Scattering correction method of cone-beam X-ray CT based on slanted hole scattering correction plate

-

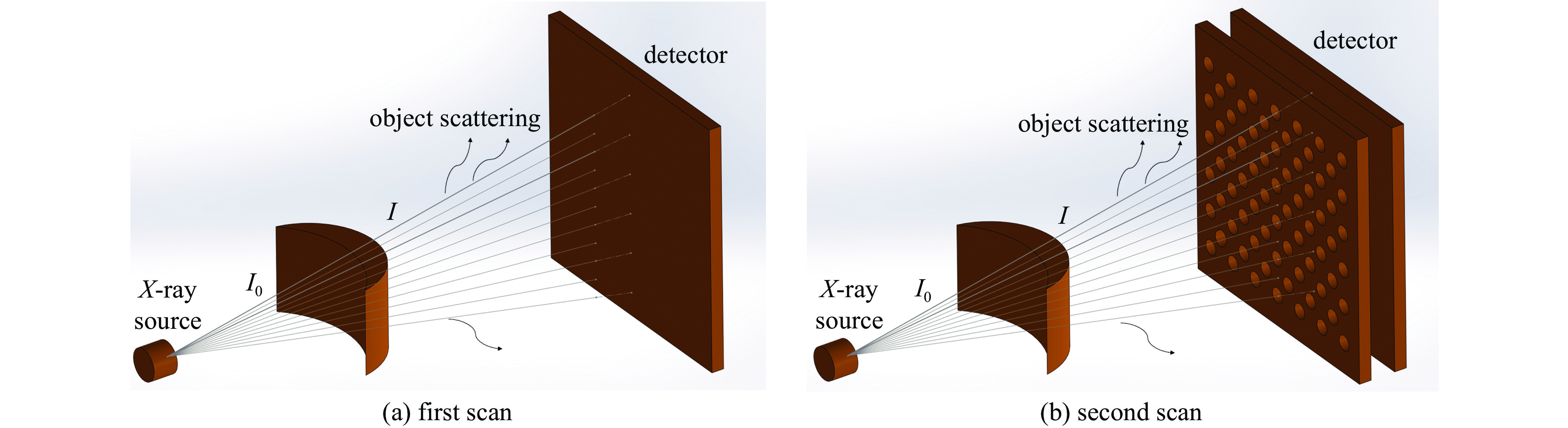

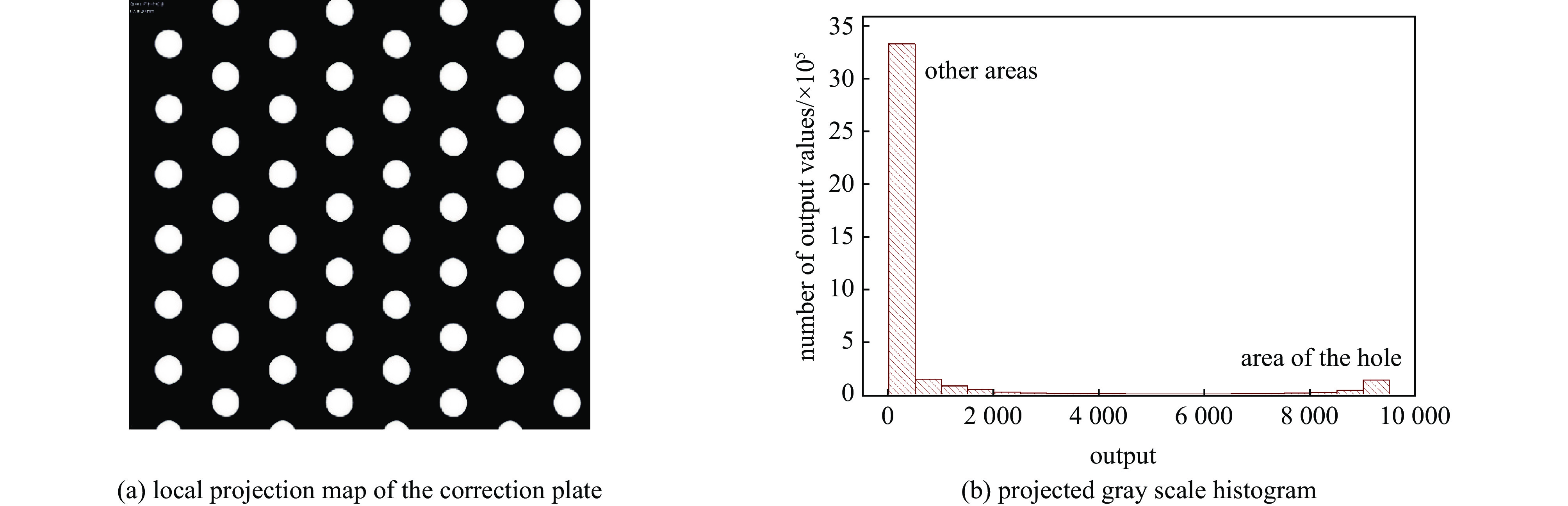

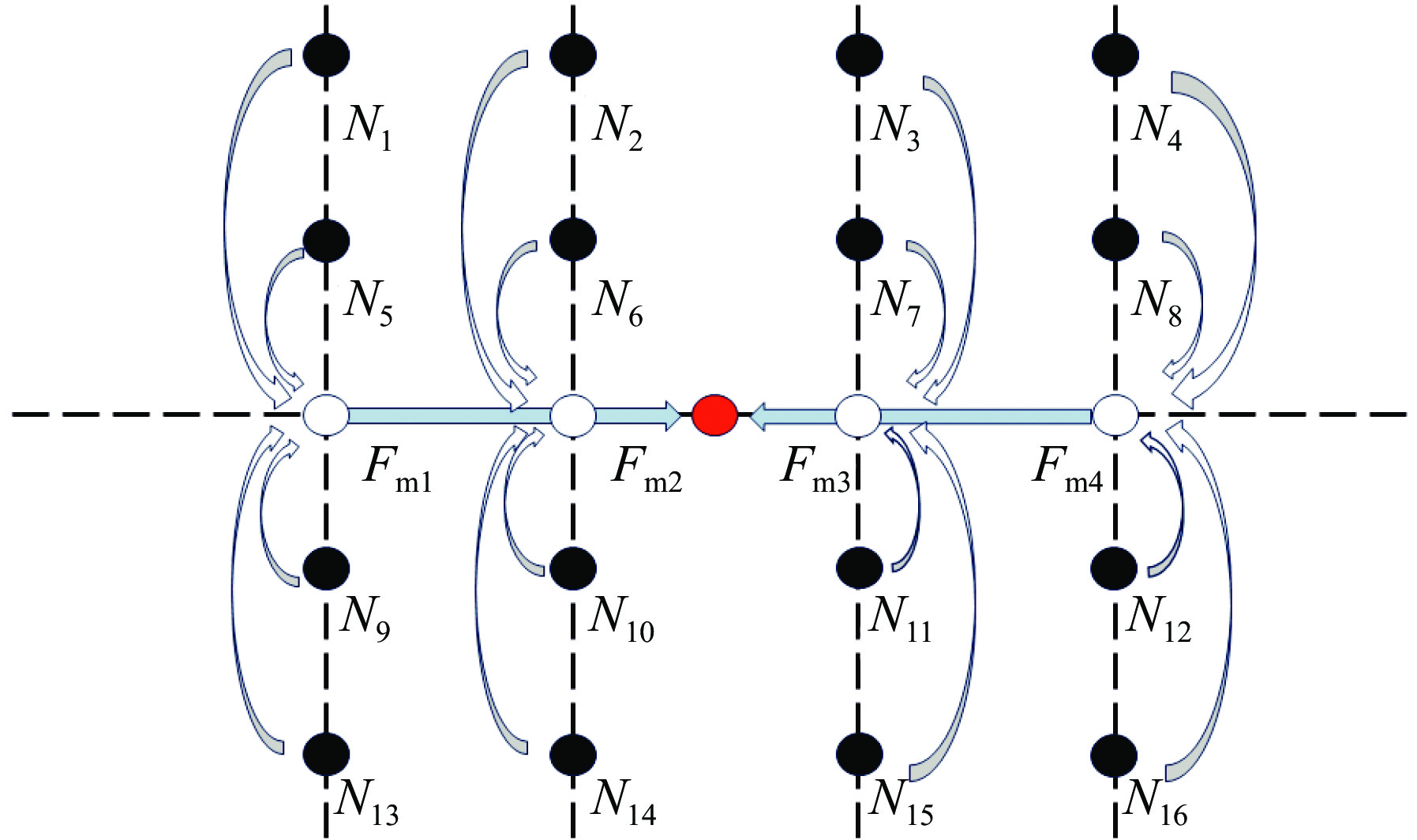

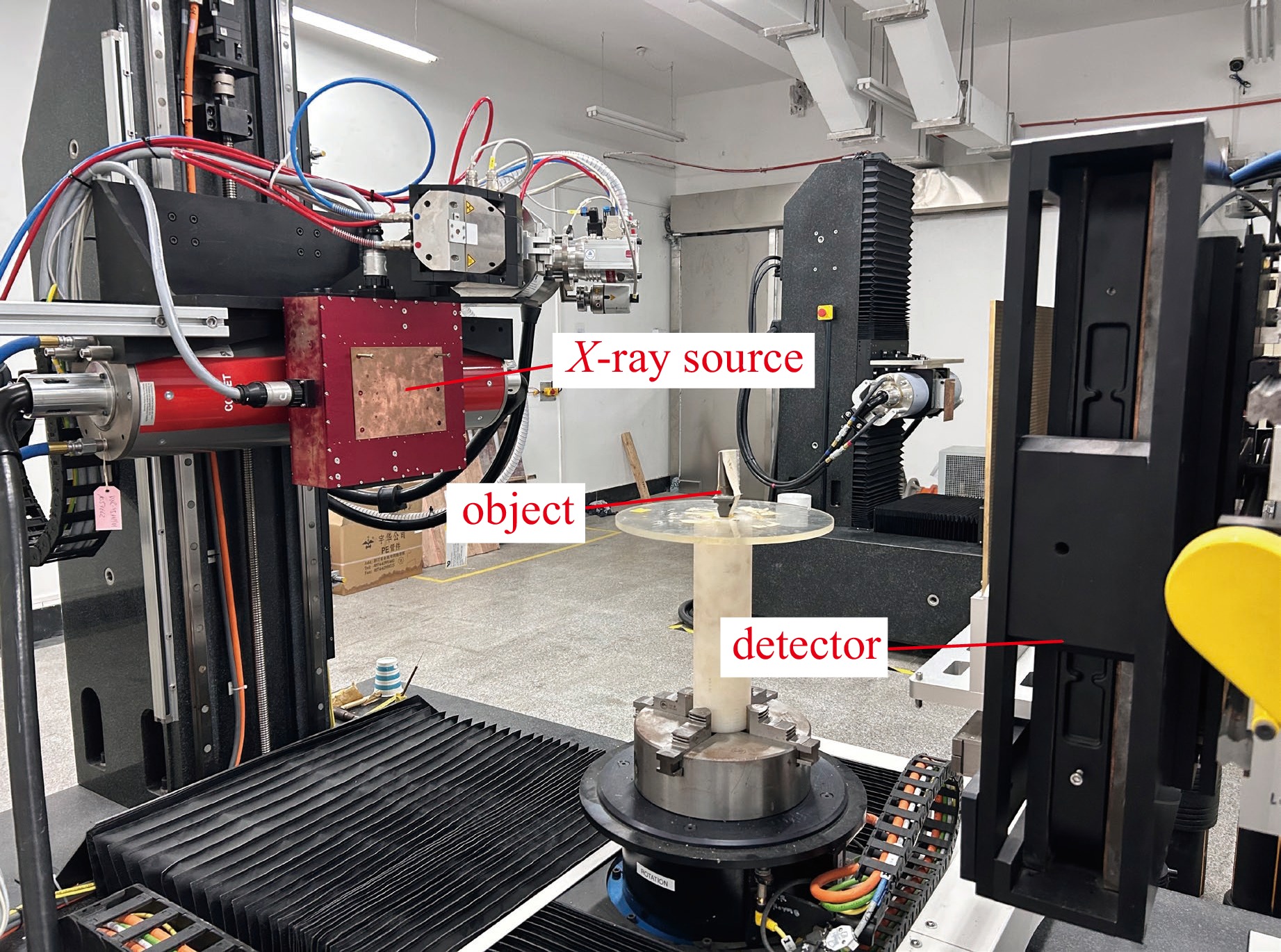

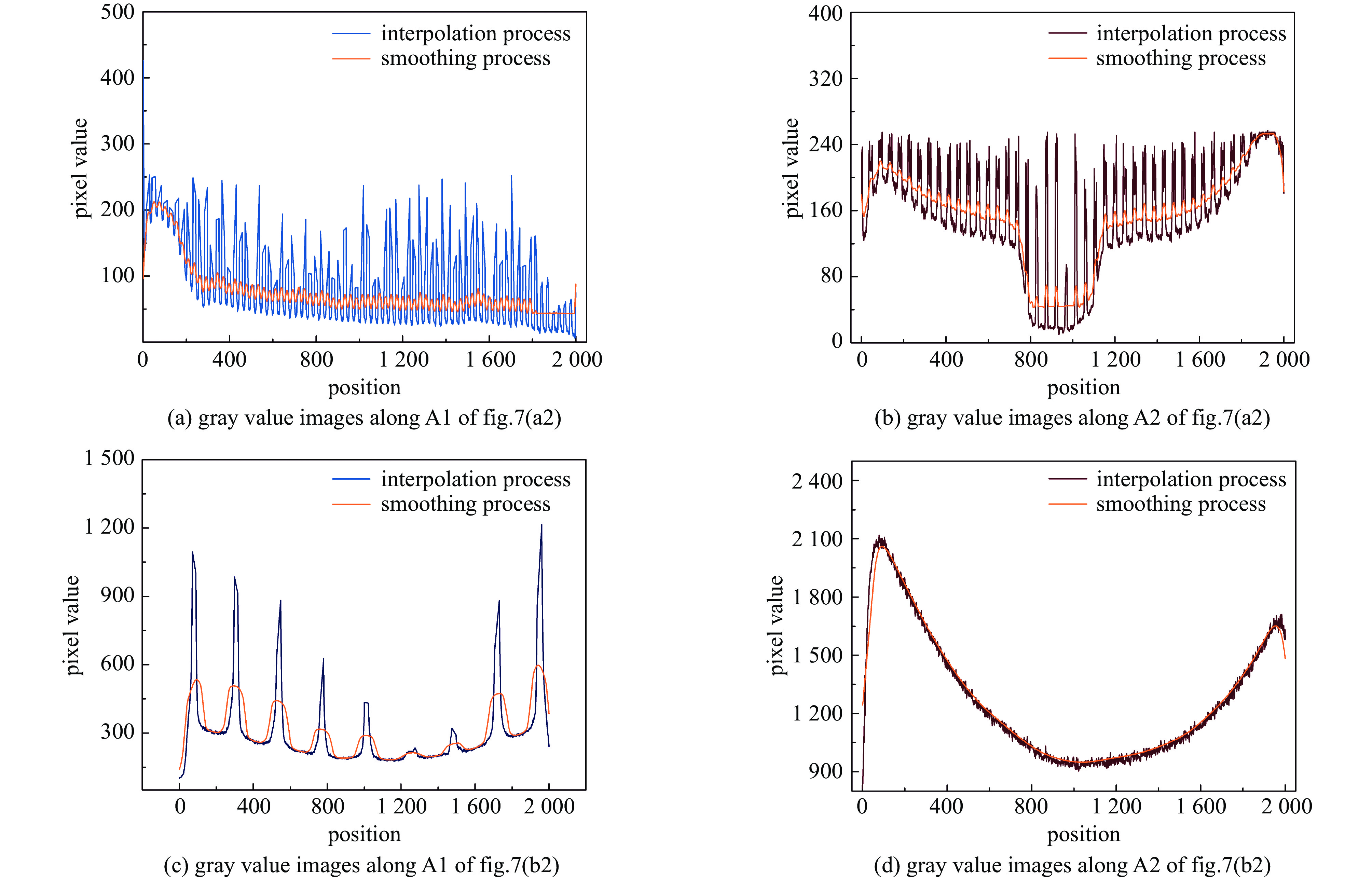

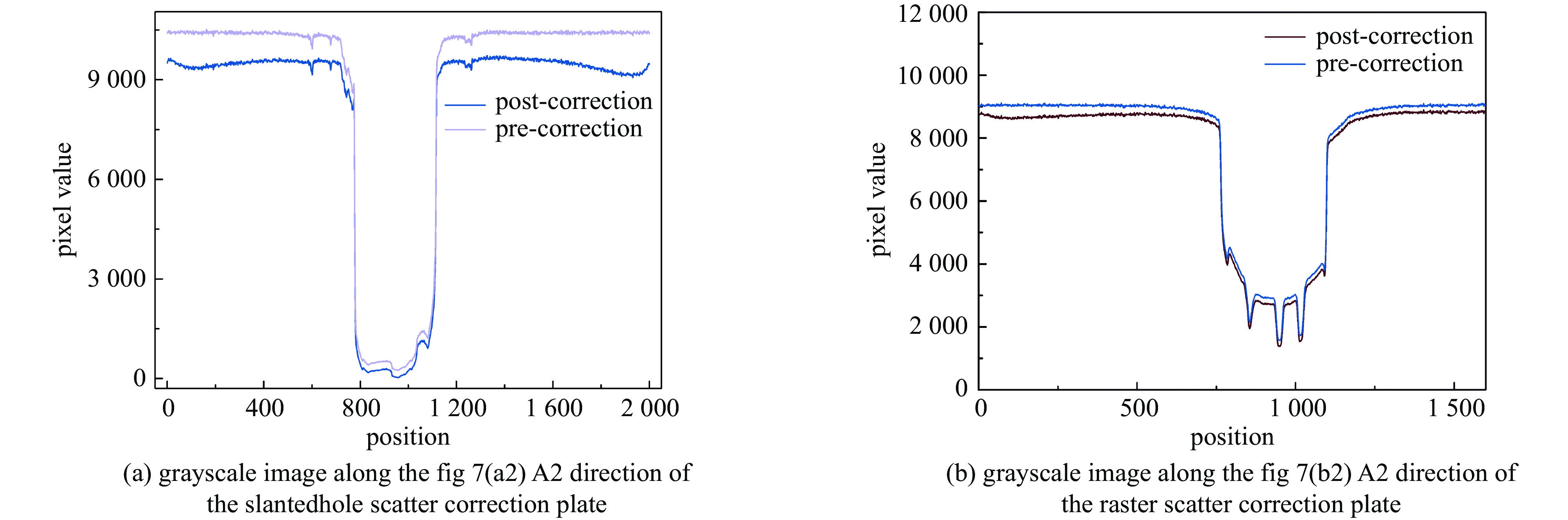

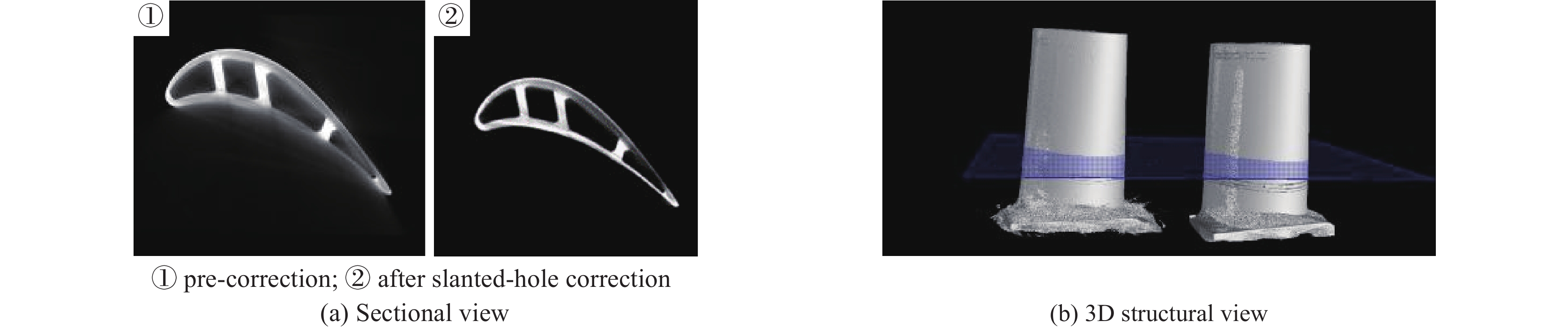

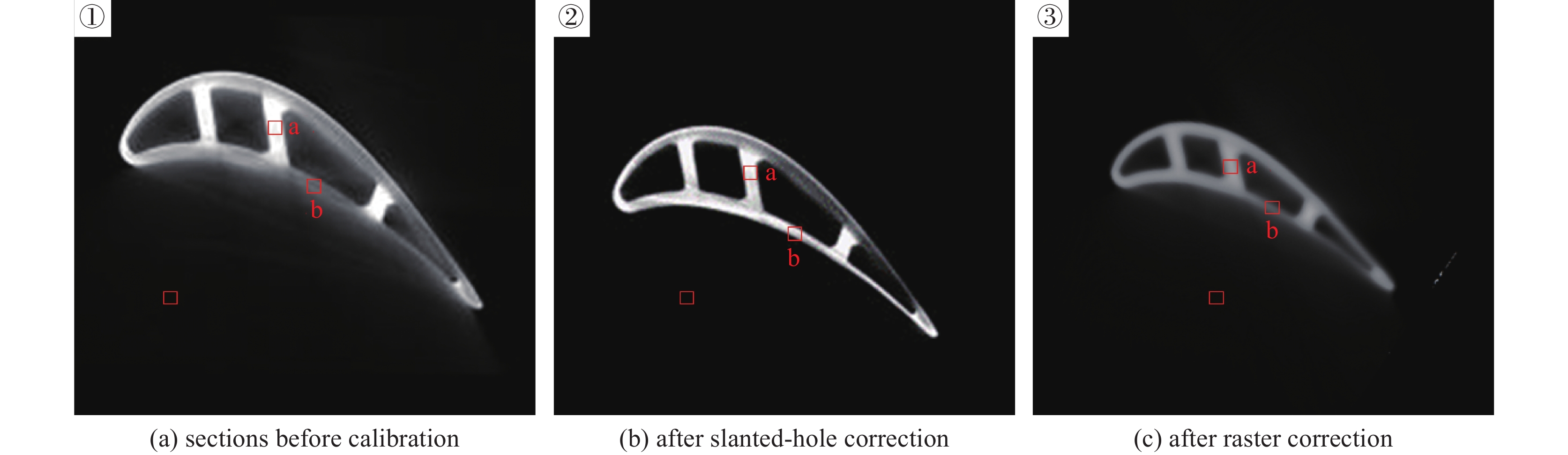

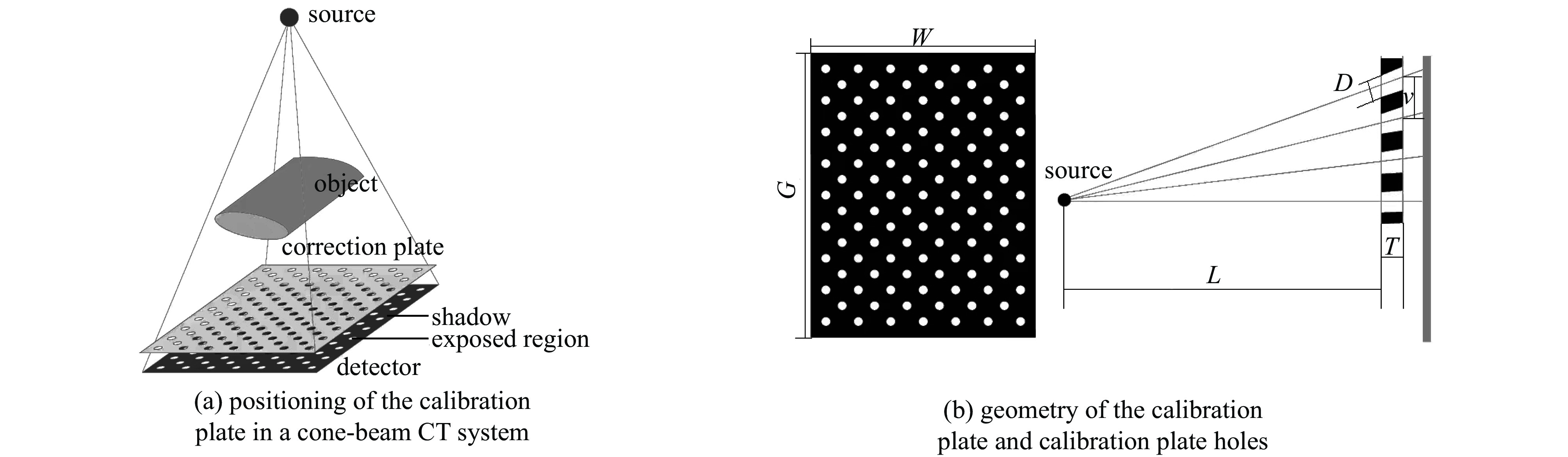

摘要: 锥束X射线CT和二维扇束、平行束CT系统相比具有扫描速度快、射线利用率高、重建图像轴向分辨率和水平分辨率一致等优点,是当前工业CT技术发展的重点。然而,由于散射线的存在,其成像质量受到影响。为了减小散射线对图像质量的影响,提出一种新的基于斜孔散射校正板的散射校正方法,对该方法的原理和实现进行了深入的研究,通过获取原始扫描数据以及斜孔散射校正板后的扫描数据,利用插值和平滑处理的方法获得散射场数据。然后,通过将原始数据减去散射场数据后进行重建,即可得到无散射的CT图像。通过与光栅式散射校正板校正方法进行对比,结果表明,该方法应用于涡轮叶片的锥束CT扫描结果校正,典型区域(叶片内冷却通道及叶片内壁)对比度噪声比分别提升了14.2%和56.8%,而光栅式散射校正板校正后,同一位置对比度噪声比分别仅提升了5.6%和27.6%,验证了基于斜孔散射校正板散射校正方法的优越性。Abstract: Compared with two-dimensional fan-beam and parallel-beam CT systems, cone-beam X-ray CT has advantages such as fast scanning speed, high X-ray utilization efficiency, consistent axial and horizontal resolution of reconstructed images, and is the focus of current industrial CT technology development. However, the imaging quality is affected by the presence of scattered radiation. In order to reduce the impact of scattered radiation on image quality, this paper proposes a new scatter correction method based on an slanted hole scatter correction plate. The principle and implementation of this method are thoroughly investigated. By acquiring raw scan data and scan data after using the slanted hole scatter correction plate, scatter field data is obtained using interpolation and smoothing techniques. Then, by subtracting the scatter field data from the original data and performing reconstruction, scatter-free CT images can be obtained. Compared with the grating-based scatter correction plate method, the results show that when applied to cone-beam CT scans of turbine blades, the contrast-to-noise ratio of typical regions (cooling channels within the blades and inner walls of the blades) is improved by 14.2% and 56.8% respectively with the slanted hole scatter correction plate method, whereas with the grating-based scatter correction plate method, the same positions only show an improvement of 5.6% and 27.6% respectively. This validates the superiority of the slanted hole scatter correction plate scatter correction method.

-

表 1 校正板几何参数

Table 1. Correction plate geometry parameters

projects width of calibration

plate /mmcalibration plate

height/mmcalibration plate

thickness/mmhole

diameter/mmvertical hole

spacing/mmhorizontal hole

spacing/mmnumerical value 400 400 20 4 9.2 5.3 表 2 扫描参数

Table 2. Scanning parameters

Scanning parameters Scanning Voltage/$ kV $ Scanning Current/$ \mu A $ Focus size/$ mm $ image size/(pixel×pixel) FOD/mm FDD/mm value 260 180 0.4 2000*2000 149 807 表 3 校正前后切片图像对比度噪声比

Table 3. CNR of tomographic images before and after correction

Correction method Area a Area b Origin CNR CNR improvement ratio/% Origin CNR CNR improvement ratio/% pre-correction 30.3 / 7 / After slanted-hole correction 35.3 14.2% 16.2 56.8% After raster correction 32.1 5.6% 9.7 27.6% -

[1] 李新越, 杨龙, 孙春贵, 等. 基于微焦点工业CT的高压涡轮叶片缺陷检测技术[J]. 铸造, 2023, 72(7):904-908Li Xinyue, Yang Long, Sun Chungui, et al. High-pressure turbine blade defect detection technology based on micro-focus industrial CT[J]. Foundry, 2023, 72(7): 904-908 [2] 杨光, 高嘉保, 韩瑞. 基于深度学习建立模型去除工业CT伪影的技术研究[J]. 无损探伤, 2023, 47(3):18-22Yang Guang, Gao Jiabao, Han Rui. Research on the technology of removing artifacts in industrial CT based on deep learning modeling[J]. Nondestructive Testing Technology, 2023, 47(3): 18-22 [3] 阳庆国, 谭伯仲. 高性能锥束工业X射线CT系统研制与应用[J]. 光学 精密工程, 2023, 31(6):804-812 doi: 10.37188/OPE.20233106.0804Yang Qingguo, Tan Bozhong. Development and application of high-performance cone-beam industrial X-ray CT system[J]. Optical and Precision Engineering, 2023, 31(6): 804-812 doi: 10.37188/OPE.20233106.0804 [4] 齐子诚, 倪培君, 姜伟, 等. 金属材料内部缺陷精确工业CT测量方法[J]. 强激光与粒子束, 2018, 30:025102Qi Zicheng, Ni Peijun, Jiang Wei, et al. CT method for accurately sizing flaws in metallic material[J]. High Power Laser and Particle Beams, 2018, 30: 025102 [5] 唐杰, 张丽, 高文焕. 基于平板探测器的锥束CT系统综述[J]. 中国体视学与图像分析, 2004, 9(2):65-70 doi: 10.3969/j.issn.1007-1482.2004.02.001Tang Jie, Zhang Li, Gao Wenhuan. Review of cone-beam CT systems based on flat panel detector[J]. Chinese Journal of Stereology and Image Analysis, 2004, 9(2): 65-70 doi: 10.3969/j.issn.1007-1482.2004.02.001 [6] Huang Kuidong, Zhang Hua, Shi Yikai, et al. Scatter correction method for cone-beam CT based on interlacing-slit scan[J]. Chinese Physics B, 2014, 23: 098106. doi: 10.1088/1674-1056/23/9/098106 [7] Halmshaw R. Industrial radiology: theory and practice[M]. Dordrecht: Springer, 1995. [8] 李双镭, 张丽, 陈志强, 等. 450keV锥束CT系统的散射校正研究[J]. 核电子学与探测技术, 2006, 26(6):908-911 doi: 10.3969/j.issn.0258-0934.2006.06.059Li Shuanglei, Zhang Li, Chen Zhiqiang, et al. X-ray scatter correction algorithm for 450keV cone-beam CT system[J]. Nuclear Electronics & Detection Technology, 2006, 26(6): 908-911 doi: 10.3969/j.issn.0258-0934.2006.06.059 [9] Cai Weixing, Ning Ruola, Conover D. Scatter correction using beam stop array algorithm for cone-beam CT breast imaging[C]//Proceedings of SPIE 6142, Medical Imaging 2006: Physics of Medical Imaging. 2006: 1157-1165. [10] Liu Wenlei, Rong Junyan, Gao Peng, et al. Algorithm for X-ray beam hardening and scatter correction in low-dose cone-beam CT: phantom studies[C]//Proceedings of SPIE 9783, Medical Imaging 2016: Physics of Medical Imaging. 2016: 785-792. [11] 邵义文, 卢文婷, 周凌宏. 锥形束CT系统的散射校正方法分析[J]. 中国医学物理学杂志, 2008, 25(3):634-637Shao Yiwen, Lu Wenting, Zhou Linghong. Review of the methods for X-ray scatter correction in cone-beam CT system[J]. Chinese Journal of Medical Physics, 2008, 25(3): 634-637 [12] Sisniega A, Zbijewski W, Xu J, et al. High-fidelity artifact correction for cone-beam CT imaging of the brain[J]. Physics in Medicine & Biology, 2015, 60(4): 1415-1439. [13] Iskender B, Bresler Y. Scatter correction in X-ray CT by physics-inspired deep learning[J]. IEEE Transactions on Computational Imaging, 2022, 8: 1074-1088. doi: 10.1109/TCI.2022.3226300 [14] Lalonde A, Winey B, Verburg J, et al. Evaluation of CBCT scatter correction using deep convolutional neural networks for head and neck adaptive proton therapy[J]. Physics in Medicine & Biology, 2020, 65: 245022. [15] Naimuddin S, Hasegawa B, Mistretta C A. Scatter-glare correction using a convolution algorithm with variable weighting[J]. Medical Physics, 1987, 14(3): 330-334. doi: 10.1118/1.596088 [16] Ning Ruola, Tang Xiangyang, Conover D. X-ray scatter correction algorithm for cone-beam CT imaging[J]. Medical Physics, 2004, 31(5): 1195-1202. doi: 10.1118/1.1711475 [17] 邹伟, 朱国平, 凌云龙, 等. 集装箱CT检查系统二维防散射滤线栅作用分析[J]. 强激光与粒子束, 2023, 35:086001Zou Wei, Zhu Guoping, Ling Yunlong, et al. A simulation study of two-dimensional anti-scatter grid in container CT inspection systems[J]. High Power Laser and Particle Beams, 2023, 35: 086001 [18] 杨富强. 基于知识的涡轮叶片高质量锥束CT成像技术研究[D]. 西安: 西北工业大学, 2018Yang Fuqiang. High quality imaging research on turbine lades for knowledge-based cone beam CT[D]. Xi’an: Northwestern Polytechnical University, 2018 [19] Kaufmann M, Pfaffelhuber C, Vater I, et al. Quantitative assessment of a beam hole scatter correction in industrial computed tomography[J]. tm - Technisches Messen, 2022, 89(9): 625-633. doi: 10.1515/teme-2022-0018 [20] Zhu Yubin, Dai Yonghang, Han Kaining, et al. An efficient bicubic interpolation implementation for real-time image processing using hybrid computing[J]. Journal of Real-Time Image Processing, 2022, 19(6): 1211-1223. doi: 10.1007/s11554-022-01254-8 [21] 秦彦平, 张军, 多化琼, 等. 木材节子图像增强的小波变换与双三次插值融合方法[J]. 西北林学院学报, 2021, 36(5):183-189Qin Yanping, Zhang Jun, Duo H Q, et al. Fusion method of wavelet transform and bicubic interpolation for wood knot image enhancement[J]. Journal of Northwest Forestry University, 2021, 36(5): 183-189 [22] 唐天旭, 段晓礁, 周志政, 等. 基于散射校正板的锥束微纳CT系统的散射校正[J]. 光学学报, 2019, 39:0834001 doi: 10.3788/AOS201939.0834001Tang Tianxu, Duan Xiaojiao, Zhou Zhizheng, et al. Scatter correction based on beam stop array for cone-beam micro-computed tomography[J]. Acta Optica Sinica, 2019, 39: 0834001 doi: 10.3788/AOS201939.0834001 [23] 胡栋材, 陈浩, 张定华. 基于平板探测器的锥束CT散射校正方法[J]. CT理论与应用研究, 2009, 18(1):16-22Hu Dongcai, Chen Hao, Zhang Dinghua. Scatter correction method for flat-panel detector-based cone beam CT[J]. CT Theory and Applications, 2009, 18(1): 16-22 -

点击查看大图

点击查看大图

计量

- 文章访问数: 28

- HTML全文浏览量: 16

- PDF下载量: 3

- 被引次数: 0

下载:

下载: