Development of analog temperature control and detection system for distributed feedback laser

-

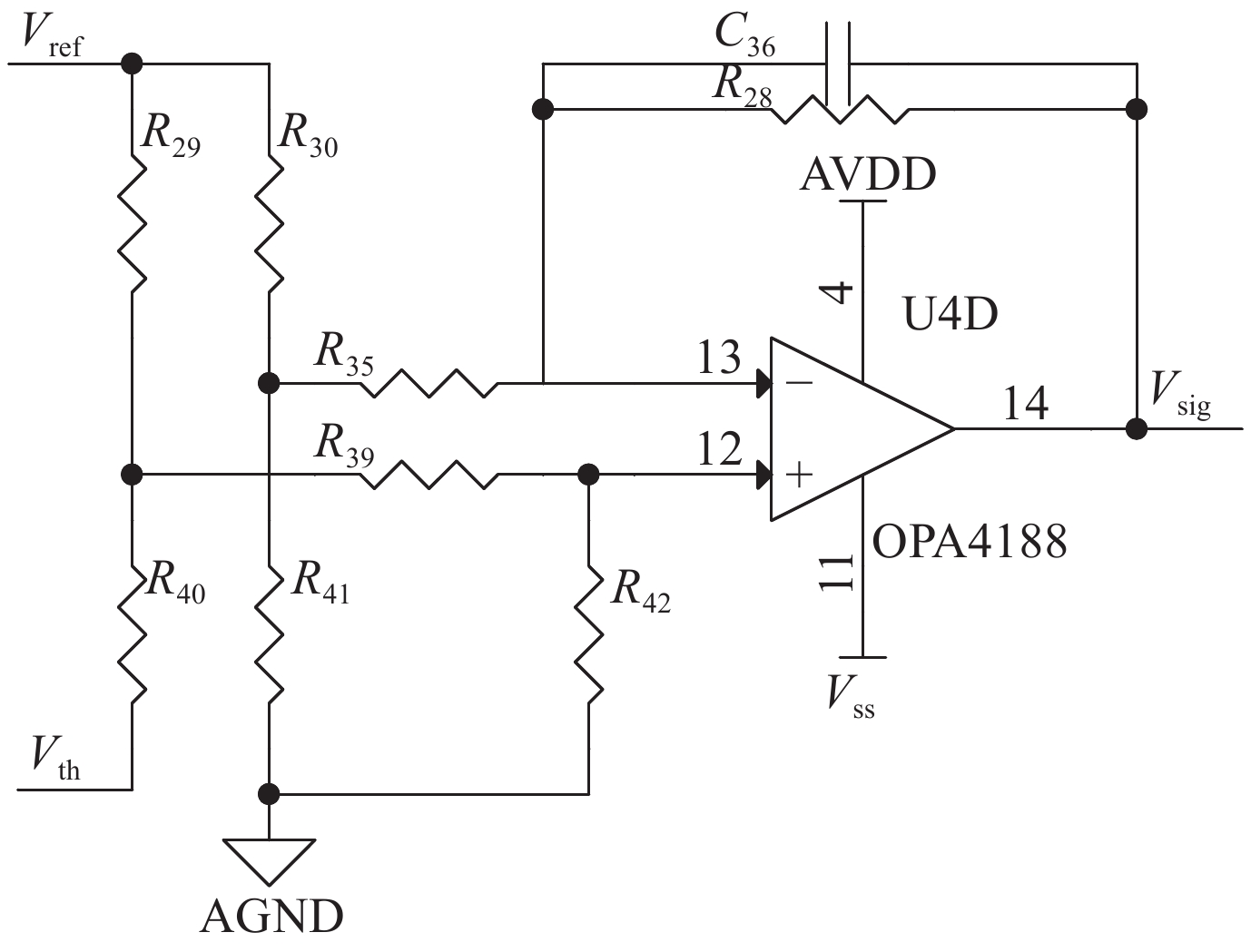

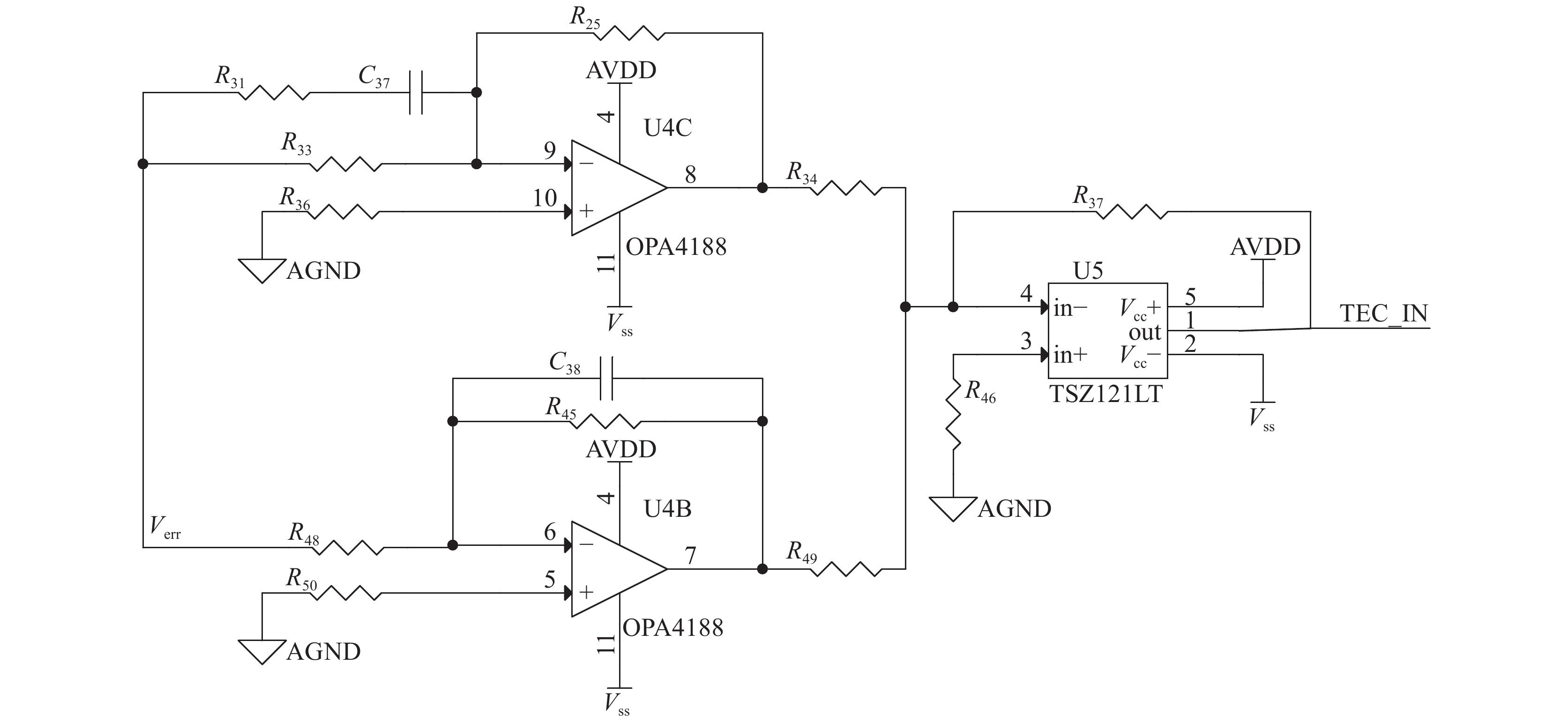

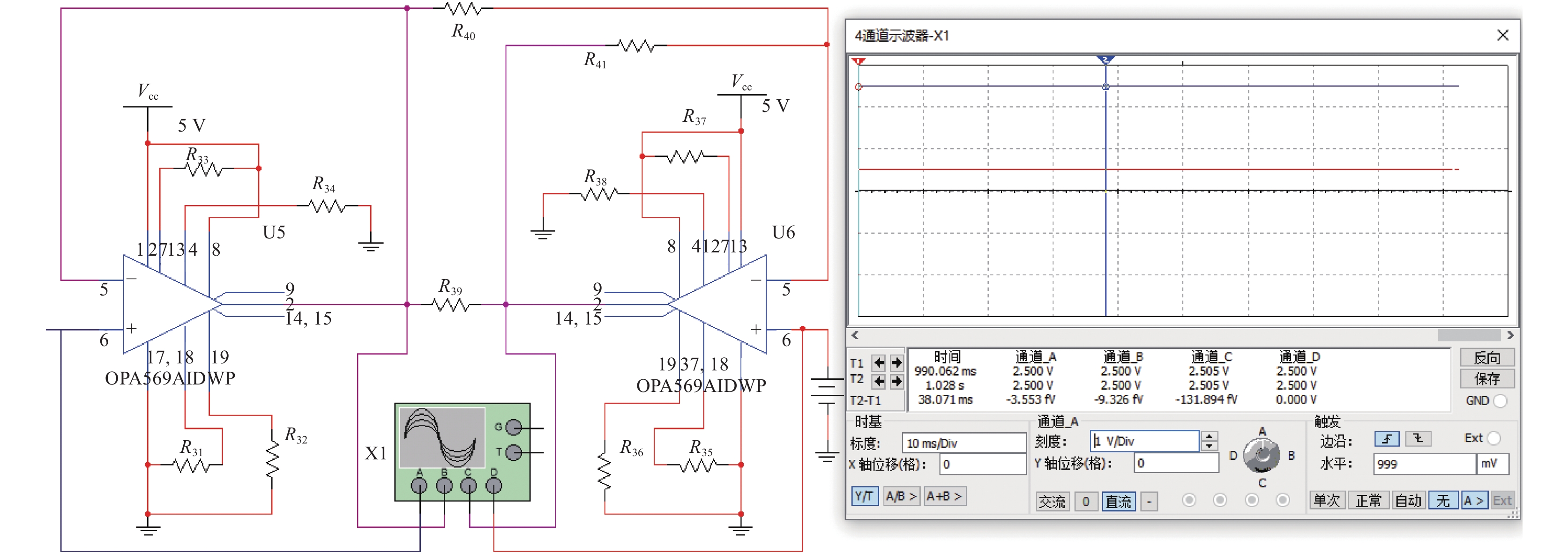

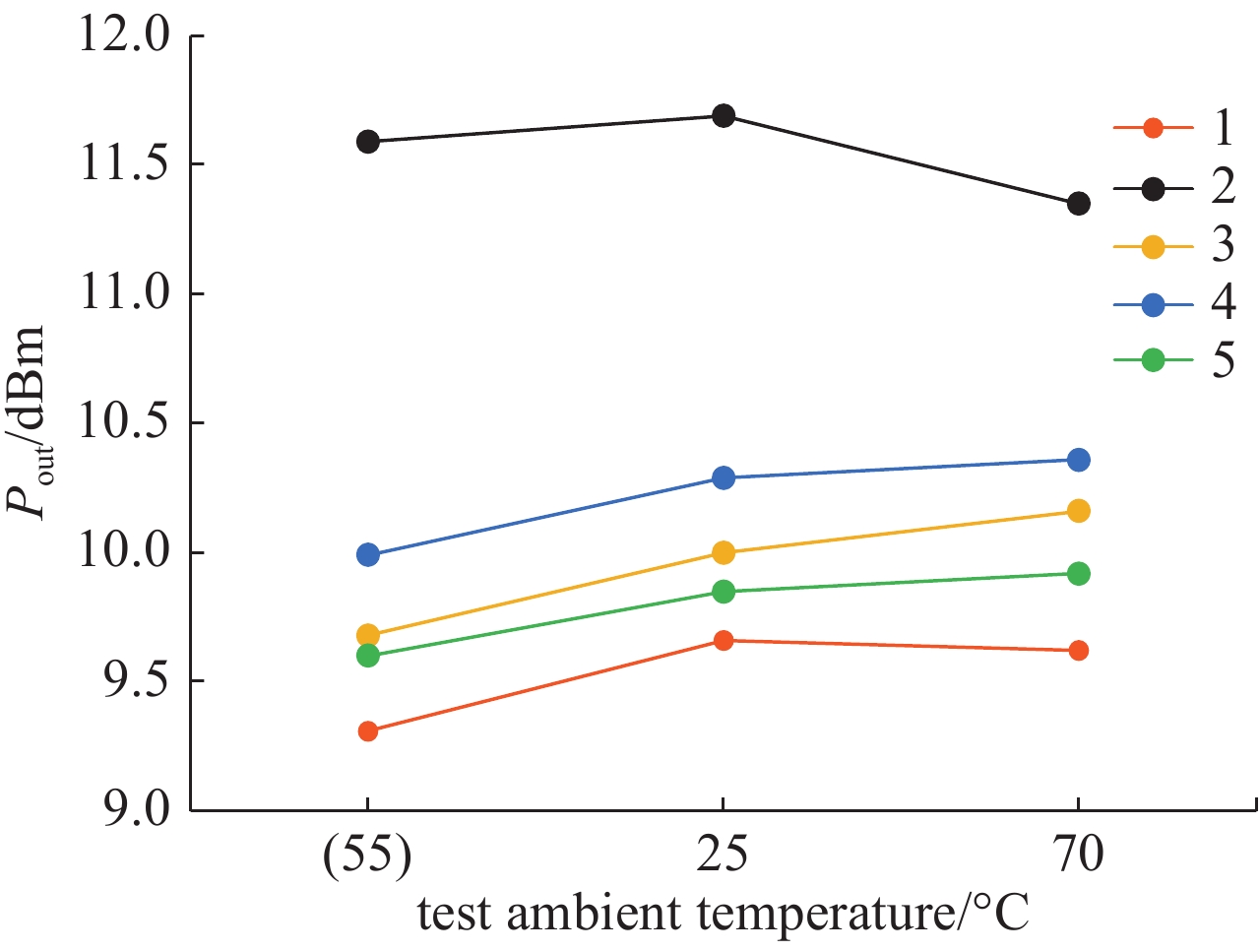

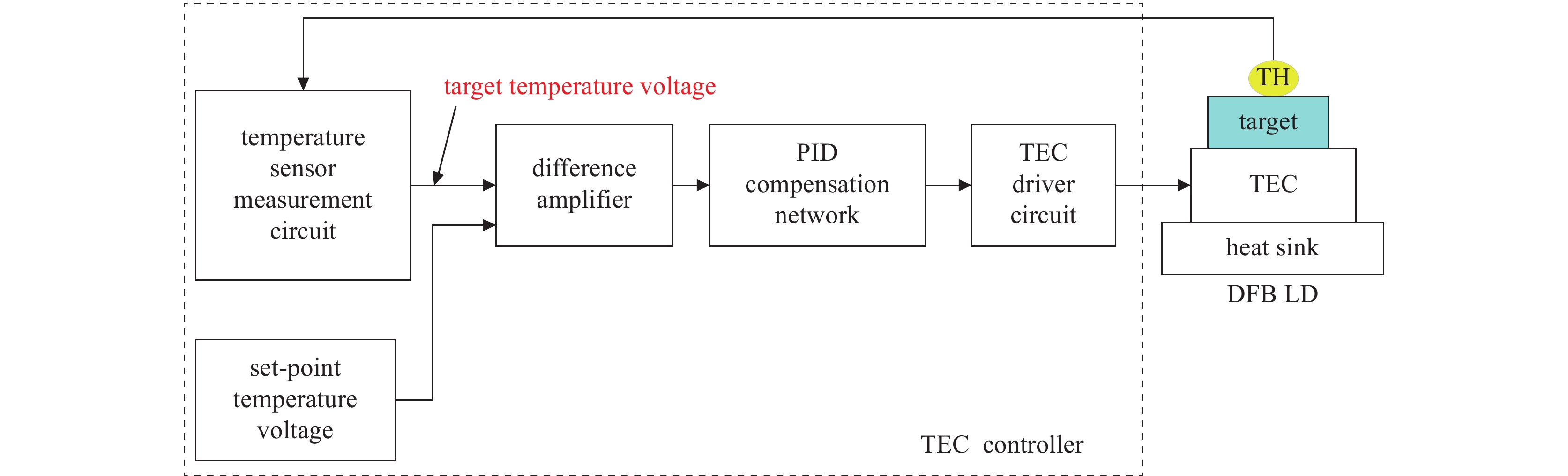

摘要: 温度对分布式反馈(DFB)激光器的性能指标和工作寿命有着重要影响。针对宽温度范围下的激光器应用,分析了激光器温控系统的研究现状及趋势,给出了温控系统的设计原理,采用线性驱动与PID闭环控制方法,应用模拟器件,研制了一种DFB激光器的模拟控温检测系统,并利用该系统对1550 nm的DFB激光器进行了试验验证。结果表明,系统在−55 ℃~70 ℃的全温度范围下,保持长时间工作(≥2 h),激光器的工作状态稳定,中心波长未出现漂移。系统的温度控制精度随着工作环境温度的范围不同而有所差异,在室温环境下可达到±0.02 ℃,在全温范围内控制精度在±0.8 ℃以内,跟踪误差小于±0.5 dB。与传统的激光器温控系统相比,本系统工作温度范围宽、控制精度高,且体积小、成本低、简单可靠,对于温度环境要求较为严苛的DFB激光器应用场景,具有重要的工程实践意义。Abstract: Temperature has an important influence on the performance index and working life of distributed feedback (DFB) laser. Aiming at the laser application in a wide temperature range, the research status and trend of laser temperature control system are analyzed, and the design principle is given. A simulated temperature control and detection system of DFB laser is developed by using linear drive and PID closed-loop control method and simulator, and the system is used to verify the 1550 nm DFB laser. The results show that the system could work for a long time (≥2 h) in the full temperature range of −55 ℃−70 ℃, the working state of the laser was stable, and the central wavelength did not drift. The temperature control precision of the system varies with the temperature range of the working environment. It can reach ±0.02 ℃ at room temperature within ±0.8 ℃ in the full temperature range, and the tracking error is less than ±0.5 dB. Compared with the traditional laser temperature control system, the system has wider working temperature range, higher control precision, smaller volume, and lower cost, being simple and reliable. For the application of DFB laser with strict temperature environment requirements, it has important engineering practical significance.

-

Key words:

- TEC driver /

- PID compensation /

- distributed feedback laser /

- operational power amplifier

-

表 1 5只LD的常温测试数据表

Table 1. Test data table of 5 LDs at 25 ℃

No. condition Te/℃ Iatc/mA Vth/V Pout/dBm λ/nm Rth/kΩ T/℃ ΔT/℃ 1 initial state 25 80 0.847 9.66 1547.63 10 25 / after 2 h 25 79 0.847 9.66 1547.63 10.00788 24.98201 −0.01789 2 initial state 25 60 0.847 11.69 1548.04 10 25 / after 2 h 25 62 0.847 11.68 1548.04 10.00788 24.98201 −0.01789 3 initial state 25 60 0.848 10.0 1548.71 10 25 / after 2 h 25 62 0.848 9.99 1548.71 10.00654 24.98507 −0.01493 4 initial state 25 59 0.847 10.29 1547.93 10 25 / after 2 h 25 60 0.847 10.29 1547.93 10.00788 24.98201 −0.01789 5 initial state 25 77 0.848 9.85 1548.54 10 25 / after 2 h 25 78 0.848 9.85 1548.54 10.00654 24.98507 −0.01493 表 2 5只LD的三温环境测试数据表

Table 2. Three-temperature environment test data table of 5 LDs

No. Te/℃ Iatc/mA Vth/V Pout/dBm λ/nm Rth/kΩ T/℃ ΔT/℃ TE/dB 1 +25 80 0.847 9.66 1547.63 10 25 / / −55 790 0.851 9.31 1547.63 10.14879 24.66305 −0.33695 0.35 +70 640 0.841 9.62 1547.62 9.801321 25.45906 0.45906 / 2 +25 60 0.847 11.69 1548.04 10 25 / / −55 753 0.851 11.59 1548.03 10.14879 24.66305 −0.33695 / +70 636 0.842 11.35 1548.03 9.835354 25.37966 0.37966 0.34 3 +25 60 0.848 10.0 1548.71 10 25 / / −55 740 0.852 9.68 1548.7 10.14707 24.66689 −0.3331 0.48 +70 580 0.838 10.16 1548.7 9.666254 25.77731 0.77731 / 4 +25 59 0.847 10.29 1547.93 10 25 / / −55 745 0.849 9.99 1547.92 10.07801 24.82263 −0.17737 0.37 +70 627 0.839 10.36 1547.92 9.733716 25.61771 0.61771 / 5 +25 77 0.848 9.85 1548.54 10 25 / / −55 779 0.85 9.6 1548.56 10.07648 24.82608 −0.17391 0.32 +70 599 0.843 9.92 1548.55 9.834462 25.381742 0.38174 / -

[1] 穆叶, 胡天立, 陈晨, 等. 采用模拟PID控制的DFB激光器温度控制系统研制[J]. 红外与激光工程, 2019, 48:0405001. (Mu Ye, Hu Tianli, Chen Chen, et al. Development of temperature control system of DFB laser using analog PID control[J]. Infrared and Laser Engineering, 2019, 48: 0405001 doi: 10.3788/IRLA201948.0405001 [2] 胡杨, 张亚军, 于锦泉. 用于半导体激光器的温控电路设计[J]. 红外与激光工程, 2010, 39(5):839-842. (Hu Yang, Zhang Yajun, Yu Jinquan. Design of temperature control circuit for laser diode[J]. Infrared and Laser Engineering, 2010, 39(5): 839-842 doi: 10.3969/j.issn.1007-2276.2010.05.012 [3] 杨鹏, 胡业荣, 王贵山, 等. 温度对半导体激光器退化的影响[J]. 国防科技大学学报, 2020, 42(1):45-50. (Yang Peng, Hu Yerong, Wang Guishan, et al. Impact of temperature on degradations of laser diode[J]. Journal of National University of Defense Technology, 2020, 42(1): 45-50 doi: 10.11887/j.cn.202001007 [4] 陈晨, 党敬民, 黄渐强, 等. 高稳定、强鲁棒性DFB激光器温度控制系统[J]. 吉林大学学报(工学版), 2013, 43(4):1004-1010. (Chen Chen, Dang Jingmin, Huang Jianqiang, et al. DFB laser temperature control system with high stability and strong robustness[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(4): 1004-1010 [5] 李江澜, 石云波, 赵鹏飞, 等. TEC的高精度半导体激光器温控设计[J]. 红外与激光工程, 2014, 43(6):1745-1749. (Li Jianglan, Shi Yunbo, Zhao Pengfei, et al. High precision thermostat system with TEC for laser diode[J]. Infrared and Laser Engineering, 2014, 43(6): 1745-1749 doi: 10.3969/j.issn.1007-2276.2014.06.009 [6] 夏金宝, 刘兆军, 张飒飒, 等. 快速半导体激光器温度控制系统设计[J]. 红外与激光工程, 2015, 44(7):1991-1995. (Xia Jinbao, Liu Zhaojun, Zhang Sasa, et al. Design of semiconductor laser quick temperature control system[J]. Infrared and Laser Engineering, 2015, 44(7): 1991-1995 doi: 10.3969/j.issn.1007-2276.2015.07.005 [7] 鲍梦. 模糊理论和神经网络的激光器温控系统[J]. 激光杂志, 2017, 38(10):123-126. (Bao Meng. Laser temperature control system based on fuzzy theory and neural network[J]. Laser Journal, 2017, 38(10): 123-126 [8] 刘熙明, 魏旭, 窦立刚. 激光系统中半导体激光器温度稳定系统研究与设计[J]. 强激光与粒子束, 2019, 31:021002. (Liu Ximing, Wei Xu, Dou Ligang. Research and design of semiconductor laser temperature stabilization system in laser system[J]. High Power Laser and Particle Beams, 2019, 31: 021002 doi: 10.11884/HPLPB201931.180335 [9] 刘云芳, 张晓, 李建伟. 模拟PID电路参数自整定温控系统设计[J]. 低温工程, 2013(2):68-72. (Liu Yunfang, Zhang Xiao, Li Jianwei. Design of analog PID circuit system with parameter auto-tuning[J]. Cryogenics, 2013(2): 68-72 doi: 10.3969/j.issn.1000-6516.2013.02.013 [10] GB/T 21548-2008, 光通信用高速直接调制半导体激光器的测量方法[S]GB/T 21548-2008, 光通信用高速直接调制半导体激光器的测量方法[S]. (GB/T 21548-2008, Methods of measurement of the high speed semiconductor lasers directly modulated for optical fiber communication systems[S] -

下载:

下载: