Simulation and experimental investigation on nano-second pulsed laser drilling of titanium alloy

-

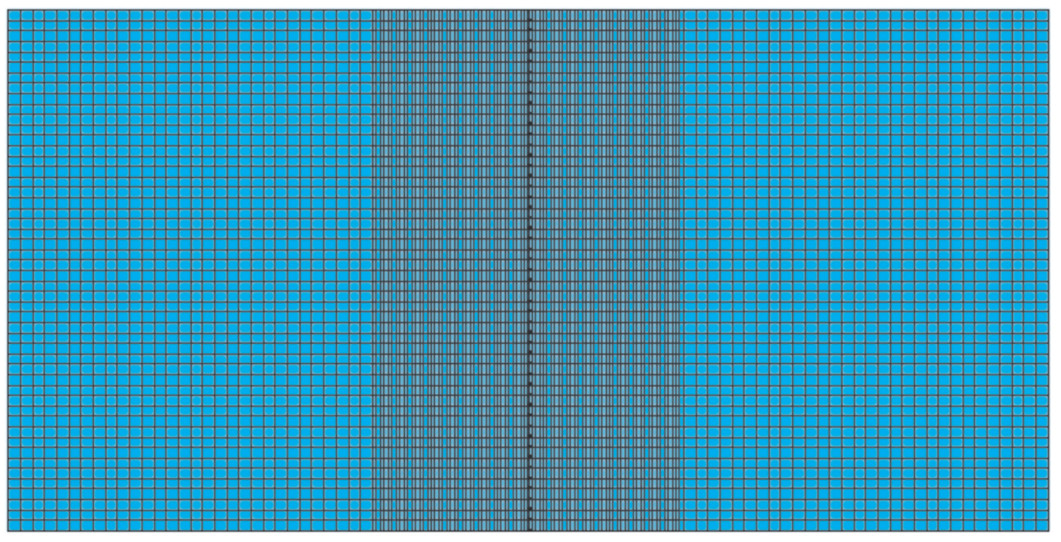

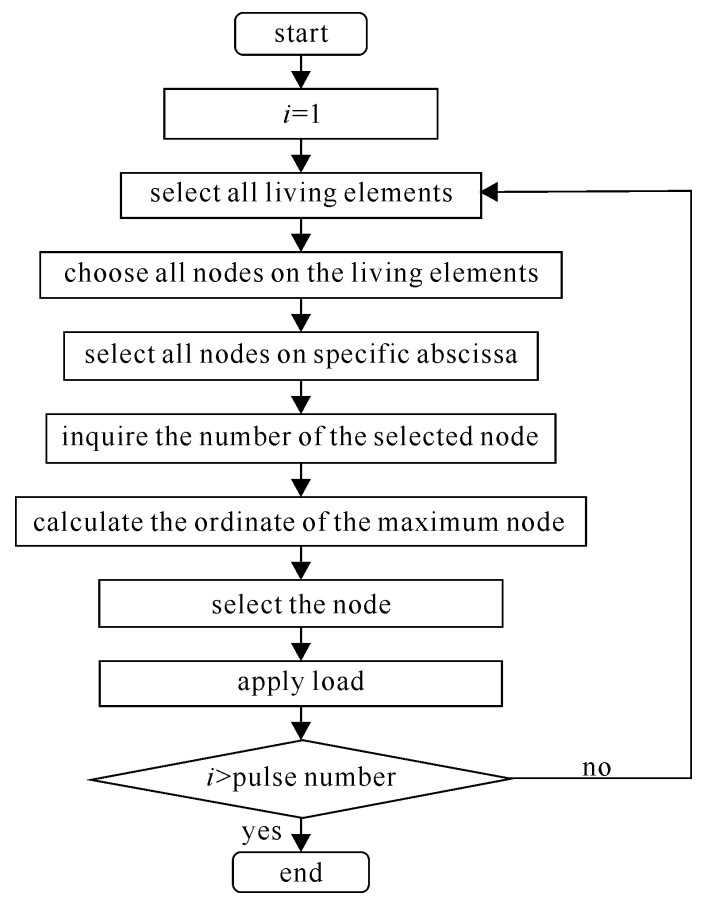

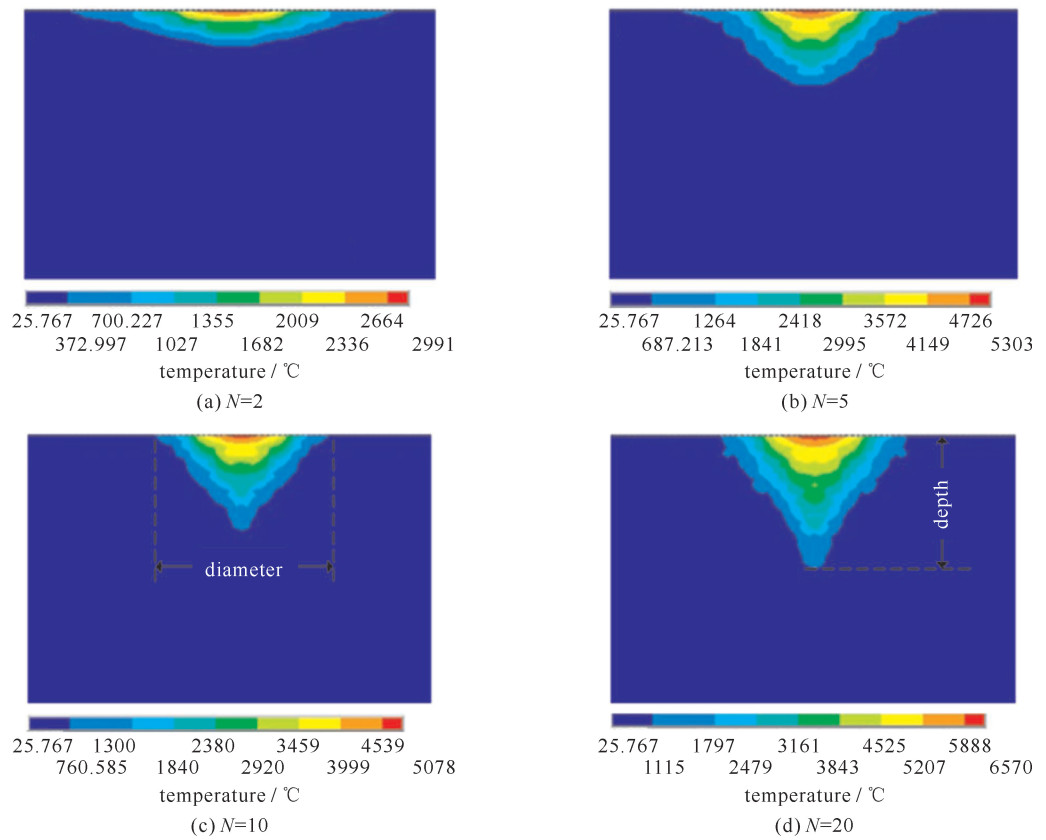

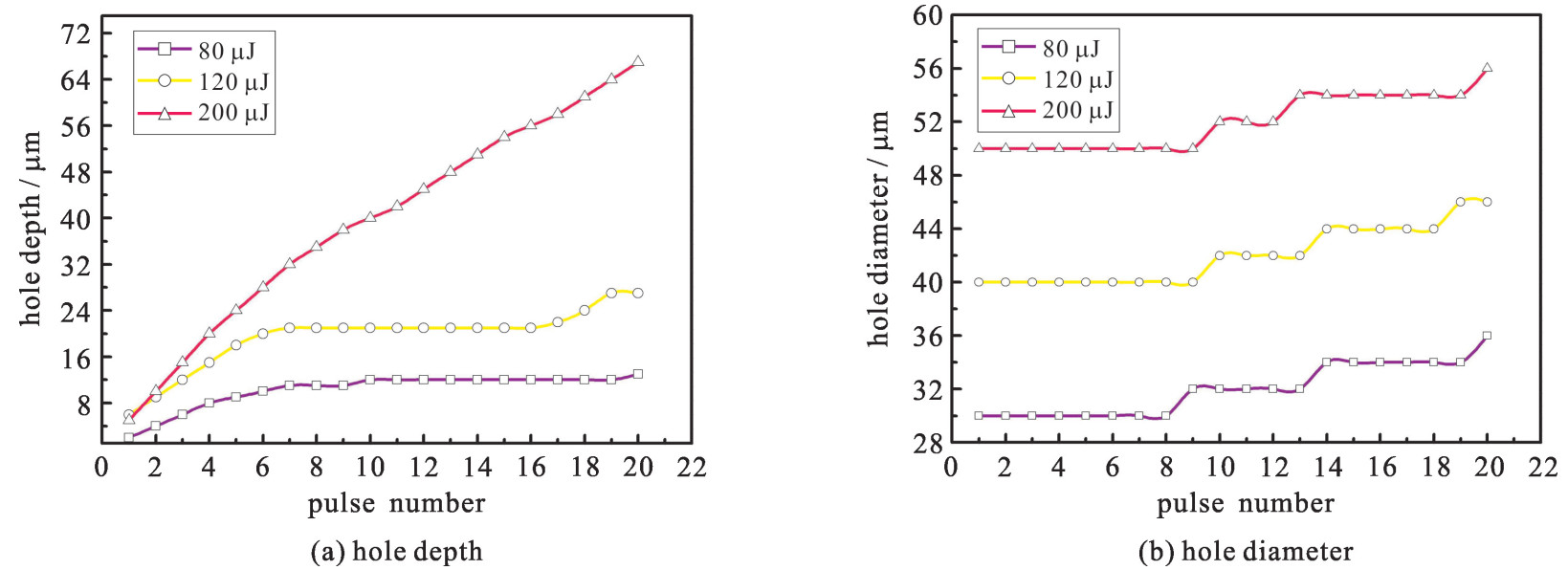

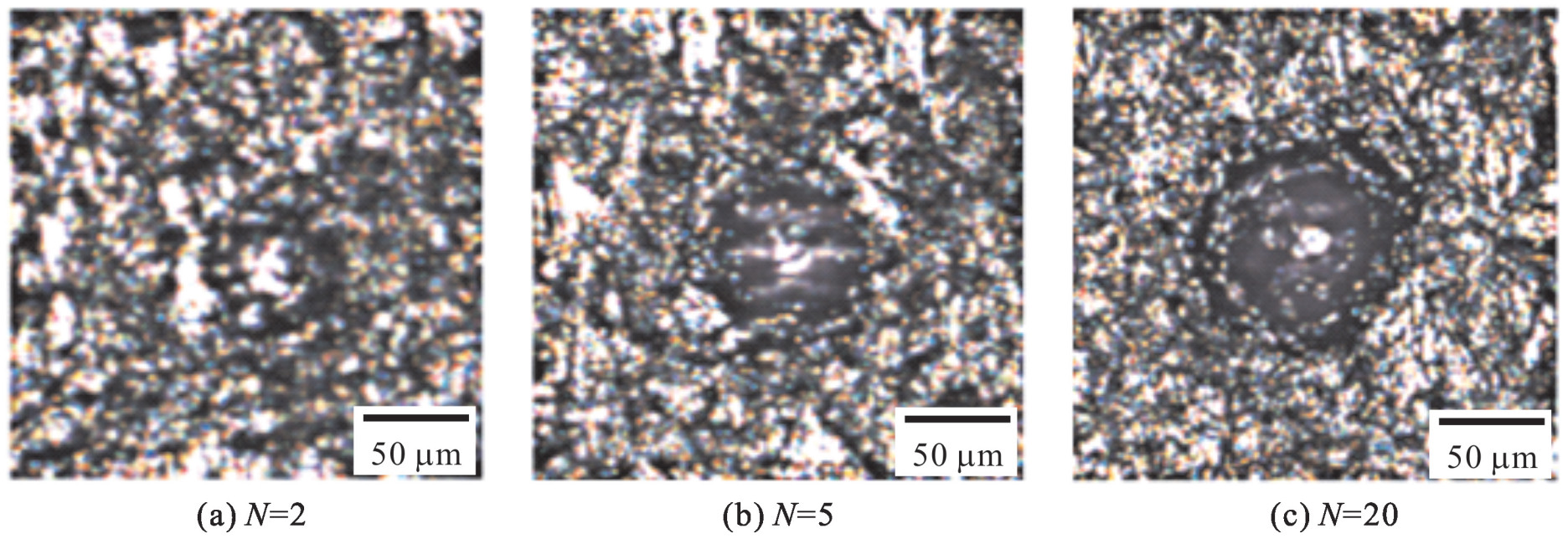

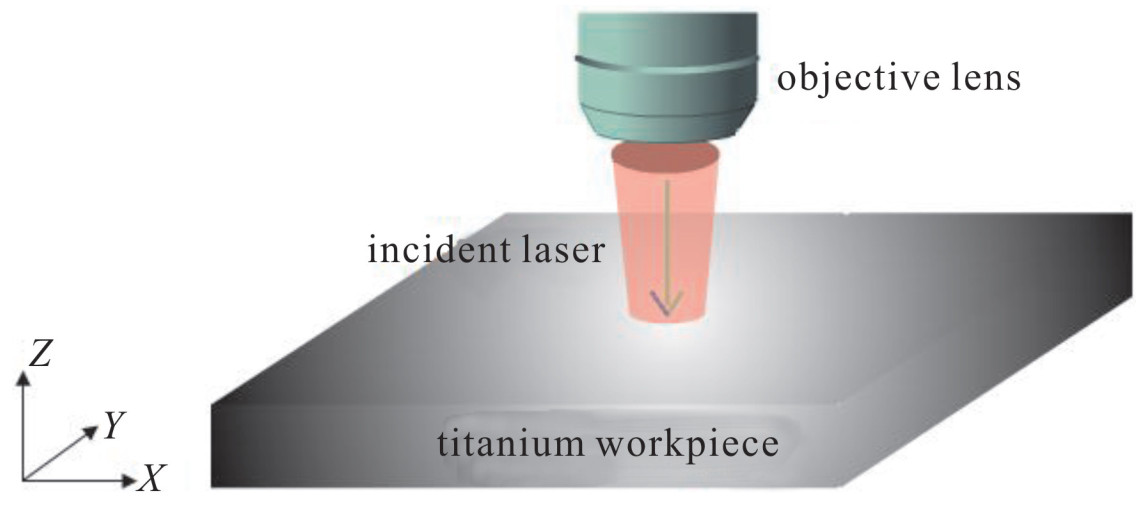

摘要: 为了描述纳秒激光对钛合金打孔过程中孔的形貌及温度场的变化规律,建立激光打孔的物理模型,利用ANSYS中APDL语言进行编程,对温度场进行仿真分析,并利用单元生死技术模拟孔形貌的变化过程。从有限元数值模拟和实验两方面综合分析比较了激光工艺参数(脉冲能量和脉冲数量)对打孔质量(孔深和孔径)的影响,系统论述了钛合金纳秒激光打孔的一般规律,以达到工艺参数优化,提高打孔质量的目的。Abstract: To describe morphological changes in the drilling hole and simulate the temperature distribution during nanosecond laser drilling, a physical model of titanium nanosecond-pulsed laser drilling was established and programmed using ANSYS Parametric Design Language (APDL). Elements birth and death technology was applied to simulate the drilling process in the finite element analysis software ANSYS. Experimental and simulation results were compared, and curve changes in the laser drilling results (hole depth and diameter) together with laser machining parameters (laser energy and pulse number) were obtained and investigated. Effects of process parameters on hole quality are analyzed and compared from finite element simulation and experiment to optimize process parameters and improve hole quality. The universal law of nano-second pulsed laser drilling on titanium alloy is discussed systematically.

-

Key words:

- nanosecond-pulsed laser /

- titanium alloy /

- laser drilling /

- temperature field

-

表 1 钛合金的热物理性能参数

Table 1. Thermal physical parameters of titanium alloy

temperature/℃ ENTH/(109·J·m-3) specific heat/(103·J·kg-1·℃-1) thermal conductivity/(W·m-1·℃-1) 25 0.7 0.52 21.9 500 1.81 0.52 21.9 1000 2.99 0.52 21.9 1500 4.16 0.52 21.9 2000 5.33 0.52 21.9 表 2 钛合金TC4的化学成分

Table 2. Composition of titanium alloy TC4

chemical composition content/% Ti Al V Fe C N H O Ti-6Al-4V surplus 5.5~6.8 3.5~4.5 0.30 0.10 0.05 0.015 0.20 -

[1] 颜鸣皋. 航空材料技术的发展与应用[J]. 新材料产业, 2009(10): 24-27. doi: 10.3969/j.issn.1008-892X.2009.10.006Yan Minggao. The development and application of aviation materials technology. Advanced Material Industry, 2009(10): 24-27 doi: 10.3969/j.issn.1008-892X.2009.10.006 [2] 李晓红. 一代材料一代装备——浅谈航空新材料与飞机、发动机的发展[J]. 航空工业经济研究, 2008, (5): 5-11. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJZM200810003.htmLi Xiaohong. Generation materials Generation equipment—New introduction to aviation materials and the development of aircraft engine. Aviation Industry Economy, 2008, (5): 5-11 https://www.cnki.com.cn/Article/CJFDTOTAL-ZJZM200810003.htm [3] Özcan M, Hämmerle C. Titanium as a reconstruction and implant material in dentistry: Advantages and Pitfalls[J]. Materials, 2012 (5): 1528-1545. [4] 齐歆霞, 朱海南. 航空发动机叶片气膜孔加工工艺分析[C]//第14届全国特种加工学术会议论文集. 哈尔滨: 哈尔滨工业大学出版社, 2011: 160-163.Qi Xinxia, Zhu Hainan. Analysis of the process of gas holes on aero-engine blade//The 14th Special Processing Academic Conference. Harbin: Harbin Institute of Technology Press, 2011: 160-163 [5] Herrera G, Padilla A, Hernandez-Rivera S, et al. Surface enhanced Raman scattering (SERS) studies of gold and silver nanoparticles prepared by laser ablation[J]. Nanomaterials, 2013, 3: 158-172. doi: 10.3390/nano3010158 [6] Canel T, Kaya A U, Çelik B, et al. Parameter optimization of nanosecond laser for microdrilling on PVC by Taguchi method[J]. Optics & Laser Technology, 2012, 44: 2347-2353. [7] 宋林森, 史国权, 李占国, 等. ANSYS在激光打孔温度场仿真中的应用[J]. 长春理工大学学报, 2006, 29(4): 19-21. doi: 10.3969/j.issn.1672-9870.2006.04.006Song Linsen, Shi Guoquan, Li Zhanguo, et al. Simulation on laser drilling temperature field by using ANSYS. Journal of Changchun University of Science and Technology, 2006, 29(4): 19-21 doi: 10.3969/j.issn.1672-9870.2006.04.006 [8] 倪晓昌, 王清月. 飞秒、皮秒激光烧蚀金属表面的有限差分热分析[J]. 中国激光, 2004, 31(3): 22-25. https://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ200403005.htmNi Xiaochang, Wang Qingyue. Finite difference method for thermal analysis of femtosecond-picosecond pulse laser ablation on metal surface. Chinese Journal of Lasers, 2004, 31(3): 22-25 https://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ200403005.htm [9] 孙立华. 陶瓷激光打孔技术研究[D]. 长春: 长春理工大学, 2006.Sun Lihua. The research of laser drilling on ceramics. Changchun: Changchun University of Science and Technology, 2006 [10] 徐庆仁. 激光加工技术的地位、现状和发展趋势(上)[J]. 航空制造工程, 1996(9): 22-24. https://www.cnki.com.cn/Article/CJFDTOTAL-KONG609.018.htmXu Qingren. Status, current situation and development of laser processing technology(part one). Aviation Engineering & Maintenance, 1996(9): 22-24 https://www.cnki.com.cn/Article/CJFDTOTAL-KONG609.018.htm [11] Leitz K H, Koch H, Otto A, et al. Numerical simulation of process dynamics during laser beam drilling with short pulses[J]. Applied Physics A, 2011, 106: 885-891. [12] Zhang H S, Hu R X, Kang S T, et al. ANSYS12.0 thermodynamic finite element analysis from entry to the master[M]. Beijing: China Machine Press, 2010. [13] Yan Y Z, Ji L F, Bao Y, et al. An experimental and numerical study on laser percussion drilling of thick-section alumina[J]. Journal of Materials Processing Technology, 2012, 212: 1257-1270. doi: 10.1016/j.jmatprotec.2012.01.010 [14] Sowdari D, Majumdar P. Finite element analysis of laser irradiated metal heating and melting processes[J]. Optics & Laser Technology, 2010, 42: 855-865. doi: 10.3969/j.issn.1002-2082.2010.05.038 [15] Collins J, Gremaud P. A simple model for laser drilling[J]. Computers in Simulation, 2011, 81: 1541-1552. doi: 10.1016/j.matcom.2010.07.010 [16] Chen B C, Tsai Y H, Ho C Y, et al. Parametric effects on femtosecond laser ablation of Al2O3 ceramics[J]. Ceramics International, 2013, 39: 341-344. doi: 10.1016/j.ceramint.2012.10.090 [17] Mishra S, Yadava V. Modeling and optimization of laser beam percussion drilling of thin aluminum sheet[J]. Optics & Laser Technology, 2013, 48: 461-474. [18] Zhang Y, Li S, Chen G, et al. Experimental observation and simulation of keyhole dynamics during laser drilling[J]. Optics & Laser Technology, 2013, 48: 405-414. [19] Otto A, Koch H, Vazquez R G, et al. Multiphysical simulation of laser material processing[J]. Physics Procedia, 2012, 39: 843-852. [20] Ren X D, Zhan Q B, Yang H M, et al. The effects of residual stress on fatigue behavior and crack propagation from laser shock processing-worked hole[J]. Material Design, 2013, 44: 149-154. -

下载:

下载: