Dual suppression on the vacuum surface flashover from composite surface modification

-

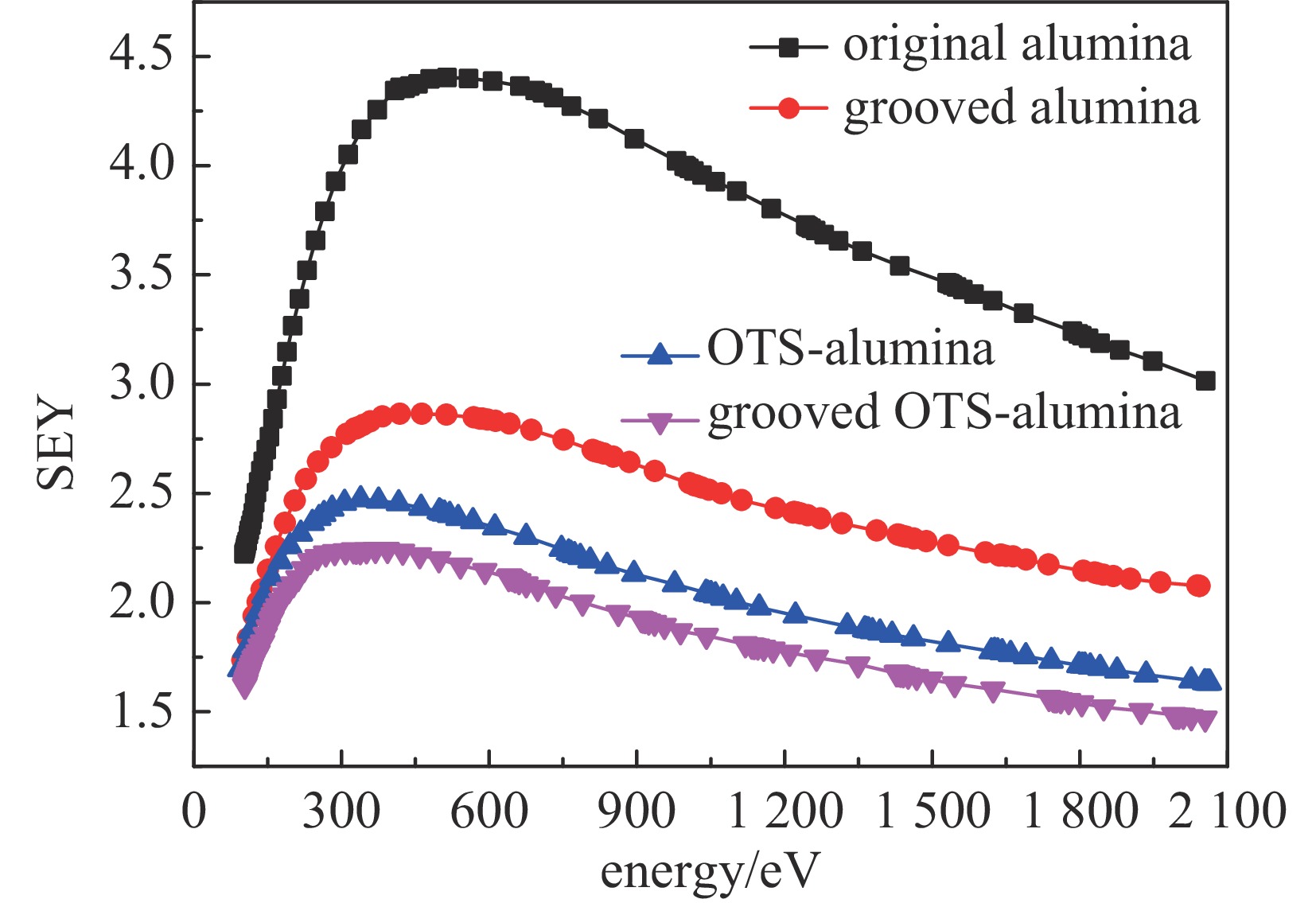

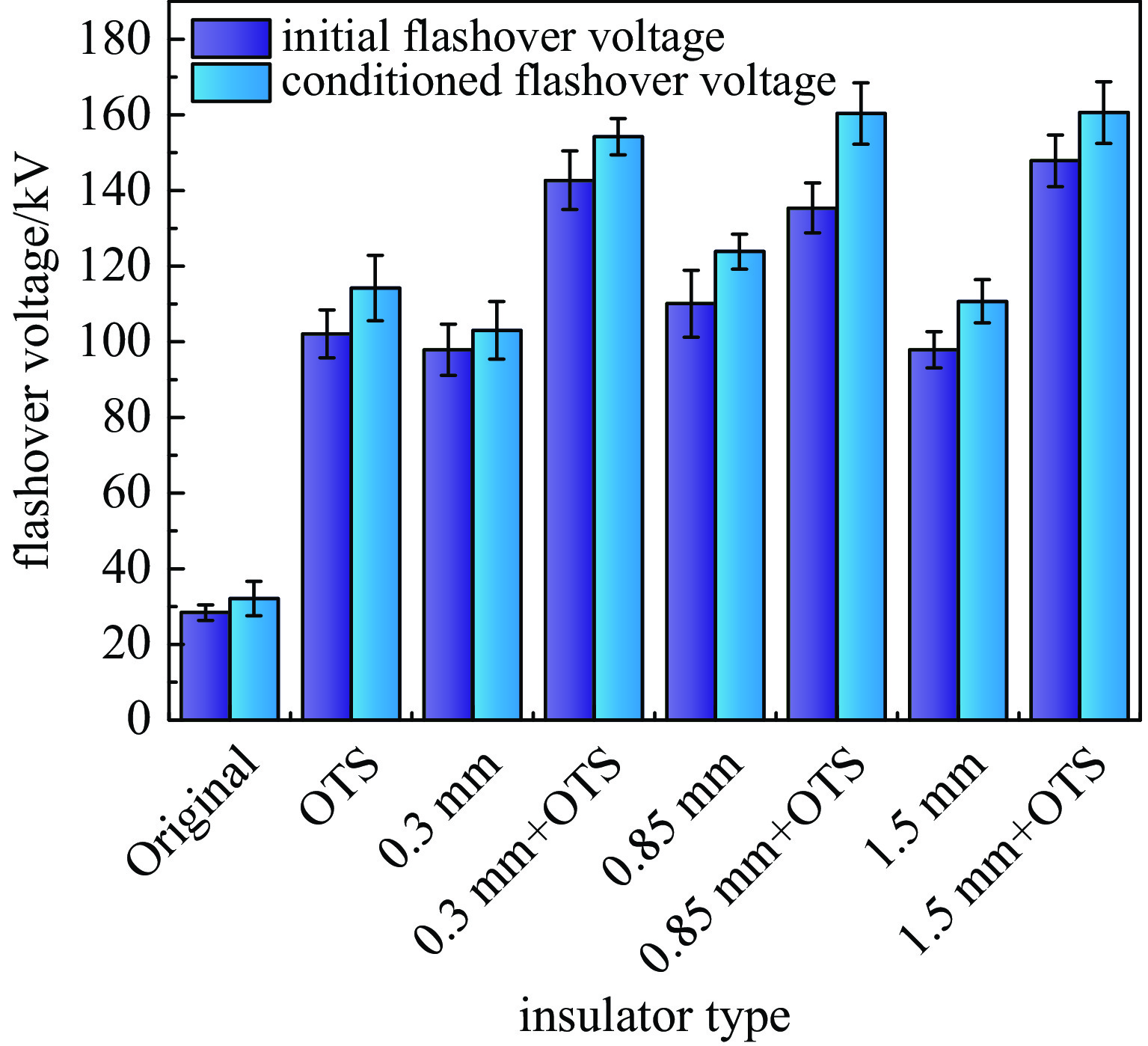

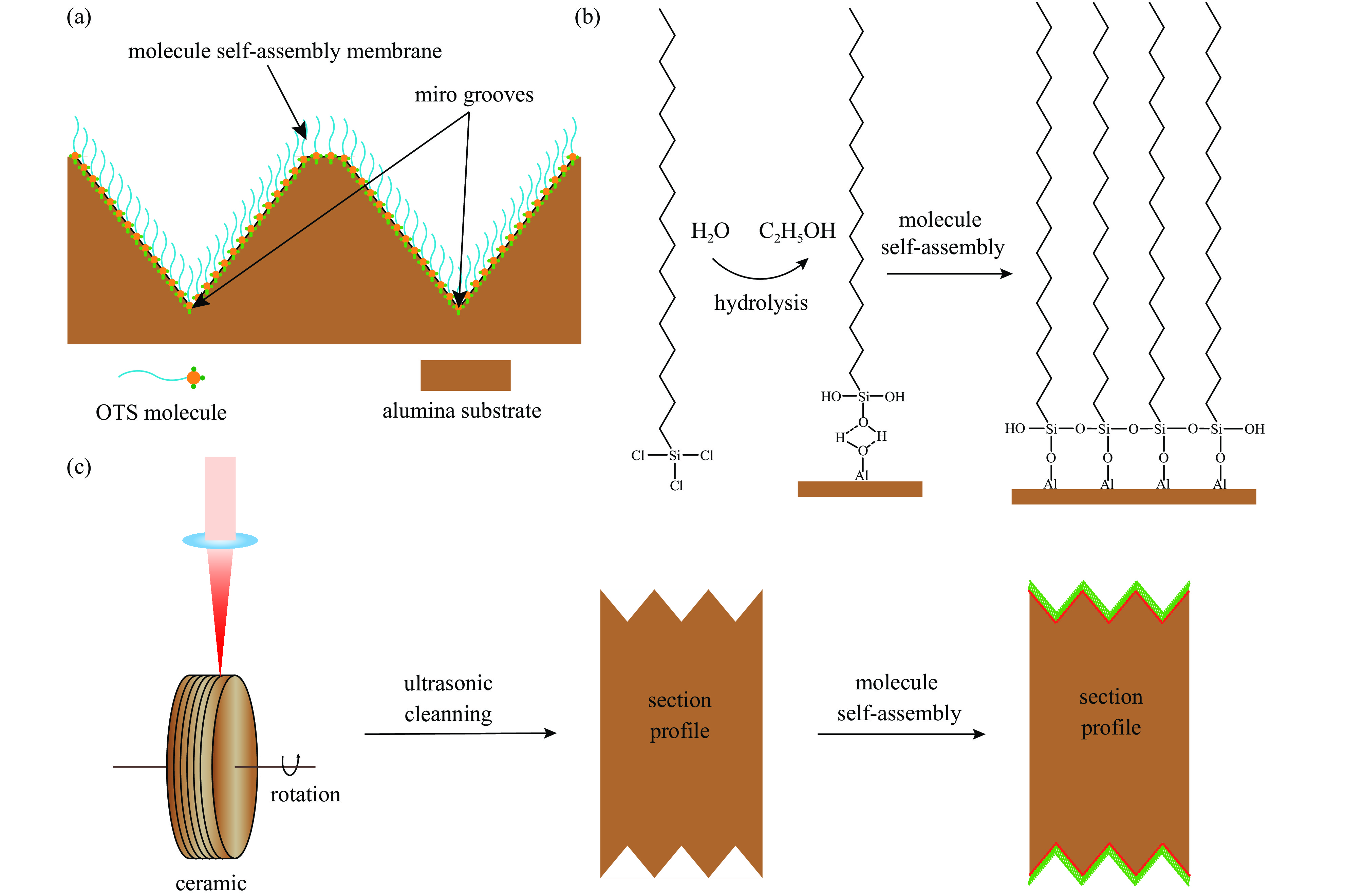

摘要: 为提升绝缘材料真空沿面耐压,提出了一种由微槽与分子自组装膜结合的复合结构,并采用激光微刻蚀、超声清洗、分子自组装等方法,在氧化铝真空绝缘子表面制备了该表面复合结构。作为对比,同时制备了仅有微槽或分子自组装膜的绝缘子。二次电子发射系数测试结果表明,表面微槽结构和表面分子自组装膜都可以降低绝缘子的二次电子发射系数,而他们相结合形成的复合结构能够进一步降低绝缘子的二次电子发射系数;相应的,闪络电压测试结果表明表面微槽结构和表面分子自组装膜都可以提升绝缘子的真空沿面闪络电压,而两者相结合形成的复合结构能够进一步提升闪络电压。该结果证明了复合结构中分子自组装膜和微槽能够对真空沿面闪络的发展进行双重抑制。Abstract: To improve the vacuum surface flashover of insulators, in this paper, a kind of composite surface structure consisting of micro grooves and molecule self-assembly membrane was proposed and prepared on the surface of alumina vacuum insulators by laser carving, water cleaning and molecule self-assembly. Meanwhile, insulators with only micro grooves or pure molecule membrane were also prepared. Secondary electron emission yield test shows that both the micro groove construction and molecule self-assembly can decrease the secondary electron emission yield of the alumina insulator. Their combination the composite surface structure can further decrease the secondary electron emission yield. Correspondingly, surface flashover voltage test indicated that surface micro groove construction and molecule self-assembly could both improve the surface flashover voltages and their combination could further improve the flashover voltages. The results demonstrate that molecule membrane and the micro grooves in the composite structure can form dual suppression to the development of the vacuum flashover.

-

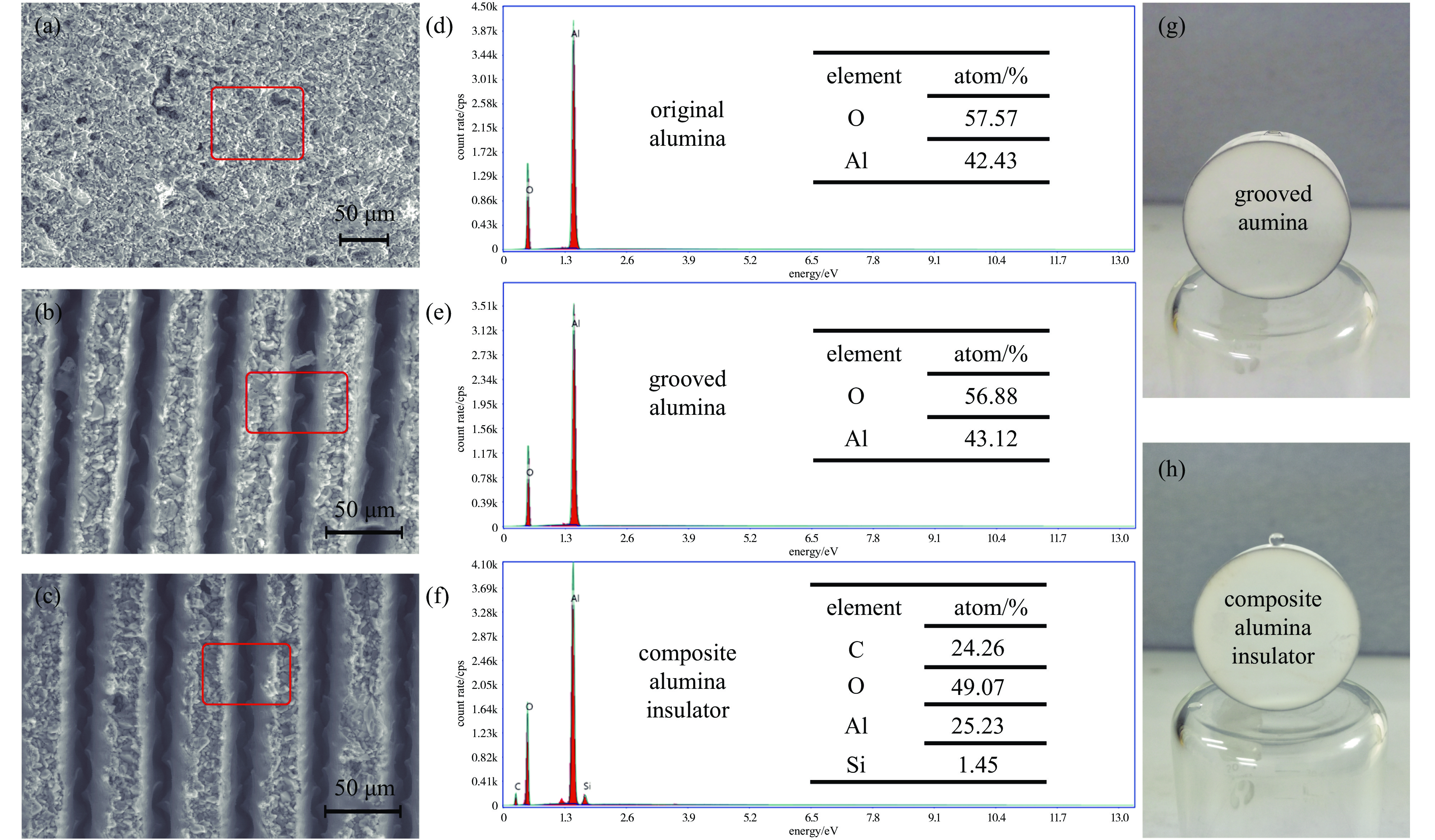

图 2 绝缘子的SEM、EDS与水接触角测试结果

Figure 2. SEM, EDS and water contact test results of the insulators

(a) Original alumina. (b) Grooved alumina. (c) Composite insulator. (d) EDS of original alumina. (e) EDS of grooved alumina. (f) EDS of composite insulator. (g) Water contact test of grooved alumina insulator. (h) Water contact test of composite alumina insulator.

-

[1] Sun Guangyu, Song Baipeng, Zhang Guanjun, et al. Investigation of multipactor-induced surface plasma discharge and temporal mode transition[J]. Applied Physics Letters, 2018, 113: 011603. doi: 10.1063/1.5041874 [2] Gleizer J Z, Krasik Y E, Dai U, et al. Vacuum surface flashover: experiments and simulations[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2014, 21(5): 2394-2404. doi: 10.1109/TDEI.2014.004628 [3] Sterling R C, Hughes M D, Mellor C J, et al. Increased surface flashover voltage in microfabricated devices[J]. Applied Physics Letters, 2013, 103: 143504. [4] Leopold J G, Leibovitz C, Navon I, et al. Different approach to pulsed high-voltage vacuum-insulation design[J]. Physical Review Accelerators and Beams, 2007, 10: 060401. doi: 10.1103/PhysRevSTAB.10.060401 [5] Stygar W A, Lott J A, Wagoner T C, et al. Improved design of a high-voltage vacuum-insulator interface[J]. Physical Review Accelerators and Beams, 2005, 8: 050401. [6] Zhang Guanjun, Su Guoqiang, Song Baipeng, et al. Pulsed flashover across a solid dielectric in vacuum[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2018, 25(6): 2321-2339. doi: 10.1109/TDEI.2018.007133 [7] Harris J R. A tutorial on vacuum surface flashover[J]. IEEE Transactions on Plasma Science, 2018, 46(6): 1872-1880. doi: 10.1109/TPS.2017.2759248 [8] Wang Chao, Li Wendong, Guo Jia, et al. Unraveling the role of surface molecular structure on vacuum flashover for fluorinated copolymers[J]. Applied Surface Science, 2020, 505: 144432. doi: 10.1016/j.apsusc.2019.144432 [9] Zhou Rundong, Sun Guangyu, Song Baipeng, et al. Mechanism of F2/N2 fluorination mitigating vacuum flashover of polymers[J]. Journal of Physics D: Applied Physics, 2019, 52: 375304. [10] Guo Baohong, Sun Guangyu, Zhang Shu, et al. Mechanism of vacuum flashover on surface roughness[J]. Journal of Physics D: Applied Physics, 2019, 52: 215301. doi: 10.1088/1361-6463/ab05a0 [11] Miller H C. Flashover of insulators in vacuum: the last twenty years[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2015, 22(6): 3641-3657. [12] Gleizer J Z, Krasik Y E, Leopold J. Time- and space-resolved light emission and spectroscopic research of the flashover plasma[J]. Journal of Applied Physics, 2015, 117: 073301. doi: 10.1063/1.4913213 [13] Lauer E J, Lauer C J. Electron avalanche on a dielectric-vacuum interface[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2017, 24(2): 1295-1299. doi: 10.1109/TDEI.2017.005837 [14] Sun Guangyu, Song Baipeng, Guo Baohong, et al. Estimation of surface flashover threshold in vacuum: from multipactor to discharge plasma[J]. Journal of Physics D: Applied Physics, 2018, 51: 295201. doi: 10.1088/1361-6463/aacccf [15] 张贝, 刘文元, 霍艳坤, 等. 大气等离子体表面改性对PEI绝缘子真空沿面耐压性能的影响[J]. 现代应用物理, 2021, 12:040404Zhang Bei, Liu Wenyuan, Huo Yankun, et al. Effect of atmospheric plasma treatment on vacuum surface voltage-withstand performance of PEI insulators[J]. Modern Applied Physics, 2021, 12: 040404 [16] Zhang Penghao, Zhang Shuai, Kong Fei, et al. Atmospheric-pressure plasma jet deposition of bumpy coating improves polypropylene surface flashover performance in vacuum[J]. Surface and Coatings Technology, 2020, 387: 125511. doi: 10.1016/j.surfcoat.2020.125511 [17] Huang Yin, Min Daomin, Li Shengtao, et al. Surface flashover performance of epoxy resin microcomposites improved by electron beam irradiation[J]. Applied Surface Science, 2017, 406: 39-45. doi: 10.1016/j.apsusc.2017.02.093 [18] Huo Yankun, Liu Wenyuan, Ke Changfeng, et al. Sharp improvement of flashover strength from composite micro-textured surfaces[J]. Journal of Applied Physics, 2017, 122: 115105. doi: 10.1063/1.4991934 [19] Kong Fei, Chang Chao, Ma Yiyang, et al. Surface modifications of polystyrene and their stability: a comparison of DBD plasma deposition and direct fluorination[J]. Applied Surface Science, 2018, 459: 300-308. doi: 10.1016/j.apsusc.2018.07.211 [20] Chen Sile, Wang Shuai, Wang Yibo, et al. Surface modification of epoxy resin using He/CF4 atmospheric pressure plasma jet for flashover withstanding characteristics improvement in vacuum[J]. Applied Surface Science, 2017, 414: 107-113. doi: 10.1016/j.apsusc.2017.03.278 [21] Shao Tao, Yang Wenjin, Zhang Cheng, et al. Enhanced surface flashover strength in vacuum of polymethylmethacrylate by surface modification using atmospheric-pressure dielectric barrier discharge[J]. Applied Physics Letters, 2014, 105: 071607. doi: 10.1063/1.4893884 [22] Kelkar S S, Chiavetta D, Wolden C A. Formation of octadecyltrichlorosilane (OTS) self-assembled monolayers on amorphous alumina[J]. Applied Surface Science, 2013, 282: 291-296. doi: 10.1016/j.apsusc.2013.05.121 [23] Liu Wenyuan, Guo Yuewen, Huo Yankun, et al. Construction of microgrooves on the surface of alumina ceramic insulator to enhance its flashover strength[J]. AIP Advances, 2020, 10: 045009. doi: 10.1063/5.0003592 [24] Huo Yankun, Liu Wenyuan, Guo Yuewen, et al. Molecule self-assembly on alumina ceramic insulator to enhance its vacuum surface voltage withstand strength[J]. Journal of Applied Physics, 2020, 127: 243304. doi: 10.1063/5.0006233 [25] 霍艳坤, 刘文元, 何亚姣, 等. 聚合物真空绝缘子表面二级微结构[J]. 强激光与粒子束, 2024, 36:055017 doi: 10.11884/HPLPB202436.230423Huo Yankun, Liu Wenyuan, He Yajiao, et al. Two-stage microstructure on surface of vacuum polymer insulators[J]. High Power Laser and Particle Beams, 2024, 36: 055017 doi: 10.11884/HPLPB202436.230423 [26] Cai Libing, Wang Jianguo, Ceng Guoxin, et al. Simulation of multipactor on the rectangular grooved dielectric surface[J]. Physics of Plasmas, 2015, 22: 113506. doi: 10.1063/1.4935385 [27] Chang Chao, Huang H J, Liu G Z, et al. The effect of grooved surface on dielectric multipactor[J]. Journal of Applied Physics, 2009, 105: 123305. doi: 10.1063/1.3153947 -

下载:

下载: