Analysis of heat transfer and thermal ablation of honeycomb sandwich composite structure under laser irradiation

-

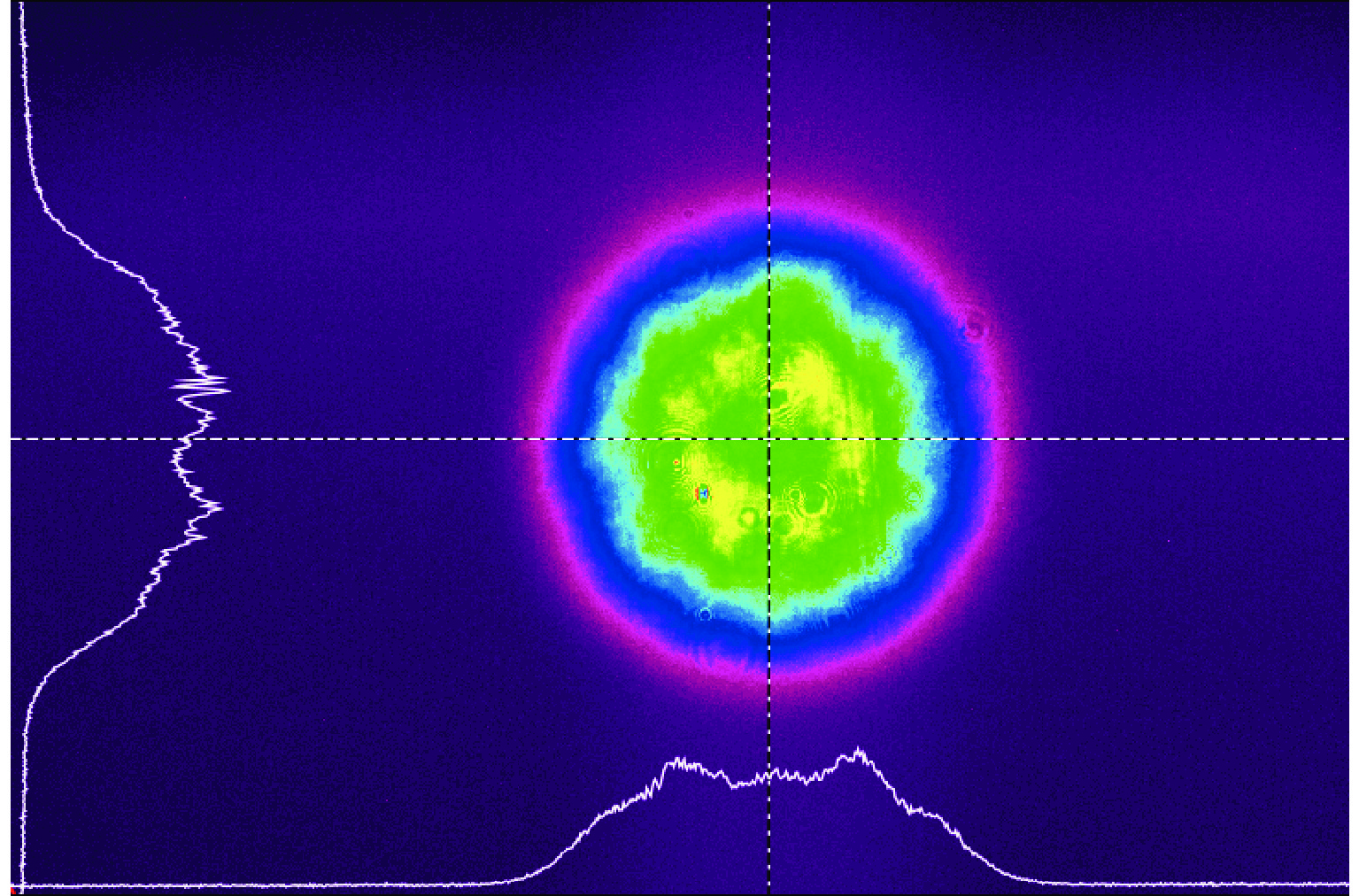

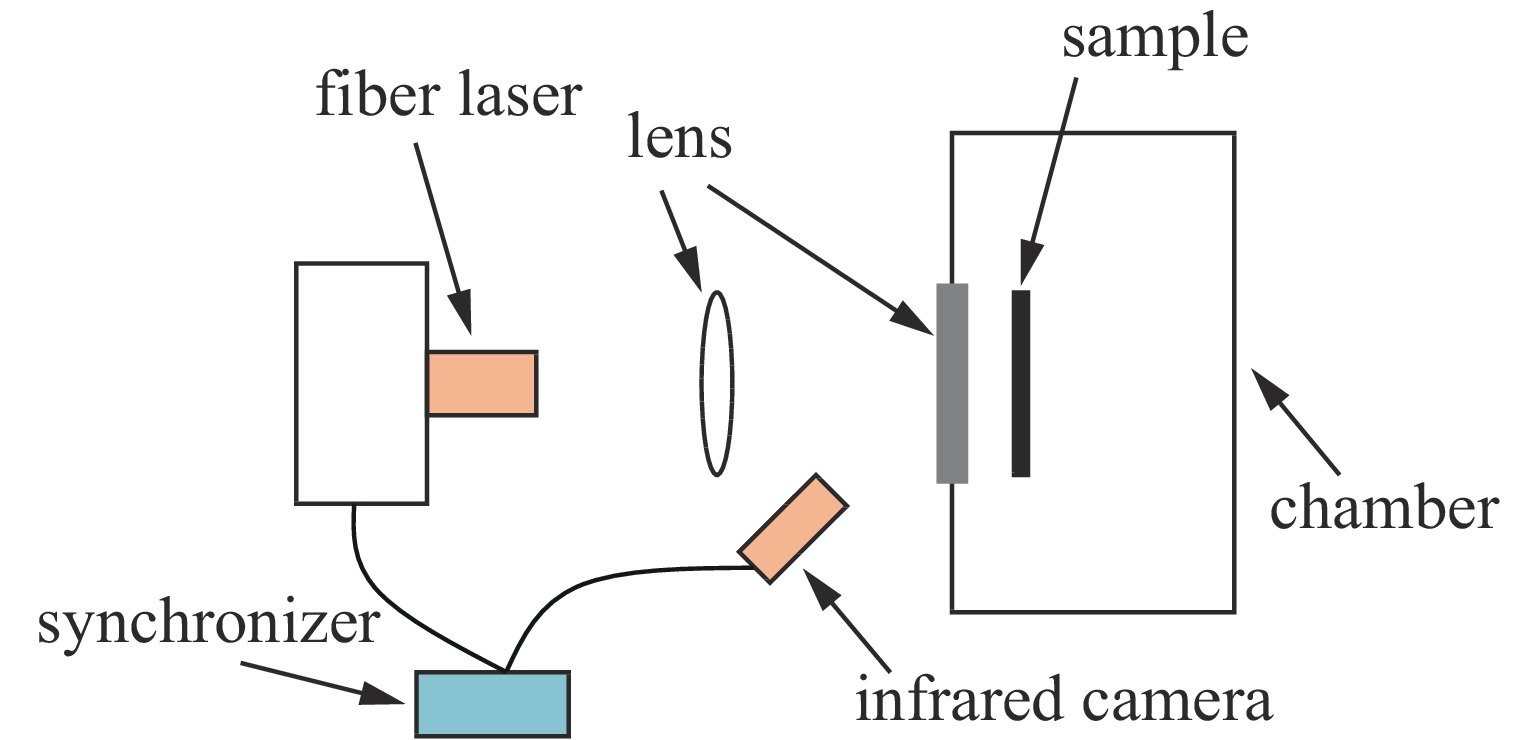

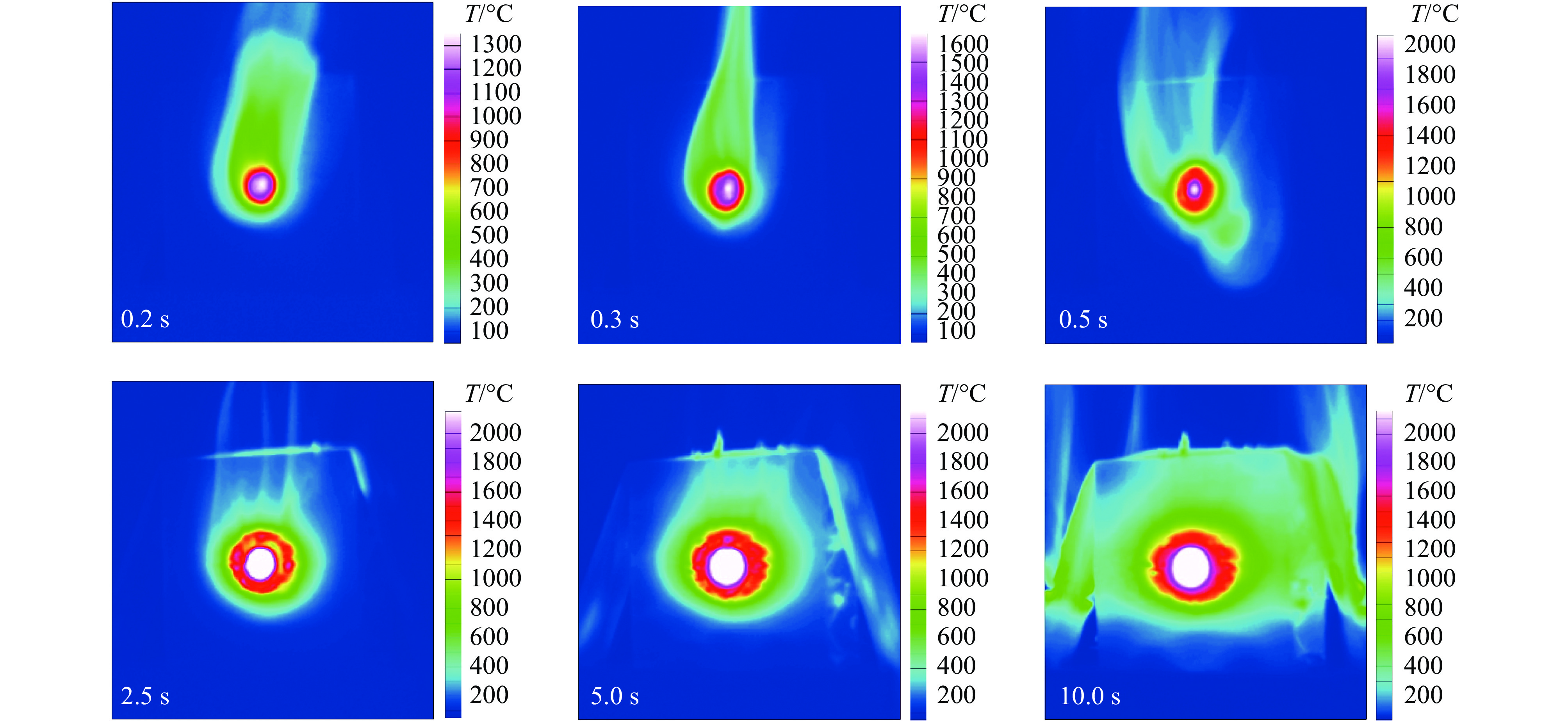

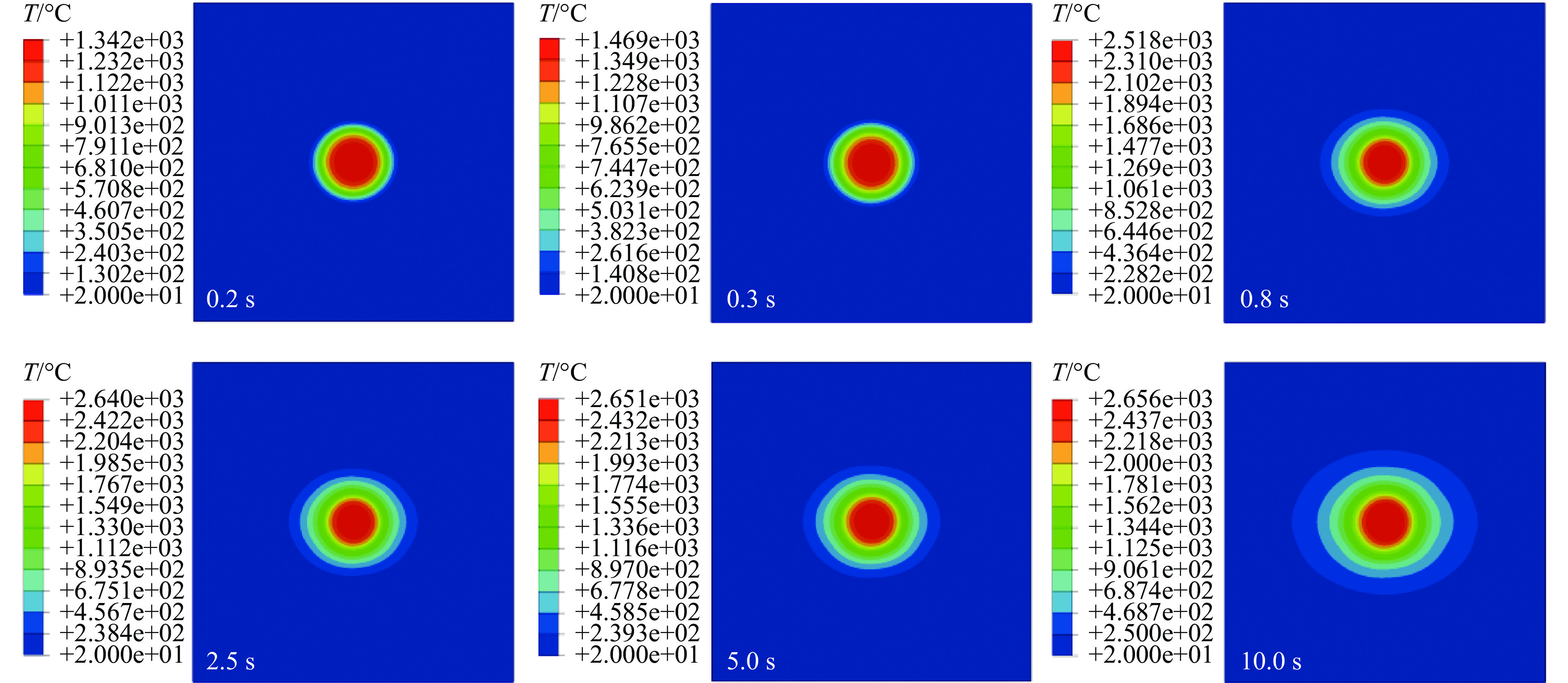

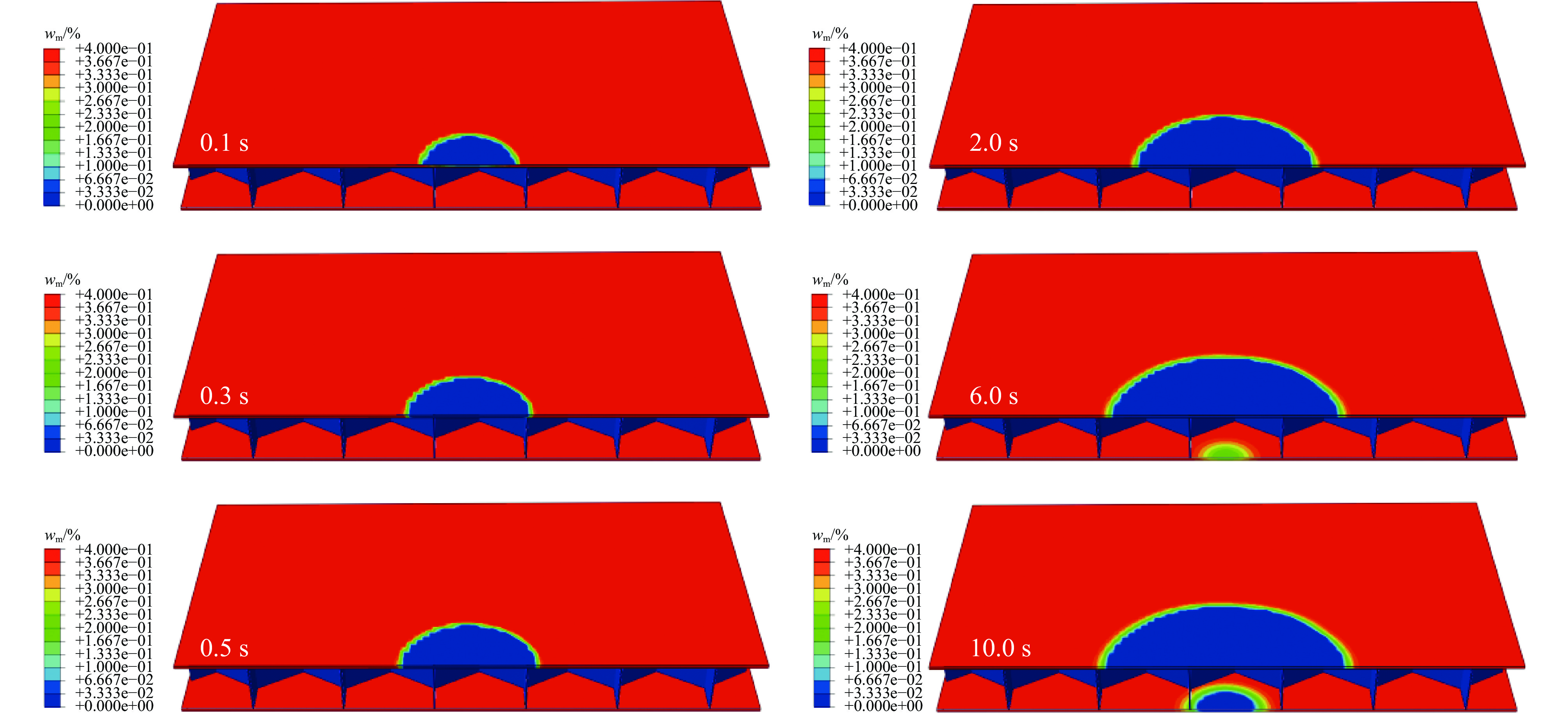

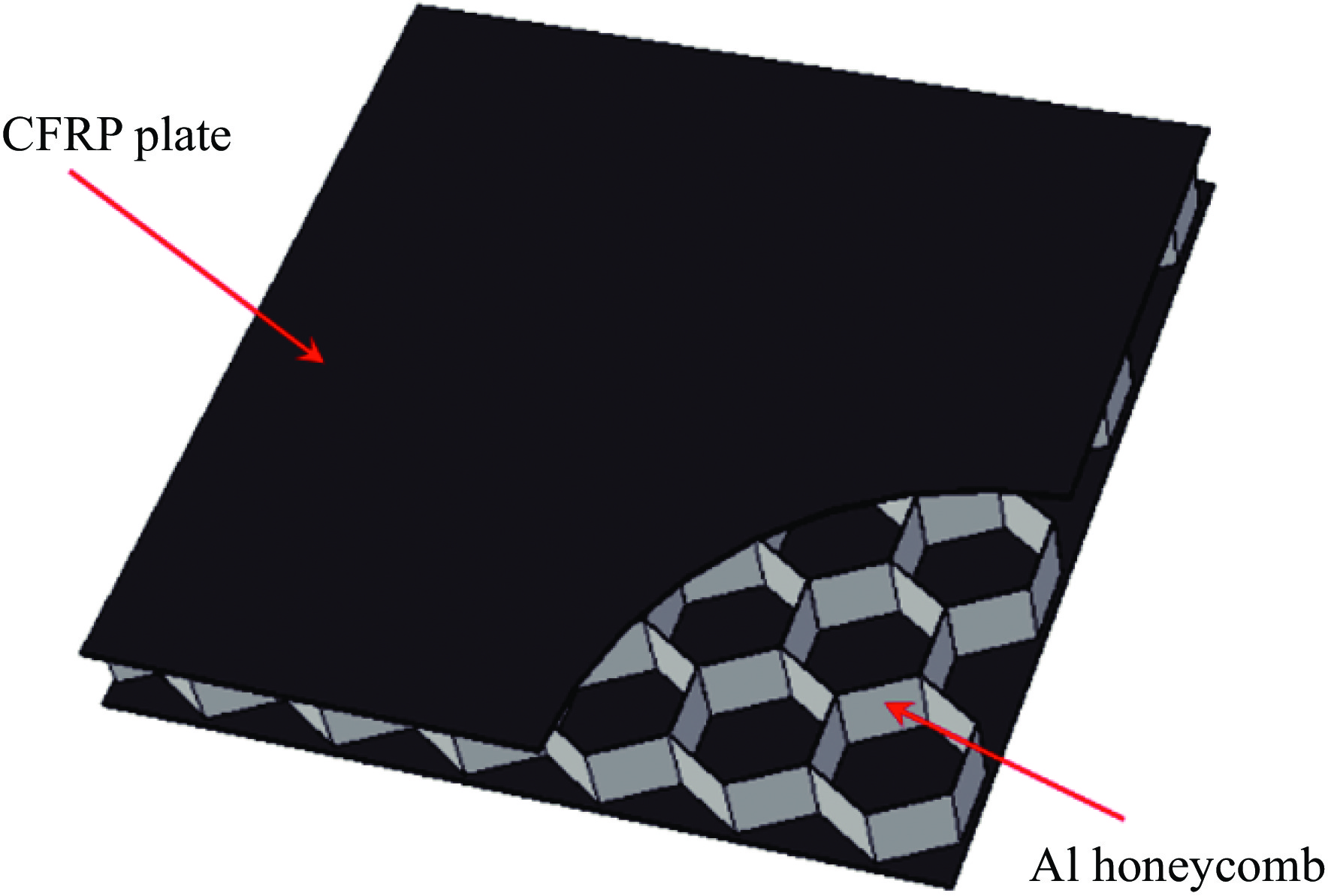

摘要: 结合蜂窝结构传热机制与复合材料烧蚀机制,研究了蜂窝夹芯复合材料结构在激光辐照条件下的热响应。针对典型蜂窝单元,建立了细观导热及烧蚀理论模型。基于有限元软件热分析模块和二次开发程序构建了蜂窝夹芯结构的高温传热数值模型,考虑了热物性参数的非线性变化、树脂热解和纤维烧蚀过程。采用连续激光作为加载热源,设计并开展了大气环境中蜂窝结构的热烧蚀实验,获得了蜂窝结构的动态烧蚀特征。结果表明,蜂窝夹芯复合材料结构在激光功率密度为102 W/cm2量级时具有良好的抗烧蚀能力,数值模型能够较为准确地模拟激光加载蜂窝结构过程中的烧蚀温度和树脂、纤维的烧蚀情况,并获得较为真实的烧蚀形貌。Abstract: Combined with the heat transfer mechanism of honeycomb structure and the ablation mechanism of composites, the thermal response of honeycomb sandwich composite structure under laser irradiation was studied. For typical honeycomb cells, a theoretical microstructure model of thermal conduction and ablation is established. Based on the finite element software thermal analysis module and secondary development program, a high temperature heat transfer numerical model of honeycomb sandwich structure was constructed, taking into account the nonlinear changes of thermal physical parameters, resin pyrolysis and fiber ablation process. Using continuous laser as the loading heat source, the thermal ablation experiments of honeycomb structure in atmospheric environment were designed and carried out, and the dynamic ablation characteristics of honeycomb structure were obtained. The results show that the honeycomb sandwich composite structure has good ablation resistance when the laser power density is 102 W/cm2; The numerical model can accurately simulate the temperature field and the ablation of resin and fiber in the process of laser loading the honeycomb structure, and can obtain comparatively real ablation morphology.

-

Key words:

- composites /

- honeycomb /

- laser /

- ablation /

- heat transfer

-

表 1 CFRP各组分热物性参数

Table 1. Thermophysical parameters of CFRP components

parameter value thermal conductivity of fiber/(W·m−1·K−1) 30 density of fiber/(kg·m−3) 1760 specific heat capacity of fiber/(J·kg−1·K−1) 956 thermal conductivity of resin/(W·m−1·K−1) 0.5 density of resin/(kg·m−3) 1200 specific heat capacity of resin/(J·kg−1·K−1) 1690 thermal conductivity of char/(W·m−1·K−1) 5 density of char/(kg·m−3) 1300 specific heat capacity of char/(J·kg−1·K−1) 1589 thermal conductivity of gas (CO2) /(W·m−1·K−1) 0.025 density of gas (CO2) /(kg·m−3) 1.997 heat capacity at constant pressure for gas (CO2) /(J·kg−1·K−1) 720 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):12 doi: 10.3321/j.issn:1000-3851.2007.01.001Du Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica, 2007, 24(1): 12 doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] Arao Y, Koyanagi J, Utsunomiya S, et al. Analysis of thermal deformation on a honeycomb sandwich CFRP mirror[J]. Mechanics of Advanced Materials and Structures, 2010, 17(5): 328-334. doi: 10.1080/15376494.2010.488533 [3] 吴楠, 郝旭峰, 史耀辉, 等. 高精度碳纤维增强树脂复合材料夹层天线面板热变形影响参数仿真与实验[J]. 复合材料学报, 2020, 37(7):1619-1628Wu Nan, Hao Xufeng, Shi Yaohui, et al. Simulation and experiment on thermal deformation influence parameters of high accuracy carbon fiber reinforced plastic sandwiched antenna panels[J]. Acta Materiae Compositae Sinica, 2020, 37(7): 1619-1628 [4] Wei Xingyu, Xiong Jian, Wang Jie, et al. New advances in fiber-reinforced composite honeycomb materials[J]. Science China Technological Sciences, 2020, 63(8): 1348-1370. doi: 10.1007/s11431-020-1650-9 [5] 解维华, 张博明, 杜善义. 重复使用飞行器金属热防护系统的有限元分析与设计[J]. 航空学报, 2006, 27(4):650-656Xie Weihua, Zhang Boming, Du Shanyi. Analysis and design of metallic thermal protection systems for reusable launch vehicle[J]. Acta Aeronautica et Astronautica Sinica, 2006, 27(4): 650-656 [6] 梁伟, 张立春, 吴大方, 等. 金属蜂窝夹芯板瞬态热性能的计算与试验分析[J]. 航空学报, 2009, 30(4):672-677Liang Wei, Zhang Lichun, Wu Dafang, et al. Computation and analysis of transient thermal performance of metal honeycomb sandwich panels[J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(4): 672-677 [7] 邢春鹏. 金属蜂窝夹芯结构性能研究与多层隔热结构优化设计[D]. 哈尔滨: 哈尔滨工业大学, 2008Xing Chunpeng. Research on properties of metallic honeycomb structure and optimization of multilayer insulations[D]. Harbin: Harbin Institute of Technology, 2008 [8] 景丽, 王广飞, 唐绍锋, 等. 金属蜂窝夹芯板辐射导热耦合问题[J]. 哈尔滨工业大学学报, 2010, 42(5):827-831Jing Li, Wang Guangfei, Tang Shaofeng, et al. Radiation and conduction coupling problems of honeycomb sandwich panel[J]. Journal of Harbin Institute of Technology, 2010, 42(5): 827-831 [9] 张黎, 张永强, 贺佳, 等. 高速气流作用下能量加载金属蜂窝板数值模拟[J]. 强激光与粒子束, 2017, 29:071005 doi: 10.11884/HPLPB201729.160467Zhang Li, Zhang Yongqiang, He Jia, et al. Numerical simulation of metallic honeycomb plates with energy addition in high velocity flow[J]. High Power Laser and Particle Beams, 2017, 29: 071005 doi: 10.11884/HPLPB201729.160467 [10] 郑吉良, 孙勇. 单层与多层蜂窝芯玻璃钢蜂窝板的热性能模拟[J]. 复合材料学报, 2014, 31(2):505-511Zheng Jiliang, Sun Yong. Simulation of thermal performance for single layer and multilayer of the FRP honeycomb panel[J]. Acta Materiae Compositae Sinica, 2014, 31(2): 505-511 [11] 邱志平, 林强. 蜂窝夹层复合材料结构非线性传热分析[J]. 复合材料学报, 2005, 22(5):147-154Qiu Zhiping, Lin Qiang. Nonlinear heat transfer of honeycomb sandwich composite material structure[J]. Acta Materiae Compositae Sinica, 2005, 22(5): 147-154 [12] Wang Jiangtao, Yuan Wu, Liu Yuwen, et al. High-power laser resistance of filled sandwich panel with truss cores: ablation mechanisms and numerical simulation[J]. Composite Structures, 2018, 203: 574-584. doi: 10.1016/j.compstruct.2018.07.050 [13] 彭国良, 杜太焦, 张相华, 等. 蜂窝夹芯复合材料激光烧蚀效应的数值模拟[J]. 现代应用物理, 2014, 5(2):140-145 doi: 10.3969/j.issn.2095-6223.2014.02.010Peng Guoliang, Du Taijiao, Zhang Xianghua, et al. Numerical simulation of ablation of honeycomb sandwich composite materials by laser beam[J]. Modern Applied Physics, 2014, 5(2): 140-145 doi: 10.3969/j.issn.2095-6223.2014.02.010 [14] 张家雷, 王伟平, 刘仓理. 激光辐照下二维编织碳纤维/环氧树脂复合材料的烧蚀特征[J]. 复合材料学报, 2017, 34(3):494-500Zhang Jialei, Wang Weiping, Liu Cangli. Ablation characteristics of 2D braided carbon fiber/epoxy composites under laser irradiation[J]. Acta Materiae Compositae Sinica, 2017, 34(3): 494-500 [15] Chippendale R D, Golosnoy I O, Lewin P L. Numerical modelling of thermal decomposition processes and associated damage in carbon fibre composites[J]. Journal of Physics D: Applied Physics, 2014, 47: 385301. doi: 10.1088/0022-3727/47/38/385301 [16] Meng Songhe, Zhou Yinjia, Xie Weihua, et al. Multiphysics coupled fluid/thermal/ablation simulation of carbon/carbon composites[J]. Journal of Spacecraft and Rockets, 2016, 53(5): 930-935. doi: 10.2514/1.A33612 [17] Nan Pengyu, Shen Zhonghua, Han Bing, et al. The influences of laminated structure on the ablation characteristics of carbon fiber composites under CW laser irradiation[J]. Optics & Laser Technology, 2019, 116: 224-231. [18] 赵伟娜. 复杂热-力载荷下CFRP层合板的失效行为及破坏机理研究[D]. 北京: 中国科学院大学, 2018Zhao Weina. Failure behavior and failure mechanism of CFRP laminates under complex thermal mechanical loads[D]. Beijing: University of Chinese Academy of Sciences, 2018 -

下载:

下载: