Investigation into preparation of thin-walled polystyrene hollow microspheres for ICF

-

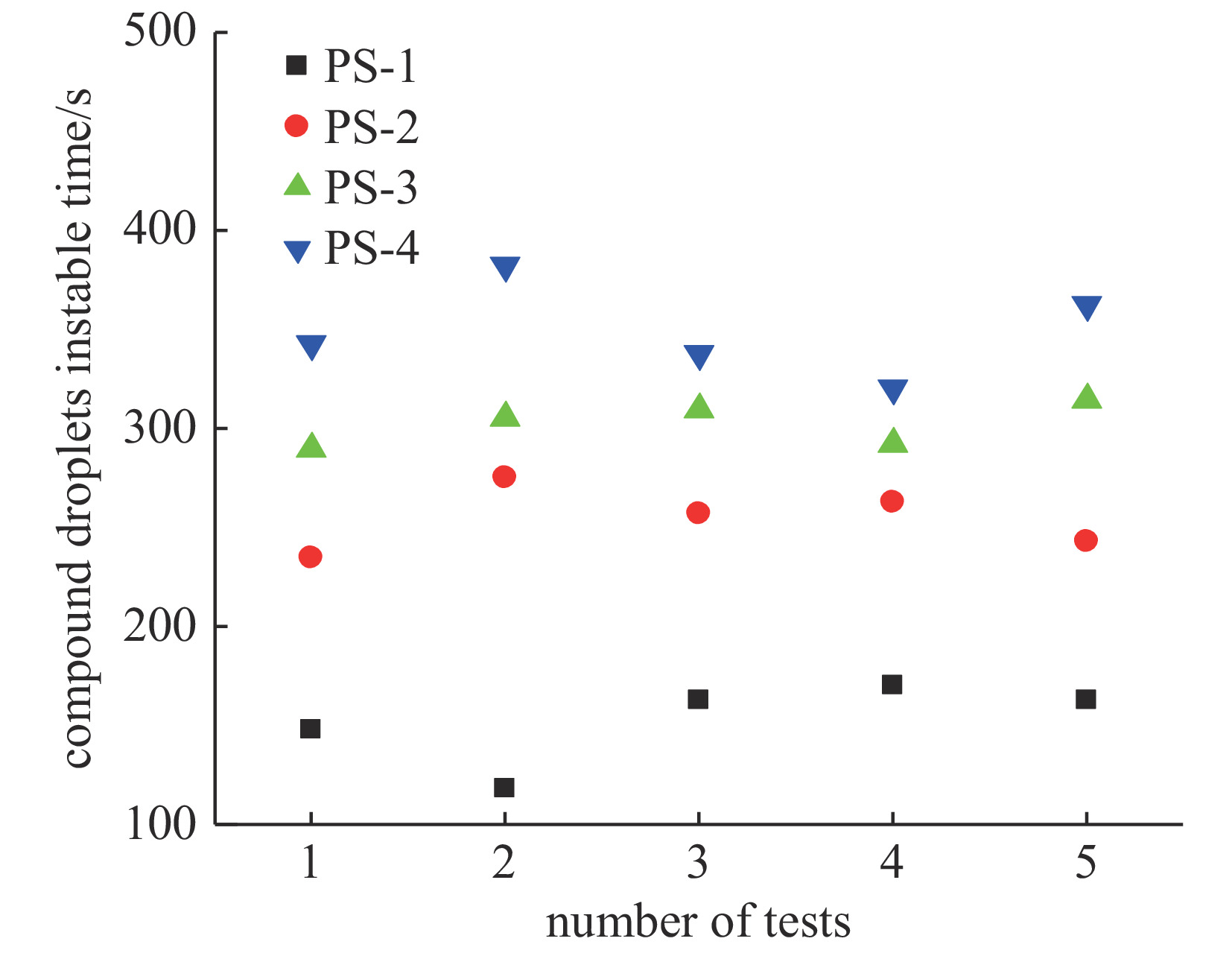

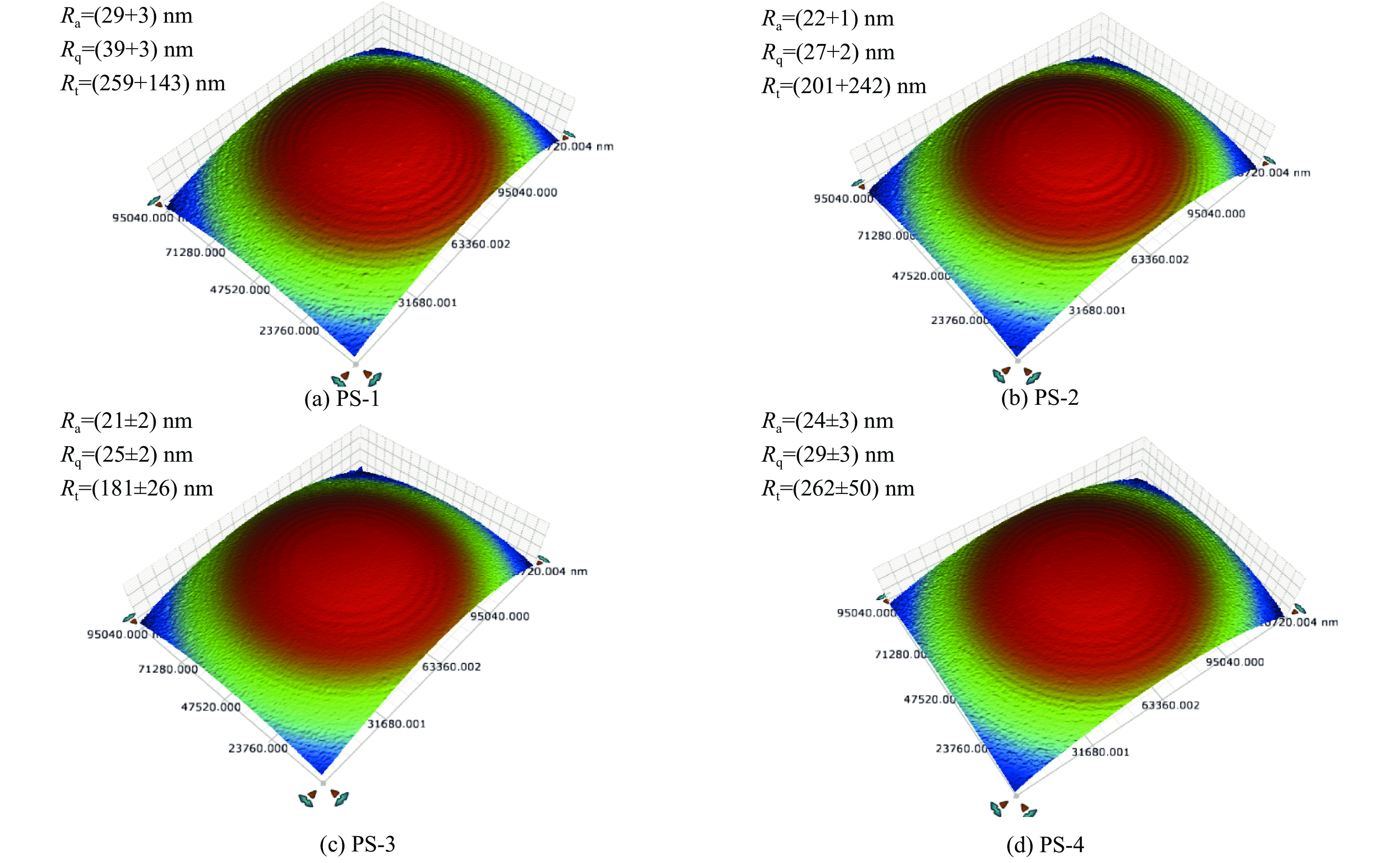

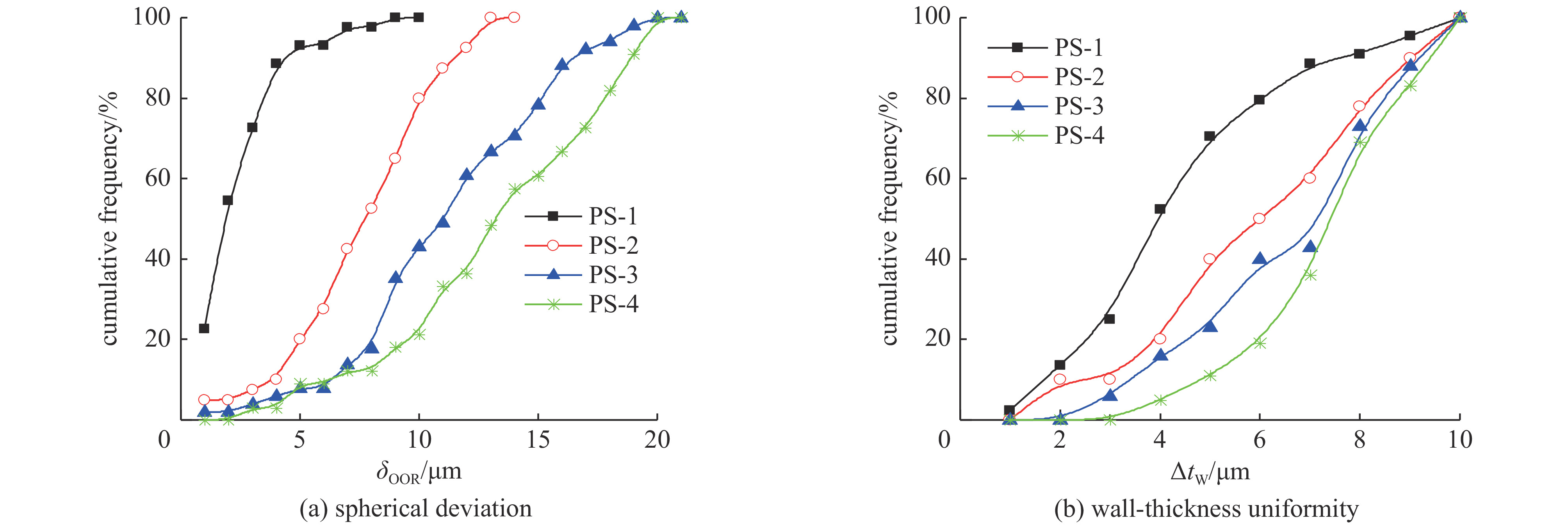

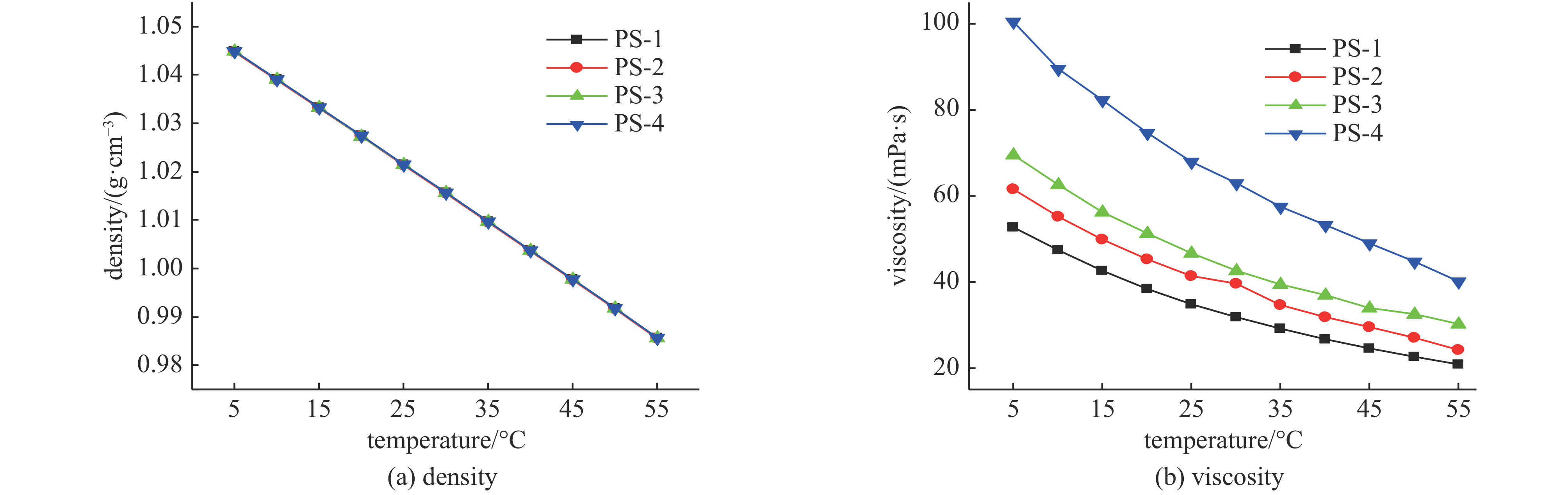

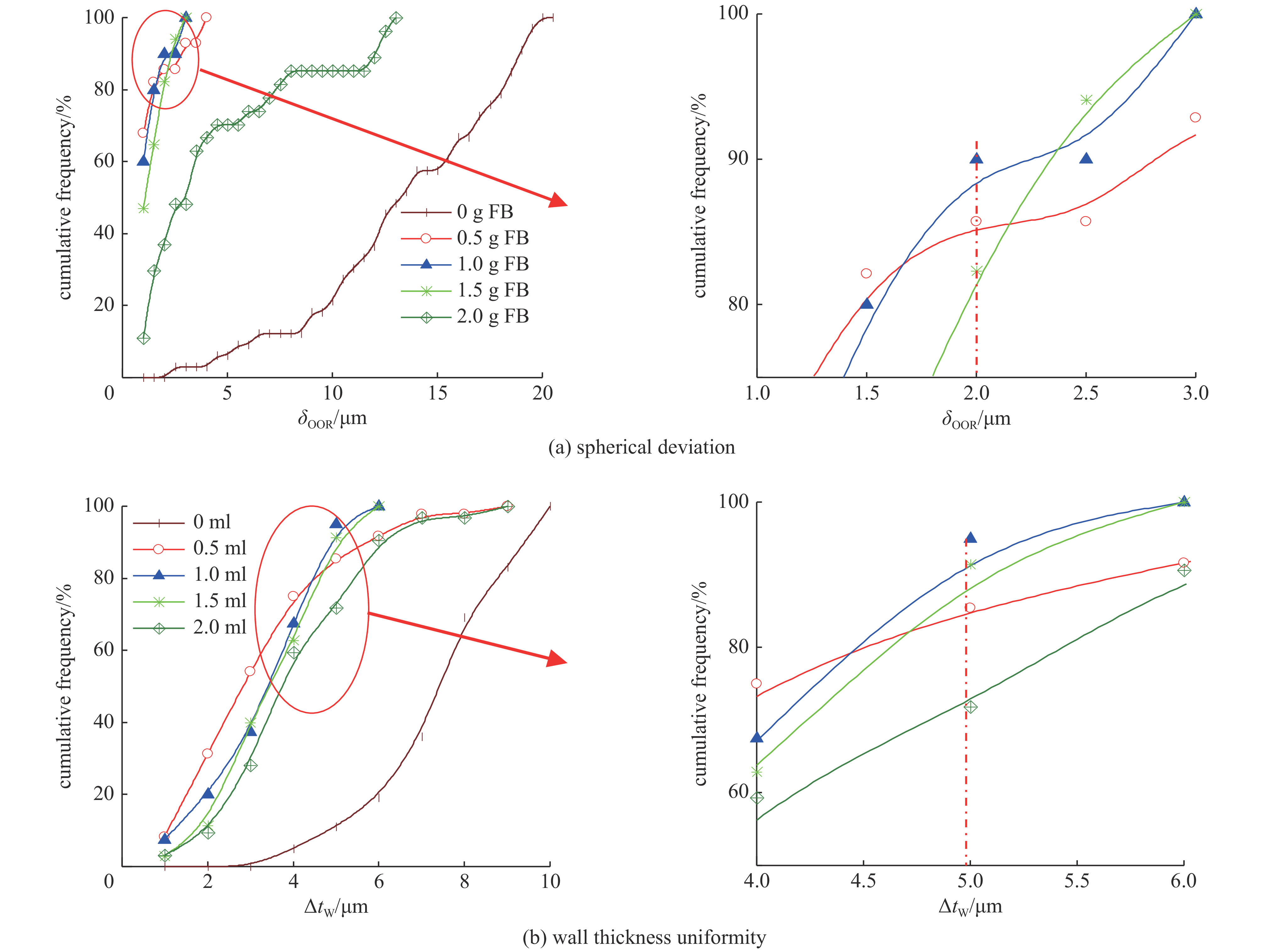

摘要: 激光惯性约束聚变(ICF)作为探索受控核聚变的有效途径,有望获得清洁无污染的能源,而薄壁聚苯乙烯(PS)空心微球是ICF物理实验中亟需的一类微球。针对薄壁空心微球因径厚比(直径/壁厚)增大导致其在干燥、使用中易开裂的问题,研究了PS原料对薄壁微球质量的影响,探讨了其影响机制。结果表明:当油相PS质量分数为4%时,随着油相粘度增加,W1/O/W2复合乳粒稳定性逐渐提高;当油相质量分数不低于8%时,复合乳粒稳定性良好。PS原料对微球表面粗糙度影响较小,微球球形度和壁厚均匀性随初始油相粘度的增大而降低,在干燥过程中微球开裂率随原料力学性能提高而减小。在外水相中引入氟苯(FB)液滴,延缓固化速率,可减小油相粘度增加对微球球形度和壁厚均匀性的不利影响。Abstract: As an effective way to explore controlled nuclear fusion, laser inertial confinement fusion (ICF) is expected to obtain clean and pollution-free energy. Thin-walled polystyrene (PS) hollow microspheres are a type of microspheres urgently needed in ICF physics experiments. Thin-walled hollow microspheres are easy to crack while drying and being used due to the increase in diameter-to-thickness ratio (diameter/wall thickness). In this work, the influence of the PS materials on the quality of thin-walled microspheres was studied, and the mechanism was discussed. The results show that when the oil phase (PS) mass fraction was 4%, the stability of W1/O/W2 composite emulsion particles gradually increased with the increase of oil phase viscosity; when the oil phase mass fraction was not less than 8%, the stability of compound droplets was fine. There is no significant difference in the surface roughness of the corresponding microspheres. The sphericity and wall thickness uniformity of microspheres decreased with the increase of initial oil phase viscosity. In the drying process, the cracking rate of microspheres decreased with the increase of oil phase viscosity. The rate of microsphere cracking decreases as the mechanical properties of the raw material improves. To compensate for the adverse effect of the increase in oil phase viscosity on the sphericity and uniformity of the wall thickness of the microspheres, fluorobenzene (FB) droplets were introduced into the external water phase to reduce the solidification rate.

-

表 1 不同PS原料的分子量及分子量分布

Table 1. Molecular weight and distribution of different PS materials

sample Mw /(kg·mol−1) Mn /(kg·mol−1) Mw/Mn PS-1 206.0 79.6 2.6 PS-2 250.4 119.3 2.1 PS-3 297.8 92.9 3.2 PS-4 356.9 254.2 1.4 表 2 质量分数4%PS-FB油相粘度(25 ℃)

Table 2. Mass fraction 4% PS-FB oil phase viscosity at room temperature (25 ℃)

sample viscosity /(mPa·s) PS-1 3.55 PS-2 3.95 PS-3 4.69 PS-4 5.50 表 3 PS微球乙醇置换后上浮率和干燥过程开裂率

Table 3. Floating rate after ethanol replacement and the cracking rate during the drying process of PS microspheres

sample microsphere

uplifting rate/%cracking rate of uplifted

microspheres during drying/%PS-1 90 62 PS-2 91 51 PS-3 90 47 PS-4 90 40 表 4 不同PS原料力学性能

Table 4. Mechanical properties of different PS

sample elongation at fracture/% tensile strength/MPa Young’s modulus/MPa PS-1 2.00 18.06 875.51 PS-3 2.28 24.14 936.62 PS-4 2.49 28.46 1076.38 表 5 油相与外水相水溶液界面张力

Table 5. Interfacial tension between oil phase and external water phase

sample interfacial tension /(mN·m−1) PS-1 7.58±0.05 PS-2 8.36±0.19 PS-3 8.66±0.13 PS-4 8.02±0.36 -

[1] 张民, 张正炜, 张艳红. 液滴微流控技术制备功能型微球的研究进展[J]. 高校化学工程学报, 2020, 34(5):1102-1112. (Zhang Min, Zhang Zhengwei, Zhang Yanhong. Research progress on functional microsphere preparation by droplet microfluidic technology[J]. Journal of Chemical Engineering of Chinese Universities, 2020, 34(5): 1102-1112 doi: 10.3969/j.issn.1003-9015.2020.05.002 [2] Wang Jianmei, Wang Xueying, Li Yan, et al. Preparation and properties of magnetic polymer microspheres[J]. Polymer, 2020, 199: 122569. doi: 10.1016/j.polymer.2020.122569 [3] 王月桐, 商珞然, 赵远锦. 基于液滴界面不稳定性的表面粗糙聚合物微球的制备及其细胞捕获应用[J]. 物理学报, 2020, 69:084701. (Wang Yuetong, Shang Luoran, Zhao Yuanjin. Surface-textured polymer microspheres generated through interfacial instabilities of microfluidic droplets for cell capture[J]. Acta Physica Sinica, 2020, 69: 084701 doi: 10.7498/aps.69.20200362 [4] 高莎莎, 吴小军, 何智兵, 等. 激光惯性约束聚变靶制备技术研究进展[J]. 强激光与粒子束, 2020, 32:032001. (Gao Shasha, Wu Xiaojun, He Zhibing, et al. Research progress of fabrication techniques for laser inertial confinement fusion target[J]. High Power Laser and Particle Beams, 2020, 32: 032001 [5] 门艳茹, 桑晓明, 杨贤金, 等. 惯性约束聚变靶丸的研究进展[J]. 材料导报, 2004, 18(s2):284-286,290. (Men Yanru, Sang Xiaoming, Yang Xianjin, et al. Research progress of target capsule for inertial confinement fusion[J]. Materials Review, 2004, 18(s2): 284-286,290 [6] 张林, 涂海燕, 唐永健, 等. ICF靶PVA-PS双层空心微球的研制[J]. 高分子材料科学与工程, 1997, 13(s1):137-139. (Zhang Lin, Tu Haiyan, Tang Yongjian, et al. Fabrication of PVA-PS double-layered shells for ICF targtets[J]. Polymeric Materials Science and Engineering, 1997, 13(s1): 137-139 [7] 许晓颖, 简科, 纪小宇. 靶丸用空心微球制备技术研究进展[J]. 硅酸盐学报, 2019, 47(12):1784-1791. (Xu Xiaoying, Jian Ke, Ji Xiaoyu. Research progress on preparation technology of hollow microspheres for targets[J]. Journal of the Chinese Ceramic Society, 2019, 47(12): 1784-1791 [8] Arriaga L R, Amstad E, Weitz D A. Scalable single-step microfluidic production of single-core double emulsions with ultra-thin shells[J]. Lab on a Chip, 2015, 15(16): 3335-3340. doi: 10.1039/C5LC00631G [9] Nakano H, Fukuda T. Fabrication of a thin-walled plastic shell using emulsion technique[J]. Fusion Technology, 1999, 35(2): 189-193. doi: 10.13182/FST99-A11963920 [10] 潘大伟, 杨璨, 李洁, 等. 聚α-甲基苯乙烯空心微球的开裂机理[J]. 高分子材料科学与工程, 2019, 35(4):47-51. (Pan Dawei, Yang Can, Li Jie, et al. Formation mechanisms of crack on surface of poly-alpha-methylstyrene shells[J]. Polymer Materials Science & Engineering, 2019, 35(4): 47-51 [11] Pan Dawei, Huang Weixing, Chen Qiang, et al. Investigation of craze and cracks of polystyrene shells during drying process[J]. Fusion Science and Technology, 2018, 73(1): 59-67. doi: 10.1080/15361055.2017.1372678 [12] Wagner H N R, Hühne C, Zhang J, et al. On the imperfection sensitivity and design of spherical domes under external pressure[J]. International Journal of Pressure Vessels and Piping, 2020, 179: 104015. doi: 10.1016/j.ijpvp.2019.104015 [13] Gentekos D T, Sifri R J, Fors B P. Controlling polymer properties through the shape of the molecular-weight distribution[J]. Nature Reviews Materials, 2019, 4(12): 761-774. doi: 10.1038/s41578-019-0138-8 [14] Liu Meifang, Liu Yiyang, Li Jie, et al. Improvement of sphericity of thick-walled polystyrene shell[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2015, 484: 463-470. doi: 10.1016/j.colsurfa.2015.08.031 [15] Chen Qiang, Huang Yong, Liu Meifang, et al. Parabolic effects of viscosity on dispersion and stability of millimeter-scale W1/O/W2 double droplets for ICF polymer shells[J]. Journal of Dispersion Science and Technology, 2021,doi: 10.1080/01932691.2021.1883441. [16] Park J I, Saffari A, Kumar S, et al. Microfluidic synthesis of polymer and inorganic particulate materials[J]. Annual Review of Materials Research, 2010, 40: 415-443. doi: 10.1146/annurev-matsci-070909-104514 [17] Liu Meifang, Chen Sufen, Qi Xiaobo, et al. Improvement of wall thickness uniformity of thick-walled polystyrene shells by density matching[J]. Chemical Engineering Journal, 2014, 241: 466-476. doi: 10.1016/j.cej.2013.08.120 [18] Liu Meifang, Su Lin, Li Jie, et al. Investigation of spherical and concentric mechanism of compound droplets[J]. Matter and Radiation at Extremes, 2016, 1(4): 213-223. doi: 10.1016/j.mre.2016.07.002 [19] Liu Meifang, Ai Xing, Liu Yiyang, et al. Fabrication of solid CH-CD multilayer microspheres for inertial confinement fusion[J]. Matter and Radiation at Extremes, 2021, 6: 025901. doi: 10.1063/5.0033103 [20] Chen Qiang, Chen Sufen, Liu Meifang, et al. Influence of fluorobenzene mass transfer on the qualities of poly-α-methylstyrene shells[J]. RSC Advances, 2018, 8(7): 3687-3693. doi: 10.1039/C7RA09799A -

下载:

下载: