Effect of target current on microstructure and properties of Al film for nuclear radiation detector

-

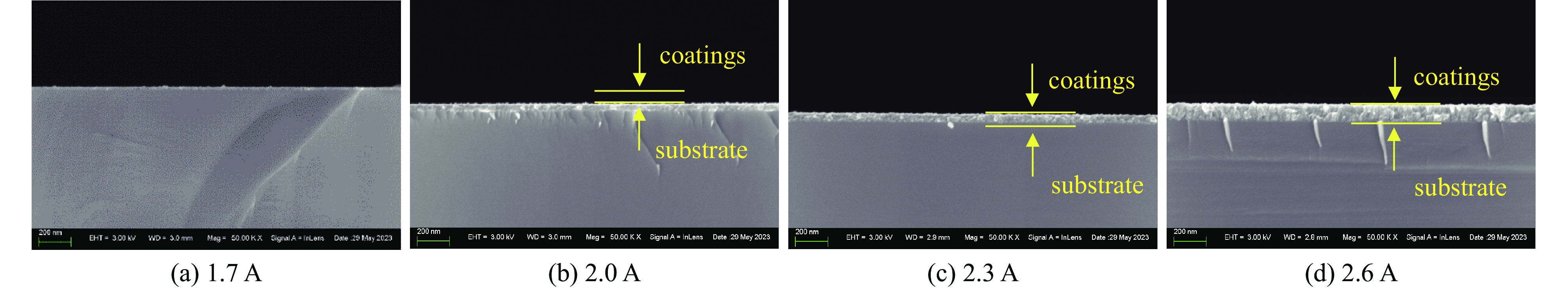

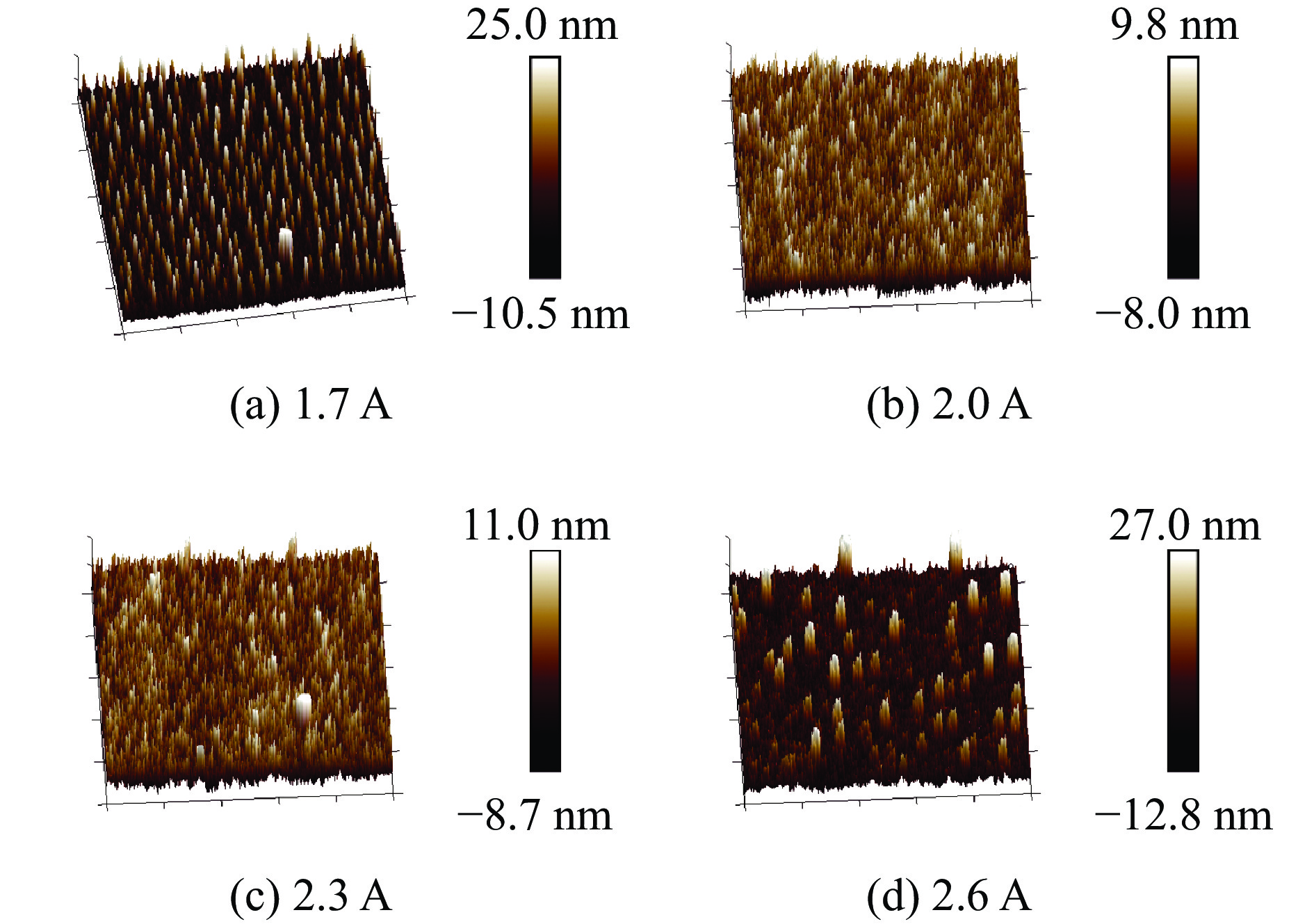

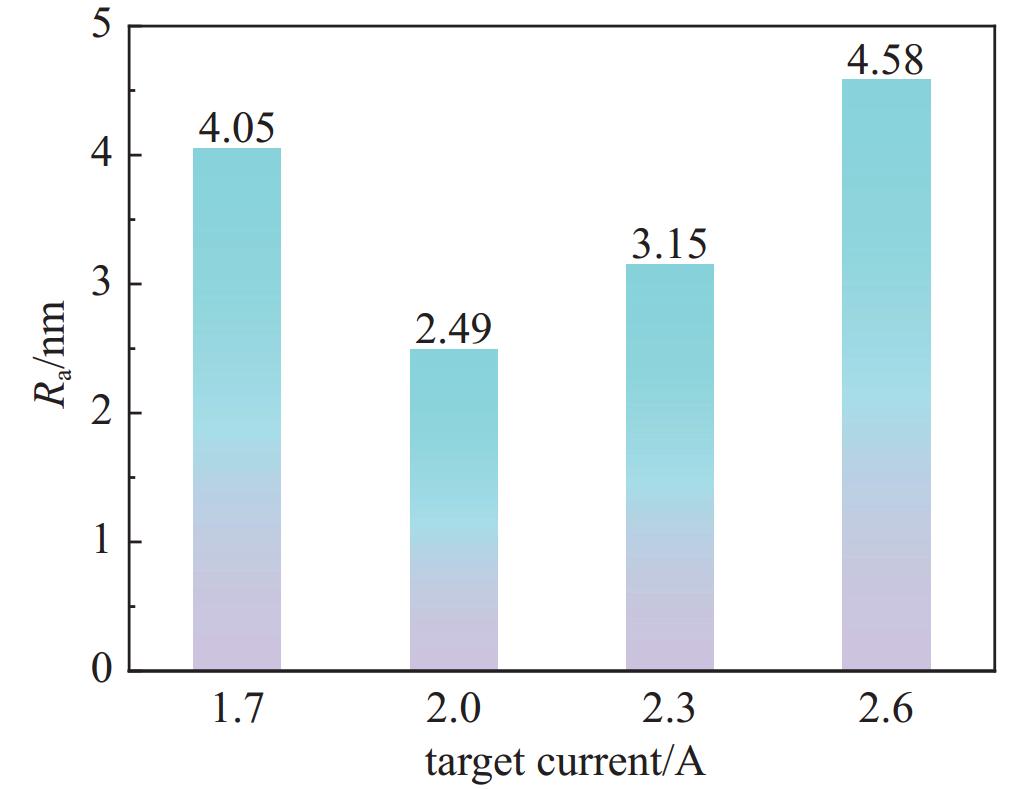

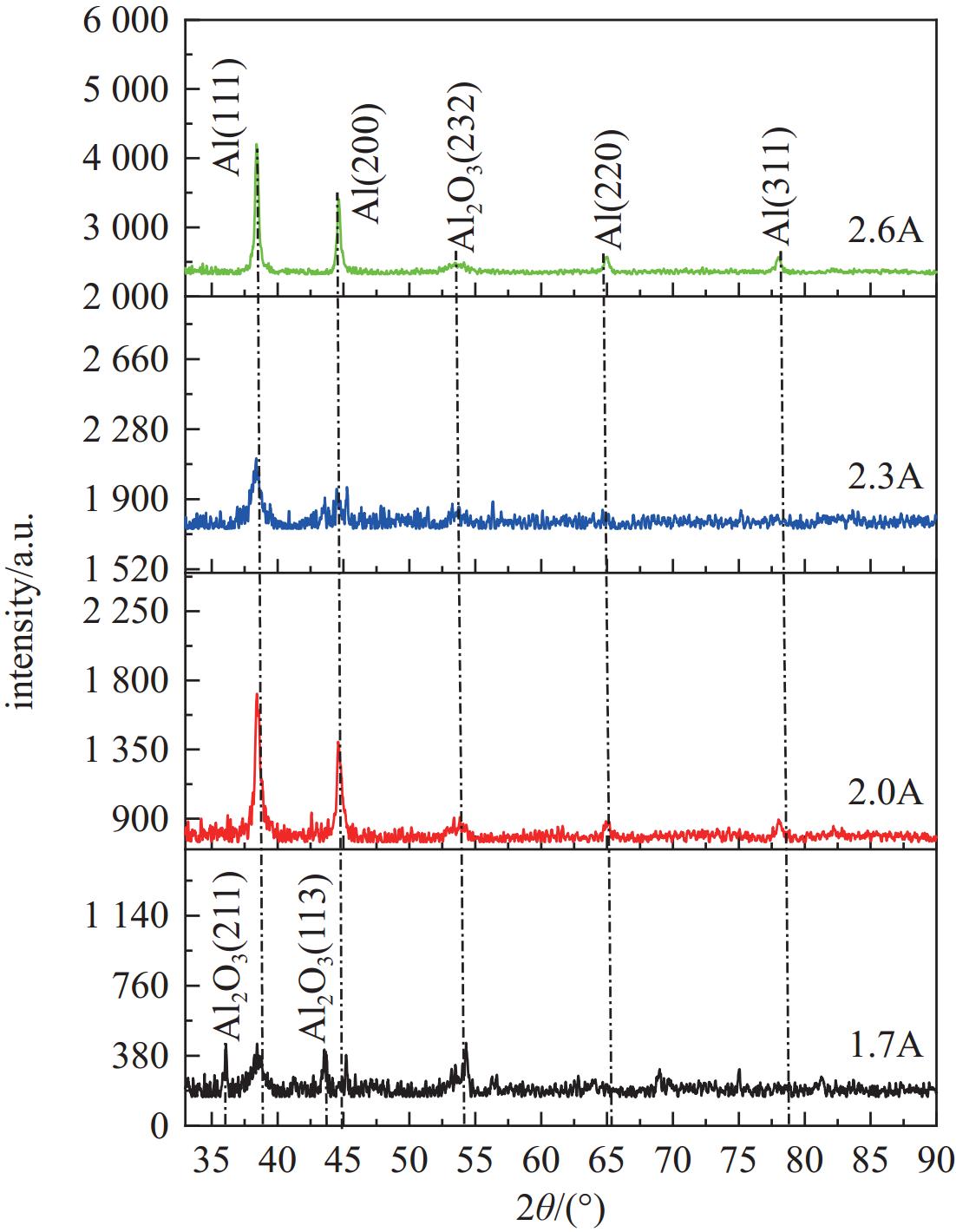

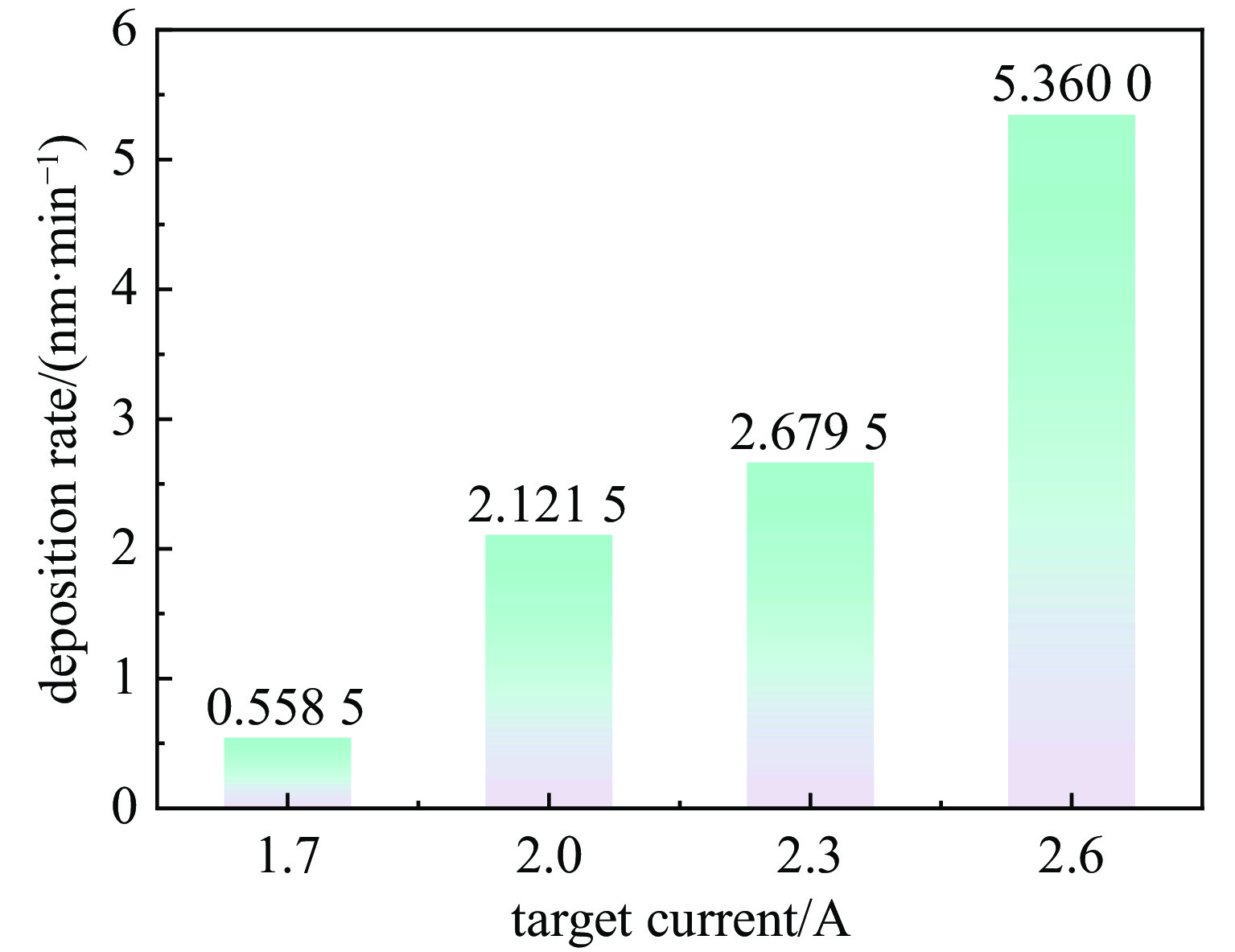

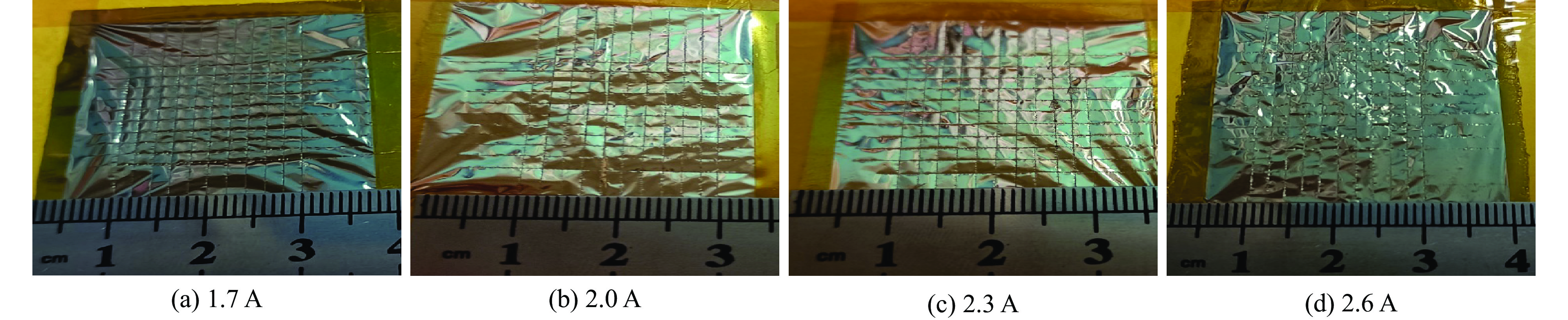

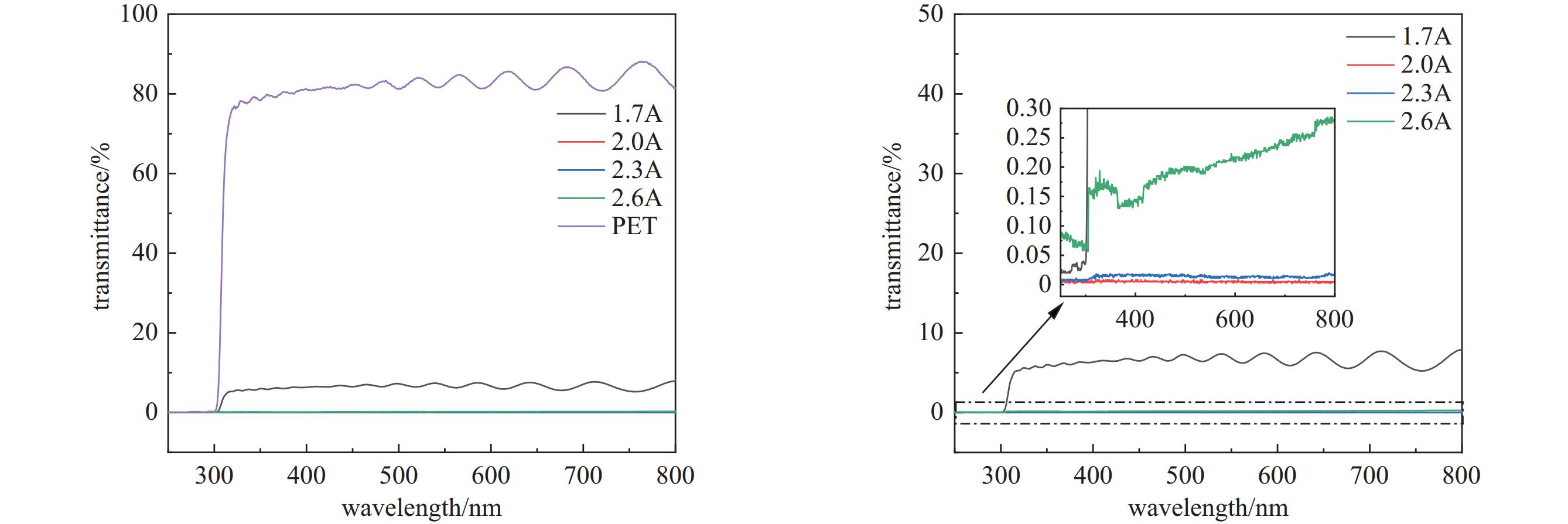

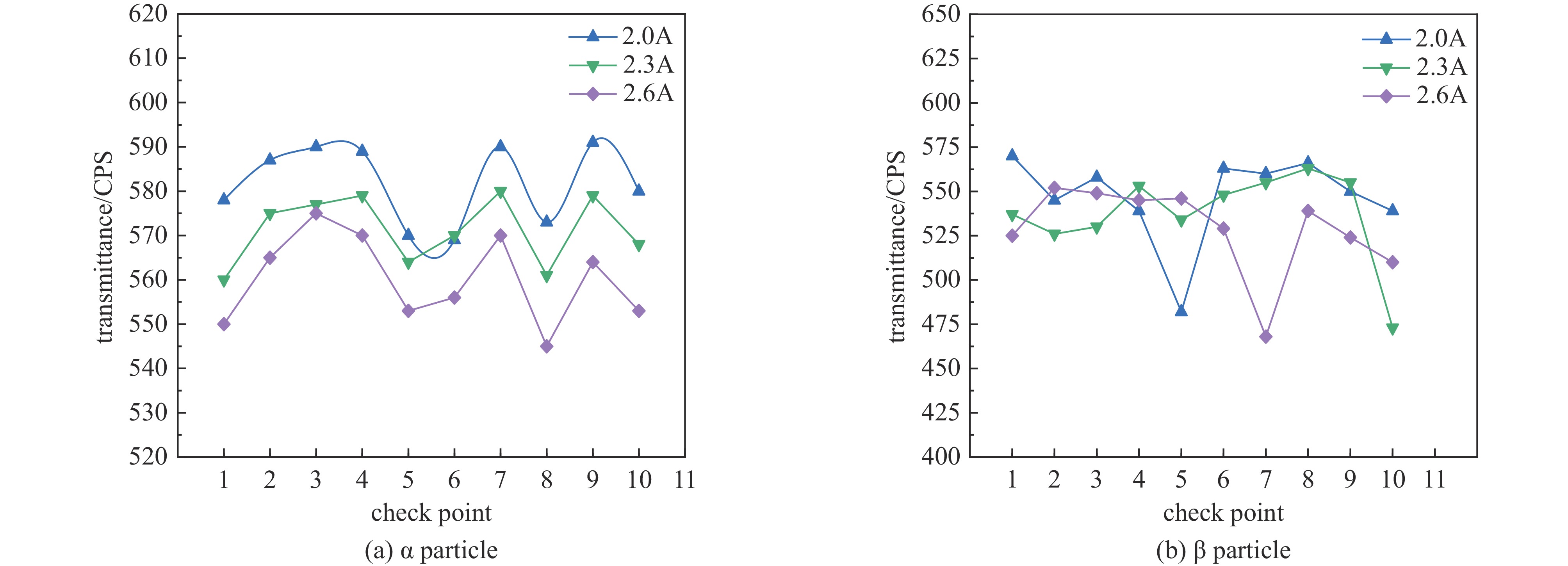

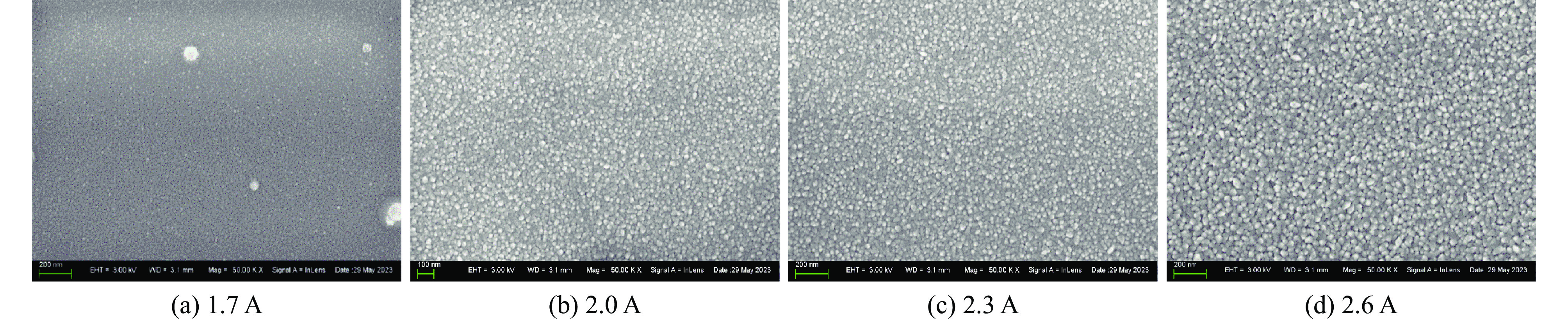

摘要: 采用磁控溅射技术控制不同的铝靶电流在 聚对苯二甲酸乙二醇酯 (PET)的表面制备双面铝薄膜。利用扫描电子显微镜(SEM)和原子力显微镜(AFM)观察铝薄膜的微观形貌,使用X射线衍射仪(XRD)对铝薄膜进行物相分析,利用划格法检测铝薄膜和PET的结合情况,利用紫外-可见分光光度计检测铝薄膜的挡光性,采用手持式核辐射探测器检测α和β粒子射线粒子在铝薄膜中的透过率。结果表明:铝薄膜表面光滑平整,具有金属光泽,Al晶粒均匀致密。铝薄膜无孔洞、裂纹等缺陷;随着Al靶电流增加,Al晶粒尺寸、铝薄膜厚度及沉积速率均增大,铝薄膜粗糙度先降低后增大。铝薄膜的挡光性先提高后降低,α、β粒子的平均透过率均逐渐降低;当铝靶电流为2.0 A时,铝薄膜的粗糙度最小,为2.49 nm,光透过率最低在0.025%左右,α、β粒子的平均透过率最高,分别为581.7 CPS、547.2 CPS。Abstract: In this study, double-sided Al film was prepared on the surface of polyethylene terephthalate (PET) by controlling different Al target currents with magnetron sputtering technology. The micro-morphology of the Al film was observed using scanning electron microscope (SEM) and atomic force microscope (AFM). Phase analysis of the Al film was carried out using X-ray diffraction (XRD). The adhesion between the Al film and PET was detected by the cross-cut method. The light-blocking property of the Al film was measured by an ultraviolet-visible spectrophotometer. The transmittance of α and β particles in the Al film was detected using a handheld nuclear radiation detector. The results show that the surface of the Al film is smooth and flat with a metallic luster, and the Al grains are uniform and dense. The Al film has no defects such as pores and cracks. As the Al target current increases, the Al grain size, the thickness of the Al film, and the deposition rate all increase, and the roughness of the Al film first decreases and then increases. The light-blocking property of the Al film first improves and then decreases, and the average transmittance of both α and β particles gradually decreases. When the Al target current is 2.0 A, the roughness of the Al film is the minimum, which is 2.49 nm. The light transmittance is the lowest, around 0.025%. The average transmittance of α and β particles is the highest, being 581.7 CPS and 547.2 CPS respectively.

-

Key words:

- target current /

- flexible matrix /

- Al film /

- light blocking /

- particle transmittance

-

表 1 划格试验评级标准

Table 1. Grid test rating standards

grade explanation grid-marked surface

morphology0 The cutting edges are completely smooth, with no squares detached. / 1 Slight coating detachment occurs at the intersection of cuts, but the affected cross-cut area is not significantly greater than 5%.

2 Coating detachment occurs at the intersections of cuts and/or along the edges of cuts, with the affected cross-cut area significantly greater than 5% but not significantly greater than 15%.

3 The coating partially or completely detaches in large fragments along the cutting edges and/or partially or completely peels off in different areas of the grid. The affected cross-cut area is significantly greater than 15% but not significantly greater than 35%.

4 The coating detaches in large fragments along the cutting edges and/or partially or completely peels off in different areas of the grid. The affected cross-cut area is significantly greater than 35% but not significantly greater than 65%.

5 The extent of peeling exceeds that of Level 4. / -

[1] Nadaleti W C, de Souza E G, de Souza S N M. The potential of hydrogen production from high and low-temperature electrolysis methods using solar and nuclear energy sources: the transition to a hydrogen economy in Brazil[J]. International Journal of Hydrogen Energy, 2022, 47(82): 34727-34738. doi: 10.1016/j.ijhydene.2022.08.065 [2] 乔磊, 姚世峰, 郁俊俊. 高效发电与能源转换技术的发展趋势与前景[J]. 水电水利, 2023, 7(9):31-33 doi: 10.12238/hwr.v7i9.4990Qiao Lei, Yao Shifeng, Yu Junjun. Development trend and prospect of efficient power generation and energy conversion technology[J]. Hydropower and Water Resources, 2023, 7(9): 31-33 doi: 10.12238/hwr.v7i9.4990 [3] 吴放, 缪正强, 梁军. 我国首个核能综合利用技术品牌——“暖核一号”创新发展实践[J]. 国企管理, 2024(2):79-82 doi: 10.3969/j.issn.2095-7599.2024.02.026Wu Fang, Miao Zhengqiang, Liang Jun. China's first comprehensive use of nuclear energy technology brand - "Warm Nuclear One" innovation and development practice[J]. China State-Owned Enterprise Management, 2024(2): 79-82 doi: 10.3969/j.issn.2095-7599.2024.02.026 [4] Le Boulch D, Buronfosse M, Le Guern Y, et al. Meta-analysis of the greenhouse gases emissions of nuclear electricity generation: learnings for process-based LCA[J]. The International Journal of Life Cycle Assessment, 2024, 29(5): 857-872. doi: 10.1007/s11367-024-02293-y [5] Adams S, Odonkor S. Status, opportunities, and challenges of nuclear power development in Sub-Saharan Africa: the case of Ghana[J]. Progress in Nuclear Energy, 2021, 138: 103816. doi: 10.1016/j.pnucene.2021.103816 [6] 蔡永成, 刘学宇, 蔡永军, 等. 核辐射危害及核辐射屏蔽材料研究现状[J]. 粉末冶金工业, 2023, 33(2):96-102Cai Yongcheng, Liu Xueyu, Cai Yongjun, et al. Hazards of nuclear radiation and research progress in radiation shielding materials[J]. Powder Metallurgy Industry, 2023, 33(2): 96-102 [7] 李忠东. 核辐射的危害及应对[J]. 生命与灾害, 2023(1):24-27Li Zhongdong. Hazards of nuclear radiation and response[J]. Life & Disaster, 2023(1): 24-27 [8] 陆思全, 郁丹炯, 顾燕楠. 核辐射对人体生物学危害及其防治策略研究[J]. 绿色科技, 2015, 17(8): 244, 246Lu Siquan, YU Danjiong, GU Yannan. Study on the biological harmfulness on human of nuclear radiation and its control strategy[J]. Journal of Green Science and Technology, 2015, 17(8): 244, 246 [9] Park B, Park B, Kim J. Development of a radiation detector using a silicon photomultiplier and large Ce-doped Gd-Al-Ga-grant scintillator for gamma spectroscopy observations of radioactivation in a linear accelerator[J]. Journal of Instrumentation, 2023, 18: P05019. doi: 10.1088/1748-0221/18/05/P05019 [10] 曹保锋, 宋立军, 肇文丽, 等. 一种α、β射线探测器: 201410065825.1[P]. 2017-10-27Cao Baofeng, Song Lijun, Zhao Wenli, et al. Alpha and beta ray detector: 201410065825.1[P]. 2017-10-27 [11] 曹保锋, 宋立军, 肇文丽, 等. α、β射线探测器窗口保护罩结构: 201420080198.4[P]. 2014-08-13Cao Baofeng, Song Lijun, Zhao Wenli, et al. Window protection cover structure for alpha and beta ray detector: 201420080198.4[P]. 2014-08-13 [12] 贾雪辉. 一种大面积β射线探测装置的研究[D]. 成都: 成都理工大学, 2014Jia Xuehui. Research of a large area detection device for β-ray[D]. Chengdu: Chengdu University of Technology, 2014 [13] 李振宇, 范宇峰, 刘铖, 等. 国产超薄双面镀铝聚酯薄膜的工艺改进和热物性研究[J]. 表面技术, 2018, 47(9):219-222Li Zhenyu, Fan Yufeng, Liu Cheng, et al. Thermal properties and process improvement of domestic ultra-thin aluminized polyester films[J]. Surface Technology, 2018, 47(9): 219-222 [14] 魏威, 钱成, 邓艳, 等. 高性能VMPET镀铝薄膜[Z]. 嘉兴鹏翔包装材料有限公司, 2019-07-13Wei Wei, Qian Cheng, Deng Yan, et al. High performance VMPET aluminised film[Z]. Jiaxing Pengxiang Packaging Material Co, Ltd, 2019-07-13 [15] 邓艳, 张伟政, 余肇凯, 等. 超薄VMPET镀铝薄膜[Z]. 嘉兴鹏翔包装材料有限公司, 2019-07-13Deng Yan, Zhang Weizheng, Yu Zhaokai, et al. Ultra-thin VMPET aluminised film[Z]. Jiaxing Pengxiang Packaging Material Co, Ltd, 2019-07-13 [16] 陈建军. 柔性PEN基底表面纳米金属薄膜制备及其性能研究[D]. 兰州: 兰州理工大学, 2019: 25-32Chen Jianjun. Preparation and properties of nano-metal films on flexible PEN substrates[D]. Lanzhou: Lanzhou University of Technology, 2019: 25-32 [17] Hua Xiaodong, Li Jiahui, Liu Hao, et al. Preparation of Cu2Se thin films by vacuum evaporation and hot-pressing[J]. Vacuum, 2021, 185: 109947. doi: 10.1016/j.vacuum.2020.109947 [18] Twu M J, Chiou A H, Hu C C, et al. Properties of TiO2 films deposited on flexible substrates using direct current magnetron sputtering and using high power impulse magnetron sputtering[J]. Polymer Degradation and Stability, 2015, 117: 1-7. doi: 10.1016/j.polymdegradstab.2015.03.010 [19] Jörg T, Cordill M J, Franz R, et al. The electro-mechanical behavior of sputter-deposited Mo thin films on flexible substrates[J]. Thin Solid Films, 2016, 606: 45-50. doi: 10.1016/j.tsf.2016.03.032 [20] 王翠凤, 邱锡荣, 赵乙璇, 等. 直流磁控溅射法在PET基板上制备AZO薄膜[J]. 中国表面工程, 2012, 25(6):53-60 doi: 10.3969/j.issn.1007-9289.2012.06.009Wang Cuifeng, Qiu Xirong, Zhao Yixuan, et al. Preparation of AZO thin films on PET substrate using DC magnetron sputtering[J]. China Surface Engineering, 2012, 25(6): 53-60 doi: 10.3969/j.issn.1007-9289.2012.06.009 [21] 杨子江. 靶电流和气体流量对含Ti薄膜光学性能的影响[D]. 北京: 中国地质大学(北京), 2016: 32-37Yang Zijiang. Influence of target current and gas flow on structure and optical properties of Titanium-containing film[D]. Beijing: China University of Geosciences (Beijing), 2016: 32-37 [22] 朱秀榕, 董煜, 李晓芬. 溅射电流对钛薄膜光电性能的影响[J]. 赣南师范大学学报, 2021, 42(6):30-34Zhu Xiurong, Dong Yu, Li Xiaofen. Effect of sputtering current on photoelectric properties of titanium thin film[J]. Journal of Gannan Normal University, 2021, 42(6): 30-34 [23] 刘容宏, 孙元浩, 刘芳. 镀铝薄膜正反面阻隔性能变化研究[J]. 绿色包装, 2021(9):23-25Liu Ronghong, Sun Yuanhao, Liu Fang. Research on the change of front and back barrier property of plastic film deposited with aluminium[J]. Green Packaging Research·Technology, 2021(9): 23-25 [24] Levinson R, Chen S, Slack J, et al. Design, characterization, and fabrication of solar-retroreflective cool-wall materials[J]. Solar Energy Materials and Solar Cells, 2020, 206: 110117. doi: 10.1016/j.solmat.2019.110117 [25] 花银群, 朱爱春, 陈瑞芳, 等. 直流磁控溅射铝纳米颗粒膜的微结构及电学特性[J]. 功能材料, 2015, 46(4):4071-4075 doi: 10.3969/j.issn.1001-9731.2015.04.014Hua Yinqun, Zhu Aichun, Chen Ruifang, et al. Microstructure andelectrical properties of Al nano-particle films by DC magnetron sputtering[J]. Journal of Functional Materials, 2015, 46(4): 4071-4075 doi: 10.3969/j.issn.1001-9731.2015.04.014 [26] 庞丽侠. 磁控溅射铝镀层结构对316L不锈钢表面阳极氧化成孔的影响[D]. 哈尔滨: 哈尔滨工业大学, 2009: 25-32Pang Lixia. Effect of magnetron sputtering aluminum film structure on anodic micro-pores formed on surface of 316L stainless steel[D]. Harbin: Harbin Institute of Technology, 2009: 25-32 [27] 李海兵, 徐勇军, 蔡其文, 等. 太阳能高反射薄膜制备技术对薄膜性能的影响[J]. 中国表面工程, 2016, 29(3):34-40 doi: 10.11933/j.issn.1007-9289.2016.03.005Li Haibing, Xu Yongjun, Cai Qiwen, et al. Influences of preparation technologies on properties of solar high reflection thin films[J]. China Surface Engineering, 2016, 29(3): 34-40 doi: 10.11933/j.issn.1007-9289.2016.03.005 [28] 杨万里. 手足表面α、β污染检测仪的研制[D]. 衡阳: 南华大学, 2021: 20-27Yang Wanli. Development of α and β contamination detector for hand and foot surface[D]. Hengyang: University of South China, 2021: 20-27 [29] 王迪. 便携式辐射探测仪的设计与实现[D]. 太原: 中北大学, 2021: 17-25Wang Di. Design and realization of portable radiation detector[D]. Taiyuan: North University of China, 2021: 17-25 -

下载:

下载: