Molecular dynamics study of the effect of helium on the heat transfer performance of tungsten

-

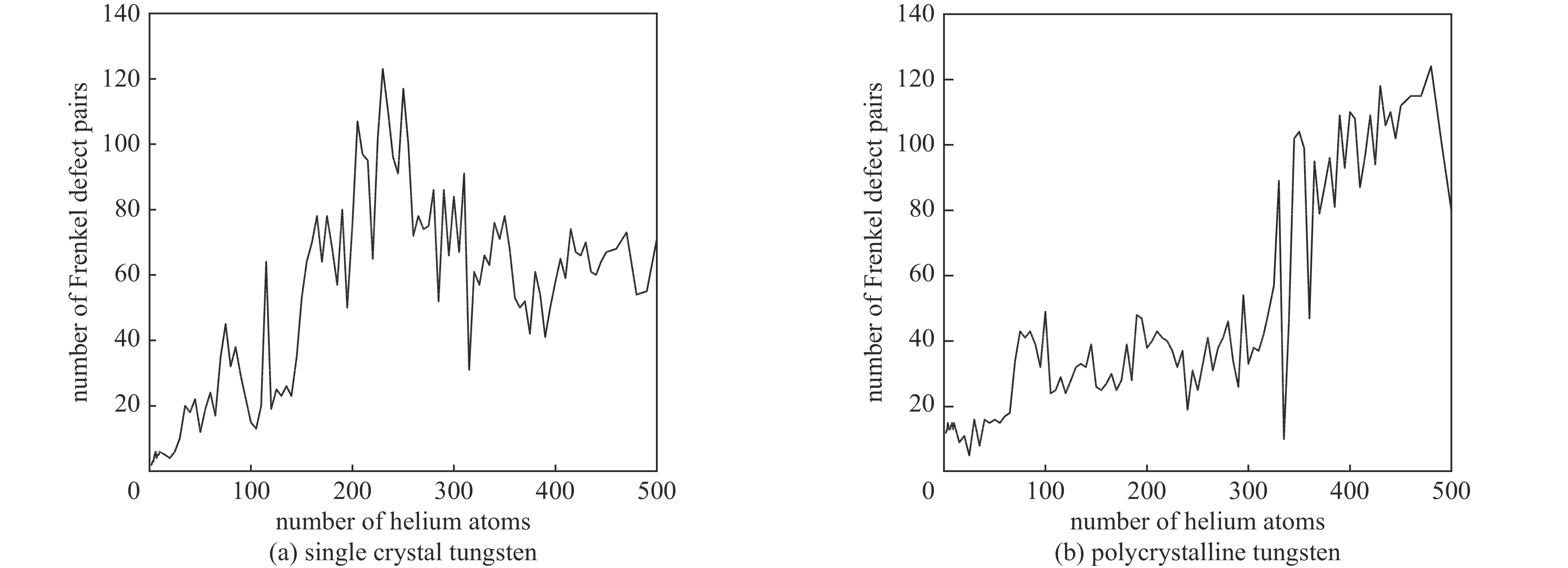

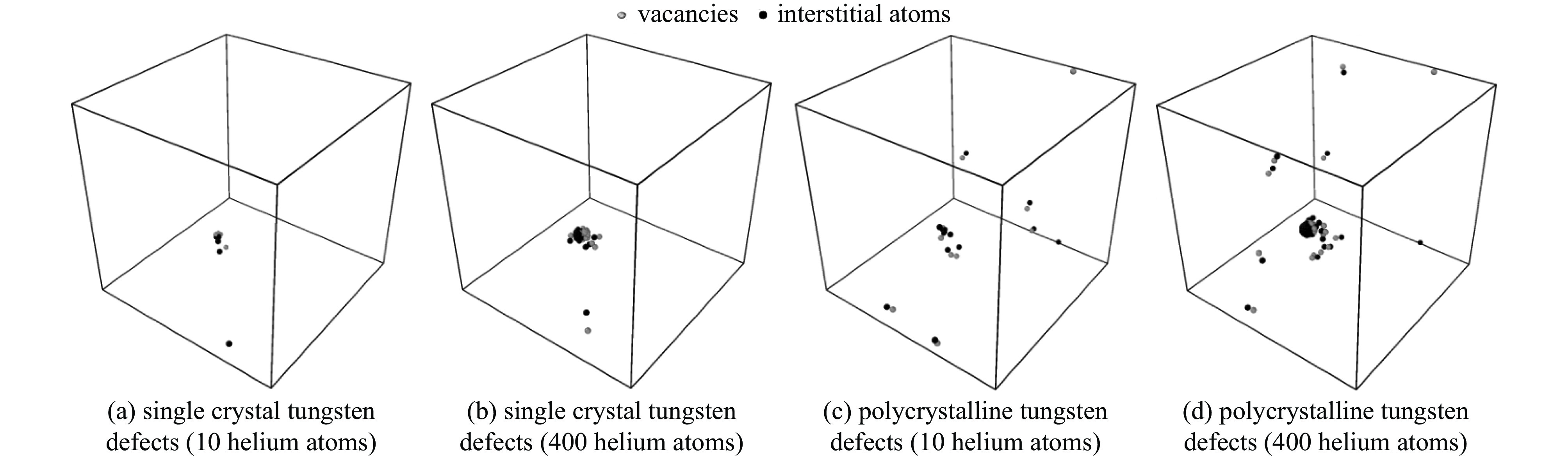

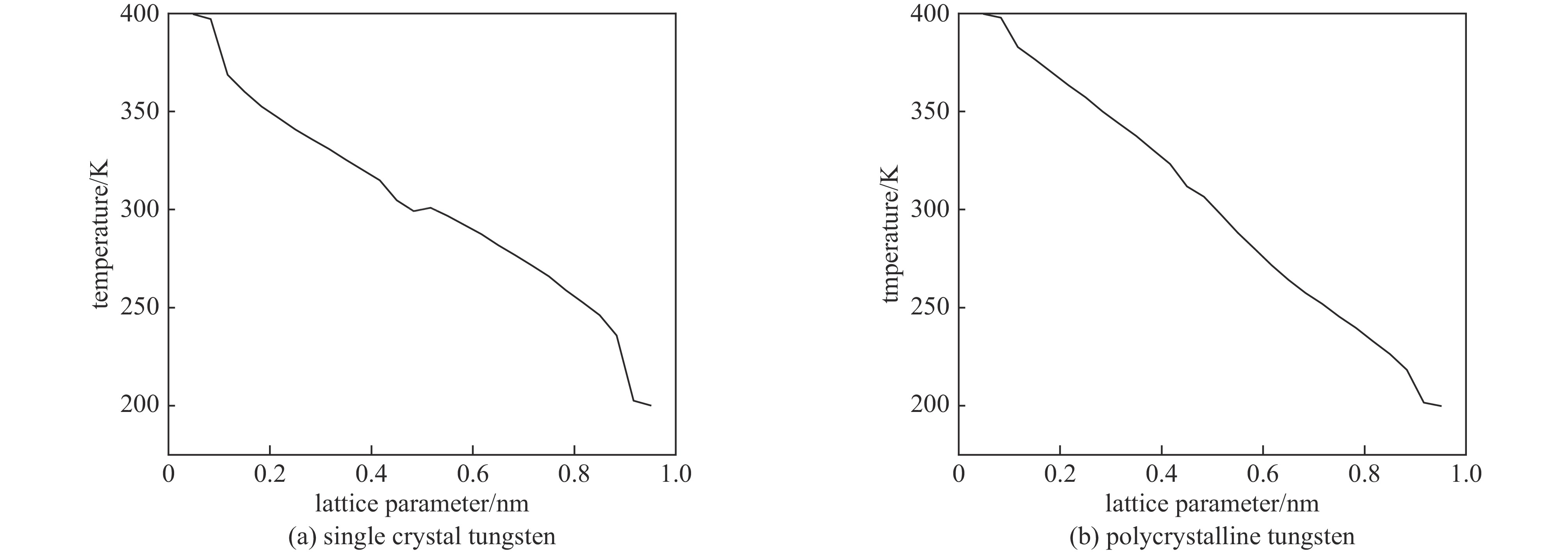

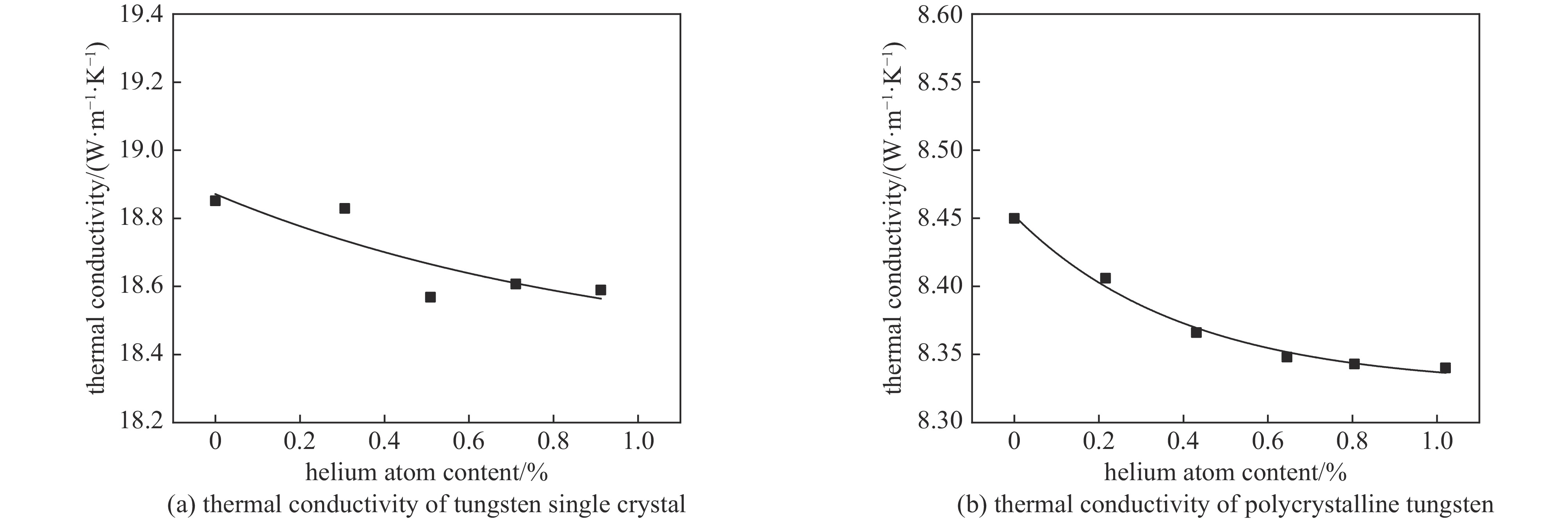

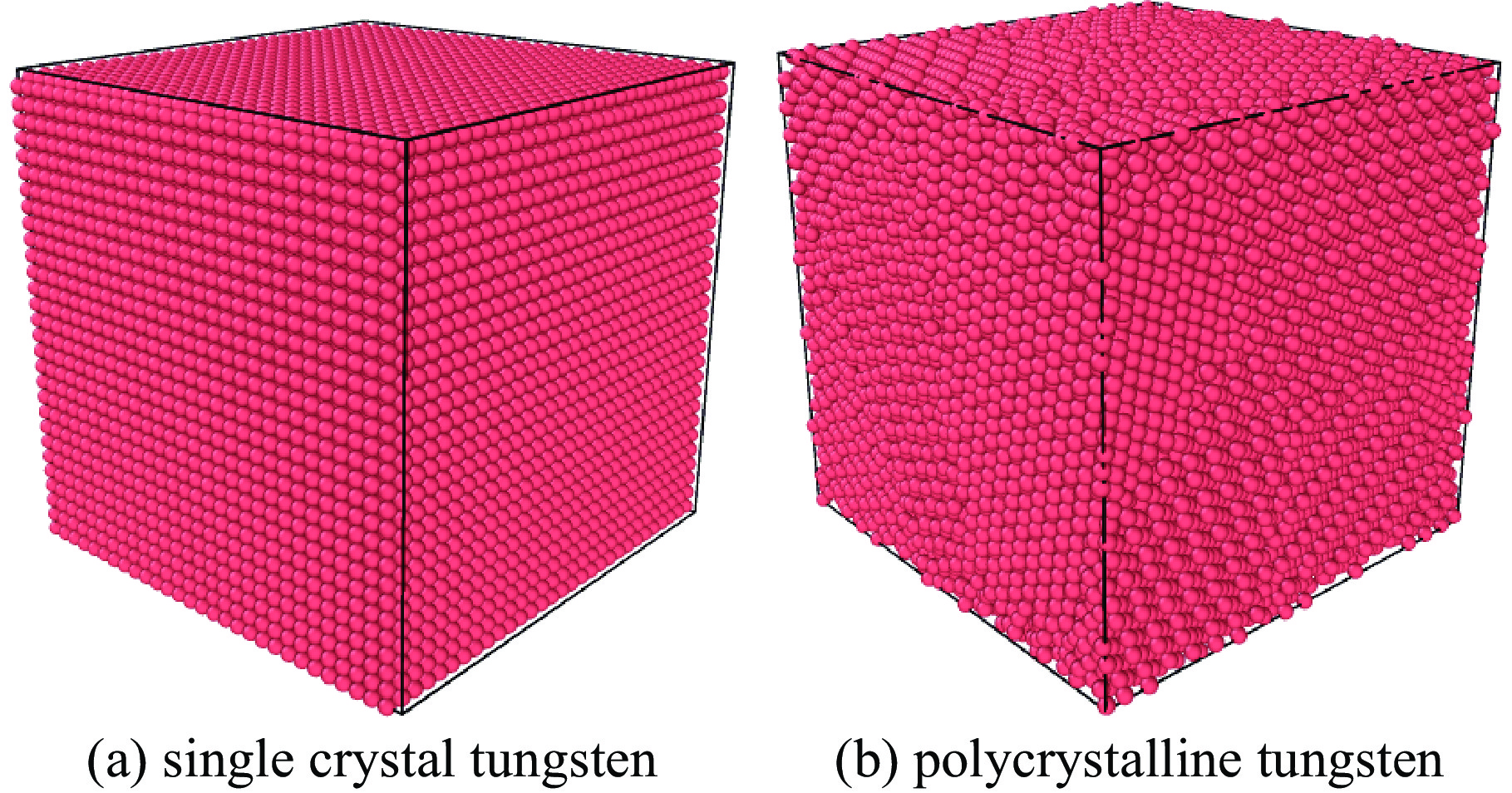

摘要: 采用分子动力学方法研究了氦辐照对金属钨传热性能的影响,从原子尺度分析了单晶钨与多晶钨的热导率随氦含量的变化及其微观机理。结果表明:随着氦原子从0增加至500,钨中的缺陷对数目呈先增加后减少的趋势,单晶钨中氦原子为230个时缺陷对数目达到峰值123,多晶钨中氦原子为480个时缺陷对数目达到峰值124;钨金属的晶体结构从bcc转变为bcc、fcc和hcp等多种结构共存。钨的热导率随氦含量增加波动明显,总体呈非线性减小趋势,在氦含量为0.75%时,单晶钨和多晶钨的热导率分别下降1.44%和1.3%。氦辐照下钨金属内缺陷的产生、聚集及晶体结构的变化是其热导率下降的主要原因。Abstract: The effect of helium radiation on the heat transfer performance of tungsten was studied using molecular dynamics method. The changes of thermal conductivity of single crystal tungsten and polycrystalline tungsten with helium content as well as the microscopic mechanism were analyzed at the atomic scale. The results show that, as the number of helium atom increases from 0 to 500, the number of defect pairs in tungsten increases first and then decreases. When the number of helium atom in single crystal tungsten is 230, the defect pair reaches a peak of 123. In polycrystalline tungsten, the number of defect pairs reaches a peak of 124 at 480 helium atoms. The lattice structure of tungsten changes from bcc to coexistence of bcc, fcc and hcp. The thermal conductivity of tungsten fluctuates significantly with the increasing helium content, which shows a trend of nonlinear decrease in general. When the helium content is 0.75%, the thermal conductivities of single crystal tungsten and polycrystalline tungsten decrease by 1.44% and 1.3%, respectively. The creation and aggregation of point defects as well as the change of crystal structure induced by helium radiation are responsible for the decrease of thermal conductivity of tungsten.

-

表 1 钨晶格异变数随氦含量的变化

Table 1. Number of tungsten lattice anomaly with helium content

helium content/% number of structural variation of W lattice 0.2 119 0.4 161 0.6 171 -

[1] 桑超峰, 周庆瑞, 王真厚, 等. 托卡马克钨偏滤器基本物理问题[J]. 南昌大学学报(理科版), 2022, 46(3):277-294Sang Chaofeng, Zhou Qingrui, Wang Zhenhou, et al. The main physical issues of the tungsten divertor in Tokamak[J]. Journal of Nanchang University (Natural Science), 2022, 46(3): 277-294 [2] 张一鸣, 曾丽萍, 沈欣媛, 等. ITER计划与聚变能发展战略[J]. 核聚变与等离子体物理, 2013, 33(4):359-365Zhang Yiming, Zeng Liping, Shen Xinyuan, et al. ITER project and fusion energy development strategy[J]. Nuclear Fusion and Plasma Physics, 2013, 33(4): 359-365 [3] Neu R, Riesch J, Coenen J W, et al. Advanced tungsten materials for plasma-facing components of DEMO and fusion power plants[J]. Fusion Engineering and Design, 2016, 109/111: 1046-1052. doi: 10.1016/j.fusengdes.2016.01.027 [4] 吴玉程, 姚刚, 罗来马, 等. 核聚变堆用钨及钨基材料热负荷损伤行为的研究进展[J]. 中国有色金属学报, 2018, 28(4):719-731Wu Yucheng, Yao Gang, Luo Laima, et al. Research progress in heat load damage behavior of tungsten and tungsten base materials for nuclear fusion reactor[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(4): 719-731 [5] Thompson M, Kluth P, Doerner R P, et al. Probing helium nano-bubble formation in tungsten with grazing incidence small angle x-ray scattering[J]. Nuclear Fusion, 2015, 55(4): 042001. doi: 10.1088/0029-5515/55/4/042001 [6] Ueda Y, Peng H Y, Lee H T, et al. Helium effects on tungsten surface morphology and deuterium retention[J]. Journal of Nuclear Materials, 2013, 442(1/3 Suppl 1): S267-S272. [7] 汪俊, 张宝玲, 周宇璐, 等. 金属钨中氦行为的分子动力学模拟[J]. 物理学报, 2011, 60:106601 doi: 10.7498/aps.60.106601Wang Jun, Zhang Baoling, Zhou Yulu, et al. Molecular dynamics simulation of helium behavior in tungsten matrix[J]. Acta Physica Sinica, 2011, 60: 106601 doi: 10.7498/aps.60.106601 [8] Allen F I, Hosemann P, Balooch M. Key mechanistic features of swelling and blistering of helium-ion-irradiated tungsten[J]. Scripta Materialia, 2020, 178: 256-260. doi: 10.1016/j.scriptamat.2019.11.039 [9] Kajita S, Yagi T, Kobayashi K, et al. Measurement of thermophysical property of plasma forming tungsten nanofiber layer[J]. Japanese Journal of Applied Physics, 2016, 55: 056203. doi: 10.7567/JJAP.55.056203 [10] Hu Lin, Wirth B D, Maroudas D. Thermal conductivity of tungsten: Effects of plasma-related structural defects from molecular-dynamics simulations[J]. Applied Physics Letters, 2017, 111: 081902. doi: 10.1063/1.4986956 [11] Wu Xuebang, Kong Xiangshan, You Yuwei, et al. Effects of alloying and transmutation impurities on stability and mobility of helium in tungsten under a fusion environment[J]. Nuclear Fusion, 2013, 53: 073049. doi: 10.1088/0029-5515/53/7/073049 [12] Zhou Zhangjian, Pintsuk G, Linke J, et al. Transient high heat load tests on pure ultra-fine grained tungsten fabricated by resistance sintering under ultra-high pressure[J]. Fusion Engineering and Design, 2010, 85(1): 115-121. doi: 10.1016/j.fusengdes.2009.08.003 [13] 刘凤, 李强, 王万景, 等. 超细晶/纳米晶钨—未来聚变堆面向等离子体材料[J]. 材料导报, 2011, 25(19):43-48,71Liu Feng, Li Qiang, Wang Wanjing, et al. Ultra-fine grained/nano-crystalline tungsten—Plasma facing material for future fusion reactors[J]. Materials Reports, 2011, 25(19): 43-48,71 [14] Plimpton S. Fast parallel algorithms for short-range molecular dynamics[J]. Journal of Computational Physics, 1995, 117(1): 1-19. doi: 10.1006/jcph.1995.1039 [15] Thompson A P, Aktulga H M, Berger R, et al. LAMMPS - a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales[J]. Computer Physics Communications, 2022, 271: 108171. doi: 10.1016/j.cpc.2021.108171 [16] Stukowski A. Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool[J]. Modelling and Simulation in Materials science and Engineering, 2010, 18: 015012. doi: 10.1088/0965-0393/18/1/015012 [17] Daw M S, Baskes M I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals[J]. Physical Review B, 1984, 29(12): 6443-6453. doi: 10.1103/PhysRevB.29.6443 [18] Bonny G, Grigorev P, Terentyev D. On the binding of nanometric hydrogen–helium clusters in tungsten[J]. Journal of Physics:Condensed Matter, 2014, 26: 485001. doi: 10.1088/0953-8984/26/48/485001 [19] 周良付, 张婧, 何文豪, 等. 氦泡在bcc钨中晶界处成核长大的分子动力学模拟[J]. 物理学报, 2020, 69:046103 doi: 10.7498/aps.69.20191069Zhou Liangfu, Zhang Jing, He Wenhao, et al. The nucleation and growth of Helium hubbles at grain boundaries of bcc tungsten: a molecular dynamics simulation[J]. Acta Physica Sinica, 2020, 69: 046103 doi: 10.7498/aps.69.20191069 [20] Zhang B L, Fang S Y, Wang J, et al. Study on helium bubble coalescence in the slip plane of titanium[J]. Fusion Science and Technology, 2021, 77(6): 437-445. doi: 10.1080/15361055.2021.1927583 [21] 张宝玲. 钛金属氦损伤的分子动力学研究[M]. 北京: 中国水利水电出版社, 2016: 3-10Zhang Baoling. Molecular dynamics study of helium damage in titanium metal[M]. Beijing: China Water Power Press, 2016: 3-10 [22] Fu Baqin, Lai Wensheng, Yuan Yue, et al. Calculation and analysis of lattice thermal conductivity in tungsten by molecular dynamics[J]. Journal of Nuclear Materials, 2012, 427(1/3): 268-273. [23] Qu Shilian, Sun Hao, Kreter A, et al. Degradation of thermal conductivity of the damaged layer of tungsten irradiated by helium-plasma[J]. Fusion Engineering and Design, 2018, 137: 97-103. doi: 10.1016/j.fusengdes.2018.08.014 -

下载:

下载: