Discharge capacity requirements of severe accident depressurization valves

-

摘要: 二代加百万千万级核电站严重事故下卸压过程中高温流体流经卸压阀,可能造成流道变形,甚至造成阀杆下落使得排放流道封闭,造成卸压失败。对严重事故专用卸压阀在卸压过程中可能经历的高温流体状态进行谱分析,获得了不同卸压能力下阀门经受的高温流体状态。开展了高温可能引起的阀门流道变形对卸压效果的影响分析。第二类阀门虽然存在阀门流道变形的可能,但能够获得较长严重事故处置时间,从优化严重事故对策的角度,严重事故专用卸压阀推荐采用第二类阀门排放能力450~600 t/h范围。

-

关键词:

- 高压熔堆 /

- 熔融物喷射 /

- 反应堆冷却剂系统卸压 /

- 严重事故卸压阀 /

- 高温流体

Abstract: In the process of depressurization during severe accidents for the second generation nuclear power plant, high temperature fluid flowing through the severe accident depressurization valves may cause deformation of the valve body or even cause the valve stem to fall down because of being heated by high temperature fluid, resulting in depressurization failure. In this paper, the spectrum analysis of the high temperature fluid state that the depressurization valve may experience in the process of pressure relief is carried out, and the high temperature fluid state under different pressure relief capacities is obtained. The influence of the valve channel deformation caused by high temperature on the depressurization effect is studied. Although the second type valve has the possibility of valve channel deformation, it can obtain a longer time window for severe accident mitigation. From the perspective of optimizing the severe accident measures, the discharge capacity range of the second type valve 450-600 t/h is recommended. -

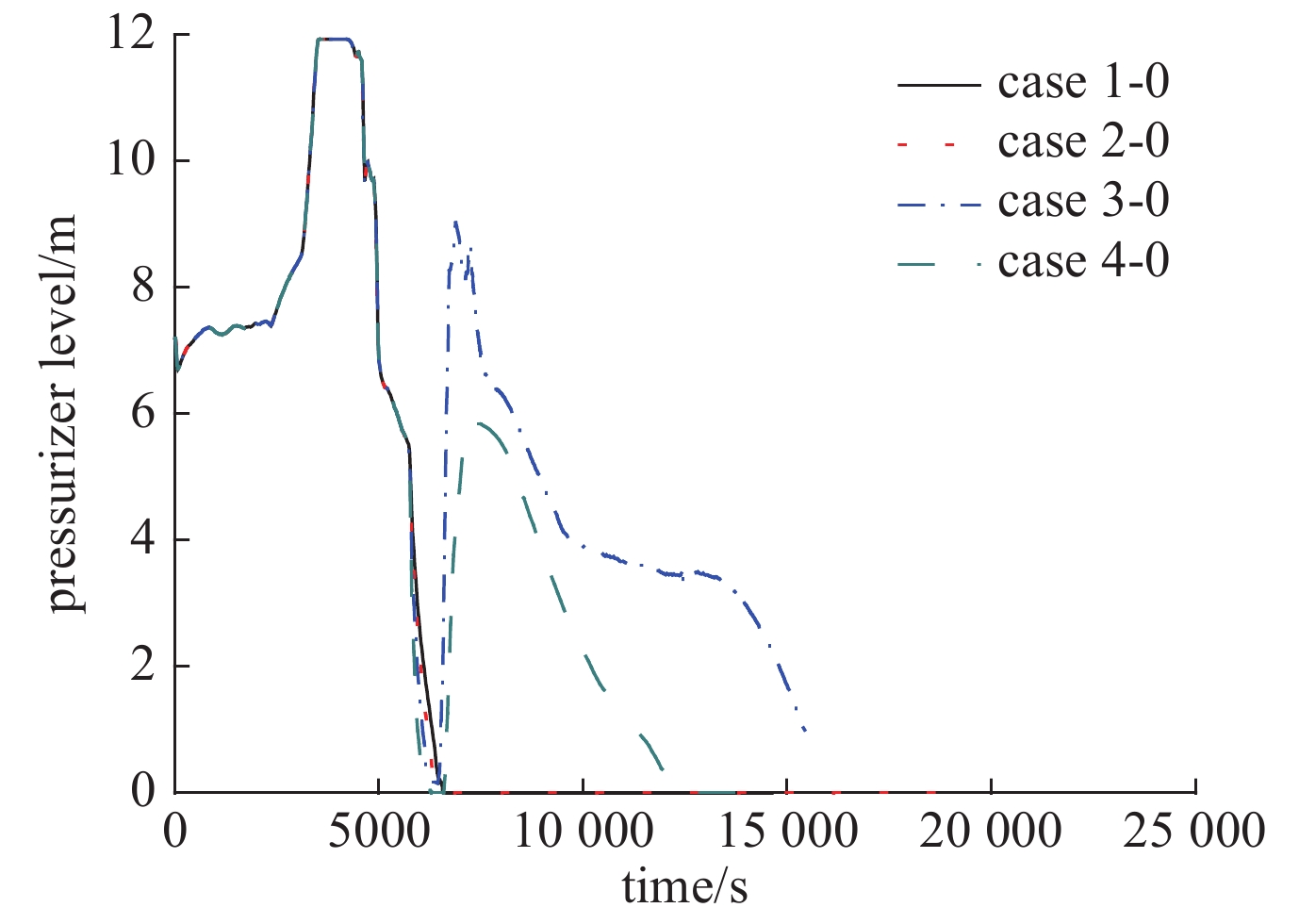

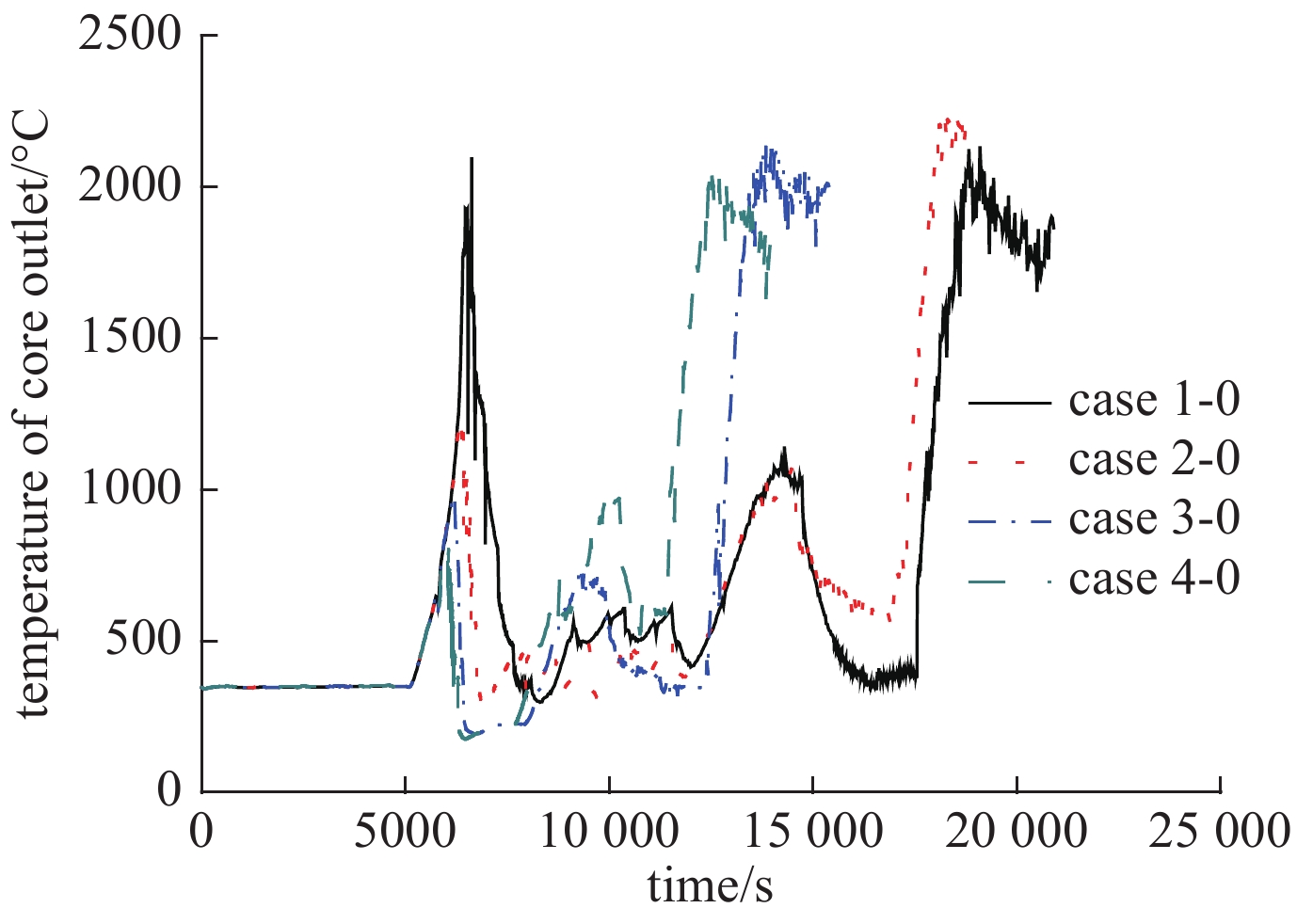

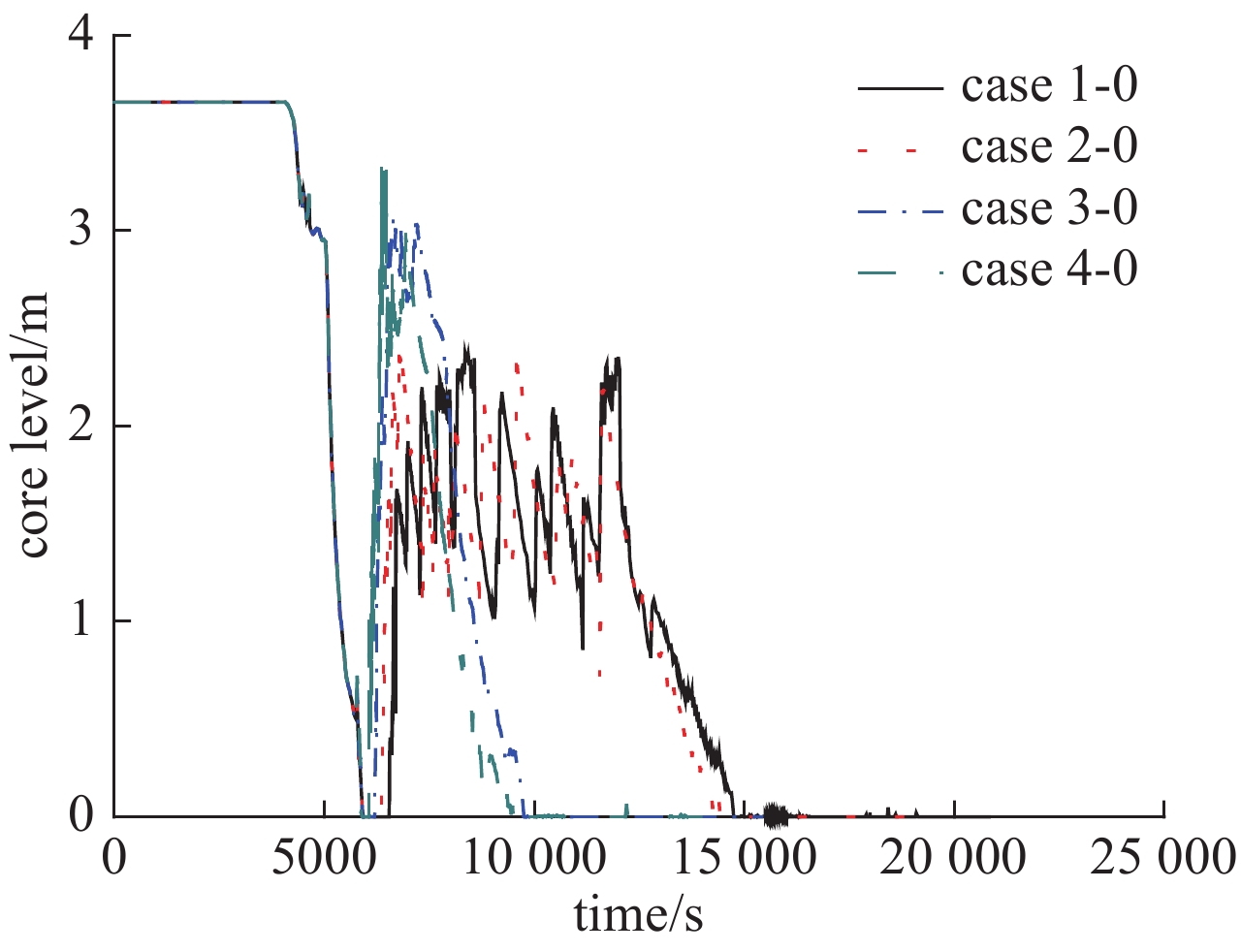

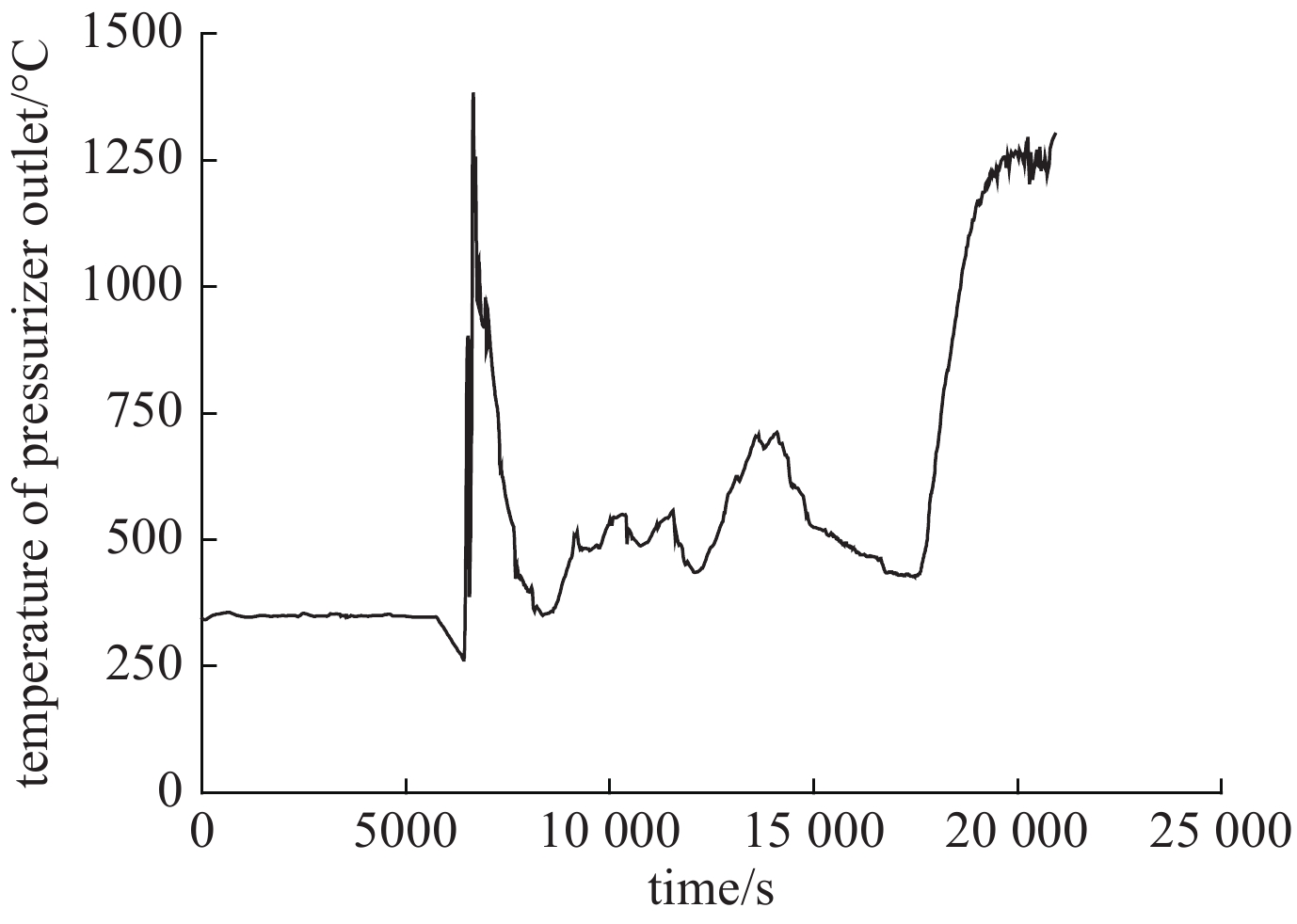

表 1 事故主要进程时间节点

Table 1. Accident process of depressurization

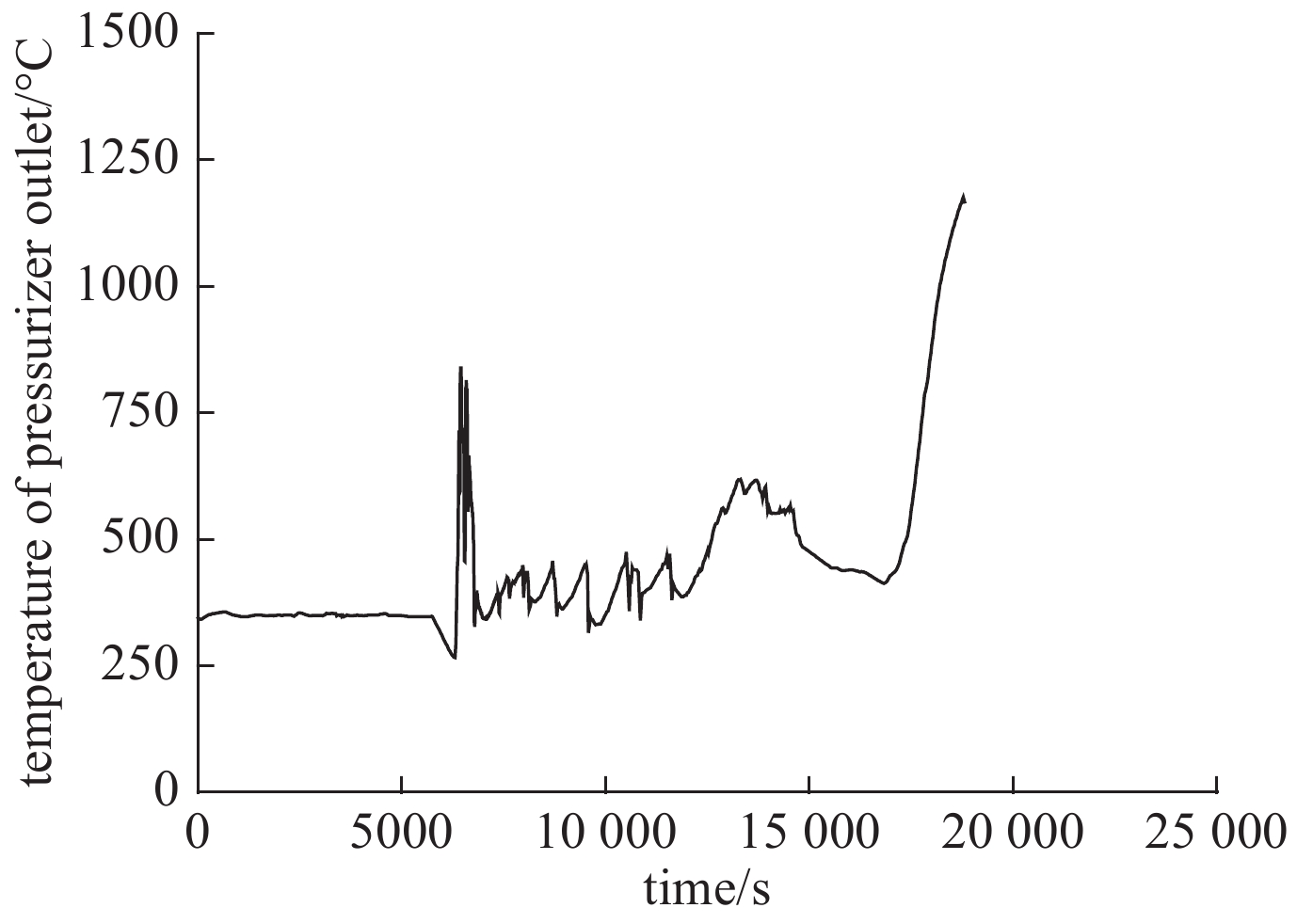

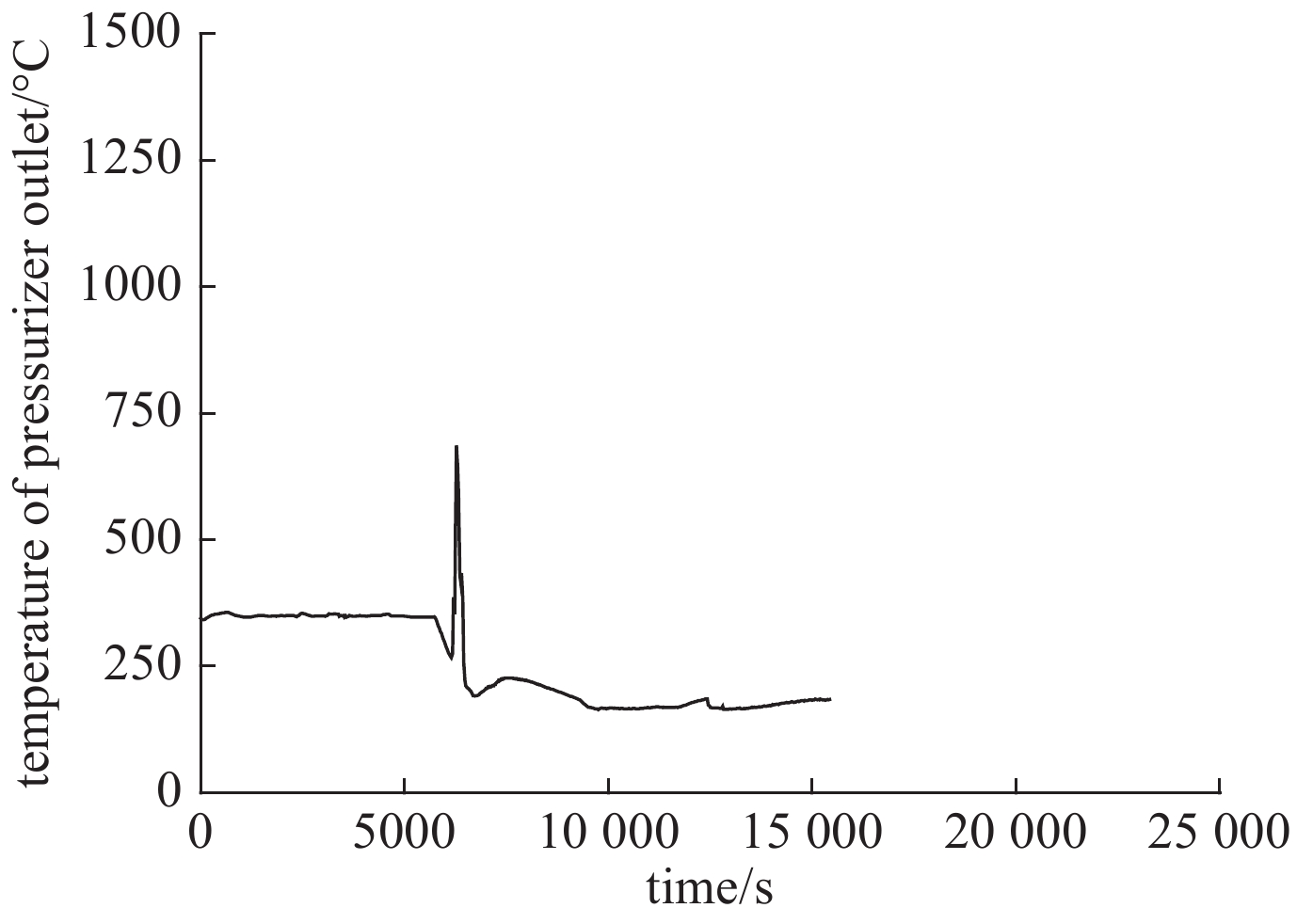

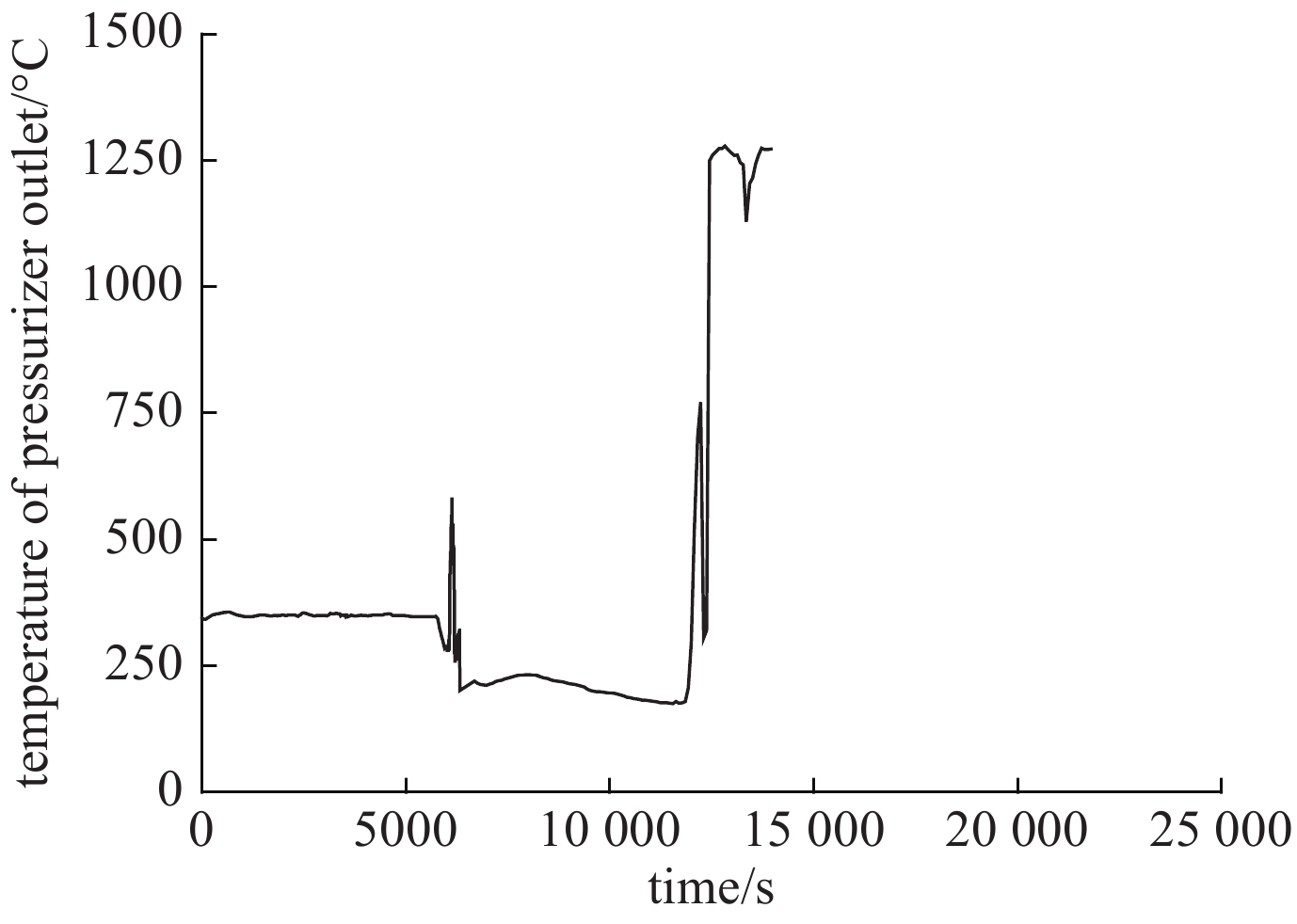

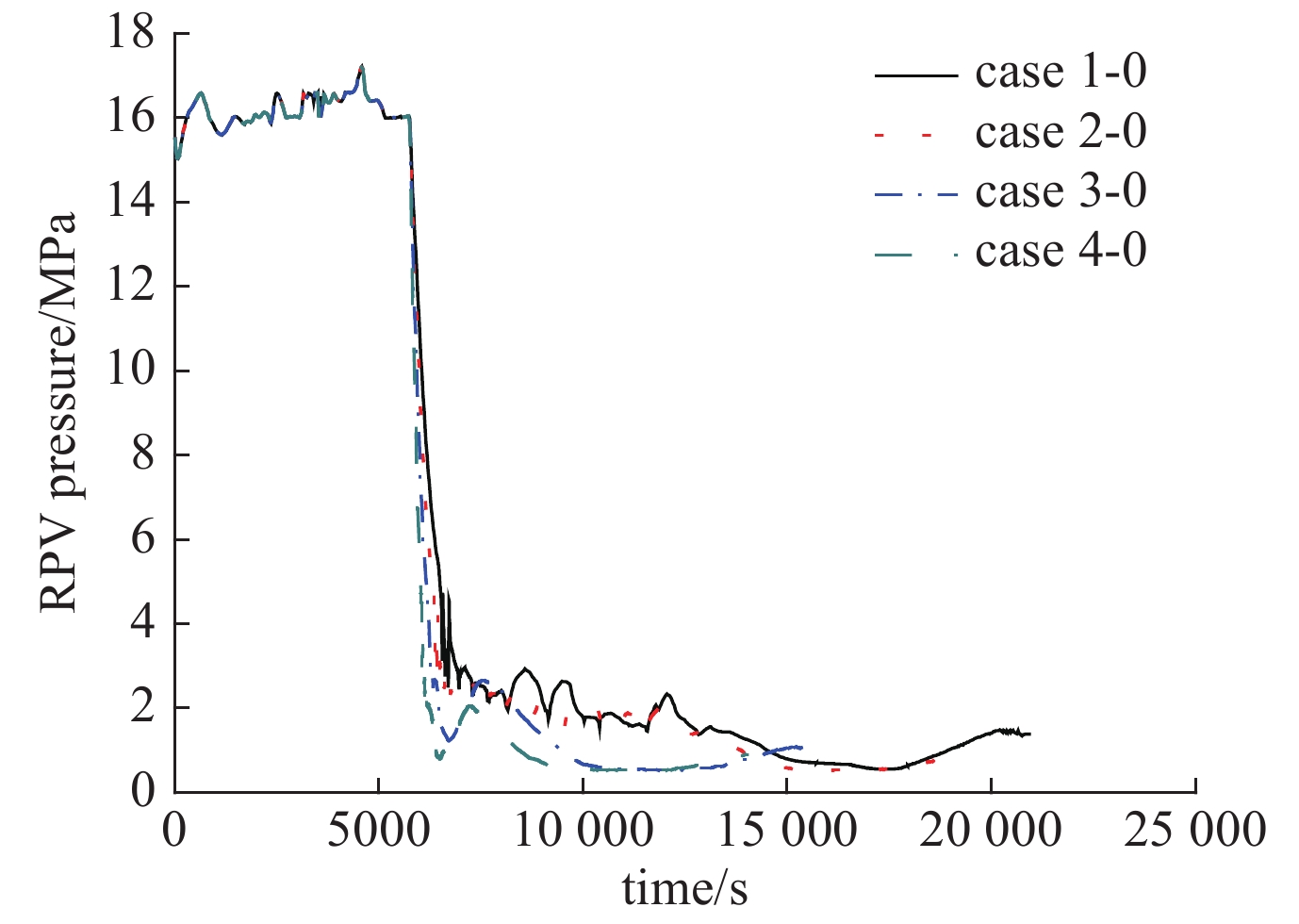

case time/s pressure/MPa open valves: Tout

(reactor is 50 ℃)accumulator

injectionpressurizer

drainaccumulator

drainTout of pressurizer

≥1000 ℃RPV lower

head failureRPV lower

head failurecase 1-0: 350 t/h 5750 6515 6575 12825 6625/18605 20925 1.39 case 2-0: 450 t/h 5750 6350 6550 12600 18145 18800 0.78 case 3-0: 600 t/h 5750 6200 — 6750 — 15425 0.99 case 4-0: 1000 t/h 5750 6000 12375 6500 12410 14000 0.90 表 2 事故主要进程时间节点(阀门开启初期发生流道变形)

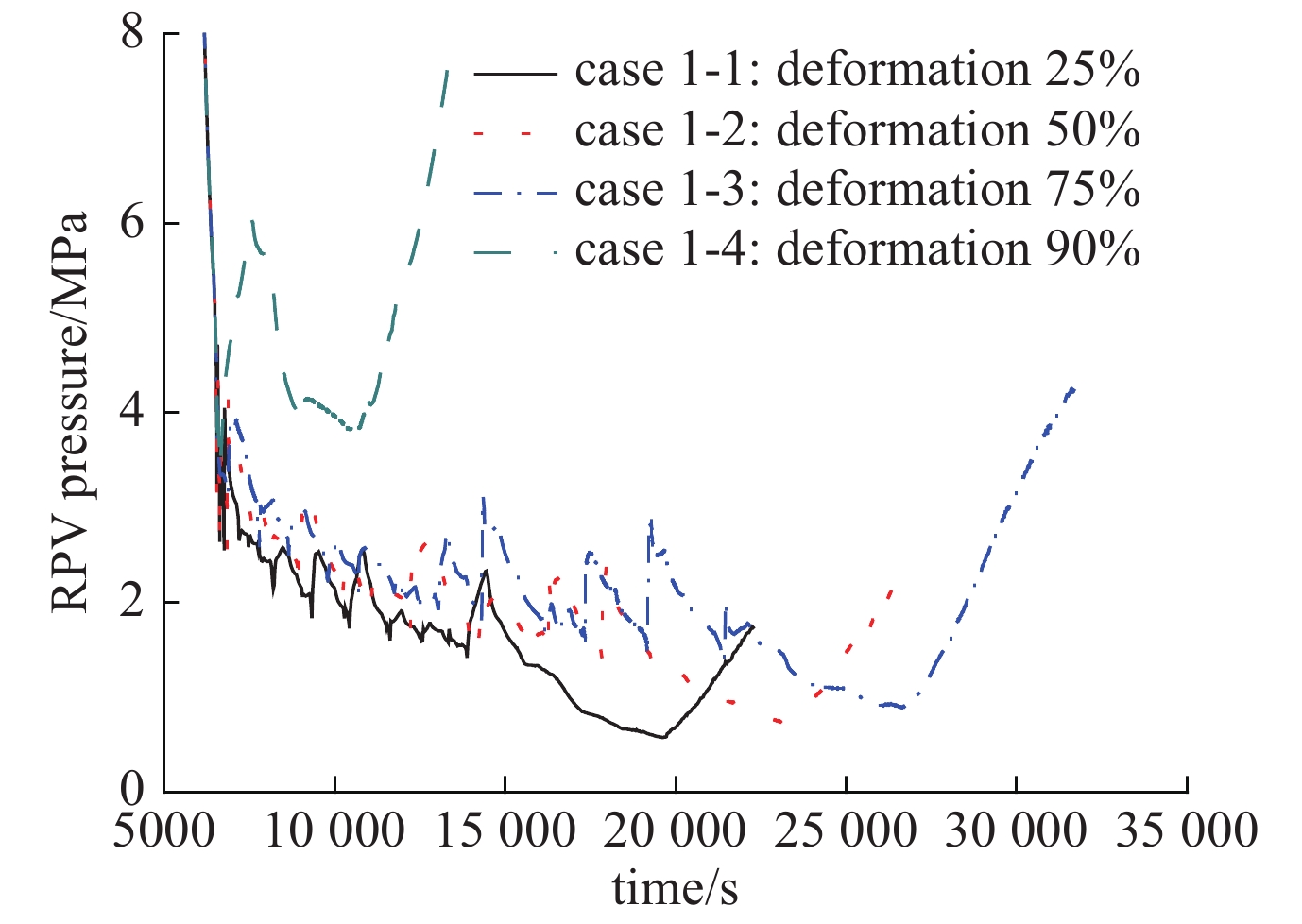

Table 2. Accident process of depressurization with valve channel deformation

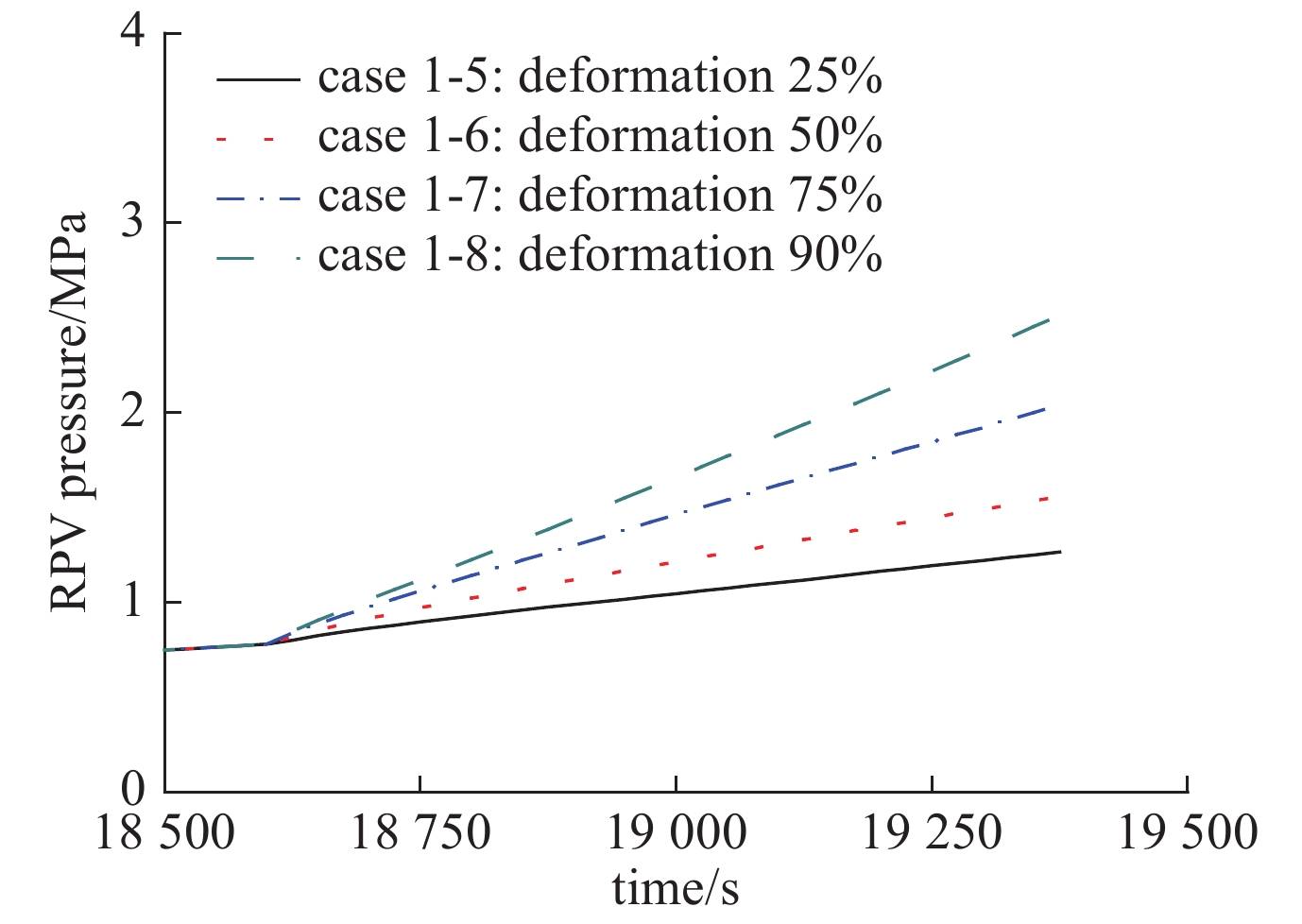

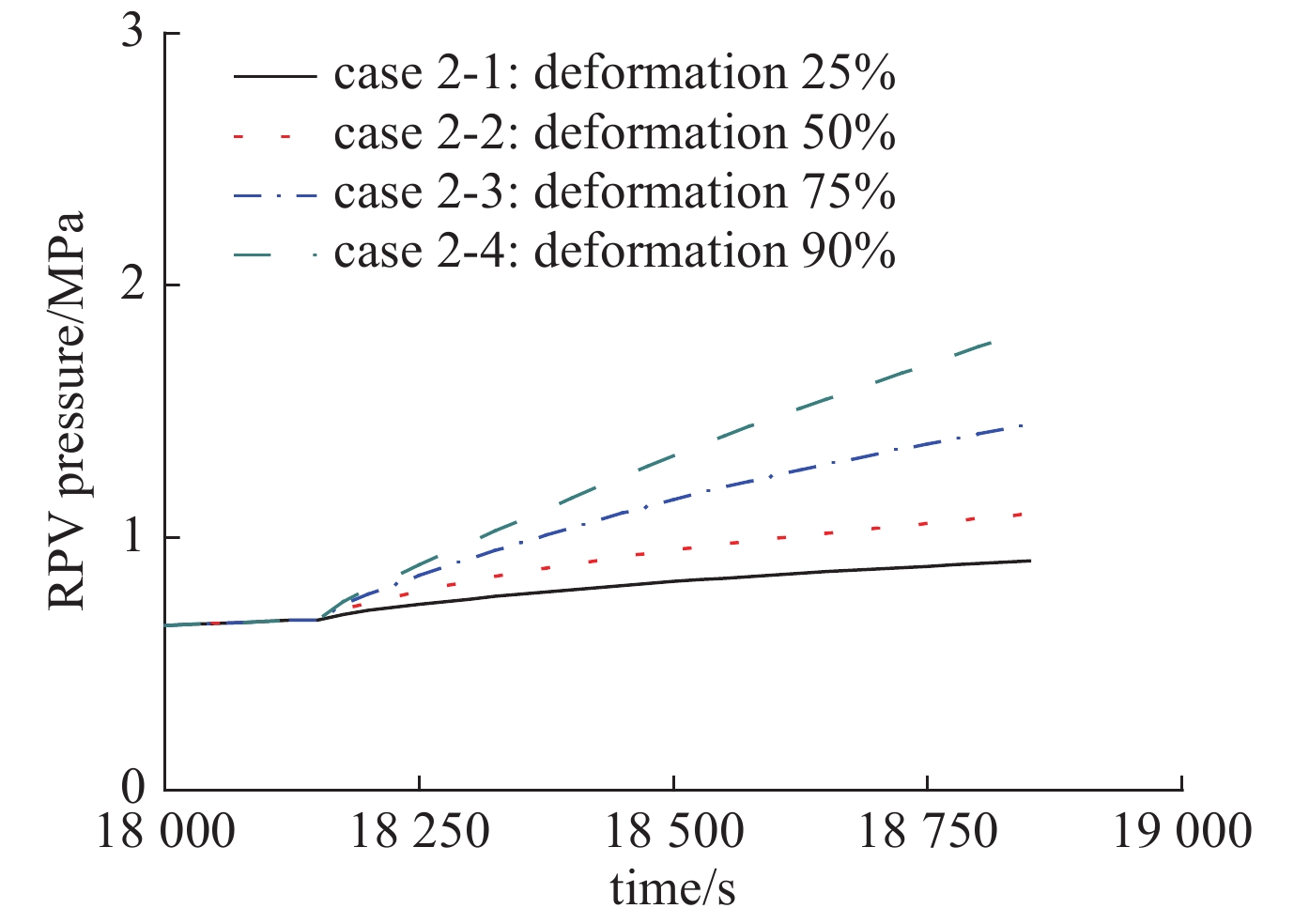

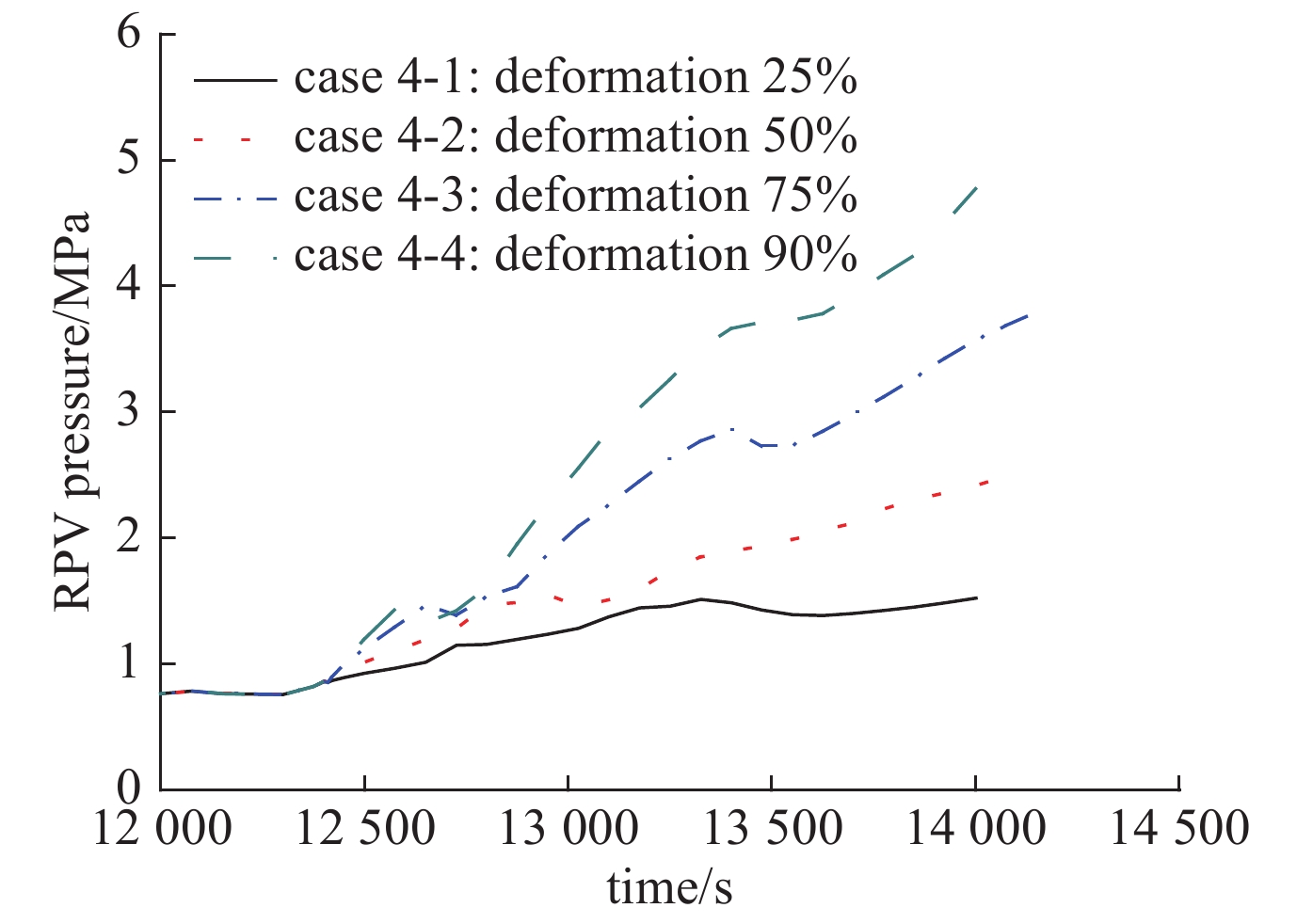

valve channel deformation(350 t/h:6625 s) time/s pressure/MPa accumulator drain RPV lower head failure RPV lower head failure case 1-1:25% 15565 22300 1.35 case 1-2:50% 15980 26650 2.32 case 1-3:75% 21050 31700 4.14 case 1-4:90% — 13300 7.62 表 3 事故主要进程时间节点(事故后期发生流道变形)

Table 3. Accident process of depressurization (with late valve channel deformation)

valve channel deformation time /s pressure/MPa 350 t/h:18605 case 1-5:25% 19400 1.27 case 1-6:50% 19410 1.56 case 1-7:75% 19415 2.04 case 1-8:90% 19400 2.51 450 t/h:18145 case 2-1:25% 18875 0.91 case 2-2:50% 18880 1.11 case 2-3:75% 18865 1.45 case 2-4:90% 18890 1.93 1000 t/h 13010 case 4-1:25% 14000 1.52 case 4-2:50% 14075 2.51 case 4-3:75% 14150 3.82 case 4-4:90% 14000 4.78 -

[1] Hanson D J, Golden D W, Chambers R, et a1. Depressurization as an accident management strategy to minimize the consequences of direct containment heating[R]. NUREG/CR-5447. 1990. [2] Brownson D, Haney L N, Chien N D. Intentional depressurization accident management strategy for PWR[R]. NUREG/CR-5937. 1993. [3] Kim S B, Lee H Y, Kim M H, et al. A parametric study of geometric effect on the debris dispersal from a reactor cavity during high pressure melt ejection[J]. International Communications in Heat and Mass Transfer, 1995, 22(1): 25-34. doi: 10.1016/0735-1933(94)00049-Q [4] Renaud M, Tanguy J. On the analysis and evaluation of direct containment heating with the multidimensional multiphase flow Code MC3D[J]. Science and Technology and Nuclear Installations, 2010(3): 1-13. [5] Shao Ge, Tong Lili, Cao Xuewu. Assessment of severe accident depressurization valve activation strategy for Chinese improved 1000 MWe PWR[J]. Science and Technology of Nuclear Installations, 2013(2): 1-8. [6] Zhang Kun, Cao Xuewu, Deng jian, et al. Evaluation of intentional depressurization strategy in Chinese 600 MWe PWR NPP – Science Direct[J]. Nuclear Engineering and Design, 2008, 238(7): 1720-1727. doi: 10.1016/j.nucengdes.2008.01.003 [7] Seo S, Lee Y, Lee S, et al. Effectiveness and adverse effects of reactor coolant system depressurization strategy with various severe accident management guidance entry conditions for OPR1000[J]. Journal of Nuclear Science and Technology, 2015, 52(5): 695-708. doi: 10.1080/00223131.2014.978407 [8] 种毅敏, 杨志义, 石雪垚, 等. 二代改进型核电厂严重事故下一回路卸压时机敏感性研究[J]. 核科学与工程, 2015, 35(1):141-147. (Chong Yimin, Yang Zhiyi, Shi Xueyao, et al. Sensitivity analysis on time of reactor coolant system depressurization under severe accident for generation II+ nuclear power plants[J]. Nuclear Science and Engineering, 2015, 35(1): 141-147 [9] 张蕾, 黄挺, 崔成鑫, 等. AP1000核电站严重事故下一回路卸压时机敏感性分析[C]//第十四届全国反应堆热工流体学术会议暨中核核反应堆热工水力技术重点实验室2015年度学术年会论文集. 2015.Zhang Lei, Huang Ting, Cui Chengxin, et al. Sensitivity analysis on timing of reactor coolant system depressurization under severe accident for AP1000 nuclear power plants// Proceedings of the 14th National Conference on Nuclear Reactor Thermal Hydraulics & 2015 Annual Conference of CNNC Nuclear Reactor Thermal Hydraulic Technology Key Laboratory, 2015 [10] Huang Gaofeng, Tong Lili, Cao Xuewu. Study on mitigation of ex-vessel release of fission products in severe accidents for Chinese two loops PWR[J]. Progress in Nuclear Energy, 2015, 78: 56-64. doi: 10.1016/j.pnucene.2014.08.004 [11] 张琨, 佟立丽, 曹学武. 压水堆核电厂自然循环对一回路卸压策略的影响[J]. 核动力工程, 2009, 30(2):70-74. (Zhang Kun, Tong Lili, Cao Xuewu. Effect of natural circulation on RCS depressurization strategy in PWR NPP[J]. Nuclear Power Engineering, 2009, 30(2): 70-74 [12] Park J W, Seol W C. Considerations for severe accident management under extended station blackout conditions in nuclear power plants[J]. Progress in Nuclear Energy, 2016, 88: 245-256. doi: 10.1016/j.pnucene.2016.01.005 [13] 陈艺芬, 黄志翱, 郑剑香, 等. CPR1000全厂断电叠加小破口失水事故下一回路外部注水策略分析[J]. 厦门大学学报(自然科学版), 2019, 58(6):855-863. (Chen Yifen, Huang Zhixiang, Zheng Jianxiang, et al. Analysis of primary system external water injection strategies of station blackout along with small break loss-of-coolant accident for CPR1000[J]. Journal of Xiamen University (Natural Science), 2019, 58(6): 855-863 [14] 唐琼辉, 周瑞, 王明毓, 等. 反应堆严重事故卸压管线瞬态传热特性与高温蠕变效应研究[J]. 中国科学: 技术科学, 2021, 51(2):176-184. (Tang Qionghui, Zhou Rui, Wang Mingyu, et al. The transient heat transfer and Larson-Miller creep failure analysis of severe accident relief pipeline[J]. Scientia Sinica (Technologica), 2021, 51(2): 176-184 [15] The SCDAP/RELAP5 Development Team. SCDAP/RELAP5/MOD3.2 code manual[R]. NUREG/CR-6150. 1997. [16] 张琨, 曹学武. 压水堆核电厂高压熔堆严重事故序列分析[J]. 原子能科学技术, 2008(6):530-534. (Zhang Kun, Cao Xuewu. Analysis of high-pressure core melt severe accidents in PWR nuclear power plant[J]. Atomic Energy Science and Technology, 2008(6): 530-534 -

下载:

下载: