Development of pointed-mouth slit for neutron engineering material diffractometer at China Spallation Neutron Source

-

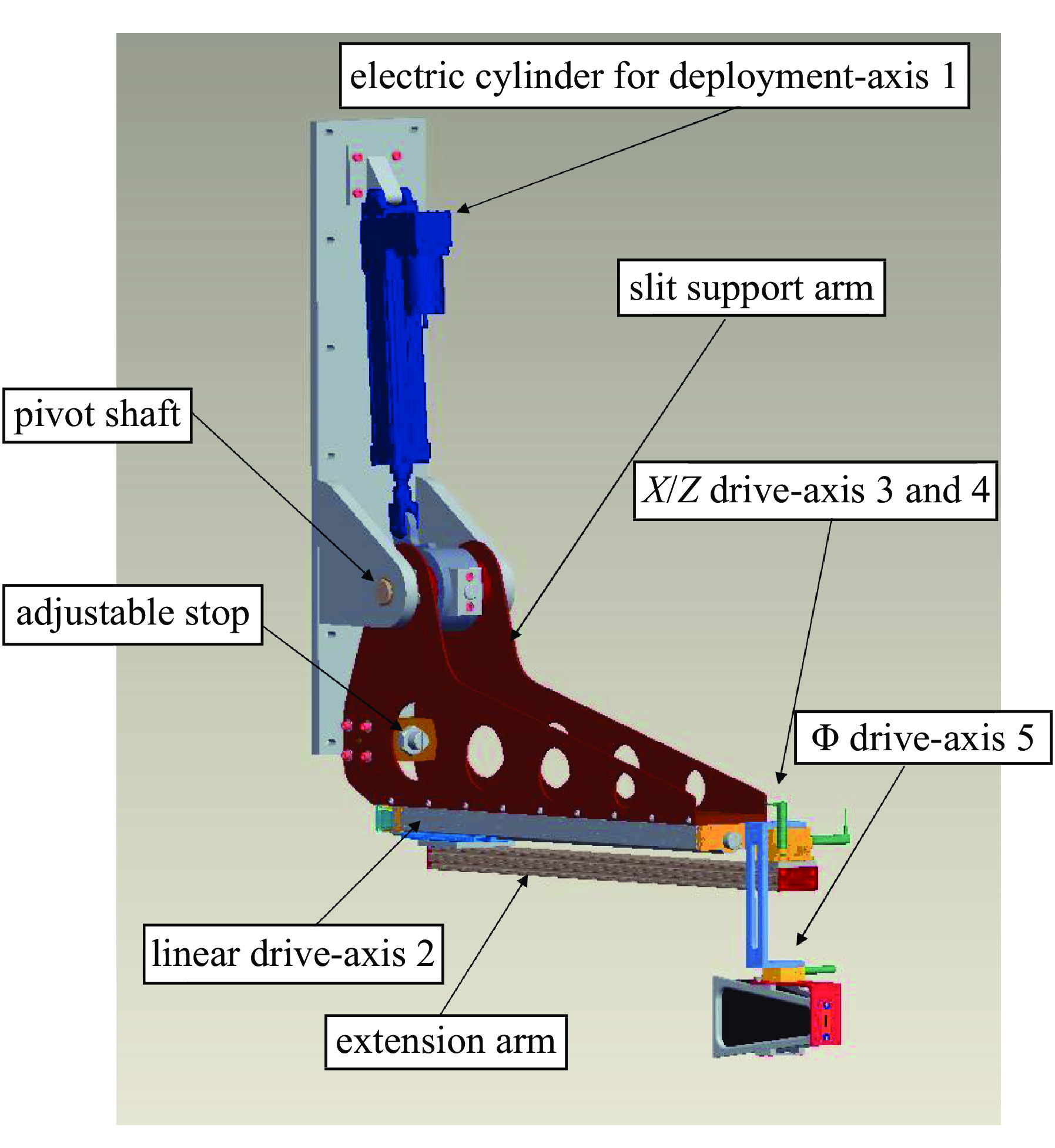

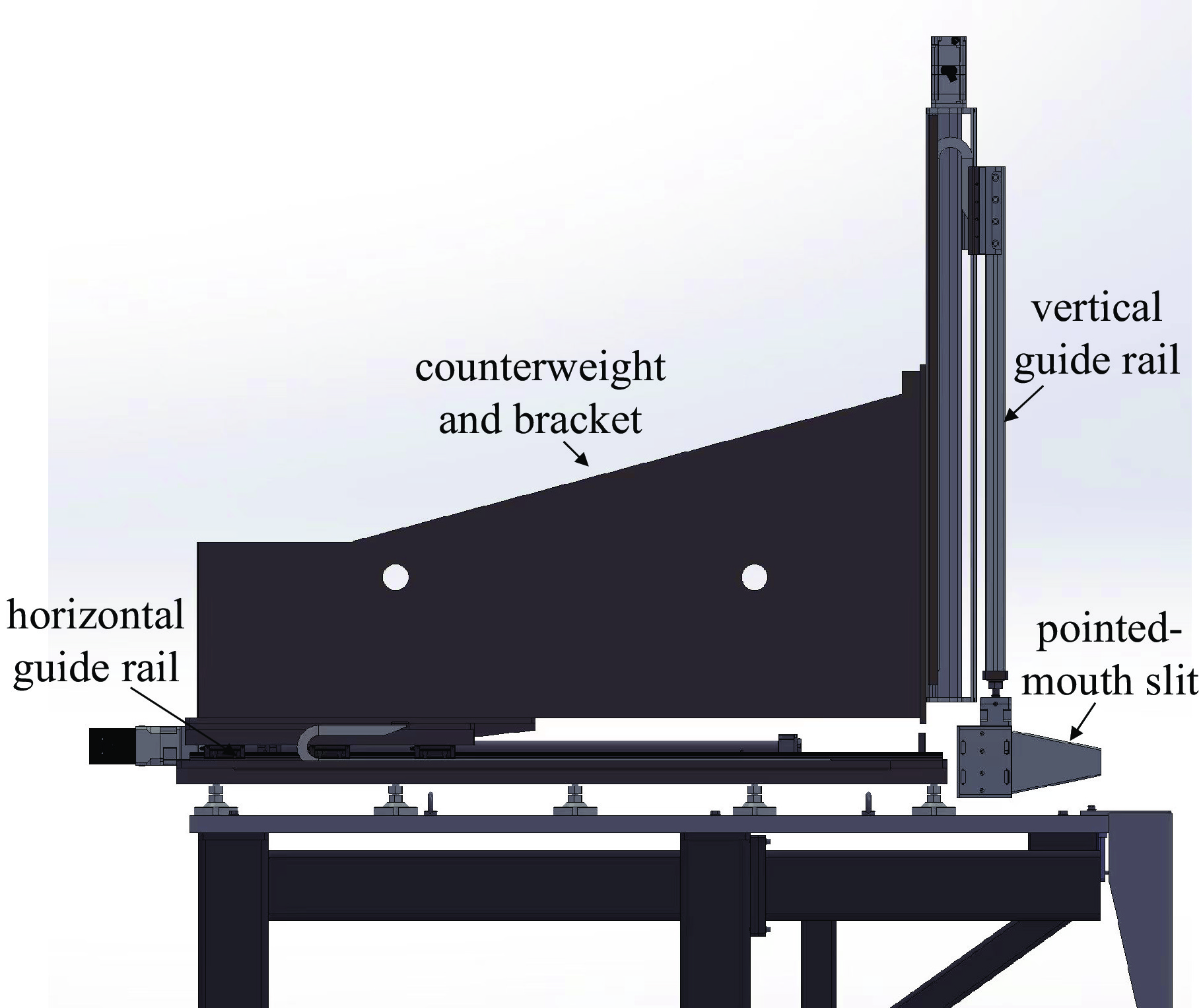

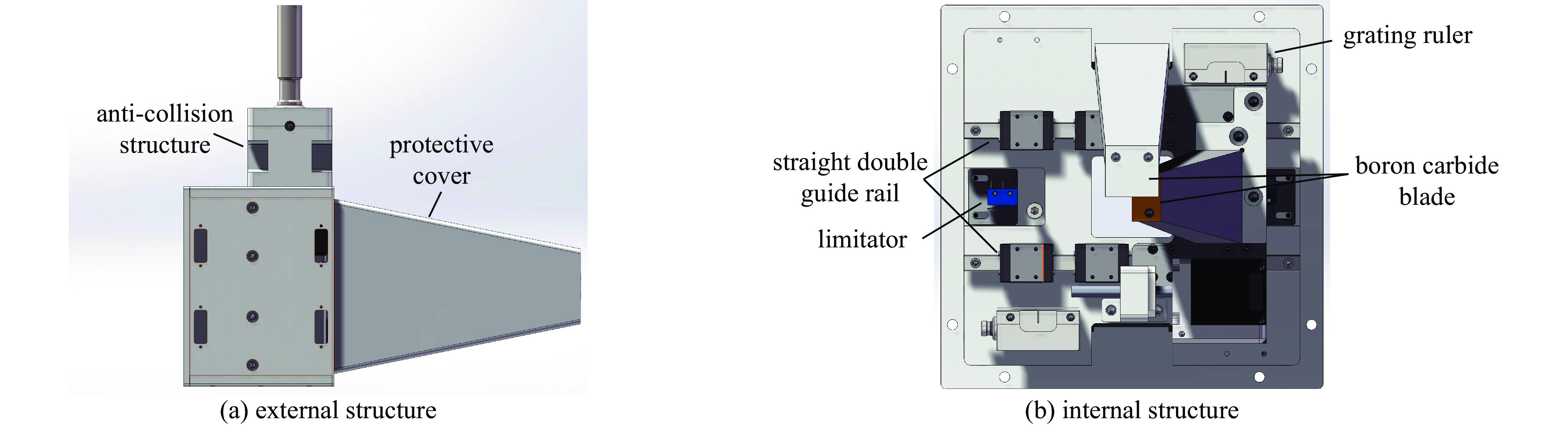

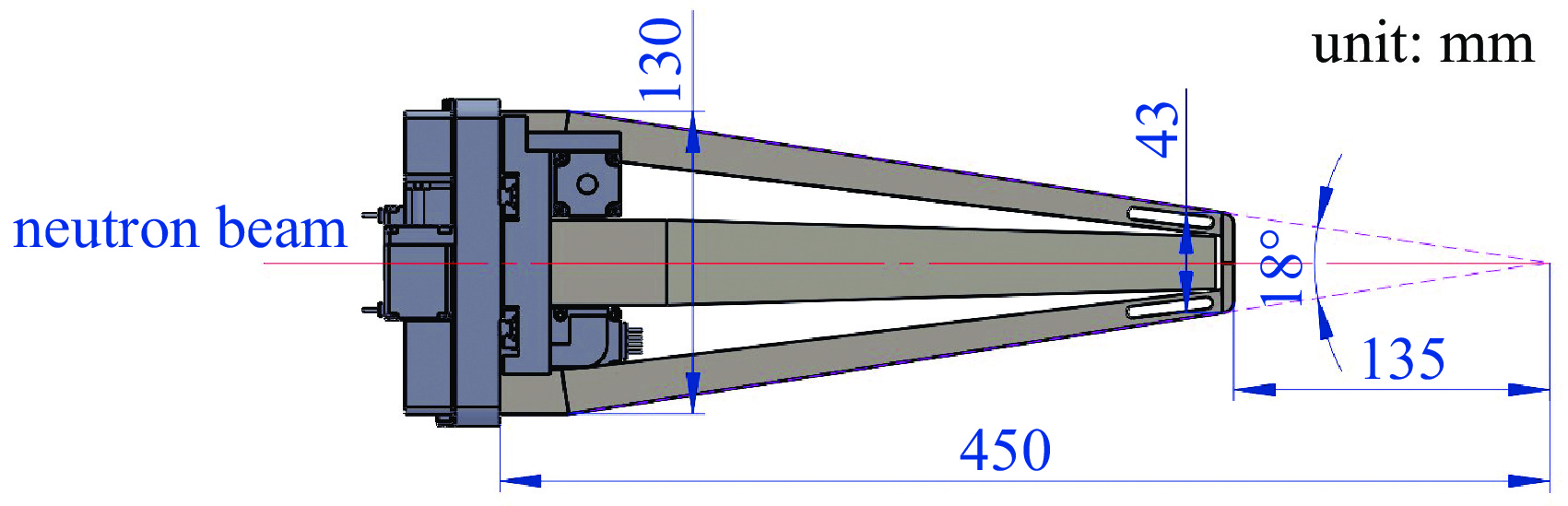

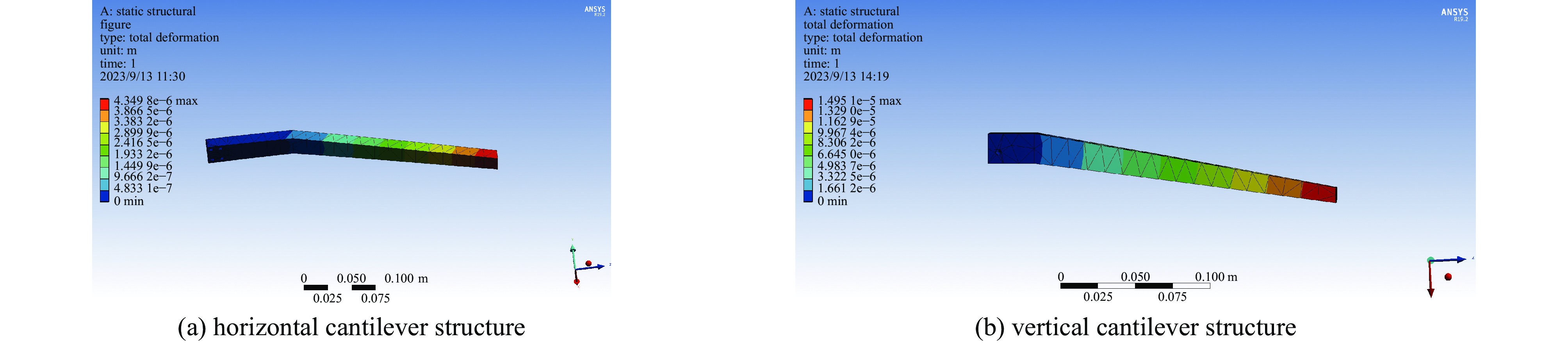

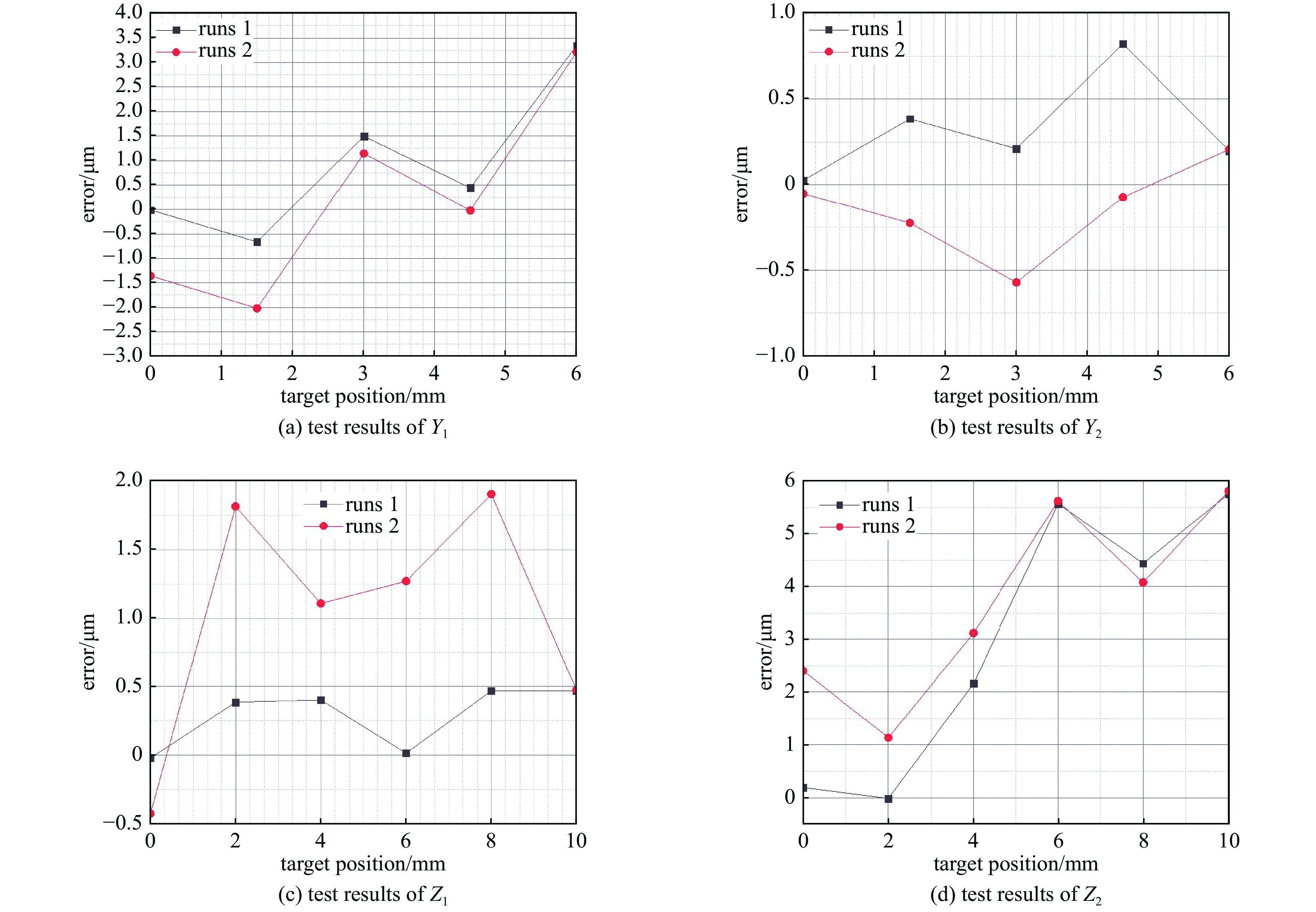

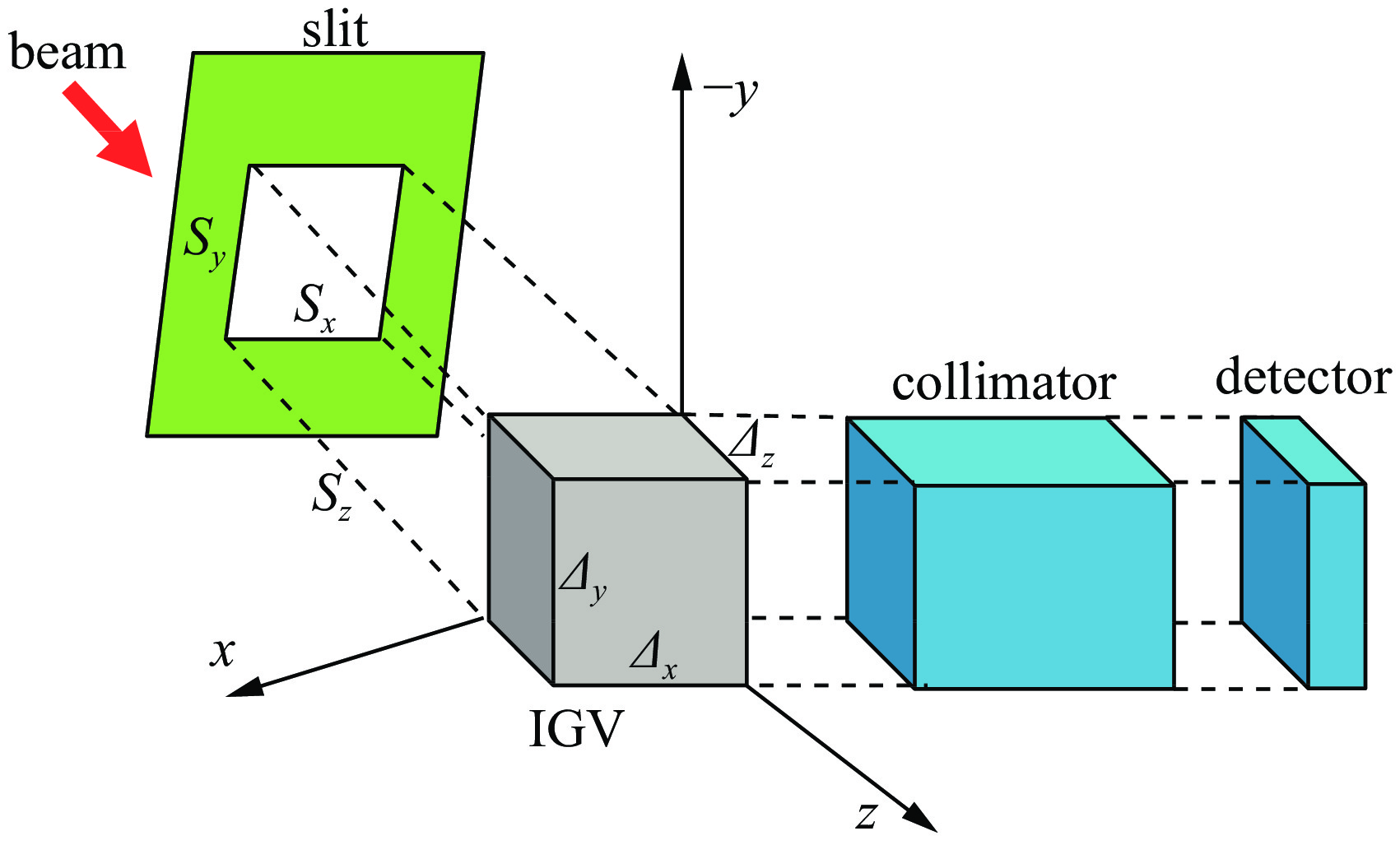

摘要: 中国散裂中子源(CSNS)工程材料中子衍射谱仪(EMD)的样品非常大,且形状各异,有些样品甚至是曲面的,中子准直光阑(狭缝)要靠近这些异形构件,需要设计成尖嘴型。狭缝的主要作用是给样品测试提供所需要的束流尺寸,并保证束流尺寸精度很高,束流没有太多杂散中子。工程材料中子衍射谱仪的尖嘴型狭缝为连续型,开口可以根据实验需求进行变化。狭缝采用双导轨结构,定位精度高,重复定位精度优于10 μm,绝对定位精度优于30 μm。狭缝刀片采用富集碳化硼,较大程度减小了刀片的厚度,可以有效降低狭缝悬臂结构的变形量,保证狭缝有足够长度的尖嘴,能够接近异形构件,特别能够深入到长管内部,提高了工程材料中子衍射谱仪的实验能力。狭缝采取双重安全设计:导轨互换系统和防撞结构,可以有效防止狭缝在使用过程中被大件样品撞坏。该狭缝已经应用到中国散裂中子源工程材料中子衍射谱仪的实验测试,为残余应力测量做出了重要贡献,它的应用为国内外尖嘴型狭缝的设计提供了非常重要的参考。Abstract: The samples of the China Spallation Neutron Source (CSNS) Engineering Material Diffraction Spectrometer (EMD) are very large and have different shapes. The neutron collimation aperture needs to be designed as a pointed-mouth slit to be close to these abnormal components. The main function of the pointed-mouth slit is to provide the beam size is needed by the sample experiment, and ensure that the beam size has high accuracy. The pointed-mouth slit is continuous, and it can be changed according to the experimental requirements. The blade uses enriched boron carbide, which can reduce the deformation of the slit cantilever structure. The slit has a very long mouth, which can approach the special-shaped components and enter into the long tubes. The deformation problem of the cantilever was simulated and analyzed using finite element software. The slit adopts a dual safety design, which can effectively prevent from being damaged by large samples. This slit has been applied to the CSNS engineering material spectrometer. It has made remarkable contributions to residual stress measurement. The application of this slit provides a very important reference for the design of the pointed-mouth slits.

-

表 1 计算结果

Table 1. Calculation results

Sx/mm $ {\alpha }_{x,y} $/(°) Sz/mm $ \mathit{\Delta}_x $/mm 1 0.2 10 1.000 033 1 0.2 30 1.000 899 1 0.2 50 1.004 147 1 0.2 70 1.011 299 1 0.2 100 1.032 262 表 2 不同厚度富集碳化硼中子透过率计算结果

Table 2. Calculation results of neutron transmittance of boron carbide with different thicknesses

thickness/mm transmittance 1 4.94×10−5 2 2.44×10−9 3 1.20×10−13 4 4.91×10−18 -

[1] 张俊荣, 庄建, 王平, 等. 中国散裂中子源中子谱仪简介[J]. 现代物理知识, 2022, 34(4):21-24 doi: 10.13405/j.cnki.xdwz.2022.04.010Zhang Junrong, Zhuang Jian, Wang Ping, et al. Introduction of China spallation neutron source neutron spectrometer[J]. Modern Physics, 2022, 34(4): 21-24 doi: 10.13405/j.cnki.xdwz.2022.04.010 [2] 中国散裂中子源工程[EB/OL]. http://csns.ihep.cas.cn/China spallation neutron source[EB/OL]. http://csns.ihep.cas.cn/. [3] 肖仁峰. 中国散裂中子源高压谱仪四刀光阑控制系统设计[D]. 成都: 电子科技大学, 2022Xiao Renfeng. Design of four-blade slit control system of China Spallation Neutron Source high pressure spectrometer[D]. Chengdu: University of Electronic Science and Technology of China, 2022 [4] Santisteban J R, Daymond M R, James J A, et al. ENGIN-X: A third-generation neutron strain scanner[J]. Journal of Applied Crystallography, 2006, 39(6): 812-825. doi: 10.1107/S0021889806042245 [5] Aizawa K, Harjo S, Ito T. The engineering materials diffractometer "TAKUMI"[J]. Hamon, 2010, 20(1): 62-65. doi: 10.5611/hamon.20.1_62 [6] Wang X L. Conceptual design of the SNS engineering diffractometer[R]. SNS Report No. IS-1.1. 8.2-6035-RE-A-00, 2000. [7] Wang X L, Holden T M, Rennich G Q, et al. VULCAN—The engineering diffractometer at the SNS[J]. Physica B:Condensed Matter, 2006, 385/386: 673-675. doi: 10.1016/j.physb.2006.06.103 [8] 肖松文, 何泳成, 何振强, 等. 微小角中子散射谱仪探测器移动小车驱动机构设计及精度测试[J]. 核技术, 2022, 45:090401Xiao Songwen, He Yongcheng, He Zhenqiang, et al. Driving system design and precision test of the VSANS detector trolleys[J]. Nuclear Techniques, 2022, 45: 090401 [9] 魏娜. 浅析步进电机的选择与使用[J]. 科技与企业, 2013(2):298 doi: 10.13751/j.cnki.kjyqy.2013.02.219Wei Na. Analysis of the selection and use of stepper motors[J]. Science-Technology Enterprise, 2013(2): 298 doi: 10.13751/j.cnki.kjyqy.2013.02.219 [10] 王零森, 方寅初, 吴芳, 等. 碳化硼在吸收材料中的地位及其与核应用有关的基本性能[J]. 粉末冶金材料科学与工程, 2000, 5(2):113-120Wang Lingsen, Fang Yingchu, Wu Fang, et al. The position of boron carbide in neutron absorbing materials and its properties relation to nuclear applications[J]. Materials Science and Engineering of Powder Metallurgy, 2000, 5(2): 113-120 [11] 刘桂荣, 裴燕斌. 含B中子吸收材料的研究进展[J]. 粉末冶金工业, 2018, 28(5):1-5 doi: 10.13228/j.boyuan.issn1006-6543.20180095Liu Guirong, Pei Yanbin. Research progress of boron-containing neutron absorber materials[J]. Powder Metallurgy Industry, 2018, 28(5): 1-5 doi: 10.13228/j.boyuan.issn1006-6543.20180095 [12] 卢希庭. 原子核物理[M]. 北京: 中国原子能出版社, 2001Lu Xiting. Nuclear physics[M]. Beijing: China Atomic Energy Press, 2001 [13] 黄骏, 马雁云. 医疗加速器治疗床以及旋转臂的受力分析[J]. 机械工程师, 2011(8):79-80 doi: 10.3969/j.issn.1002-2333.2011.08.033Huang Jun, Ma Yanyun. Force analysis of medical accelerator treatment bed and rotating arm[J]. Mechanical Engineer, 2011(8): 79-80 doi: 10.3969/j.issn.1002-2333.2011.08.033 [14] 邹易清, 康玲, 屈化民, 等. 中国散裂中子源快循环同步加速器主准直器的设计与研究[J]. 强激光与粒子束, 2013, 25(3):741-745 doi: 10.3788/HPLPB20132503.0741Zou Yiqing, Kang Ling, Qu Huamin, et al. Design and research of primary collimator for CSNS/RCS[J]. High Power Laser and Particle Beams, 2013, 25(3): 741-745 doi: 10.3788/HPLPB20132503.0741 [15] 王会永, 满忠雷, 孙立, 等. 基于激光干涉仪的机床定位精度测量与分析[J]. 检验检疫学刊, 2015(2):36-37,43 doi: 10.3969/j.issn.1674-5354.2015.02.010Wang Huiyong, Man Zhonglei, Sun Li, et al. Analysis and measurement for linear positioning accuracy of machine tools based on laser interferometer[J]. Quality Safety Inspection and Testing, 2015(2): 36-37,43 doi: 10.3969/j.issn.1674-5354.2015.02.010 [16] 吴江杰, 陈伟庆, 辛天飞. 激光干涉仪测量数控机床定位精度的方法研究[J]. 工业控制计算机, 2017, 30(11):159-160 doi: 10.3969/j.issn.1001-182X.2017.11.074Wu Jiangjie, Chen Weiqing, Xin Tianfei. Research on the method of measuring the positioning accuracy of CNC machine tools using laser interferometer[J]. Industrial Control Computer, 2017, 30(11): 159-160 doi: 10.3969/j.issn.1001-182X.2017.11.074 -

下载:

下载: