Study on recovery pressure of diffuser for DF chemical laser

-

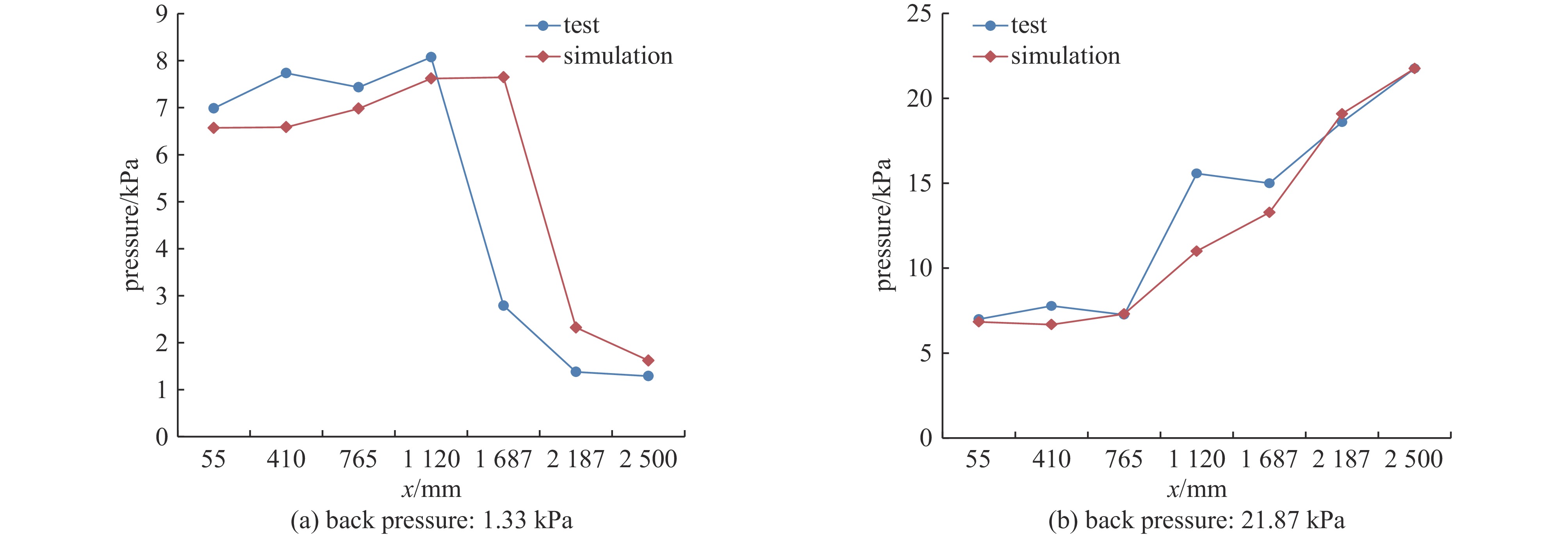

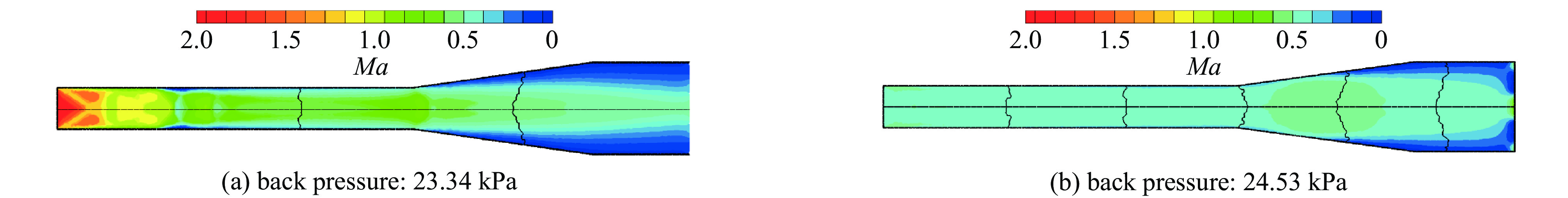

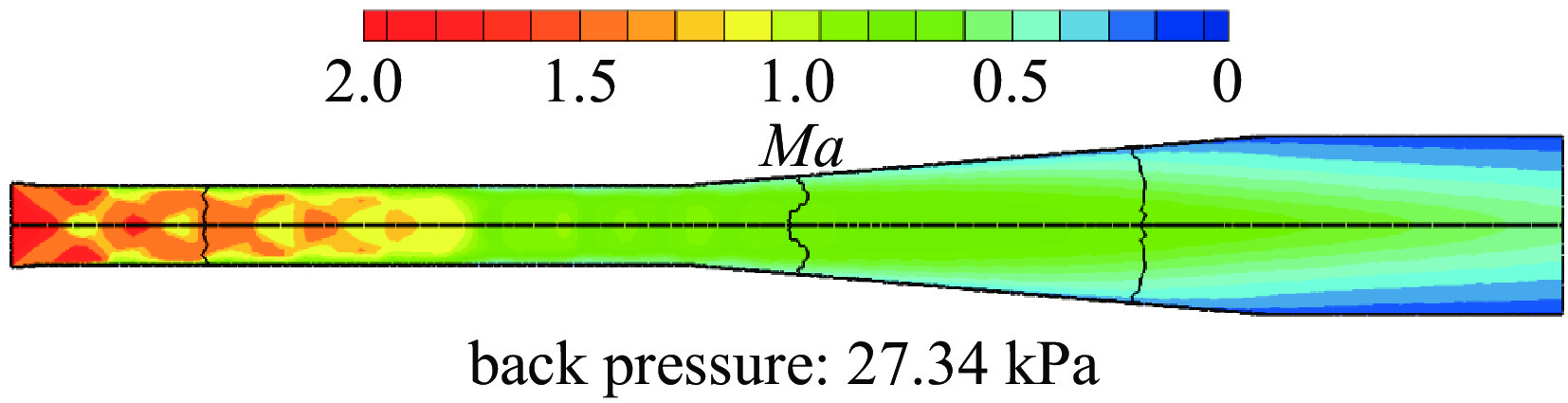

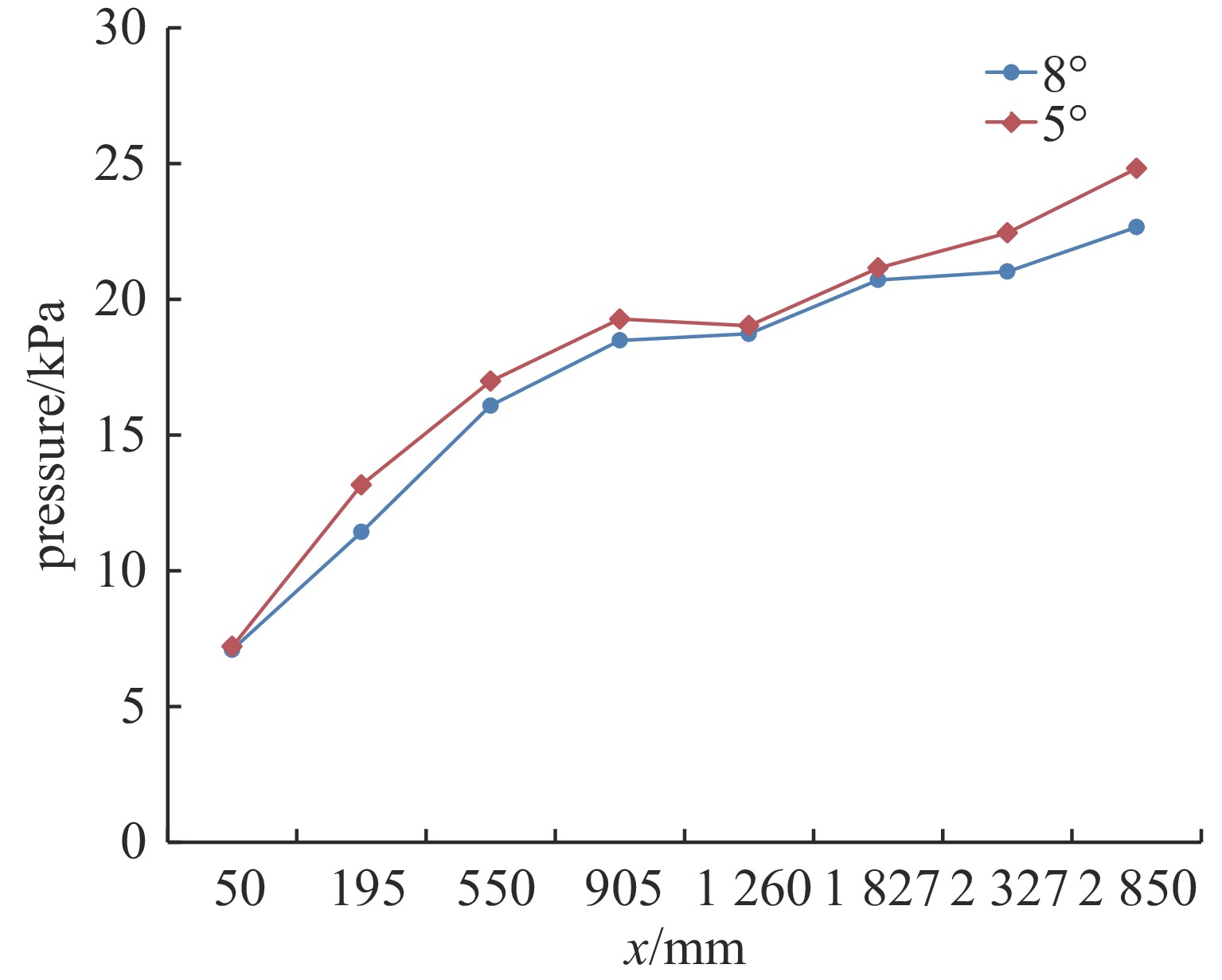

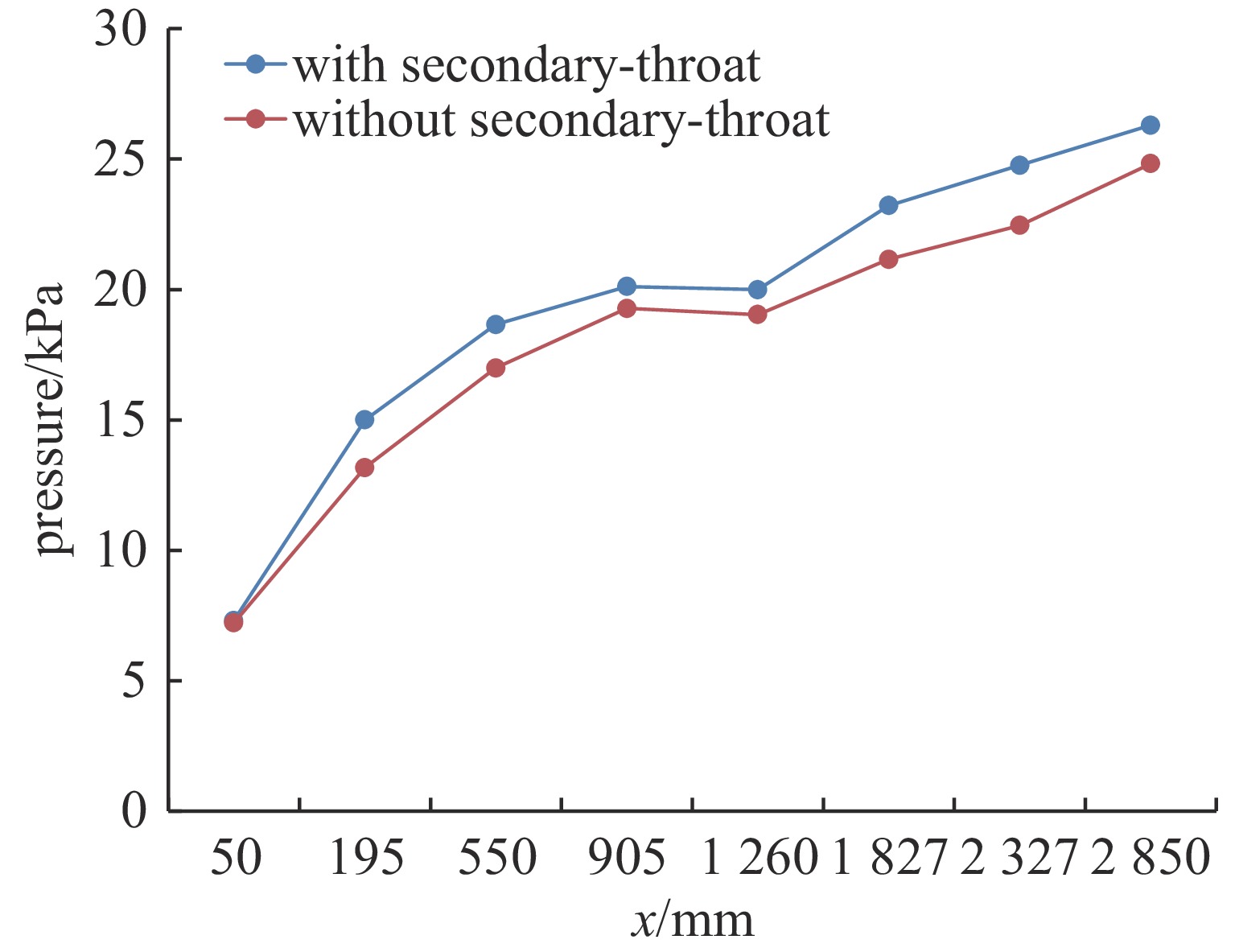

摘要: 在化学激光器的研制中,扩压器压力恢复的研究具有重要的工程应用价值,通过数值模拟结合试验的方式对氟化氘(DF)化学激光器的扩压器进行展开研究,主要针对扩压器的扩张角、结构类型等参数对扩压器性能的影响进行计算分析并进行试验验证。研究结果表明:平直段+8°扩张角的扩压器,抵抗高背压的能力较弱,通过减小扩张角至5°可以有效提高抵抗背压的能力;进一步优化后的超声速二次喉道扩压器能够再次提高扩压器的恢复压力,减小气流的能量损失,提高抗反压特性。针对不同模型的扩压器进行了实验验证,实验结果与数值模拟的结果趋势较一致。Abstract: In development of high-energy chemical laser, the research of diffuser pressure recovery has important engineering application value. In this paper, the diffuser of DF chemical laser is studied by numerical simulation and experiment. The effects of diffuser divergence angle and secondary-throat on diffuser performance are calculated, analyzed and verified by experiments. The results show that the diffuser with 8° divergence angle has weak ability to resist back pressure, and reducing the divergence angle to 5° can effectively improve the ability to resist back pressure. The further optimized supersonic diffuser with secondary-throat can increase the recovery pressure of the diffuser again, reduce the energy loss of the air flow and improve the anti-back pressure characterisitics. At the same time, experimental verification is carried out for different models of diffusers, and the result is consistent with the trend of numerical simulation results.

-

Key words:

- pressure recovery /

- diffuser /

- divergence angle /

- secondary-throat /

- chemical laser

-

表 1 8°扩张角的扩压器静压分布

Table 1. Static pressure distribution along the length of diffuser with 8° expansion

x/mm static pressure under 23.34 kPa back pressure/kPa static pressure under 24.53 kPa back pressure/kPa 25 7.08 10.71 250 8.59 16.25 500 18.88 19.05 750 19.15 20.03 1200 19.15 21.64 1800 23.24 23.8 表 2 5°扩张角的扩压器静压分布

Table 2. Static pressure distribution along the length of diffuser with 5° expansion

x/mm static pressure under 23.34 kPa back pressure/kPa static pressure under 26.67 kPa back pressure/kPa 25 7.07 7.07 250 7.93 12.03 500 8.53 18.13 750 10.2 20.76 1200 16.36 21.77 1800 19.56 24.29 2200 21.99 25.87 2500 22.85 26.64 表 3 背压试验

Table 3. Back pressure tests

back pressure/kPa pressure of laser cavity/kPa x=24 mm x=98 mm x=138 mm 1.36 4.17 5.75 7.01 13.19 4.04 5.33 6.65 17.08 4.03 5.6 7 20.63 4.13 5.71 6.96 21.8 4 5.48 6.72 -

[1] 格罗斯 R W F, 博特 J F. 化学激光手册[M]. 尹厚明, 译. 北京: 科学出版社, 1987Gross R W F, Bott J F. Hand book of chemical laser[M]. Yin Houming, trans. Beijing: Science Press, 1987 [2] 左克罗 M J, 霍夫曼 J D. 气体动力学[M]. 王汝涌, 吴宗真, 吴宗善, 等, 译. 北京: 国防工业出版社, 1984Zucrow M J, Hoffman J D. Gas dynamics[M]. Wang Ruyong, Wu Zongzhen, Wu Zongshan, et al, trans. Beijing: National Defense Industry Press, 1984 [3] Driscoll R J, Moon L F. Pressure recovery in chemical lasers[J]. AIAA Journal, 1977, 15(5): 665-673. doi: 10.2514/3.7354 [4] Merkli P E. Pressure recovery in rectangular constant area supersonic diffusers[J]. AIAA Journal, 1976, 14(2): 168-172. doi: 10.2514/3.61352 [5] White W B, Johnson S M, Dantzig G B. Chemical equilibrium in complex mixtures[J]. The Journal of Chemical Physics, 1958, 28(5): 751-755. doi: 10.1063/1.1744264 [6] 陈吉明, 任玉新. 压力恢复系统扩压器激波串现象的数值模拟[J]. 空气动力学学报, 2008, 26(3):304-309 doi: 10.3969/j.issn.0258-1825.2008.03.006Chen Jiming, Ren Yuxin. Numerical simulation to the pseudo-shock of the supersonic diffuser in the pressure recovery system[J]. Acta Aerodynamica Sinica, 2008, 26(3): 304-309 doi: 10.3969/j.issn.0258-1825.2008.03.006 [7] 童华, 孙启志, 张绍武. 高超声速风洞扩压器试验研究与分析[J]. 实验流体力学, 2014, 28(3):78-81,103 doi: 10.11729/syltlx20120201Tong Hua, Sun Qizhi, Zhang Shaowu. Investigation and analyse on the diffuser of hypersonic wind tunnel[J]. Journal of Experiments in Fluid Mechanics, 2014, 28(3): 78-81,103 doi: 10.11729/syltlx20120201 [8] 蔡光明, 刘军, 王永振, 等. 二次喉道扩压器对COIL的影响实验[J]. 强激光与粒子束, 2005, 17(12):1807-1811Cai Guangming, Liu Jun, Wang Yongzhen, et al. Experimentall study on influence of secondary-throat diffuser on COIL[J]. High Power Laser and Particle Beams, 2005, 17(12): 1807-1811 [9] 李金雪, 王杰, 颜飞雪, 等. DF化学激光器扩压器流场仿真及优化[J]. 强激光与粒子束, 2018, 30:101002 doi: 10.11884/HPLPB201830.180113Li Jinxue, Wang Jie, Yan Feixue, et al. Simulation and optimization of DF chemical lasers’ diffuser[J]. High Power Laser and Particle Beams, 2018, 30: 101002 doi: 10.11884/HPLPB201830.180113 [10] 李金雪, 颜飞雪, 王植杰. 可模拟不同背压环境的直排型扩压器装置[J]. 强激光与粒子束, 2020, 32:071003 doi: 10.11884/HPLPB202032.190474Li Jinxue, Yan Feixue, Wang Zhijie. Diffuser that can simulate different background pressure[J]. High Power Laser and Particle Beams, 2020, 32: 071003 doi: 10.11884/HPLPB202032.190474 [11] 李金雪, 任晓明, 郭洲, 等. 化学激光器扩压器启动特性研究[J]. 强激光与粒子束, 2022, 34:031008 doi: 10.11884/HPLPB202234.210273Li Jinxue, Ren Xiaoming, Guo Zhou, et al. Study of diffuser’s start up property in chemical lasers[J]. High Power Laser and Particle Beams, 2022, 34: 031008 doi: 10.11884/HPLPB202234.210273 [12] 余真, 李守先, 陈栋泉. 喷管、光腔及压力恢复系统一体化设计[J]. 强激光与粒子束, 2007, 19(4):533-537Yu Zhen, Li Shouxian, Chen Dongquan. Integrative design of nozzle, cavity and pressure recovery system[J]. High Power Laser and Particle Beams, 2007, 19(4): 533-537 [13] 符澄, 彭强, 刘卫龙, 等. 光腔与扩压器的一体化优化数值模拟[J]. 强激光与粒子束, 2014, 26:111003 doi: 10.11884/HPLPB201426.111003Fu Cheng, Peng Qiang, Liu Weilong, et al. Integrative optimization numerical simulation of cavity and diffuser[J]. High Power Laser and Particle Beams, 2014, 26: 111003 doi: 10.11884/HPLPB201426.111003 [14] 陈吉明, 彭强, 廖达雄. 压力恢复系统扩压器性能初步研究[J]. 强激光与粒子束, 2007, 19(8):1266-1270Chen Jiming, Peng Qiang, Liao Daxiong. Performance of supersonic diffuser in pressure recovery system[J]. High Power Laser and Particle Beams, 2007, 19(8): 1266-1270 [15] 李桦, 范晓樯, 丁猛. 超声速扩压器中激波串结构的数值模拟[J]. 国防科技大学学报, 2002, 24(1):18-21 doi: 10.3969/j.issn.1001-2486.2002.01.005Li Hua, Fan Xiaoqiang, Ding Meng. Numerical simulatiom of the shock train structure in the supersonic diffuser[J]. Journal of National University of Defense Technology, 2002, 24(1): 18-21 doi: 10.3969/j.issn.1001-2486.2002.01.005 -

下载:

下载: