A review of multi-field coupled in-situ stretching neutron diffraction experimental devices

-

摘要:

极端环境服役材料的研发一直是航空航天等国家战略发展的“瓶颈”,不同环境因素会影响材料的性能。中子由于其强穿透性、轻元素敏感等特点,可与同步辐射技术互为补充,运用原位装置还原材料在真实工况条件下的受力变形过程,并利用中子探针原位观察材料在服役条件下晶格应变、织构、相变和残余应力的演化。多个国家的中子谱仪均配备了不同的原位拉伸装置,实现在不同的加载环境下对样品进行原位应力加载,对样品材料的微观结构进行测试分析,能够解决材料工程领域的重要科学机理问题,进而推动材料的发展应用。介绍了国内外不同中子源谱仪原位拉伸装置的情况,重点阐述了应用于中子衍射技术的多场耦合原位拉伸装置的设计原理与结构特点,凸显了工程材料研究的发展方向。

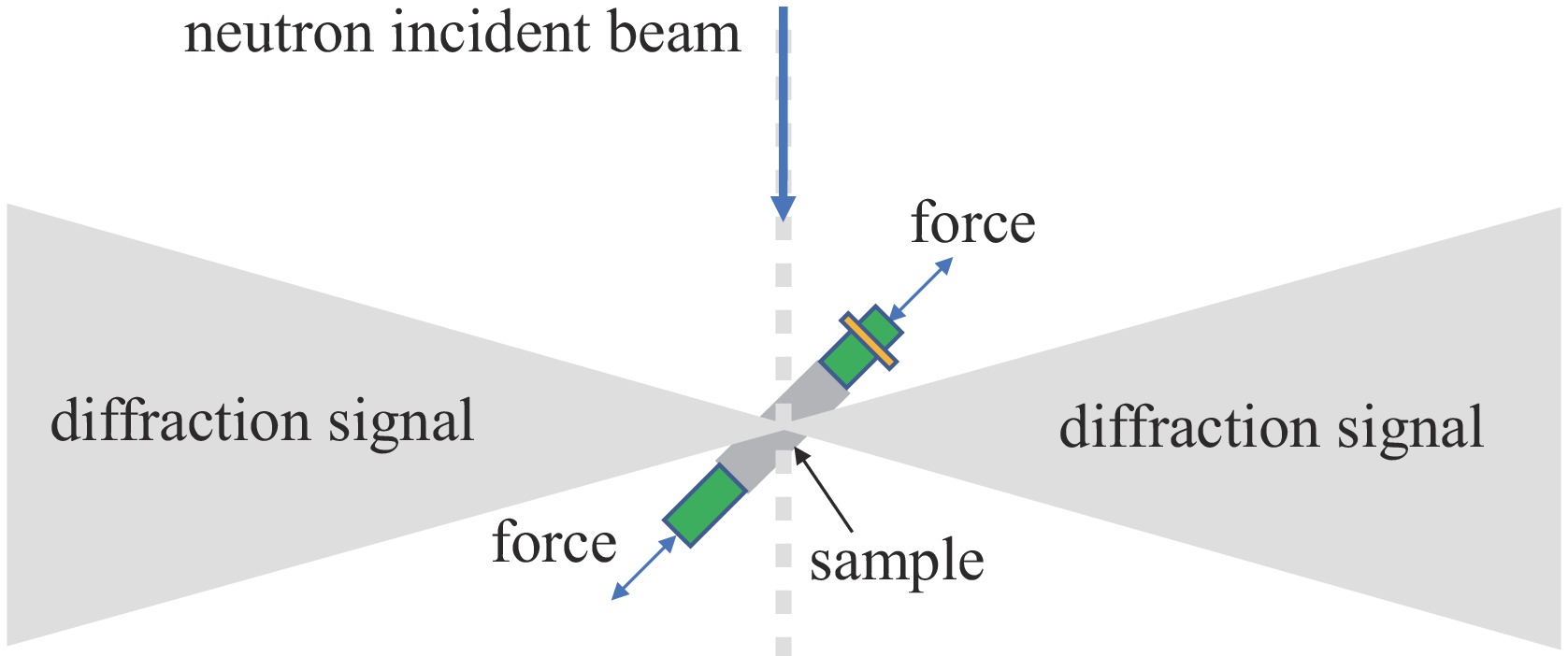

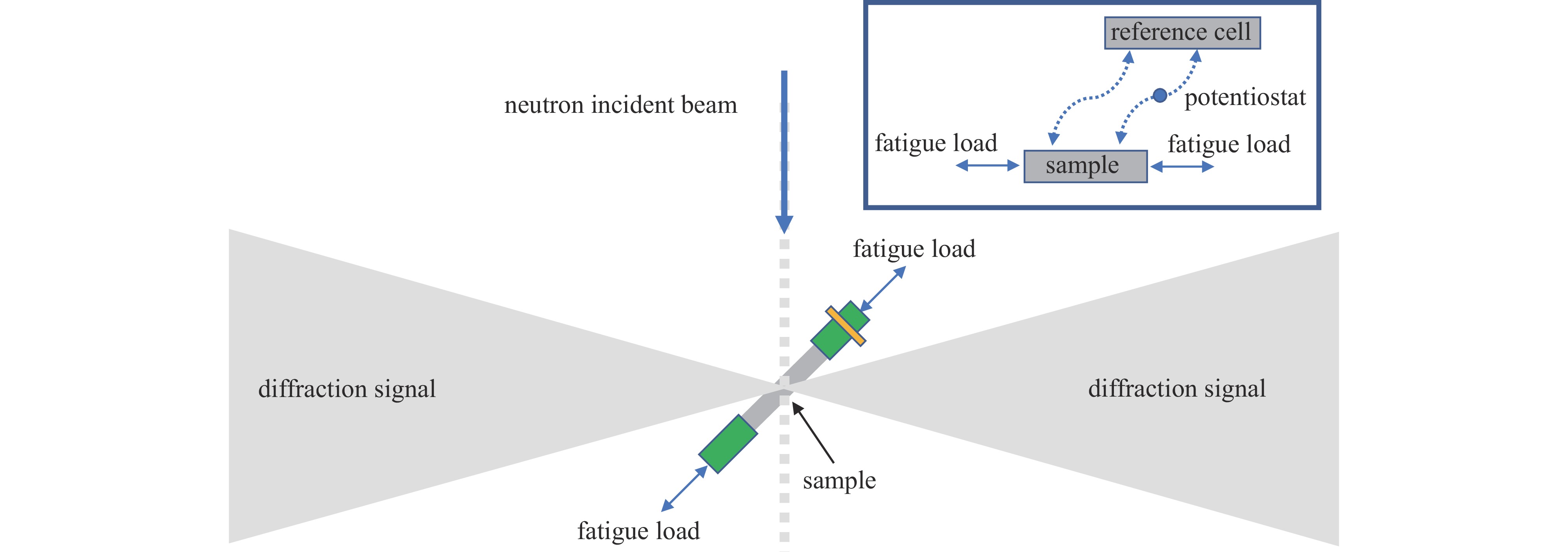

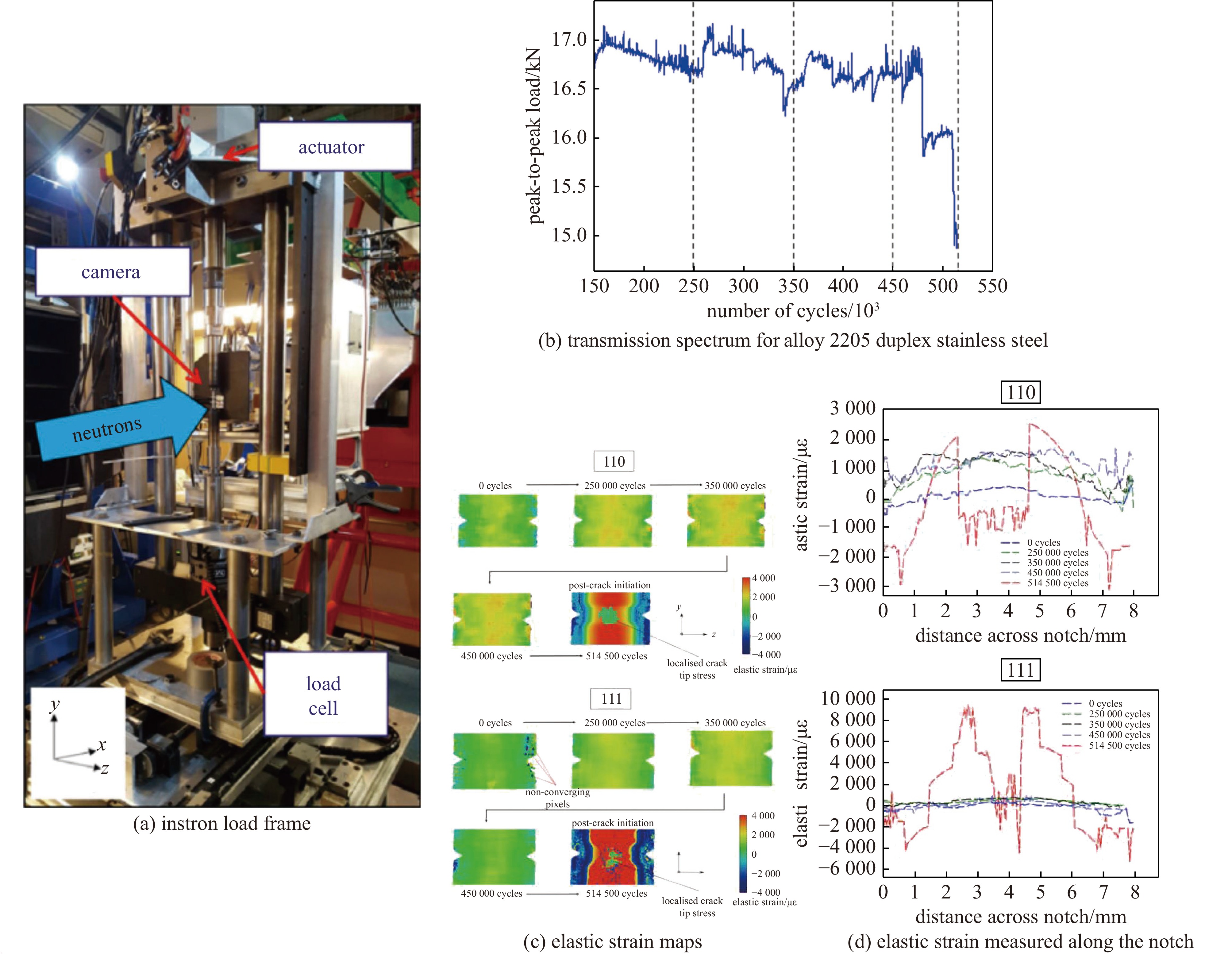

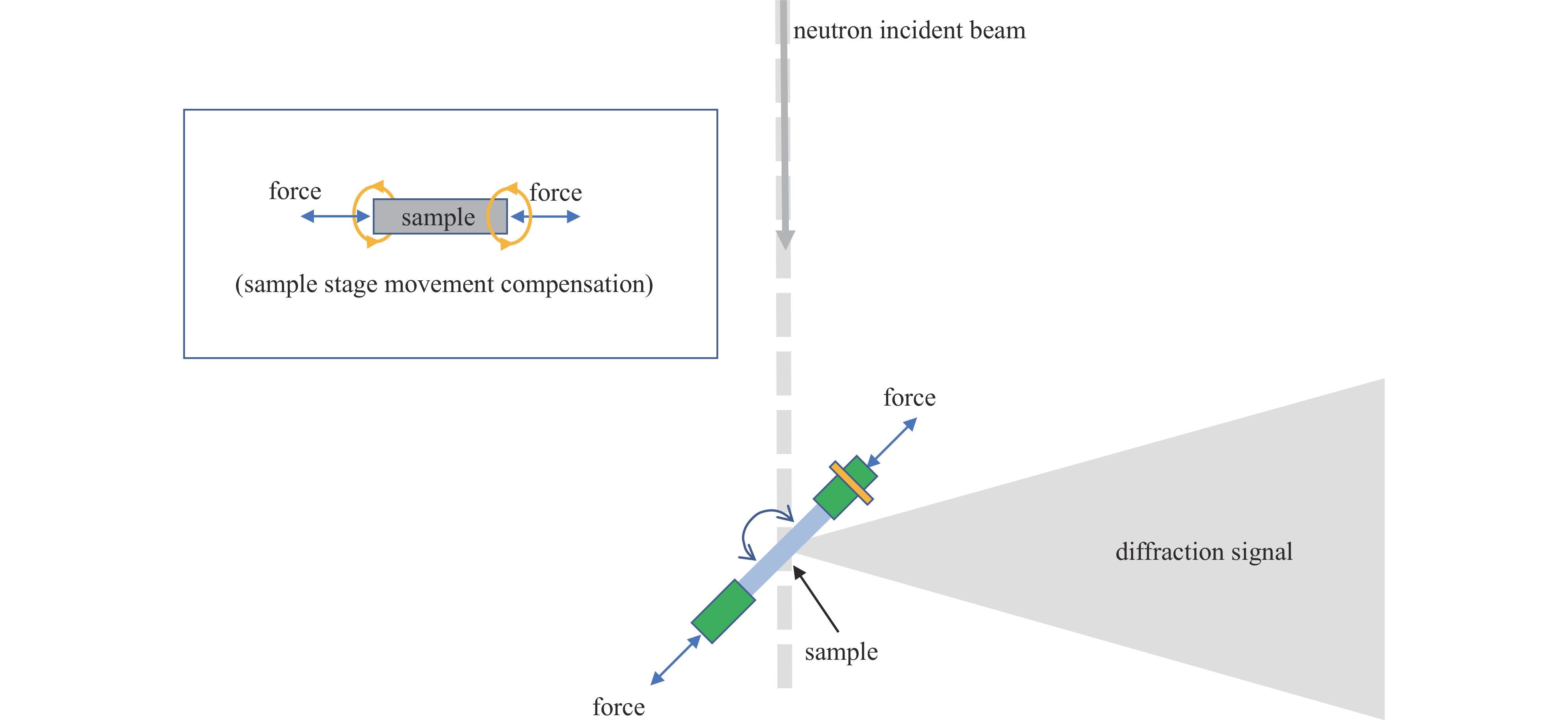

Abstract:The research and development of materials for extreme environmental service has always been a bottleneck in development of national strategies such as aerospace, and different environmental factors can affect the performance of materials. Neutrons, due to their strong penetrability and sensitivity to light elements, can complement synchrotron radiation technology. In-situ devices are used to reduce the deformation process of materials under real working conditions, and neutron probes are used to observe the evolution of lattice strain, texture, phase transition, and residual stress of materials under service conditions. Neutron spectrometers from multiple countries are equipped with different in-situ tensile devices, which enable in-situ stress loading of samples in different loading environments, testing and analyzing the microstructure of sample materials. This can solve important scientific mechanism problems in the field of materials engineering and promote the development and application of materials. This article introduces the situation of in-situ stretching devices for different neutron source spectrometers at home and abroad, focusing on the design principles and structural characteristics of multi field coupling in-situ stretching devices used in neutron diffraction technology, and highlighting the development direction of engineering materials research.

-

Key words:

- neutron diffraction /

- neutron source /

- multi-field coupling /

- in-situ stretching /

- spectrometer

-

表 1 不同加热方式的优缺点

Table 1. Advantages and disadvantages of different heating methods

heating method advantage disadvantage heating element you can choose different models based on

different temperature rangeslow heating efficiency thermal

induction coilthe heating efficiency is over 80%, and it can be heated to extremely high temperatures with minimal impact on the surrounding temperature there is a temperature gradient change around it DC heating DC current has a fast heating speed and can heat up to extremely high temperatures, with little impact on the surrounding temperature poor heating effect on samples with good conductivity halogen lamp the heating speed is fast and can reach extremely high temperatures, with little impact on the surrounding temperature halogen lamps need to be placed around the sample, which

may require gas protection such as vacuumlaser the heating speed is fast and can reach extremely high temperatures, with little impact on the surrounding temperature point light source heating with temperature gradient 表 2 部分拉伸装置的对比表

Table 2. Comparison of partial stretching devices

subordinate

deviceneutron

instrumentloading

structuremaximum

loadsample

environmentloading

methodAmerican Spallation Neutron Source (SNS) Vulcan horizontal uniaxial biaxial stretching 1 100 kN normal atmospheric temperature stretching or compressing horizontal uniaxial biaxial stretching 2 100 kN

400 N·melectrochemistry tension compression, fatigue, creep, and torsion Spallation Neutron Source, UK (ISIS) Engin-X vertical uniaxial uniaxial tension 50 kN normal atmospheric temperature tension, compression, fatigue Los Alamos National Laboratory, USA(LANSCE) SMARTS uniaxial biaxial stretching 250 kN low temperature pull and press Japan High Current Proton Accelerator Facility

(J-PARC)TAKUMI horizontal uniaxial

uniaxial tension50 kN low temperature, high temperature pull and press China Academy of Engineering Physics Mianyang Research Reactor (CMRR) RSND horizontal uniaxial

uniaxial tension2.5 kN low temperature pull and press China Spallation Neutron Source (CSNS) CSNS vertical or horizontal 50 kN high temperature, low temperature, magnetic field tension, compression, fatigue -

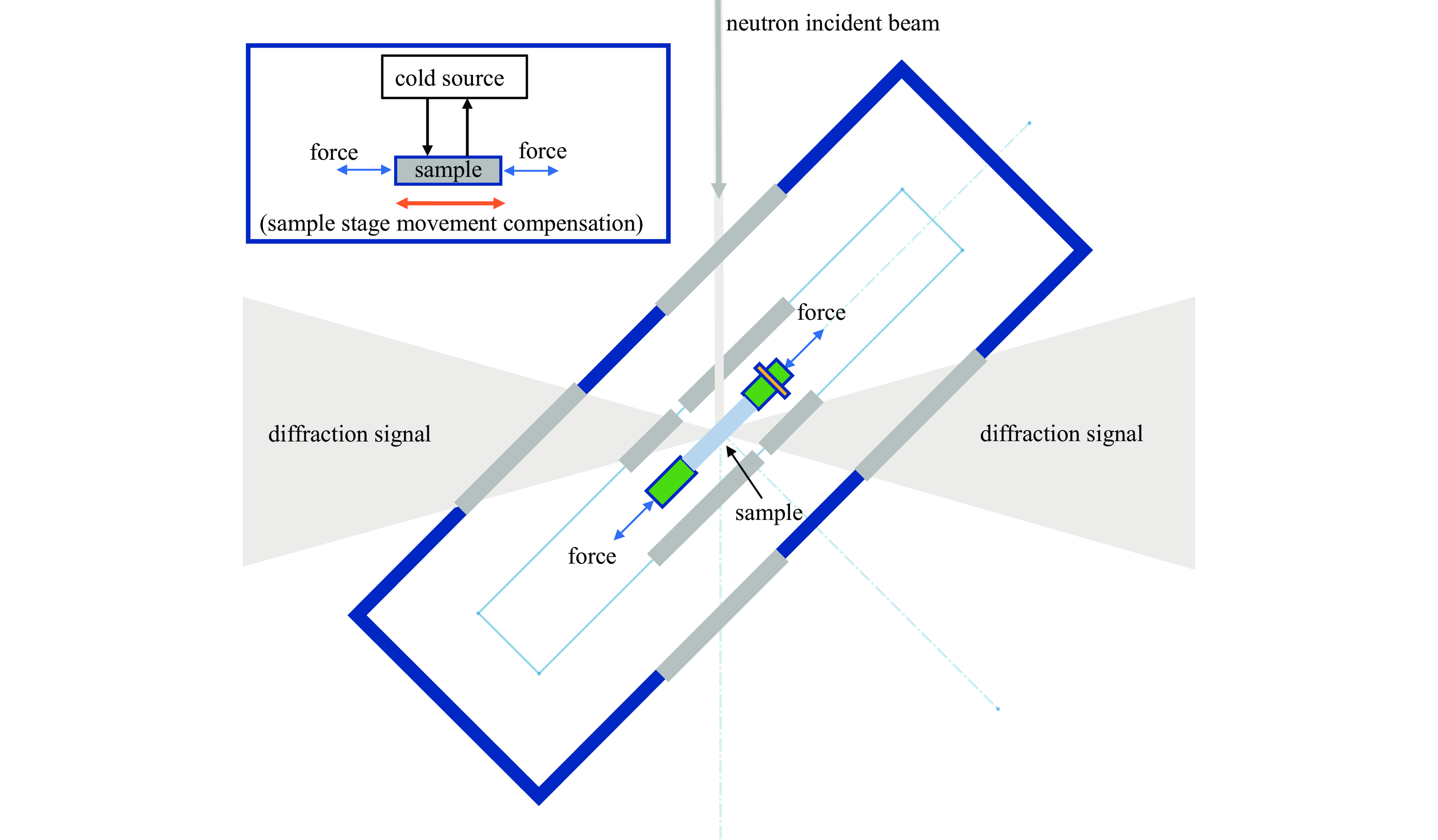

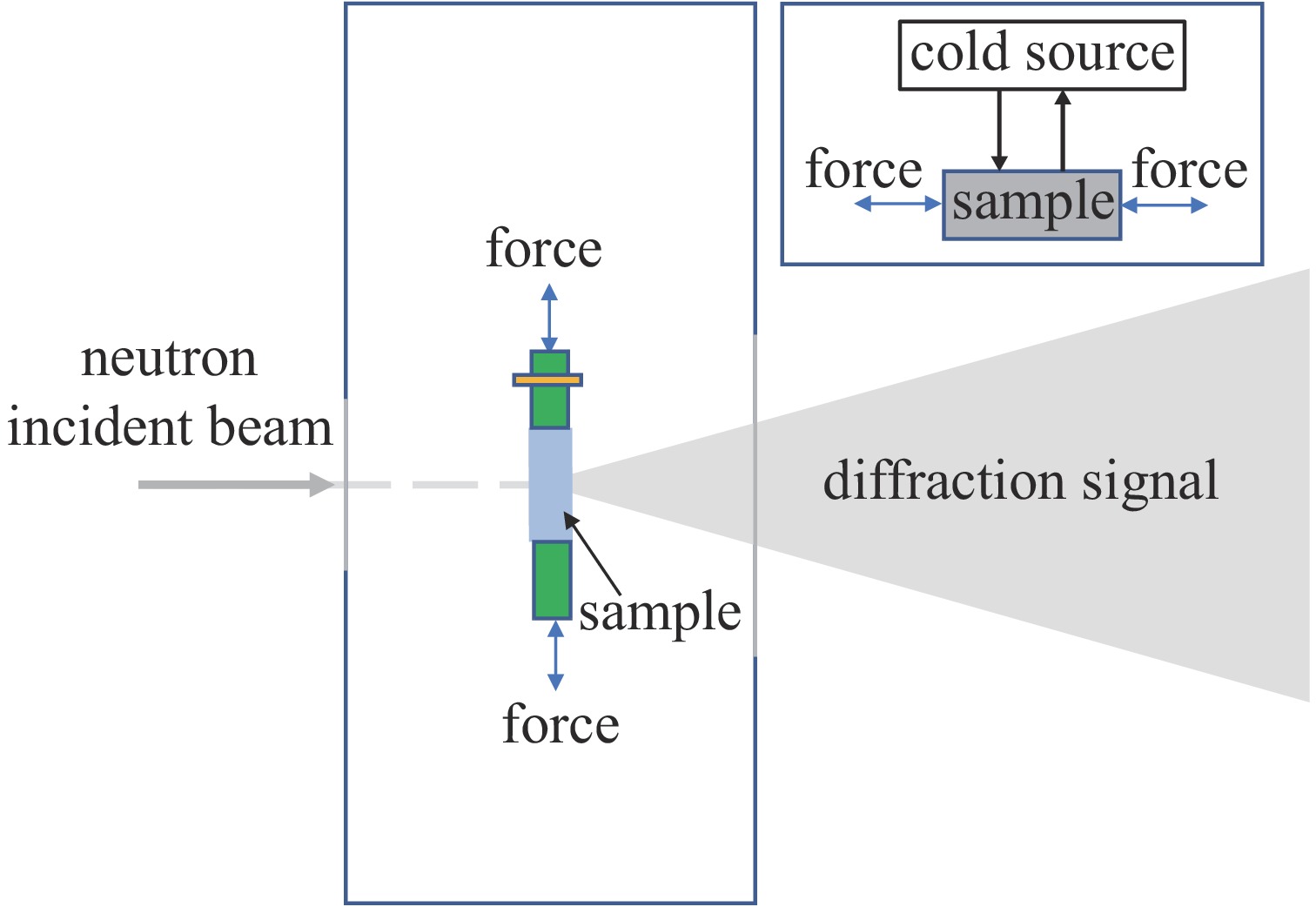

[1] 常可可, 陈雷雷, 周若男, 等. 极端环境表面工程及其共性科学问题研究进展[J]. 中国机械工程, 2022, 33(12):1388-1417Chang Keke, Chen Leilei, Zhou Ruonan, et al. Progresses of surface engineering in extreme environments and its common scientific problems[J]. China Mechanical Engineering, 2022, 33(12): 1388-1417 [2] 常可可, 王立平, 薛群基. 极端工况下机械表面界面损伤与防护研究进展[J]. 中国机械工程, 2020, 31(2):206-220 doi: 10.3969/j.issn.1004-132X.2020.02.006Chang Keke, Wang Liping, Xue Qunji. Progresses of damage and protection for surfaces and interfaces in machinery under extreme operating conditions[J]. China Mechanical Engineering, 2020, 31(2): 206-220 doi: 10.3969/j.issn.1004-132X.2020.02.006 [3] 赵传东, 李金燕, 张欢. 耐高温材料在航空发动机上的应用研究[J]. 内燃机与配件, 2021(18):55-56 doi: 10.3969/j.issn.1674-957X.2021.18.020Zhao Chuandong, Li Jinyan, Zhang Huan. Research on application of high temperature materials in aero-engine[J]. Internal Combustion Engine & Parts, 2021(18): 55-56 doi: 10.3969/j.issn.1674-957X.2021.18.020 [4] Lin Qingyun, Liu Junpeng, An Xianghai, et al. Cryogenic-deformation-induced phase transformation in an FeCoCrNi high-entropy alloy[J]. Materials Research Letters, 2018, 6(4): 236-243. doi: 10.1080/21663831.2018.1434250 [5] Bae J W, Kim J G, Park J M, et al. In situ neutron diffraction study of phase stress evolution in a ferrous medium-entropy alloy under low-temperature tensile loading[J]. Scripta Materialia, 2019, 165: 60-63. doi: 10.1016/j.scriptamat.2019.02.027 [6] Wang Yiqiang, Liu Bin, Yan Kun, et al. Probing deformation mechanisms of a FeCoCrNi high-entropy alloy at 293 and 77 K using in situ neutron diffraction[J]. Acta Materialia, 2018, 154: 79-89. doi: 10.1016/j.actamat.2018.05.013 [7] Kim J G, Enikeev N A, Seol J B, et al. Superior strength and multiple strengthening mechanisms in nanocrystalline TWIP steel[J]. Scientific Reports, 2018, 8: 11200. doi: 10.1038/s41598-018-29632-y [8] De Cooman B C, Estrin Y, Kim S K. Twinning-induced plasticity (TWIP) steels[J]. Acta Materialia, 2018, 142: 283-362. doi: 10.1016/j.actamat.2017.06.046 [9] Hany S, Milochova M, Littrell K, et al. Advanced characterization of cryogenic 9Ni steel using synchrotron radiation, neutron scattering and 57Fe Mössbauer spectroscopy[J]. Materials & Design, 2018, 146: 219-227. [10] 贾双珠, 李长安, 解田, 等. 低温超导材料研究进展[J]. 广州化工, 2018, 46(23):15-18 doi: 10.3969/j.issn.1001-9677.2018.23.011Jia Shuangzhu, Li Chang'an, Xie Tian, et al. Research progress on cryogenic superconducting[J]. Guangzhou Chemical Industry, 2018, 46(23): 15-18 doi: 10.3969/j.issn.1001-9677.2018.23.011 [11] Nishida M, Jing Tian, Muslih M R, et al. In situ stress measurement of fiber reinforced composite in low temperature state by neutron diffraction[J]. Modern Physics Letters B, 2015, 29: 1540037. doi: 10.1142/S0217984915400370 [12] Lebaudy A L, Pesci R, Fendler M. X-ray diffraction residual stress measurement at room temperature and 77 K in a microelectronic multi-layered single-crystal structure used for infrared detection[J]. Journal of Electronic Materials, 2018, 47(11): 6641-6648. doi: 10.1007/s11664-018-6560-7 [13] Duperrex L, Pesci R, Le Boterf P, et al. Simulation and measurement of residual stress and warpage in a HgCdTe-based infrared detector at 100K[J]. Materials Science and Engineering: A, 2021, 813: 141148. doi: 10.1016/j.msea.2021.141148 [14] 杨祖坤. 金属铍的中子衍射应力分析研究[D]. 北京: 中国工程物理研究院, 2018Yang Zukun. Study on neutron diffraction stress analysis of beryllium metal[D]. Beijing: China Academy of Engineering Physics, 2018 [15] Hutchings M T, Krawitz A D. Measurement of residual and applied stress using neutron diffraction[M]. Dordrecht: Springer, 1992. [16] Hutchings M T, Withers P J, Holden T M, et al. Introduction to the characterization of residual stress by neutron diffraction[M]. Boca Raton: CRC Press, 2005. [17] Lugovy M, Aman A, Chen Yan, et al. In-situ neutron diffraction of LaCoO3 perovskite under uniaxial compression. II. Elastic properties[J]. Journal of Applied Physics, 2014, 116: 013504. doi: 10.1063/1.4884336 [18] 李楠, 王曦, 刘昌奎. 中子衍射技术测量残余应力的研究进展[J]. 失效分析与预防, 2021, 16(2):148-154 doi: 10.3969/j.issn.1673-6214.2021.02.013Li Nan, Wang Xi, Liu Changkui. Research development of residual stress measured by neutron diffraction[J]. Failure Analysis and Prevention, 2021, 16(2): 148-154 doi: 10.3969/j.issn.1673-6214.2021.02.013 [19] 奂永慧, 徐平光, 殷匠. 角度分散法中子衍射应力测试技术的应用[J]. 理化检验(物理分册), 2012, 48(4):235-240Huan Yonghui, Xu Pingguang, Yin Jiang. Application of angle dispersion neutron diffraction stress testing technology[J]. Physical and Chemical Testing (Physics Volume), 2012, 48(4): 235-240 [20] Gu F, Nie Q. Introduction to characterization of residual stress by neutron diffraction[J]. Materials Today, 2005, 8: 57. [21] 闫亚东, 何俊华. 聚变反应速率测量光学系统设计[J]. 光学 精密工程, 2012, 20(11):2389-2394 doi: 10.3788/OPE.20122011.2389Yan Yadong, He Junhua. Design of optical system for fusion reaction-rate measurement[J]. Optics and Precision Engineering, 2012, 20(11): 2389-2394 doi: 10.3788/OPE.20122011.2389 [22] 温丰, 李明阳, 张小刚, 等. 几种屏蔽材料的中子屏蔽性能实验研究[J]. 实验技术与管理, 2024, 41(3):62-67Wen Feng, Li Mingyang, Zhang Xiaogang, et al. Experimental research of the neutron-shielding performance of several shielding materials[J]. Experimental Technology and Management, 2024, 41(3): 62-67 [23] An Ke, Skorpenske H D, Stoica A D, et al. First in situ lattice strains measurements under load at VULCAN[J]. Metallurgical and Materials Transactions A, 2011, 42(1): 95-99. doi: 10.1007/s11661-010-0495-9 [24] Preimesberger J I, Kang S Y, Chen Yan, et al. Investigating mechano-electrochemical coupling phenomenon in lithium-ion pouch cells using in-situ neutron diffraction[J]. ECS Transactions, 2021, 104(1): 75-85. doi: 10.1149/10401.0075ecst [25] 高建波, 贡志锋, 詹霞, 等. 中子衍射原位表征技术的应用[J]. 中国科技信息, 2019(24):95-96Gao Jianbo, Gong Zhifeng, Zhan Xia, et al. Application of neutron diffraction in-situ characterization technology[J]. China Science and Technology Information, 2019(24): 95-96 [26] Reid A, Marshall M, Kabra S, et al. Application of neutron imaging to detect and quantify fatigue cracking[J]. International Journal of Mechanical Sciences, 2019, 159: 182-194. doi: 10.1016/j.ijmecsci.2019.05.037 [27] Li Hongjia, Yang Zhaolong, Shen Huahai, et al. On the effect of detwinning during compressive deformation of martensitic NiTi: in situ neutron diffraction and micromechanical modeling[J]. Acta Materialia, 2023, 247: 118737. doi: 10.1016/j.actamat.2023.118737 [28] Sarawate N N, Dapino M J. Dynamic sensing behavior of ferromagnetic shape memory Ni–Mn–Ga[J]. Smart Materials and Structures, 2009, 18: 104014. doi: 10.1088/0964-1726/18/10/104014 [29] Bourke M A M, Dunand D C, Ustundag E. SMARTS—a spectrometer for strain measurement in engineering materials[J]. Applied Physics A, 2002, 74(1): s1707-s1709. [30] Woodruff T R, Krishnan V B, Clausen B, et al. Design, implementation, and testing of a cryogenic loading capability on an engineering neutron diffractometer[J]. Review of Scientific Instruments, 2010, 81: 063903. doi: 10.1063/1.3436637 [31] Harjo S, Aizawa K, Kowasaki T, et al. Cryogenic loading devices for materials science & engineering studies at J-PARC[C]//JAEA-Conference 2015-002. 2016: 441-447. [32] Naeem M, He Haiyan, Zhang Fan, et al. Cooperative deformation in high-entropy alloys at ultralow temperatures[J]. Science Advances, 2020, 6: eaax4002. doi: 10.1126/sciadv.aax4002 [33] Yang Jinbo, Li Jian, Liu Wei, et al. Development of a load frame for neutron diffraction and fluorescent thermometry at cryogenic temperature[J]. Review of Scientific Instruments, 2022, 93: 073904. doi: 10.1063/5.0068365 [34] 郑海彪, 陈洁, 余朝举, 等. 一种应用于中子实验的低温耦合拉伸装置及其测试方法: CN117030438A[P]. 2023-11-10Zheng Haibiao, Chen Jie, Yu Chaoju, et al. Low-temperature coupling stretching device applied to neutron experiment and testing method of low-temperature coupling stretching device: CN117030438A[P]. 2023-11-10 [35] 谢振华, 柯于斌, 杨华, 等. 一种与小角中子散射联用的耦合高低温环境的原位拉伸仪: CN115791428A[P]. 2023-03-14Xie Zhenhua, Ke Yubin, Yang Hua, et al. In-situ extensometer combined with small-angle neutron scattering and coupled with high and low temperature environments: CN115791428A[P]. 2023-03-14 [36] Huang Shenyan, Gao Yanfei, An Ke, et al. Deformation mechanisms in a precipitation-strengthened ferritic superalloy revealed by in situ neutron diffraction studies at elevated temperatures[J]. Acta Materialia, 2015, 83: 137-148. doi: 10.1016/j.actamat.2014.09.053 [37] 童欣. 极化中子技术[J]. 物理, 2020, 49(11):765-773 doi: 10.7693/wl20201105Tong Xin. Polarized neutron techniques[J]. Physics, 2020, 49(11): 765-773 doi: 10.7693/wl20201105 [38] Ke Y B, Lan S, Wu Y, et al. Unraveling magneto-structural coupling of Ni2MnGa alloy under the application of stress and magnetic field using in situ polarized neutron diffraction[J]. Applied Physics Letters, 2020, 117: 081905. doi: 10.1063/5.0016278 [39] 柯于斌, 郑海彪, 王循理, 等. 一种用于中子散射的便携式原位多场耦合加载装置: CN108459035A[P]. 2018-08-28Ke Yubin, Zheng Haibiao, Wang Xunli, et al. Portable in-situ multi-field coupling loading device for neutron scattering: CN108459035A[P]. 2018-08-28 -

下载:

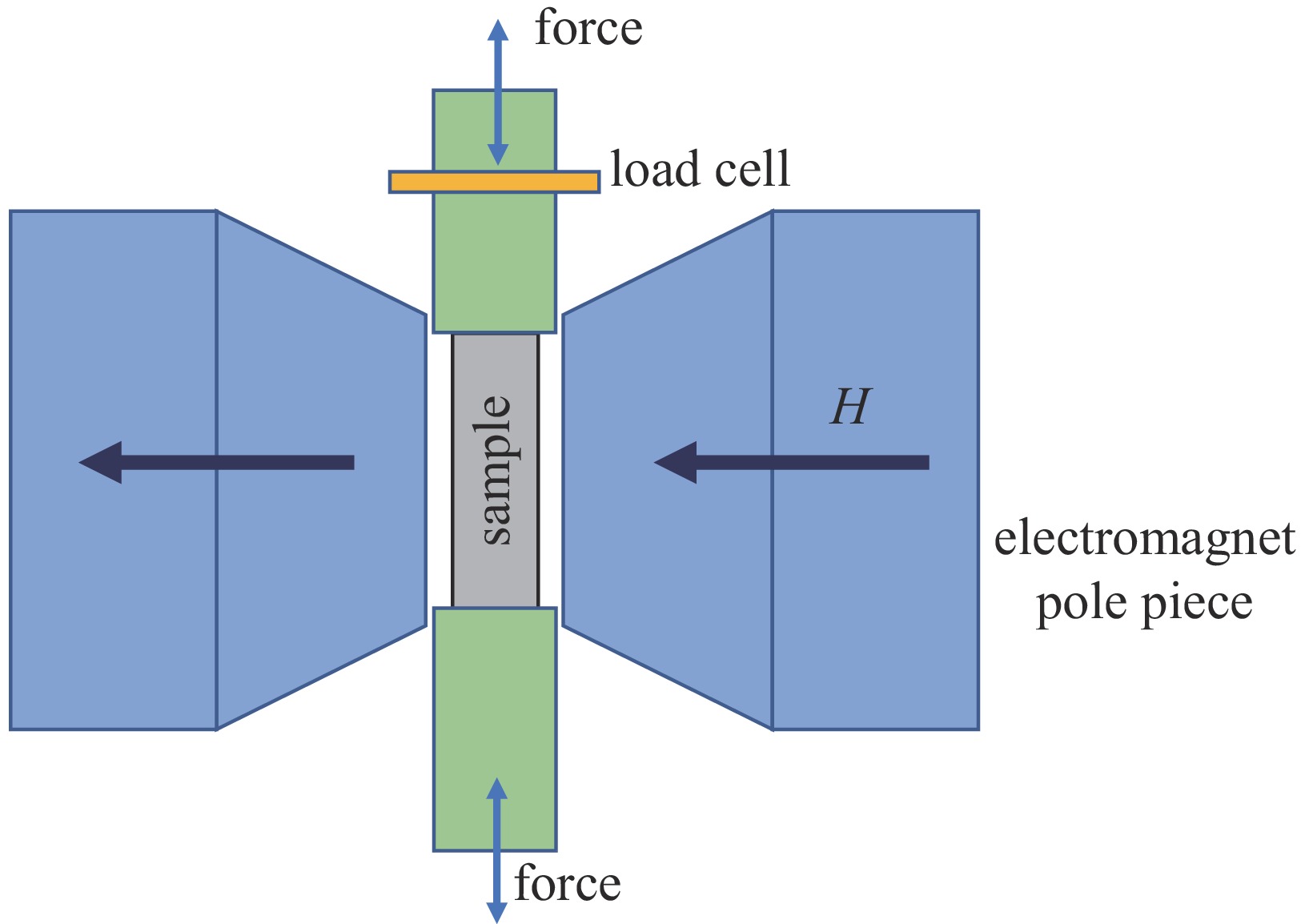

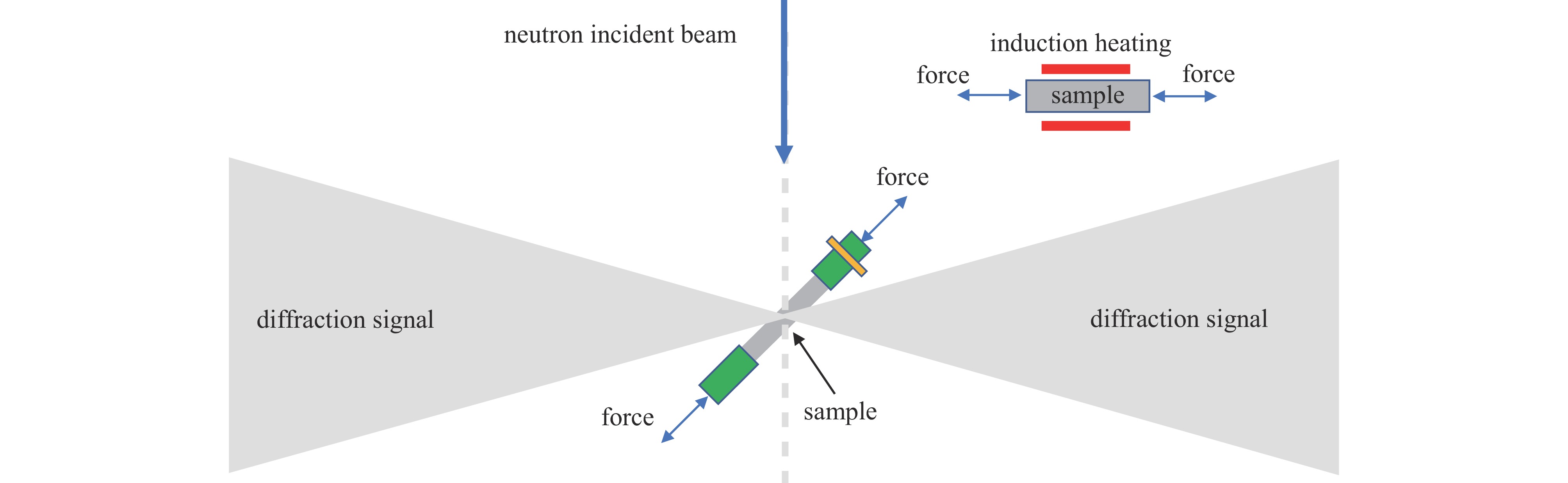

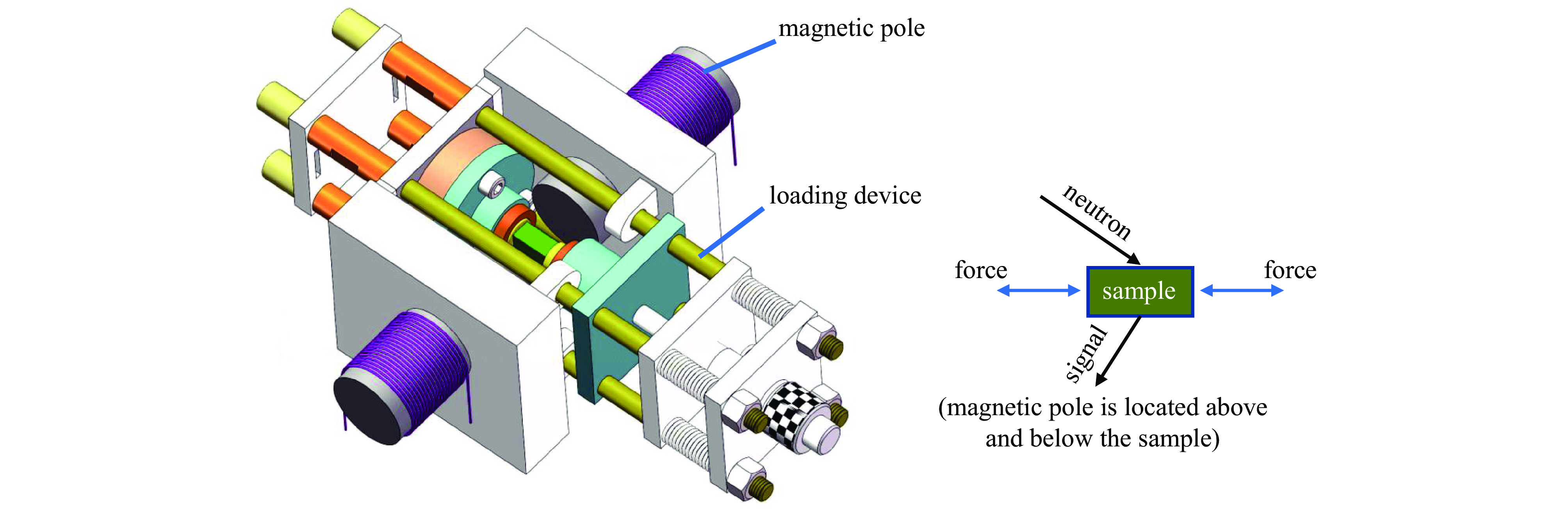

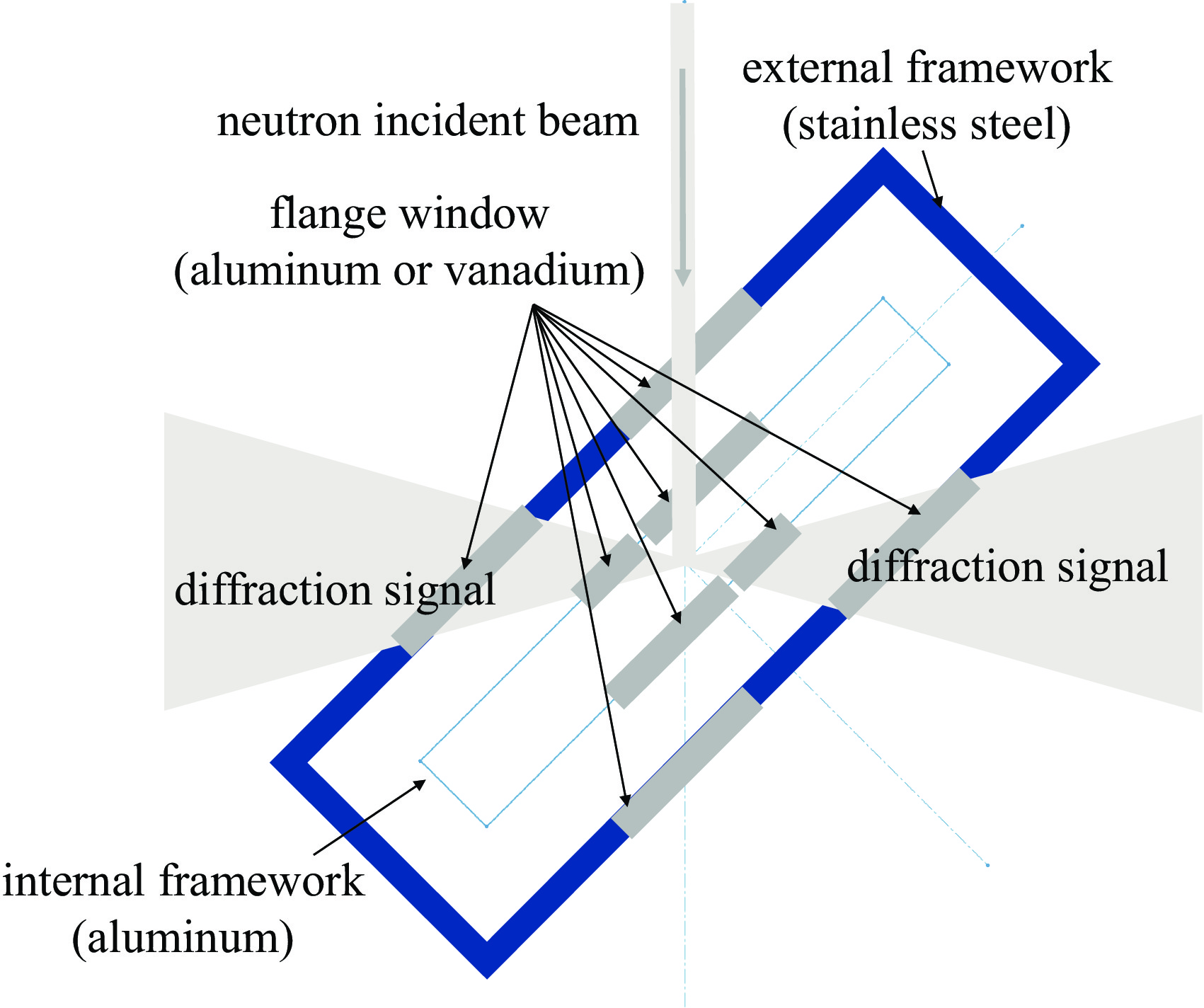

下载: