Effect of Cr2O3 coating sintered at high temperature on the vacuum surface hold-off voltage performance of Al2O3 ceramic

-

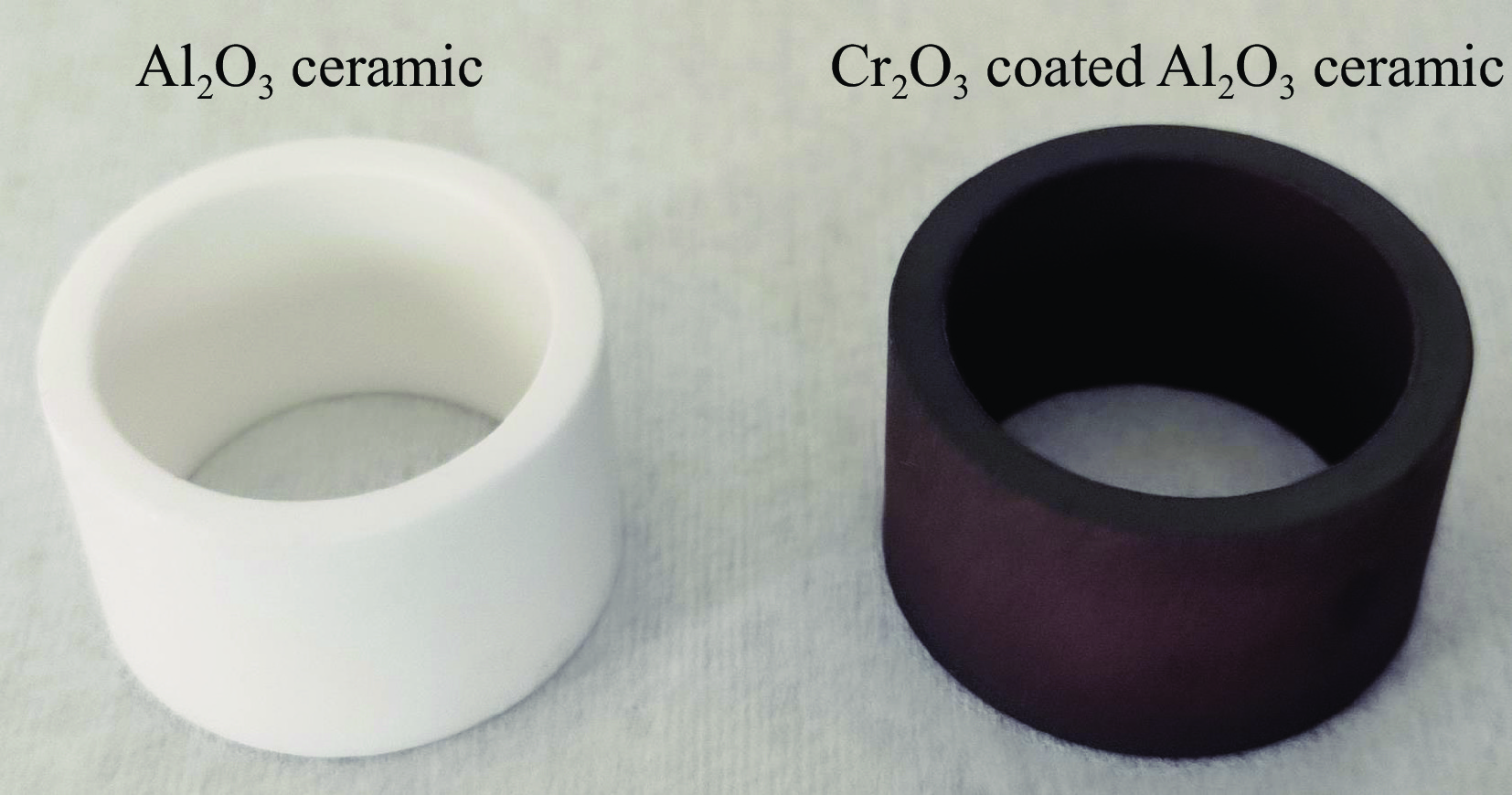

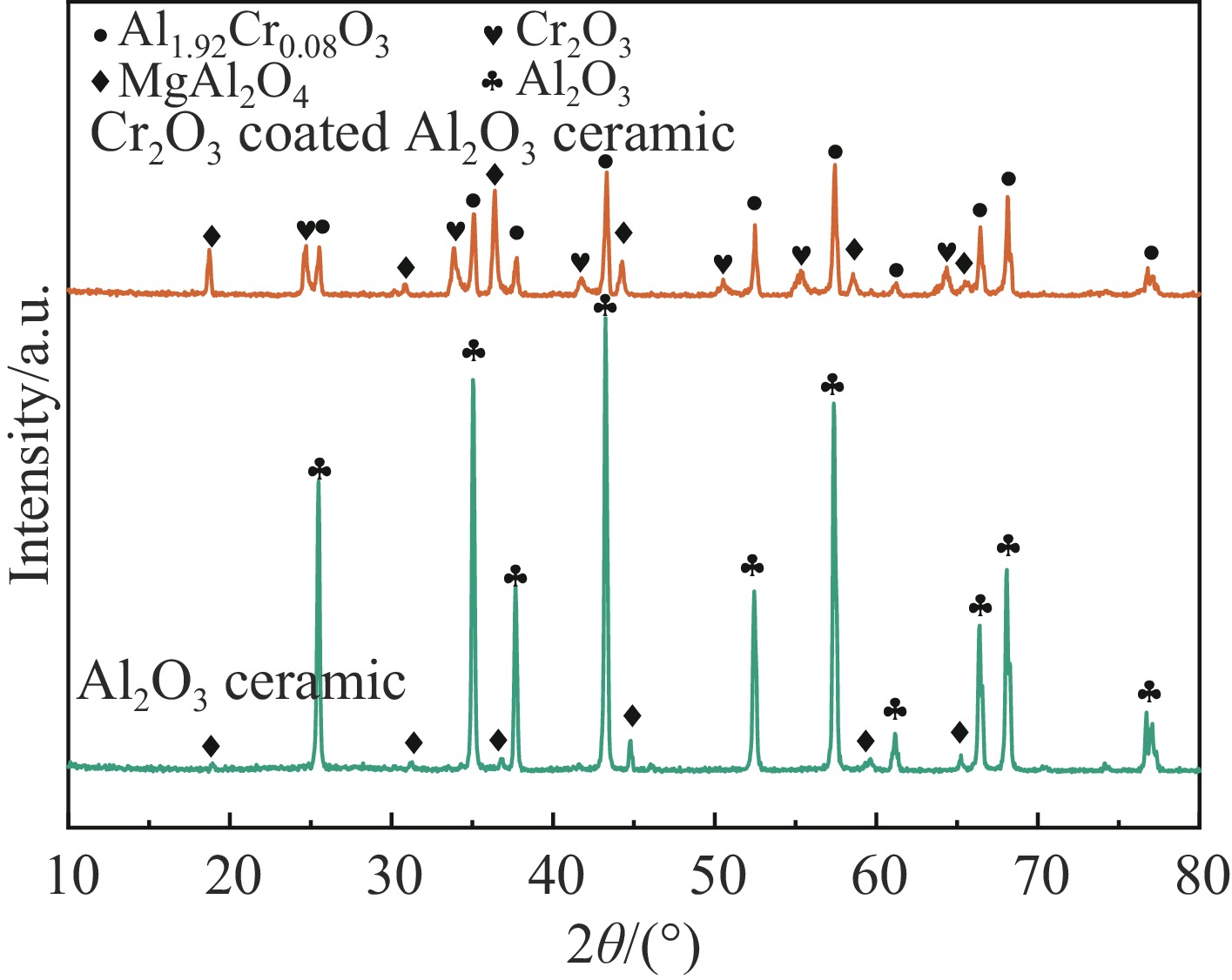

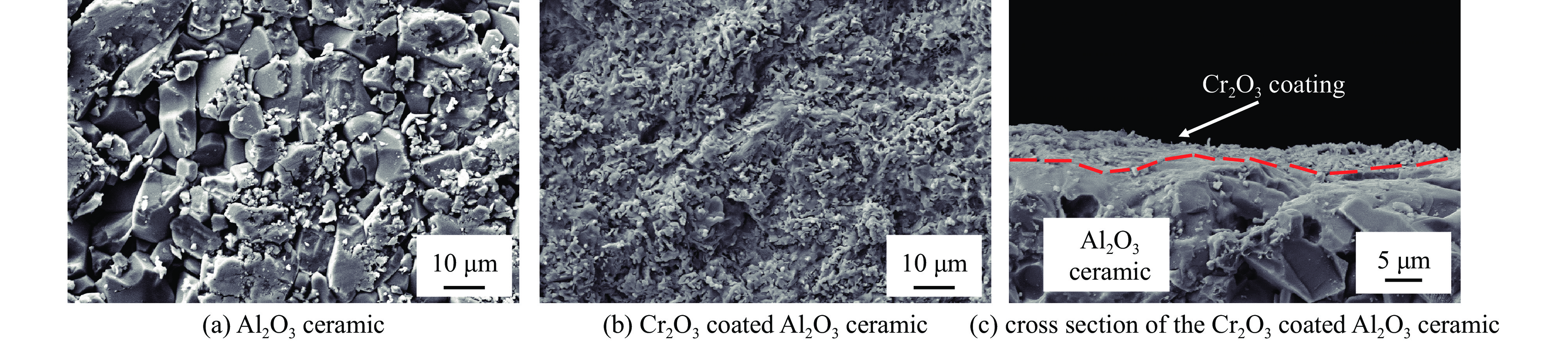

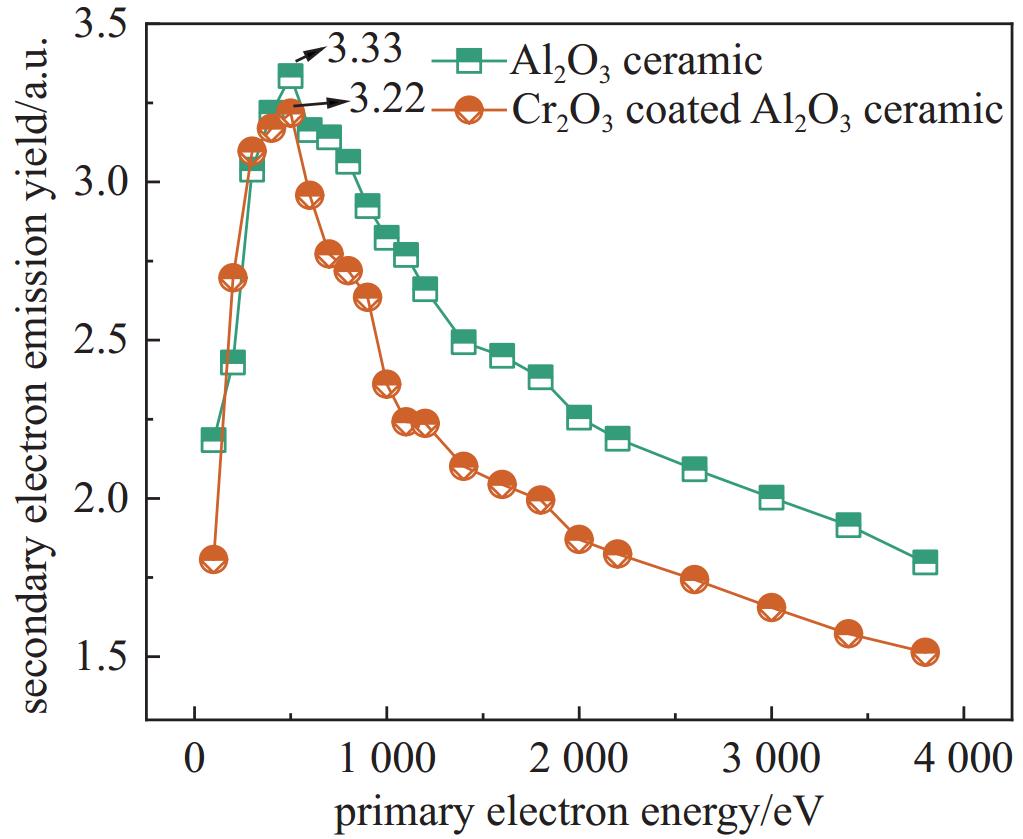

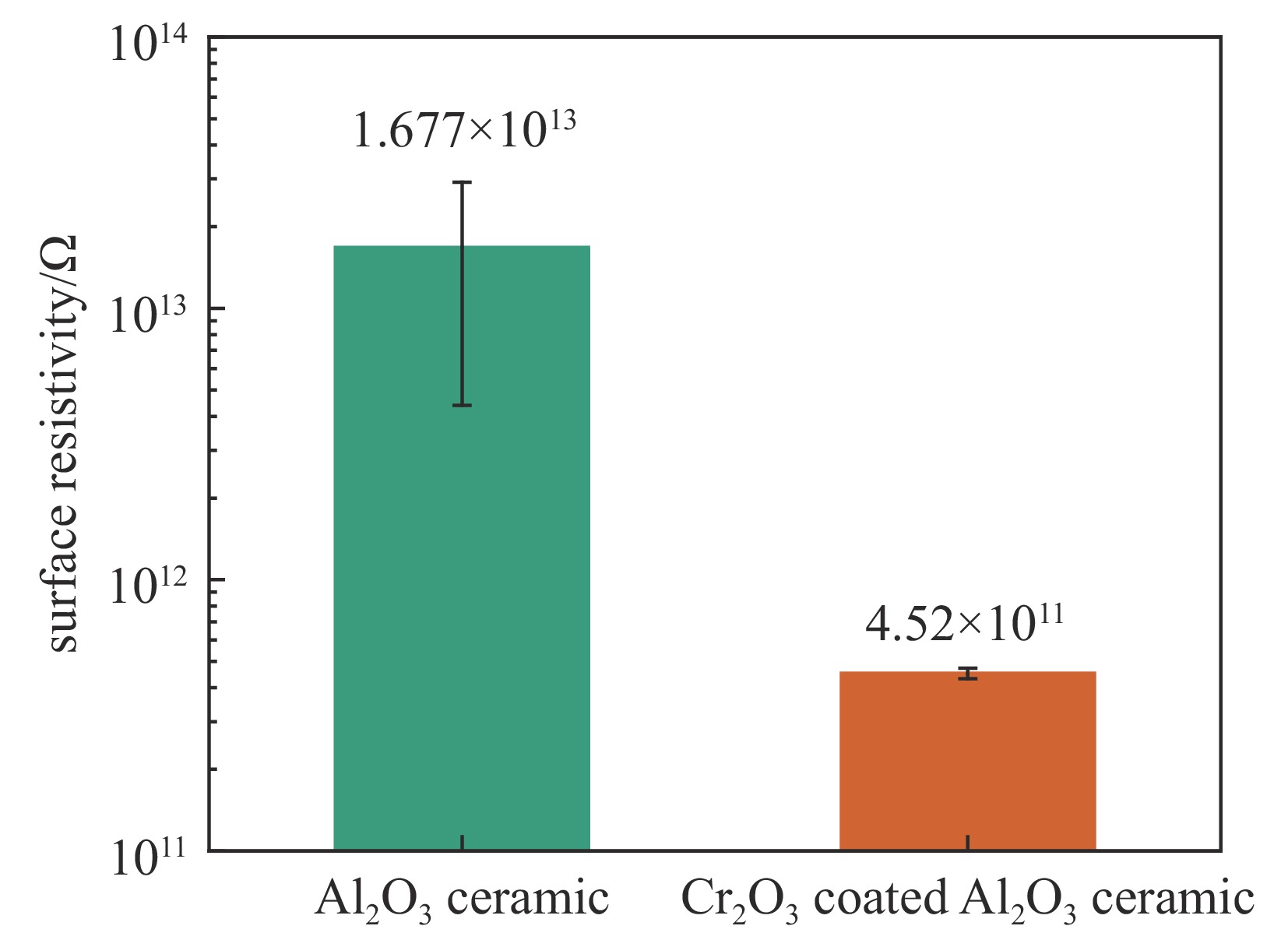

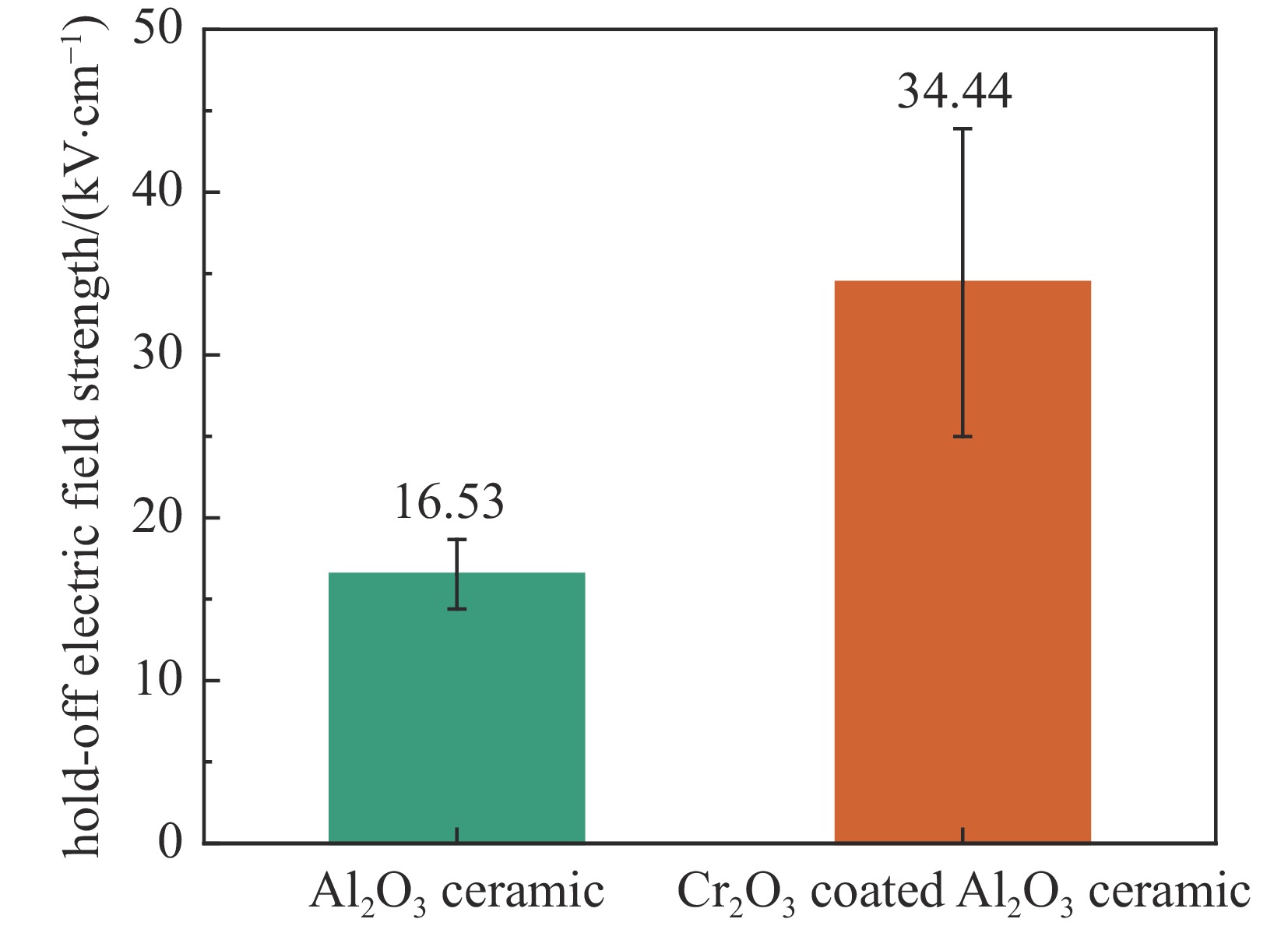

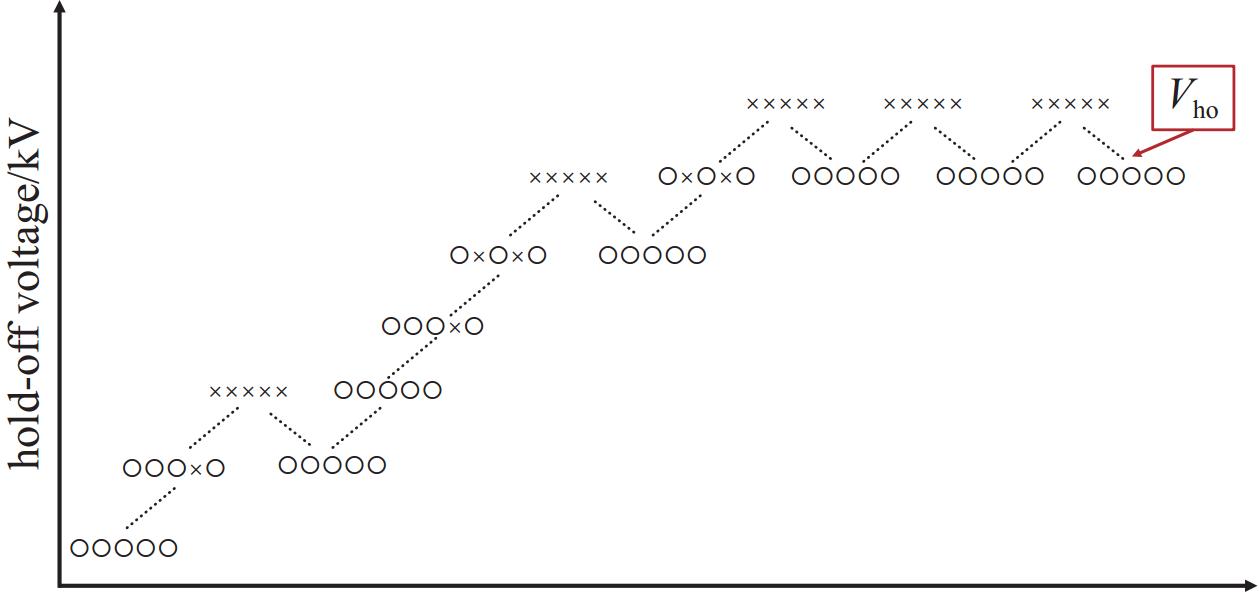

摘要: 利用浸涂法将Cr2O3涂覆于Al2O3陶瓷表面,通过高温烧结获得涂层陶瓷,并系统性地研究了Cr2O3涂层对样品的物质成分、微观形貌、二次电子发射系数、表面电阻率和真空沿面耐压性能的影响。结果表明:涂层陶瓷表面呈红黑色,其为Al2O3-Cr2O3固溶体、MgAl2O4和Cr2O3三种物质的混合物。相较于Al2O3陶瓷,涂层表面晶粒和孔洞的尺寸均较小,其晶粒尺寸均匀性也有明显提升。高温烧结后,Al、Cr两种元素相互扩散,并且涂层中有少量从陶瓷基体迁移而来的玻璃相。高温烧结的Cr2O3涂层将Al2O3陶瓷的二次电子发射系数减小至3.22,将表面电阻率减小至4.52×1011 Ω,将真空沿面耐压强度增大至34.44 kV/cm,此值较Al2O3陶瓷提高了约108%。Abstract: In this study, Cr2O3 was applied to the surface of Al2O3 ceramic via a dip-coating method. Subsequently, the final coated ceramic was obtained through high-temperature sintering. The effects of the Cr2O3 coating on material composition, microstructure, secondary electron emission coefficient, surface resistivity, and vacuum surface hold-off voltage performance were systematically investigated. The results indicate that the surface of the coated ceramic appears dark red, representing a mixture of three materials: Al2O3-Cr2O3 solid solution, MgAl2O4, and Cr2O3. Compared to the Al2O3 ceramic, both the grain size and pore size on the surface are reduced, and the homogeneity of the grain size is significantly enhanced. After high-temperature sintering, Al and Cr diffuse into each other. Additionally, a small amount of glass phase, likely migrating from the ceramic substrate, is detected in the coating. Owing to the high-temperature sintering of the Cr2O3 coating, the secondary electron emission coefficient is reduced to 3.22, and the surface resistivity is also lowered to 4.52×1011 Ω. Furthermore, the vacuum surface hold-off electric field strength of the coated ceramic increases to 34.44 kV/cm, which is approximately 108% higher than that of the Al2O3 ceramic.

-

表 1 陶瓷样品的表面成分

Table 1. Surface ingredient of ceramic samples

sample mass fraction/% O Na Mg Al Si K Ca Cr Al2O3 ceramic 40.8 0.5 0.54 56.06 0.67 0.53 0.89 / Cr2O3 coated Al2O3 ceramic 33.54 / 0.19 18.73 0.52 / 0.03 46.99 -

[1] 高陇桥. 陶瓷-金属材料实用封接技术[M]. 3版. 北京: 化学工业出版社, 2018: 9-17Gao Longqiao. Practical sealing technology for ceramic-metal materials[M]. 3rd ed. Beijing: Chemical Industry Press, 2018: 9-17 [2] 何佳龙, 陈思富, 张篁, 等. 神龙二号加速器绝缘环真空沿面闪络[J]. 强激光与粒子束, 2016, 28:095101 doi: 10.11884/HPLPB201628.150950He Jialong, Chen Sifu, Zhang Hunag, et al. Vacuum flashover of Dragon-Ⅱ accelerator insulator ring[J]. High Power Laser and Particle Beams, 2016, 28: 095101 doi: 10.11884/HPLPB201628.150950 [3] 杨雯捷, 王勐, 李逢, 等. 软X射线辐照对绝缘材料沿面闪络性能的影响[J]. 强激光与粒子束, 2005, 27:095002 (Yang Wenjie, Wang Meng, Li Feng, et al. Impact of soft X-ray irradiation on surface flashover performance of insulating material[J]. High Power Laser and Particle Beams, 2005, 27: 095002 doi: 10.11884/HPLPB201527.095002Yang Wenjie, Wang Meng, Li Feng, et al. Impact of soft X-ray irradiation on surface flashover performance of insulating material[J]. High Power Laser and Particle Beams, 2005, 27: 095002 doi: 10.11884/HPLPB201527.095002 [4] 何友辉, 陈洪斌, 李飞, 等. 固体绝缘子的真空沿面闪络研究[J]. 强激光与粒子束, 2023, 35:035004 doi: 10.11884/HPLPB202335.220214He Youhui, Chen Hongbin, Li Fei, et al. Review of surface flashover and surface charge behavior of vacuum insulators[J]. High Power Laser and Particle Beams, 2023, 35: 035004 doi: 10.11884/HPLPB202335.220214 [5] Zhang Zhousheng, Wang Zheming, Teyssedre G, et al. Gas-solid interface charge tailoring techniques: what we grasped and where to go[J]. Nanotechnology, 2021, 32: 122001. doi: 10.1088/1361-6528/abccea [6] 李逢, 王勐, 任靖, 等. 不同微槽结构绝缘子真空沿面闪络特性[J]. 强激光与粒子束, 2014, 26:045049 doi: 10.11884/HPLPB201426.045049Li Feng, Wang Meng, Ren Jing, et al. Characteristics of grooved insulator flashover under pulsed voltage[J]. High Power Laser and Particle Beams, 2014, 26: 045049 doi: 10.11884/HPLPB201426.045049 [7] Zhang Tao, Du Jishi, Lei Yangjun, et al. Effect of pores on dielectric breakdown strength of alumina ceramics via surface and volume effects[J]. Journal of the European Ceramic Society, 2020, 40(8): 3019-3026. doi: 10.1016/j.jeurceramsoc.2020.03.024 [8] Miller H C. Improving the voltage holdoff performance of alumina insulators in vacuum through quasimetallizing[J]. IEEE Transactions on Electrical Insulation, 1980, EI-15(5): 419-428. doi: 10.1109/TEI.1980.298336 [9] 朱明冬. Al2O3陶瓷表面离子注入与沉积及沿面闪络特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2020: 53-77Zhu Mingdong. Ion implantation and deposition on the surface of alumina ceramic and surface flashover characteristics[D]. Harbin: Harbin Institute of Technology, 2020: 53-77 [10] 姚舜. 体掺杂Al2O3陶瓷的制备及沿面闪络性能的研究[D]. 武汉: 武汉理工大学, 2020: 21-55Yao Shun. Preparation and surface flashover properties of bulk doped Al2O3 ceramics[D]. Wuhan: Wuhan University of Technology, 2020: 21-55 [11] Feng Dandan, Wang Xiaojing, Zhao Shike, et al. Study of TiO2 on the voltage holdoff capacity of Cr/Mn-doped Al2O3 ceramic in vacuum[J]. Materials, 2023, 16: 5048. doi: 10.3390/ma16145048 [12] Yu Weixin, Kong Fei, Dong Pan, et al. Depositing chromium oxide film on alumina ceramics enhances the surface flashover performance in vacuum via PECVD[J]. Surface and Coatings Technology, 2021, 405: 126509. doi: 10.1016/j.surfcoat.2020.126509 [13] Hamada K, Asari N, Tateyama C. The influence of chromium oxide coating of alumina surface on partial discharge in vacuum[J]. IEEE Transactions on Plasma Science, 2024, 52(9): 4378-4381. doi: 10.1109/TPS.2024.3360989 [14] Sun Xiaoliang, Xun Tao, Zhong Huihuang, et al. Improved surface flashover characteristics of ceramic vacuum interface by surface treatment[C]//Proceedings of the 2018 28th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV). 2018: 151-154. [15] Asari N, Sakaguchi W, Shioiri T, et al. Influence of coating to surface flashover characteristics of alumina ceramics in vacuum[C]//Proceedings of the 2016 27th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV). 2016: 1-4. [16] Sudarshan T S, Cross J D. The effect of chromium oxide coatings on surface flashover of alumina spacers in vacuum[J]. IEEE Transactions on Electrical Insulation, 1976, EI-11(1): 32-35. doi: 10.1109/TEI.1976.297942 [17] Shioiri T, Asari N, Saito S, et al. Effect of chromium oxide coating on surface flashover characteristics of ceramic in vacuum[C]//Proceedings of the 2006 International Symposium on Discharges and Electrical Insulation in Vacuum. 2006: 140-143. [18] Lei Yangjun, Tang Binghua, Huang Xiaojun, et al. Improving insulating performance of alumina ceramic in vacuum through surface modification[C]//Proceedings of the 2010 24th International Symposium on Discharges and Electrical Insulation in Vacuum. 2010: 27-31. [19] He Jialong, Yang Jie, Peng Yufei, et al. Measurement of yield and spectrum of secondary electron emission and their characteristics under modification of conductive materials[J]. Review of Scientific Instruments, 2019, 90: 063304. doi: 10.1063/1.5053965 [20] 曾智江, 杨秋红, 徐军. Cr3+: Al2O3透明多晶陶瓷光谱特性分析[J]. 物理学报, 2005, 54(11):5445-5449 doi: 10.3321/j.issn:1000-3290.2005.11.079Zeng Zhijiang, Yang Qiuhong, Xu Jun. Spectroscopic characteristics of Cr3+: Al2O3 polycrystalline transparent alumina ceramics[J]. Acta Physica Sinica, 2005, 54(11): 5445-5449 doi: 10.3321/j.issn:1000-3290.2005.11.079 [21] Khilla M A, Hanafi Z M, Mohamed A K. The electrical conductivity of chromium trioxide and its suboxides[J]. Thermochimica Acta, 1982, 56(3): 291-298. doi: 10.1016/0040-6031(82)87037-8 [22] Hussain S, Barbariol I, Roitti S, et al. Electrical conductivity of an insulator matrix (alumina) and conductor particle (molybdenum) composites[J]. Journal of the European Ceramic Society, 2003, 23(2): 315-321. doi: 10.1016/S0955-2219(02)00185-1 [23] Miller H C. Flashover of insulators in vacuum: the last twenty years[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2015, 22(6): 3641-3657. doi: 10.1109/TDEI.2015.004702 [24] Zhang Guanjun, Su Guoqiang, Song Baipeng, et al. Pulsed flashover across a solid dielectric in vacuum[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2018, 25(6): 2321-2339. doi: 10.1109/TDEI.2018.007133 [25] 尚阿曼, 田志英, 张巨先. 微波管用氧化铝陶瓷真空耐压性能及测试方法研究[J]. 真空电子技术, 2015(3):34-38 doi: 10.3969/j.issn.1002-8935.2015.03.011Shang A’man, Tian Zhiying, Zhang Juxian. Studies of the vacuum surface flashover and the corresponding measuring method of alumina insulators used for microwave tubes[J]. Vacuum Electronics, 2015(3): 34-38 doi: 10.3969/j.issn.1002-8935.2015.03.011 -

下载:

下载: