Three-dimensional coordinate calibration technology for high energy photon source magnets

-

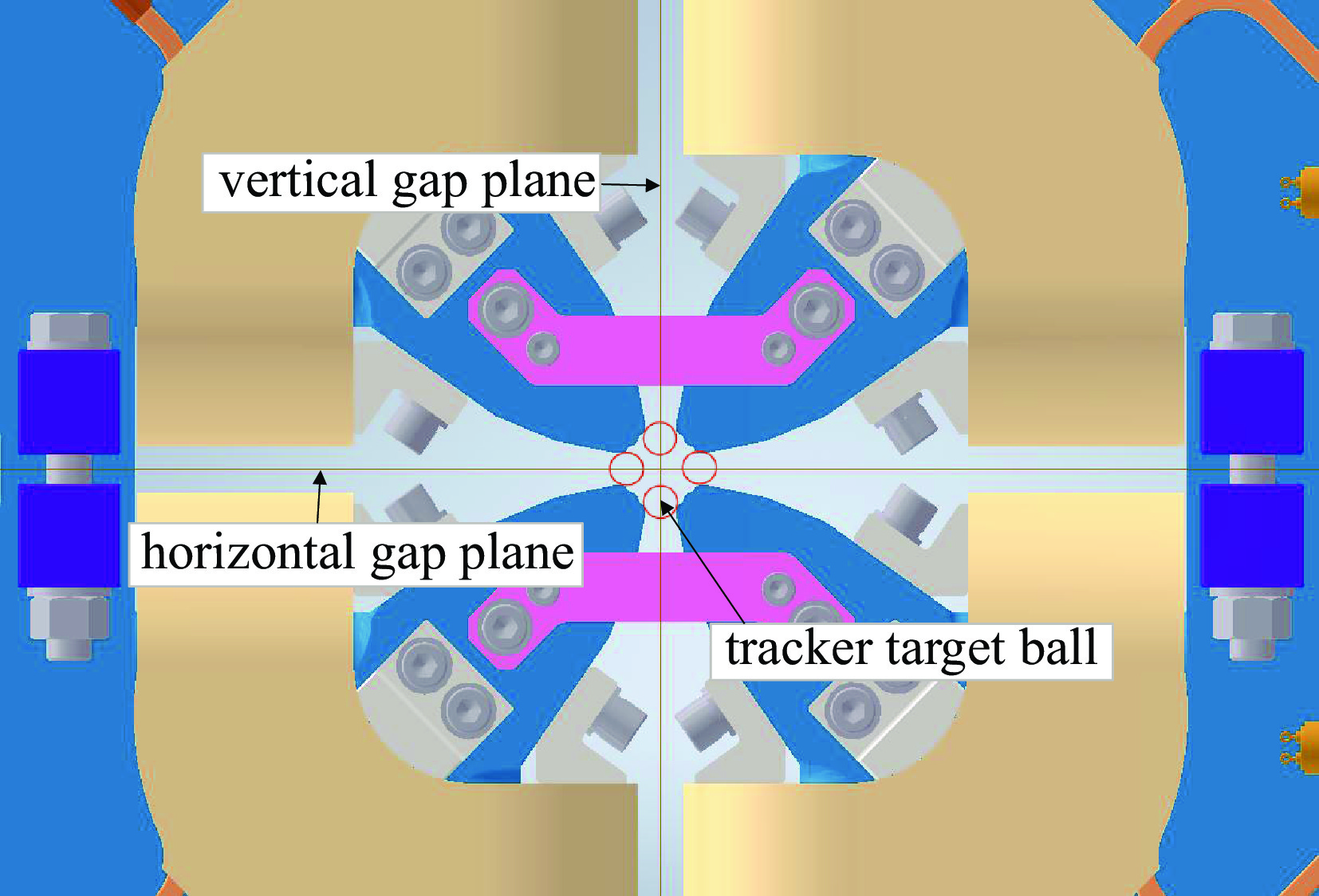

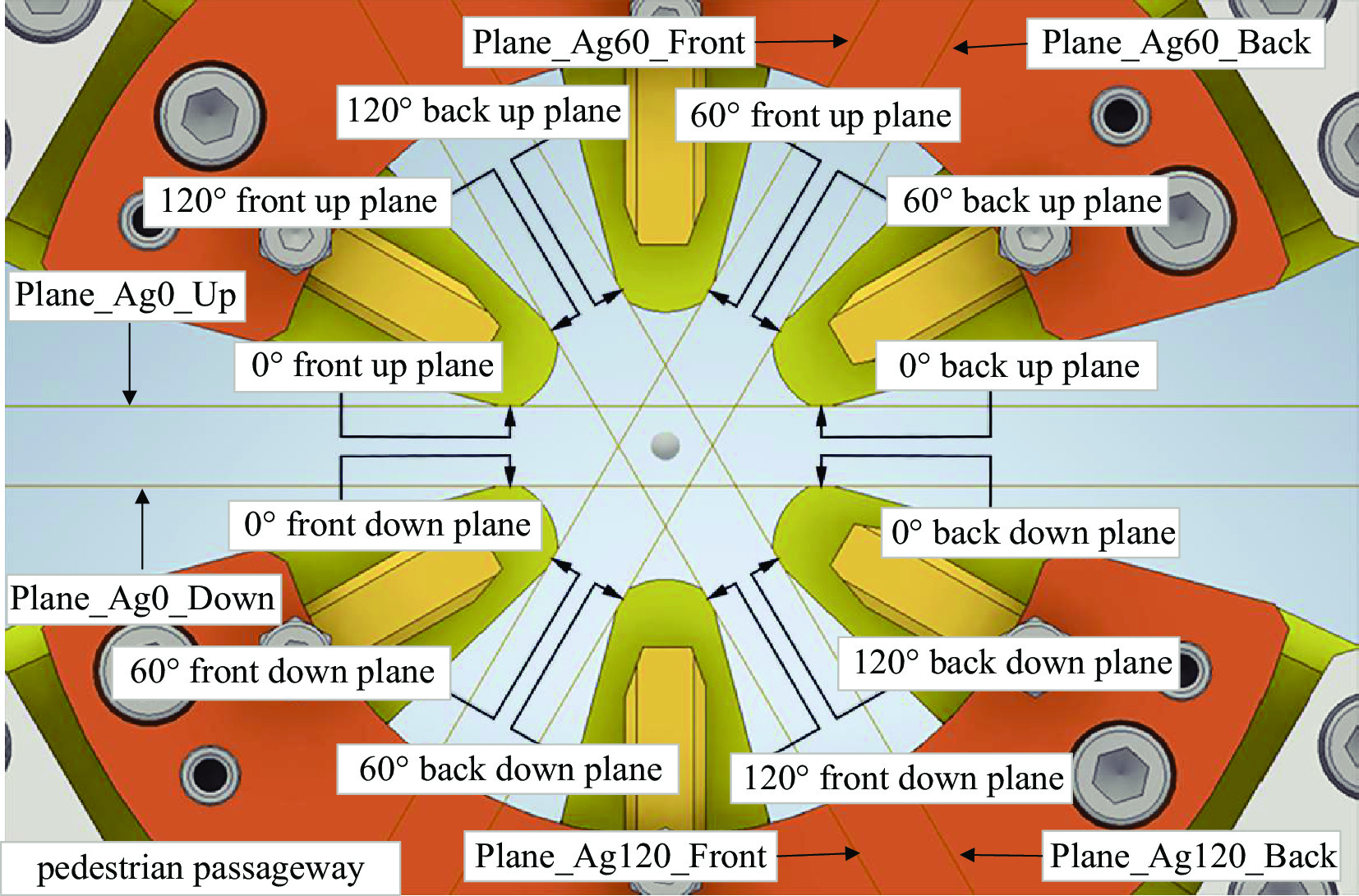

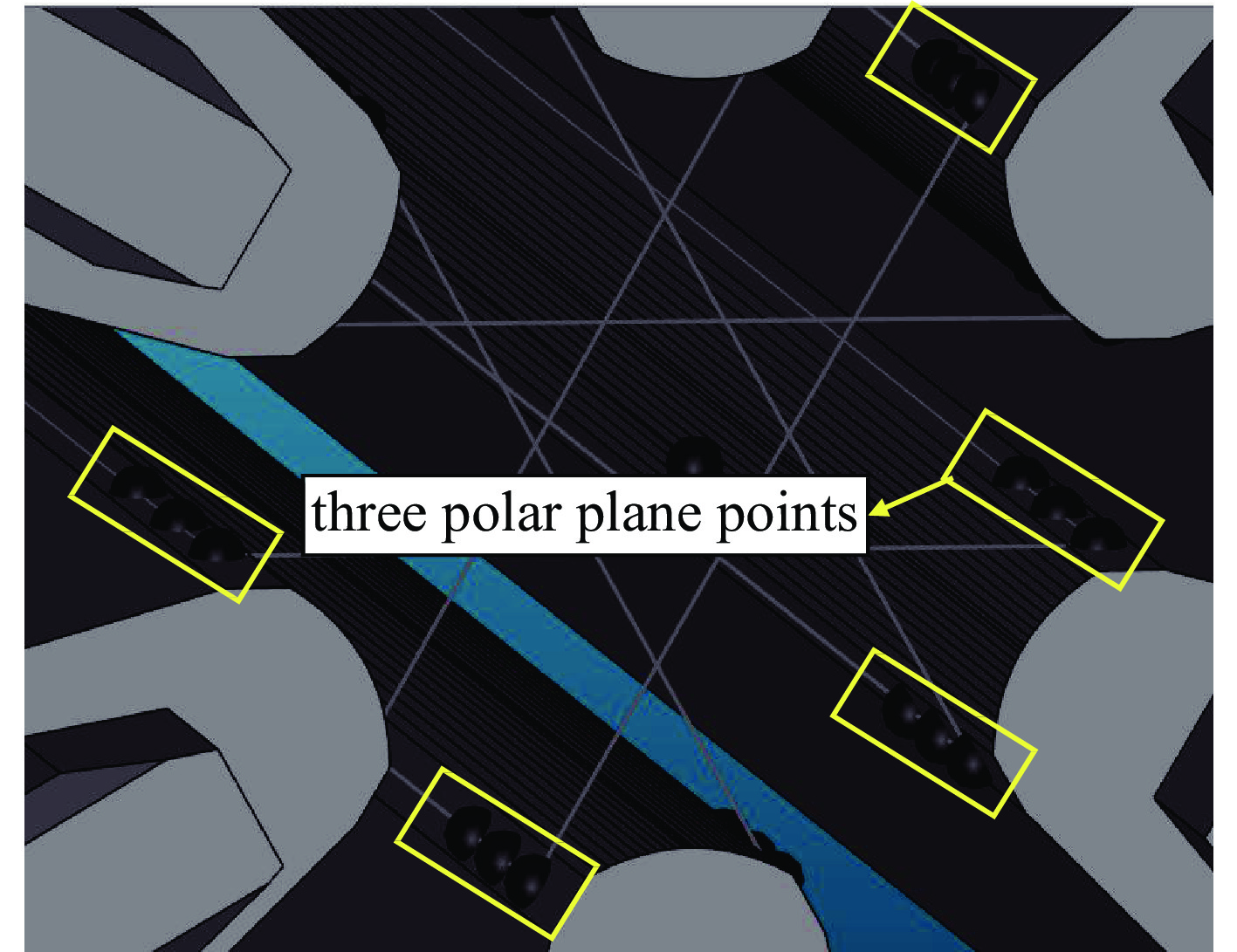

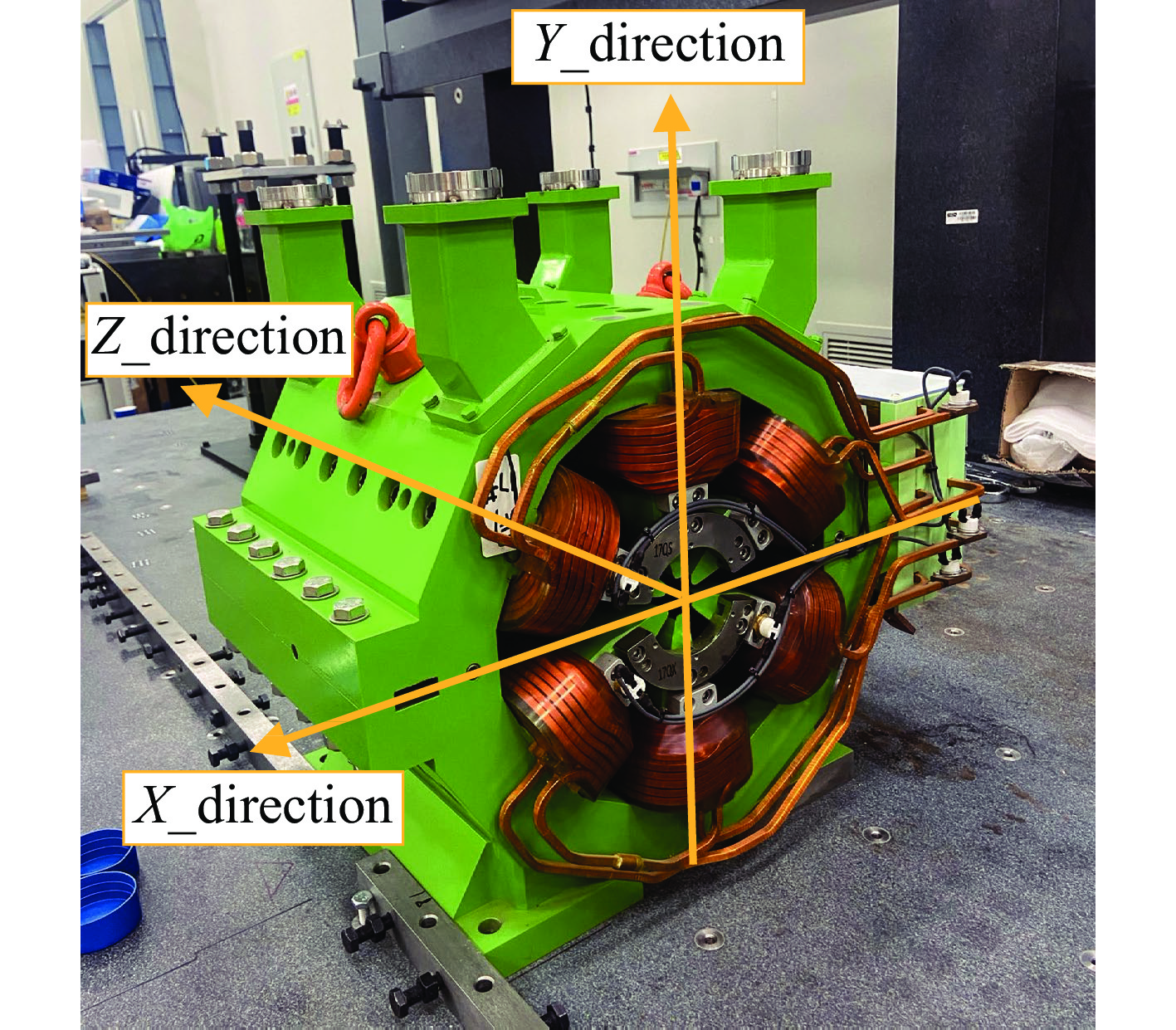

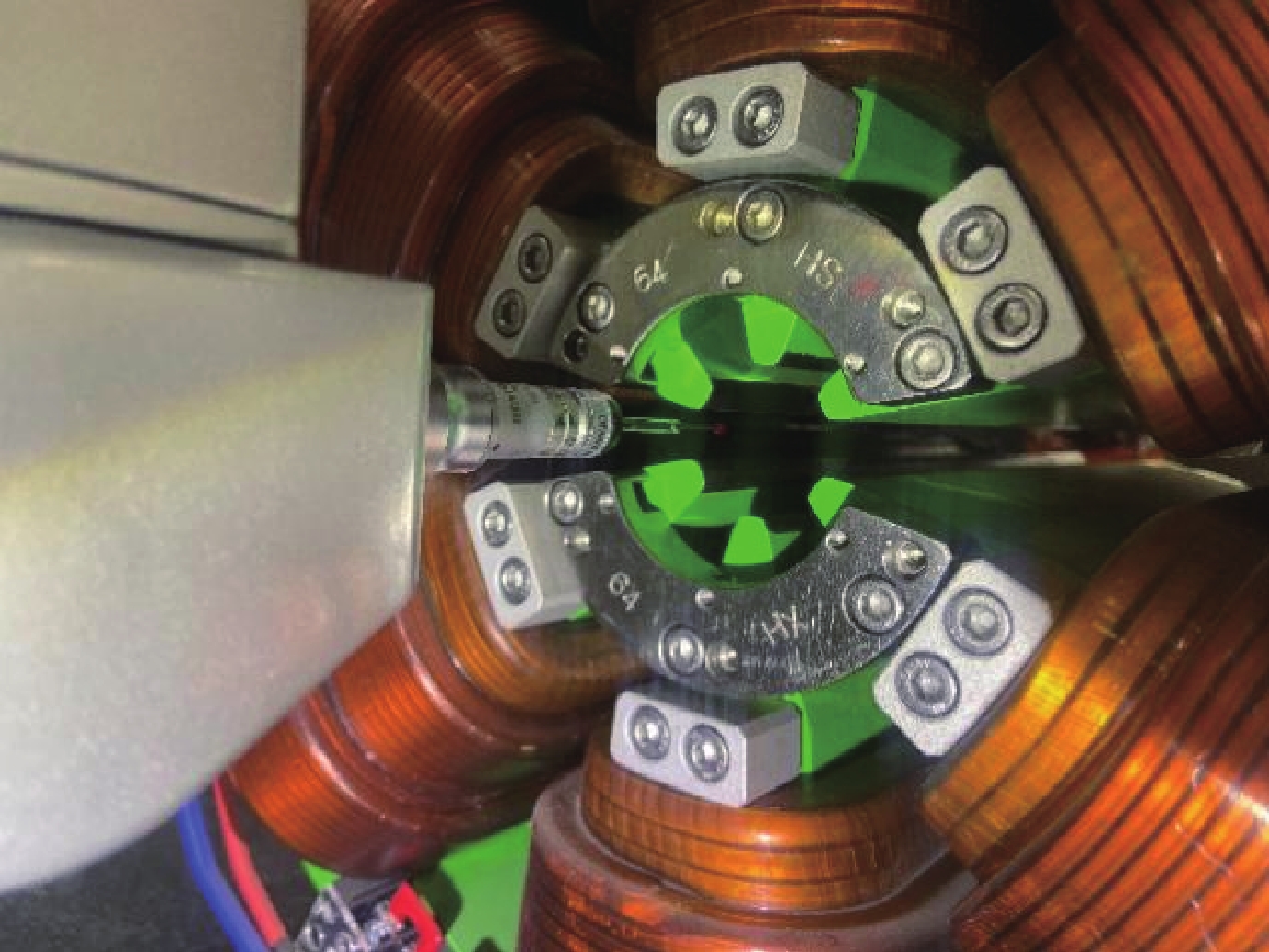

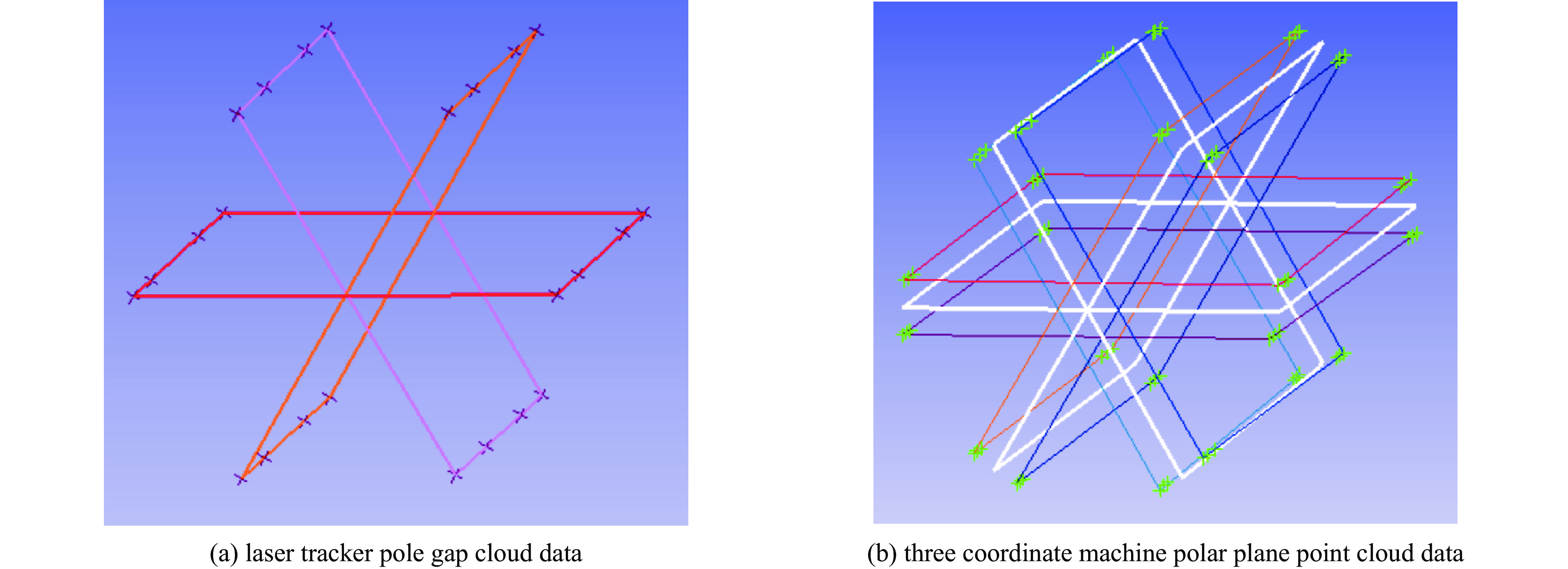

摘要: 针对高能同步辐射光源需要进行大批量磁铁的中心引出标定,提出了一种基于三坐标测量机的磁铁机械中心标定方案,确定了编写自动测量程序的流程和方法,参与完成了加速器中多种类型磁铁的标定。对176块储存环六极铁的三坐标机测量数据进行分析,结果表明:每块磁铁进行两遍机械中心标定,获得准直基准点的标定重复性在0.01 mm之内;极缝间距离的实测值与设计值标准偏差均在0.015 mm之内;标定效率相较激光跟踪仪提高了2倍。这种借助三坐标测量机的磁铁标定方法可以提高标定精度,降低人力成本,提高工作效率,能为加速器工程中磁铁中心的引出标定工作提供参考,保证加速器装置的安装顺利,满足加速器准直测量的工程进度要求。Abstract: Aiming at the High Energy Photon Source which needs to calibrate the center of a large number of magnets, a scheme of calibrating the center of magnetic machinery based on coordinate measuring machine (CMM) is proposed, the process and method of writing automatic measuring program are determined, and the calibration of various types of magnets in the accelerator is completed. The results show that the calibration repeatability of the reference point of collimation is within 0.01 mm by calibrating the mechanical center twice for each magnet. The standard deviation between the measured value and the design value is within 0.015 mm. The calibration efficiency is 2 times higher than that of the laser tracker. This method of magnet calibration with CMM can improve the calibration accuracy, reduce the labor cost, improve the work efficiency, provide reference for the magnet center extraction calibration in the accelerator work, ensure the smooth installation of the accelerator device, and meet the requirements of the accelerator alignment measurement project schedule.

-

表 1 三坐标机参与标定的磁铁数量统计

Table 1. Statistics of the number of magnets involved in calibration by the coordinate machine

type of magnet corrector magnet hexacode iron quadrupole iron transport line four grade iron quantity 195 176 30 43 表 2 HEPS磁铁预准直误差分析

Table 2. Analysis of precollimation error of HEPS magnet

mm magnetic center elicits

calibration errorpre-collimation

measurement errorpre-collimation

adjustment deviationmagnets lock the

momentumthe opening and closing

momentum of the magnetmagnets transport

momentum0.010 0.010 0.010 0.010 0.010 0.020 表 3 磁铁极头和外基准面的平面拟合标准偏差对比(储存环176块六极铁)

Table 3. Comparison of the standard deviation of the plane fit between the magnet head and the external datum plane

instrument standard deviation/mm pole seam middle/pole plane left and right plane top plane tracker 0.018 0.045 0.026 CMM 0.009 0.028 0.013 表 4 HEPS六极铁的标定重复性

Table 4. Calibration repeatability of HEPS sextupole

maximum positive deviation/mm minimum negative deviation/mm standard deviation/mm ΔX 0.009 −0.009 0.003 ΔY 0.009 −0.008 0.002 ΔZ 0.005 −0.005 0.001 表 5 HEPS环六极铁极缝偏差统计(176块铁)

Table 5. Pole seam deviation statistics of sextupole of HEPS sextupole

magnet type maximum positive deviation/mm minimum negative deviation/mm standard deviation/mm SF1/2 0.050 −0.045 0.012 SD1/4 0.047 −0.041 0.014 SD2/3 0.062 −0.082 0.014 -

[1] 任锦龙, 李世昌, 王闯, 等. 高能同步辐射光源项目综合施工技术[J]. 建筑技术, 2022, 53(7):812-817 doi: 10.3969/j.issn.1000-4726.2022.07.012Ren Jinlong, Li Shichang, Wang Chuang, et al. General construction technique for high energy photon source project[J]. Architecture Technology, 2022, 53(7): 812-817 doi: 10.3969/j.issn.1000-4726.2022.07.012 [2] 焦毅, 潘卫民. 高能同步辐射光源[J]. 强激光与粒子束, 2022, 34:104002 doi: 10.11884/HPLPB202234.220080Jiao Yi, Pan Weimin. High energy photon source[J]. High Power Laser and Particle Beams, 2022, 34: 104002 doi: 10.11884/HPLPB202234.220080 [3] 王小龙, 董岚, 李波, 等. BEPCⅡ储存环的预准直[J]. 核技术, 2010, 33(8):566-570Wang Xiaolong, Dong Lan, Li Bo, et al. The pre-alignment of the BEPCⅡ storage rings[J]. Nuclear Techniques, 2010, 33(8): 566-570 [4] 王铜, 梁静, 董岚, 等. 粒子加速器设备标定中基准面引出研究[J]. 原子能科学技术, 2016, 50(8):1524-1527 doi: 10.7538/yzk.2016.50.08.1524Wang Tong, Liang Jing, Dong Lan, et al. Research on layout of datum plane in equipment fiducialisation of particle accelerator[J]. Atomic Energy Science and Technology, 2016, 50(8): 1524-1527 doi: 10.7538/yzk.2016.50.08.1524 [5] 李海, 徐海卫. 基于3D数模的三坐标测量机曲面检测[J]. 中国测试技术, 2005, 31(4):24-26,40Li Hai, Xu Haiwei. Inspecting surfaces by CMM based on 3D CAD model[J]. China Measurement Technology, 2005, 31(4): 24-26,40 [6] 周保珍, 平雪良, 龚玉玲, 等. 基于CAD模型的复杂曲面三坐标自动测量[J]. 机床与液压, 2008, 36(4):125-127Zhou Baozhen, Ping Xueliang, Gong Yuling, et al. Auto-measurement of coordinate measuring machine based on CAD model[J]. Machine Tool & Hydraulics, 2008, 36(4): 125-127 [7] 吴志昊, 吕彦明. 航空叶片的三坐标自动测量技术[J]. 工具技术, 2017, 51(12):3-7 doi: 10.3969/j.issn.1000-7008.2017.12.001Wu Zhihao, Lv Yanming. Automatic measuring technology of CMM for aviation blade[J]. Tool Engineering, 2017, 51(12): 3-7 doi: 10.3969/j.issn.1000-7008.2017.12.001 [8] 张虎, 张润, 于连栋. 基于CAD模型的三坐标测量机测量点分布规划[J]. 自动化与仪表, 2019, 34(2):1-4,10 doi: 10.3969/j.issn.1001-9944.2019.02.001Zhang Hu, Zhang Run, Yu Liandong. Measurement point distribution planning of coordinate measuring machine based on CAD model[J]. Automation & Instrumentation, 2019, 34(2): 1-4,10 doi: 10.3969/j.issn.1001-9944.2019.02.001 [9] 卢耀晖, 周继伟, 张蔚, 等. 基于三坐标测量机的平面测量方法研究[J]. 金属加工(冷加工), 2012(1):64-66LU Yaohui, Zhou Jiwei, Zhang Wei, et al. Research on plane measurement method based on CMM[J]. Metal Working, 2012(1): 64-66 [10] 张涛. 三坐标测量机建立坐标系方法及应用[J]. 湖南工业职业技术学院学报, 2023, 23(1):24-27Zhang Tao. The methods and applications of establishing coordinate system with CMM[J]. Journal of Hunan Industry Polytechnic, 2023, 23(1): 24-27 [11] 李庆. 三坐标测量机坐标系的常用建立方法[J]. 装备制造技术, 2015(1):246-247,250 doi: 10.3969/j.issn.1672-545X.2015.01.091Li Qing. The commonly used methods to establish three coordinate measuring machine coordinate system[J]. Equipment Manufacturing Technology, 2015(1): 246-247,250 doi: 10.3969/j.issn.1672-545X.2015.01.091 [12] 龚玉玲. 基于准CAD模型的CMM自动测量技术研究[D]. 无锡: 江南大学, 2008Gong Yuling. Research on quasi-CAD model based CMM automatic measurement[D]. Wuxi: Jiangnan University, 2008 [13] 宋晨霞, 胡庆夕. 三坐标测量机在零件自动检测中的应用[J]. 现代机械, 2011(3):12-13,29 doi: 10.3969/j.issn.1002-6886.2011.03.004Song Chenxia, Hu Qingxi. Application of CMM in auto measuring of parts[J]. Modern Machinery, 2011(3): 12-13,29 doi: 10.3969/j.issn.1002-6886.2011.03.004 [14] 梁静, 董岚, 王铜, 等. 激光跟踪仪在CSNS高频腔预准直中的应用[J]. 地理空间信息, 2017, 15(3):12-13,19Liang Jing, Dong Lan, Wang Tong, et al. Application of laser tracker in the pre-alignment of RF cavity for CSNS[J]. Geospatial Information, 2017, 15(3): 12-13,19 [15] 何振强, 柯志勇, 董岚, 等. 中国散裂中子源DTL漂移管的预准直[J]. 核技术, 2017, 40(5):050201 doi: 10.11889/j.0253-3219.2017.hjs.40.050201He Zhenqiang, Ke Zhiyong, Dong Lan, et al. Pre-alignment of DTL for China Spallation Neutron Source[J]. Nuclear Techniques, 2017, 40(5): 050201 doi: 10.11889/j.0253-3219.2017.hjs.40.050201 -

下载:

下载: