. [18] Spaeth M L, Manes K R, Widmayer C C, et al. National Ignition Facility wavefront requirements and optical architecture[J]. Optical Engineering, 2004, 43(12): 2854-2865. doi: 10.1117/1.1815332 [19] 巨新. 紫外元件损伤动力学实验研究[J]. 中国科学: 物理学 力学 天文学, 2021, 51:092005. (Ju Xin. Experimental research on the dynamics of ultraviolet laser-induced damage[J]. SCIENTIA SINICA Physica, Mechanica & Astronomica, 2021, 51: 092005 doi: 10.1360/SSPMA-2021-0109 [20] Hu Guohang, ZhaoYuan’an, Sun Shaotao, et al. Growth characteristics and mechanism of surface and bulk damage in KDP and DKDP crystals[J]. Chinese Physics Letters, 2009, 26: 087805. doi: 10.1088/0256-307X/26/8/087805 [21] 朱德星. KDP/DKDP非线性晶体的激光诱导损伤特性研究[D]. 北京: 中国工程物理研究院, 2018Zhu Dexing. Study on laser induced damage characteristics of KDP / DKDP nonlinear crystals[D]. Beijing: China Academy of Engineering Physics [22] Li Xiangcao, Liu Bao’an, Yan Chunyan, et al. Structures of retired components and KDP crystals irradiated by high fluence using synchrotron μ-XRF and μ-XRD[J]. Optical Materials Express, 2019, 9(2): 845-859. doi: 10.1364/OME.9.000845 [23] Li Xiangcao, Liu Bao’an, Yan Chunyan, et al. Investigating the surface electronic structures of retired components and irradiated KDP crystals with different fluences by XANES spectroscopy[J]. Optical Materials Express, 2018, 8(4): 816-823. doi: 10.1364/OME.8.000816 [24] Hu Guohang, Zhao Yuan’an, Li Dawei, et al. Wavelength dependence of laser-induced bulk damage morphology in KDP crystal: determination of the damage formation mechanism[J]. Chinese Physics Letters, 2012, 29: 037801. doi: 10.1088/0256-307X/29/3/037801 [25] 韩伟, 周丽丹, 李富全, 等. 光束通量空间分布随机变化的统计分析[J]. 物理学报, 2014, 63:074204. (Han Wei, Zhou Lidan, Li Fuquan, et al. Statistical analysis of shot-to-shot variation of laser fluence spatial distribution[J]. Acta Physica Sinica, 2014, 63: 074204 doi: 10.7498/aps.63.074204 [26] Reyné S, Duchateau G, Hallo L, et al. Multi-wavelength study of nanosecond laser-induced bulk damage morphology in KDP crystals[J]. Applied Physics A, 2015, 119(4): 1317-1326. doi: 10.1007/s00339-015-9098-z [27] Hu Guohang, Zhao Yuan’an, Sun Shaotao, et al. A thermal approach to model laser damage in KDP and DKDP crystals[J]. Chinese Physics Letters, 2009, 26: 097803. doi: 10.1088/0256-307X/26/9/097803 [28] 吴金明, 赵元安, 汪琳, 等. 1064nm激光和355nm激光同时辐照DKDP晶体的耦合预处理效应[J]. 中国激光, 2019, 46:0501003. (Wu Jinming, Zhao Yuan’an, Wang Lin, et al. Coupling conditioning effect of DKDP crystals under simultaneous irradiation by 1064 nm laser and 355 nm laser[J]. Chinese Journal of Lasers, 2019, 46: 0501003 doi: 10.3788/CJL201946.0501003 [29] Hu Guohang, Zhao Yuan’an, Sun Shaotao, et al. One-on-one and R-on-one tests on KDP and DKDP crystals with different orientations[J]. Chinese Physics Letters, 2009, 26: 087801. doi: 10.1088/0256-307X/26/8/087801 [30] Carr C W, McMillian T H, Staggs M C, et al. Evolution of bulk damage initiation in DKDP[C]//Proceedings of SPIE 4932, Laser-Induced Damage in Optical Materials: 2002 and 7th International Workshop on Laser Beam and Optics Characterization. 2003: 429-433. [31] Lamaignere L, Bouillet S, Courchinoux R, et al. An accurate, repeatable, and well characterized measurement of laser damage density of optical materials[J]. Review of Scientific Instruments, 2007, 78: 103105. doi: 10.1063/1.2796148 [32] DeMange P, Carr C W, Radousky H B, et al. System for evaluation of laser-induced damage performance of optical materials for large aperture lasers[J]. Review of Scientific Instruments, 2004, 75(10): 3298-3301. doi: 10.1063/1.1791319 -

下载:

下载: