Research progress of femtosecond laser precision machining technology for precision experiment

-

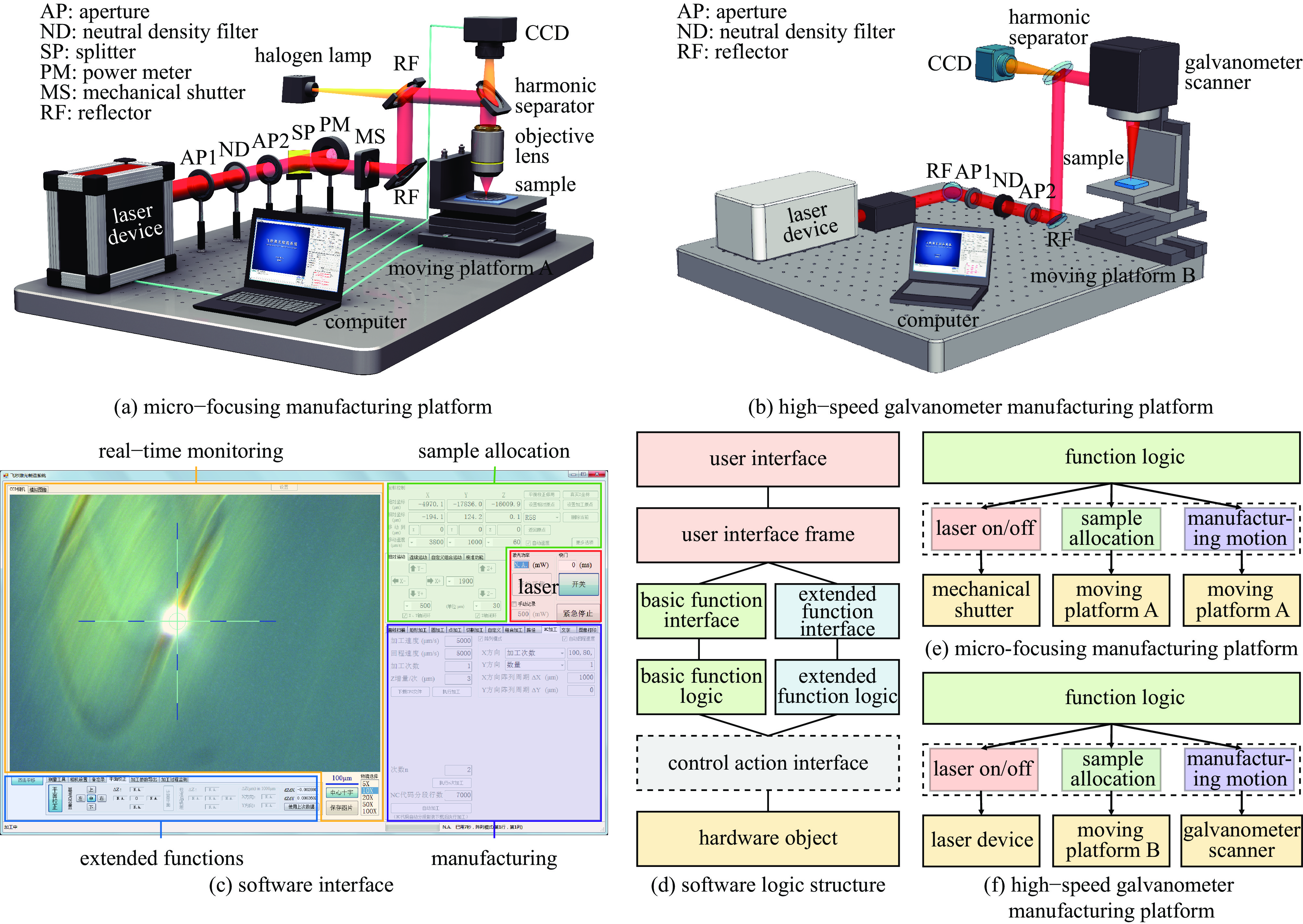

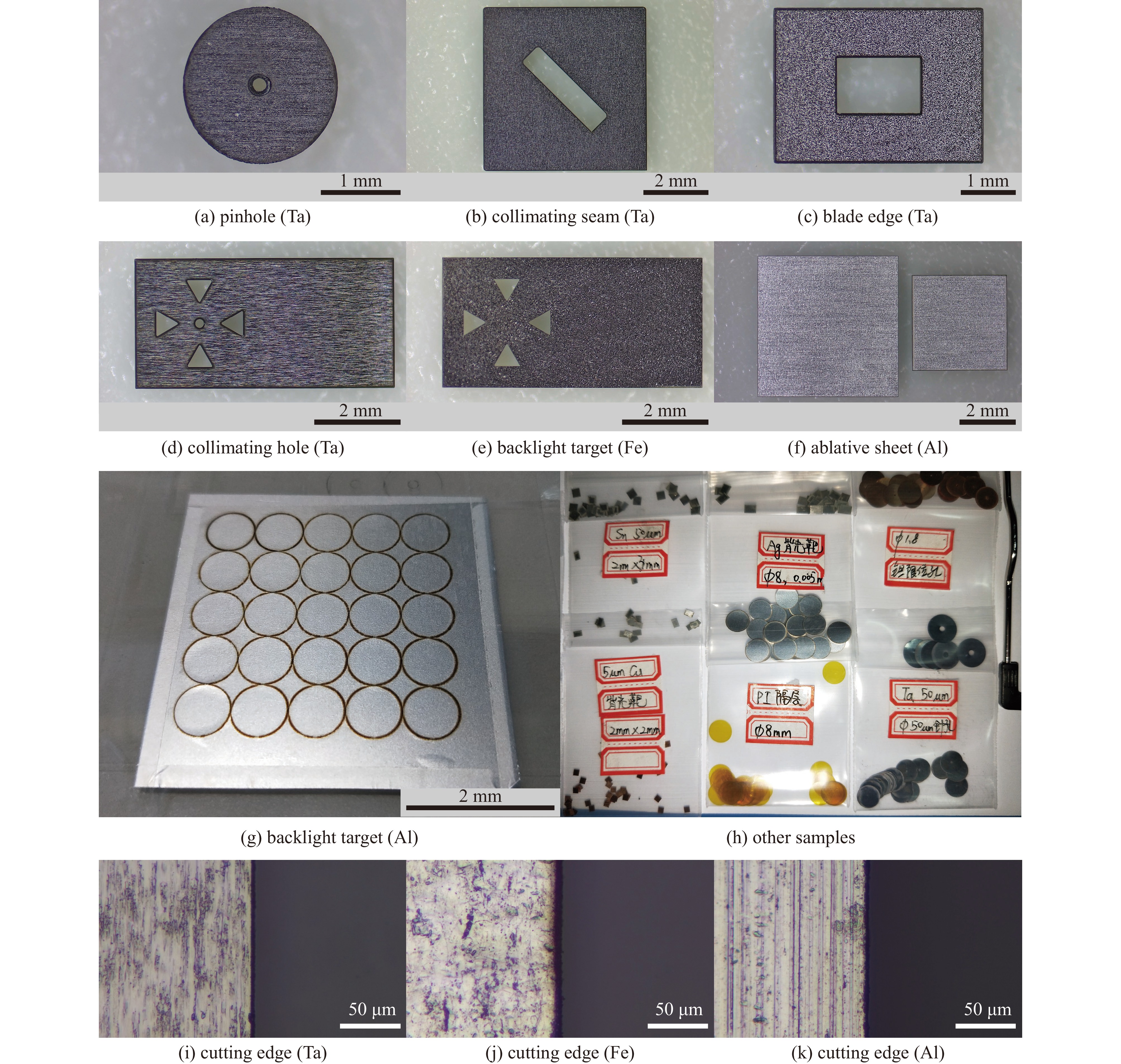

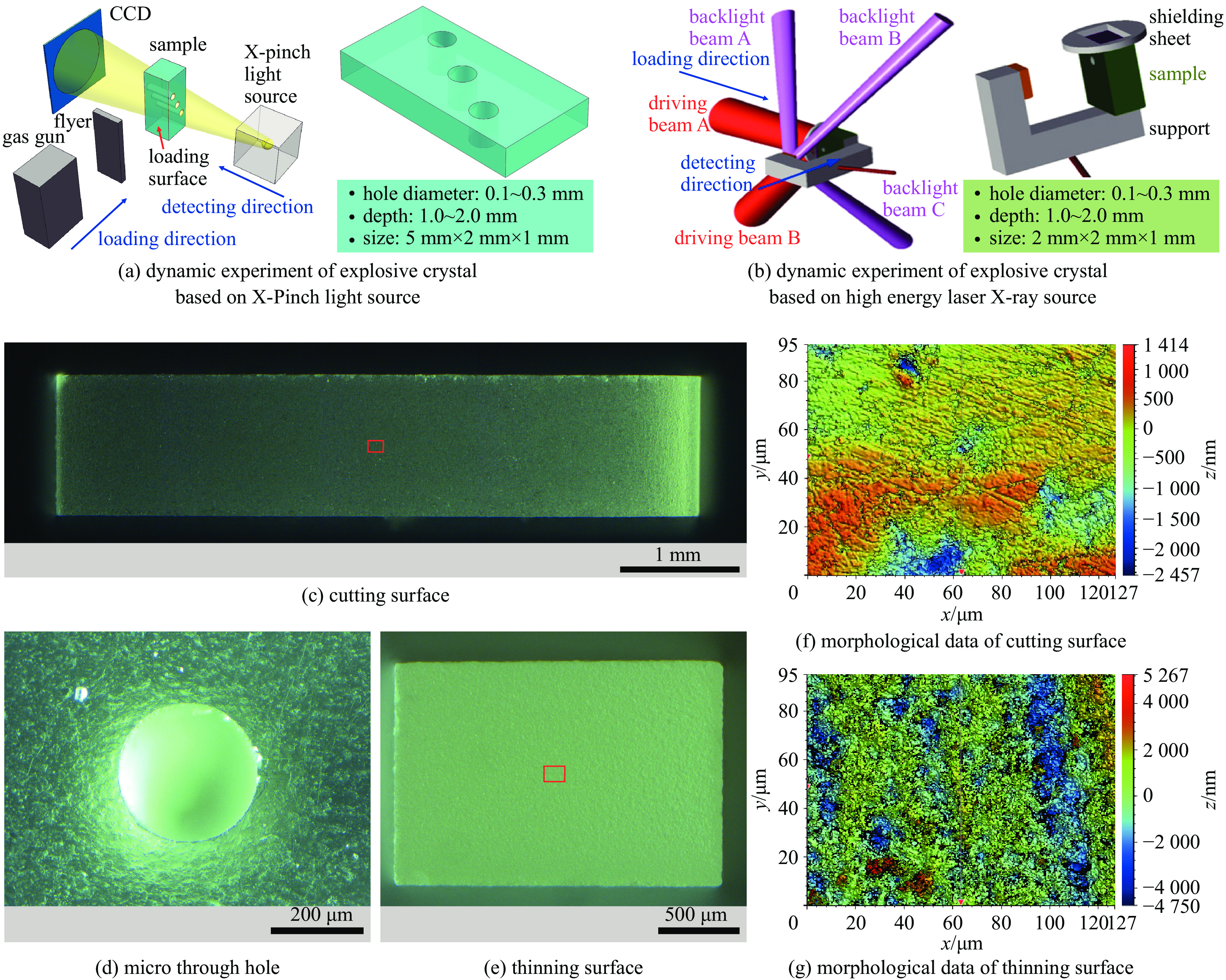

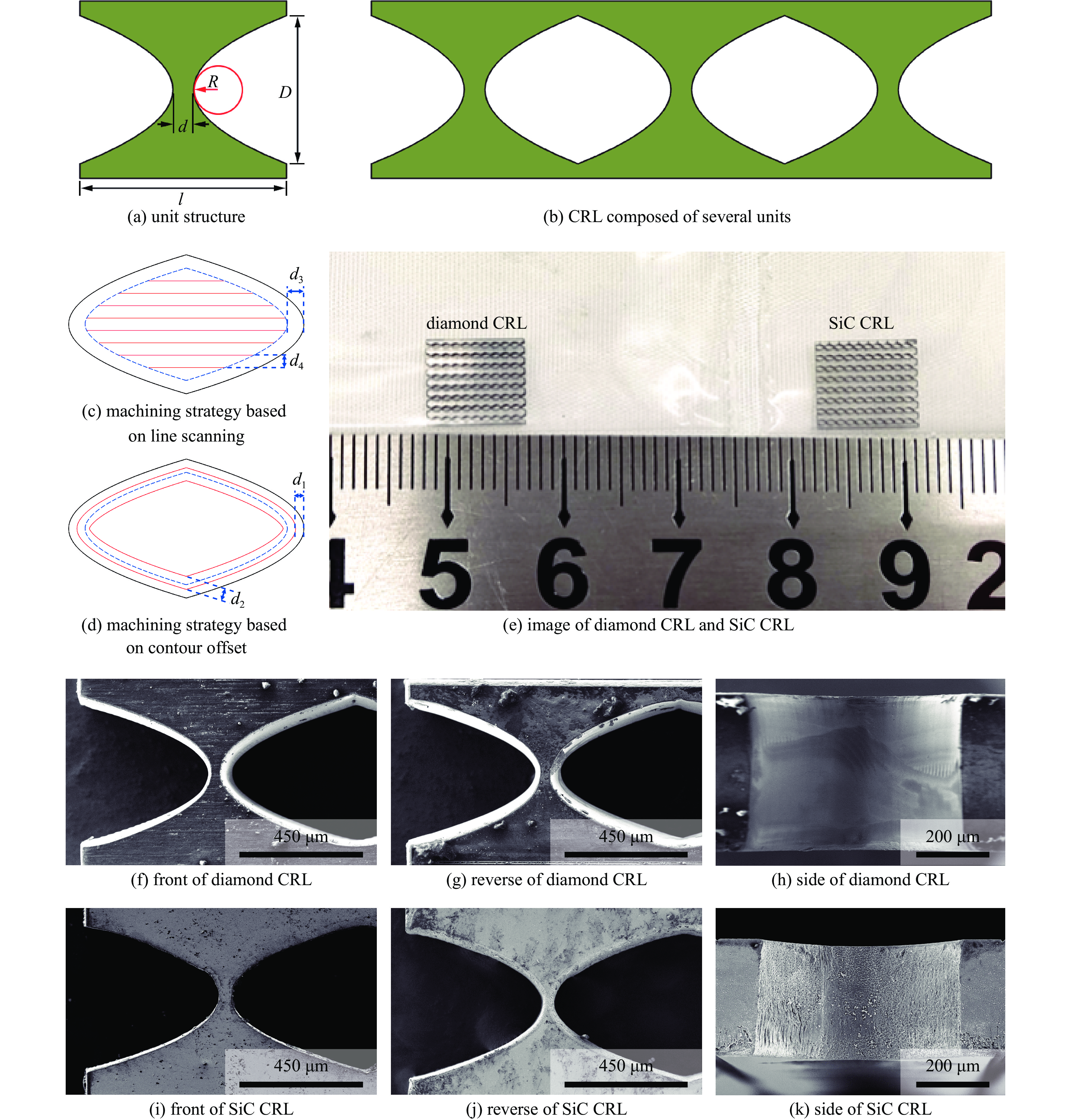

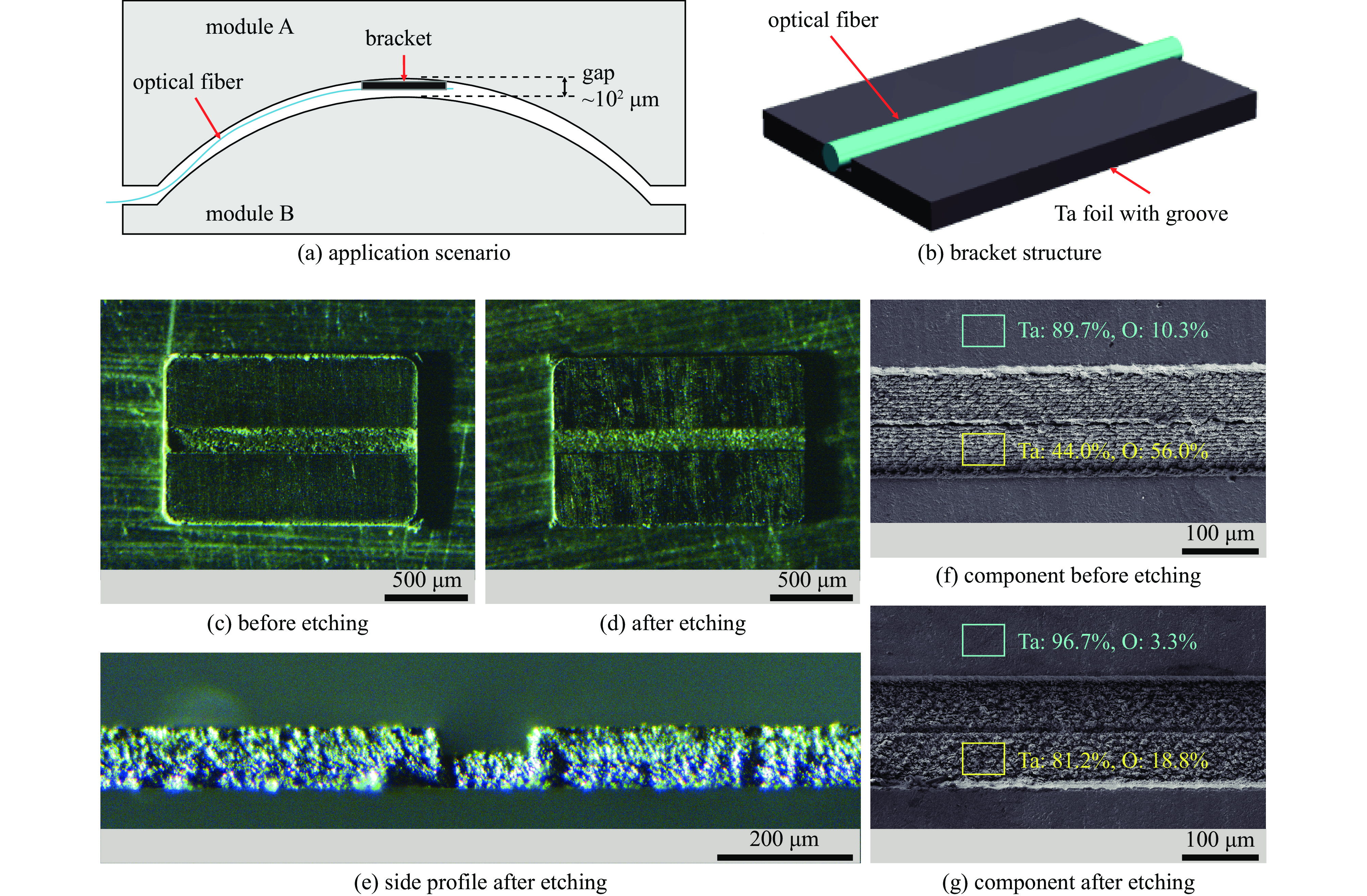

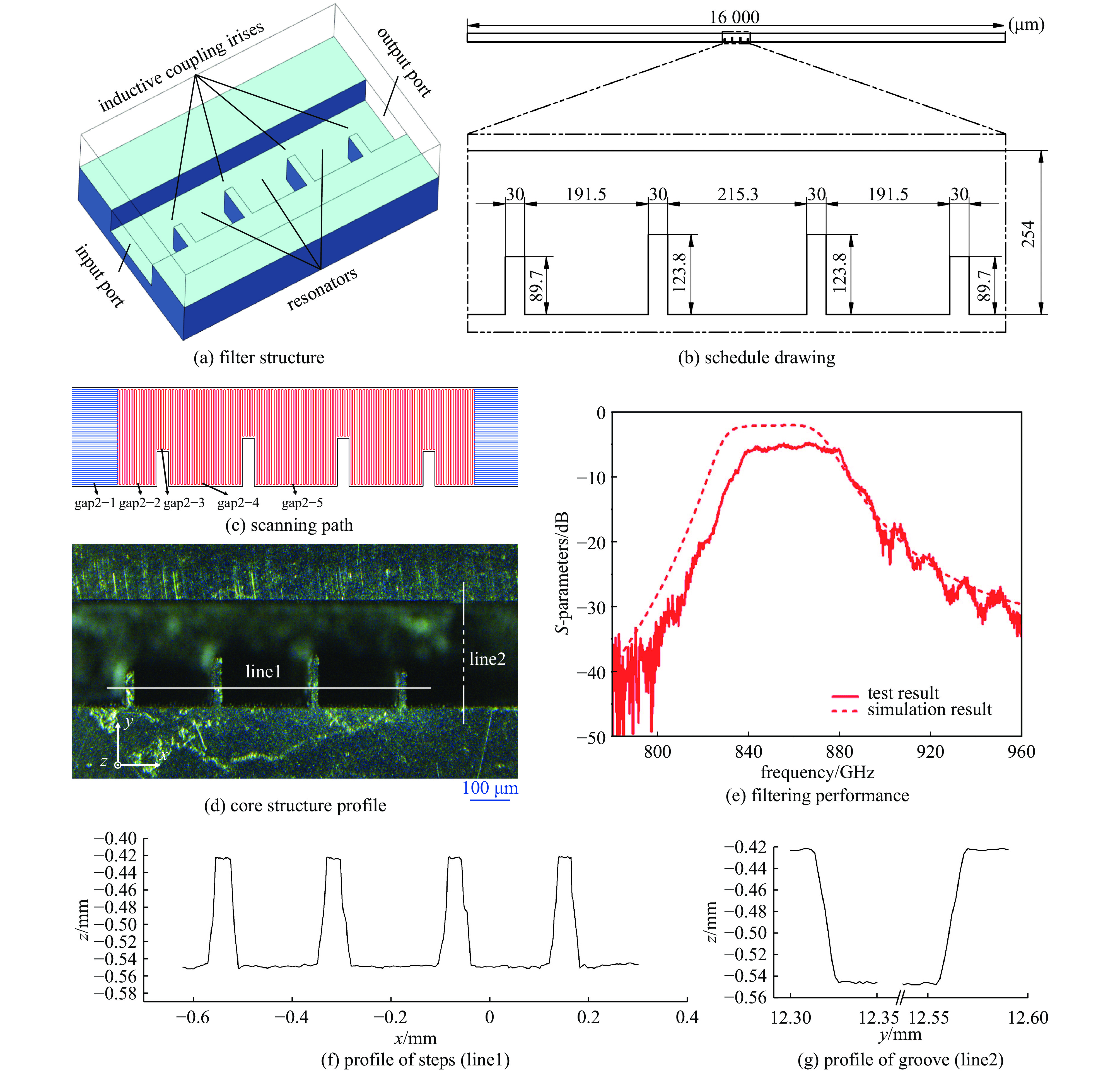

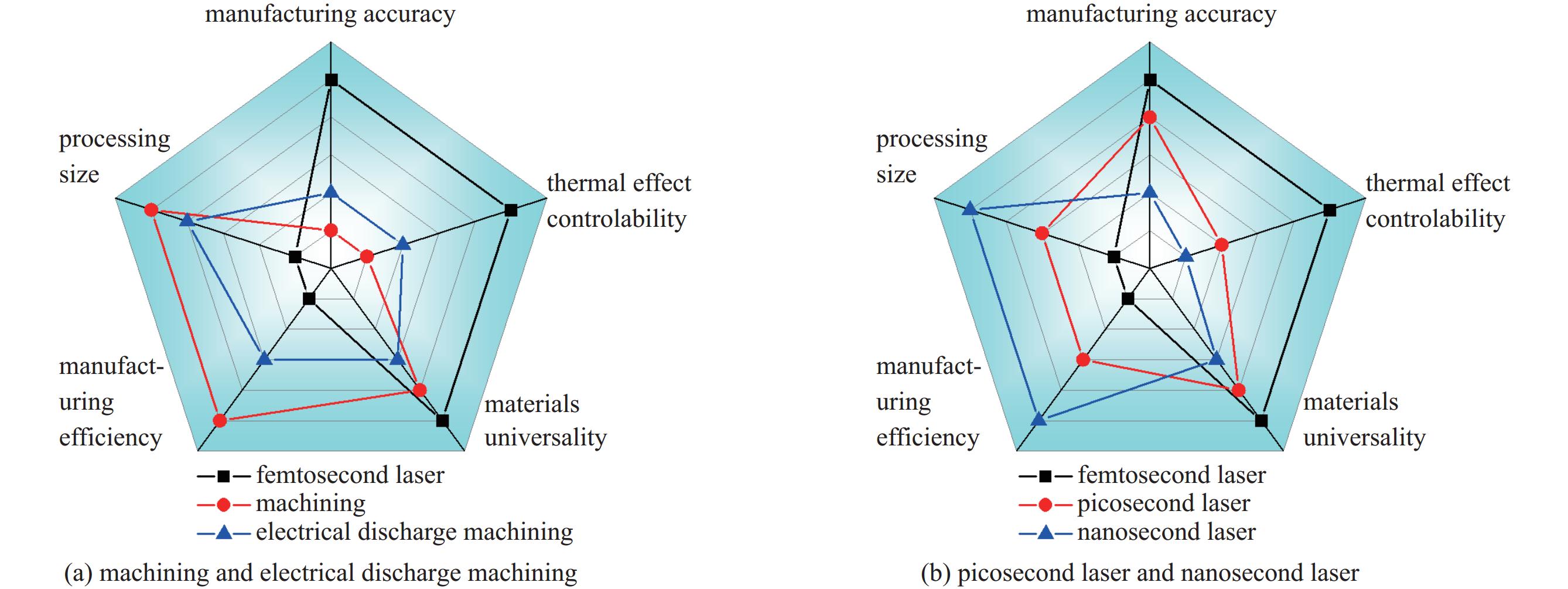

摘要: 飞秒激光精密加工技术具备极短脉冲宽度避免或缓解热效应、极高峰值功率密度适用于任意固体材料、极小焦斑尺寸实现微区精准去除或改性等三个方面的特性,满足精密诊断/测量实验涉及的各类难加工及特种材料的安全精密加工需求。高稳定性高重复频率飞秒激光器的应用,弥补了低重复频率飞秒激光难以实现高速扫描的不足,这为精密实验所需各类精密样品/样件的高效精密加工提供了重要能量源。以中国工程物理研究院各研究所精密实验对精密样品的安全高效精密加工需求为切入点,分别以激光X射线精密靶材及结构、炸药材料微结构、超硬材料复合折射透镜结构、微型探头光纤精密固定结构、太赫兹滤波器核心结构等典型应用场景为例,介绍了高重频飞秒激光精密加工技术在难加工材料和特种材料安全高效精密加工方面的研究进展。Abstract: Femtosecond laser precision machining technology has three characteristics: extremely short duration time to avoid or alleviate thermal effects, extremely high peak power density suitable for any solid material and extremely small focal spot size to achieve precise removal or modification of micro areas, meeting the safety and precision machining needs of various difficult to machine and special materials involved in precision diagnosis/measurement experiments. The application of high stability and high repetition rate femtosecond lasers fills in the gap of low repetition rate femtosecond lasers that cannot achieve high-speed scanning, providing an important energy source for efficient and precise processing of various precision samples/specimens required for precision diagnosis/measurement experiments. This article takes the precision diagnosis/measurement experiments of various institutes of China Academy of Engineering Physics as the starting point for safe, efficient and precise processing requirements of precision samples/specimens. Taking typical application scenarios such as laser X-ray precision target materials and structures, explosive material microstructures, superhard material composite refractive lens structures, micro probe fiber precision fixed structures, and terahertz filter core structures as examples, it introduces the research progress of high-frequency femtosecond laser precision processing technology in the safe, efficient and precise processing of difficult to-machine materials and special materials.

-

Key words:

- femtosecond laser /

- precision machining /

- metallic materials /

- explosive materials /

- superhard materials

-

表 1 抛物柱孔型碳化硅和金刚石复合折射透镜的几何结构参数

Table 1. Geometric structural parameters of parabolic column hole SiC CRL and diamond CRL

opening diameter

D/μmvertex interval

d/μmlength of lens

unit l/μmradius of curvature

at vertex R/μmnumber of lens

units Nrefractive index phase

factor δ@E=12 keVfocal length

f/mdiamond CRL 500 50 900 73.5 9 5.07×10−6 0.807 SiC CRL 500 50 900 73.5 9 4.66×10−6 0.876 -

[1] Daido H, Nishiuchi M, Pirozhkov A S. Review of laser-driven ion sources and their applications[J]. Reports on Progress in Physics, 2012, 75: 056401. doi: 10.1088/0034-4885/75/5/056401 [2] Nieto-Fuentes J C, Virazels T, Jacques N, et al. Gas gun driven dynamic expansion of 3D-printed AlSi10Mg rings[J]. International Journal of Impact Engineering, 2023, 180: 104556. doi: 10.1016/j.ijimpeng.2023.104556 [3] 宋力, 钟东海. 标准霍普金森压杆配置下的应力波分离及无时限实验数据处理[J]. 爆炸与冲击, 2023, 43:124101Song Li, Zhong Donghai. Stress wave separation based on standard Hopkinson pressure bar set-up and unlimited duration of experiment data processing[J]. Explosion and Shock Waves, 2023, 43: 124101 [4] Davis K M, Miura K, Sugimoto N, et al. Writing waveguides in glass with a femtosecond laser[J]. Optics Letters, 1996, 21(21): 1729-1731. doi: 10.1364/OL.21.001729 [5] Yong Jiale, Chen Feng, Yang Qing, et al. Superoleophobic surfaces[J]. Chemical Society Reviews, 2017, 46(14): 4168-4217. doi: 10.1039/C6CS00751A [6] 潘瑞, 钟敏霖. 超快激光制备超疏水超亲水表面及超疏水表面机械耐久性[J]. 科学通报, 2019, 64(12):1268-1289 doi: 10.1360/N972019-00009Pan Rui, Zhong Minlin. Fabrication of superwetting surfaces by ultrafast lasers and mechanical durability of superhydrophobic surfaces[J]. Chinese Science Bulletin, 2019, 64(12): 1268-1289 doi: 10.1360/N972019-00009 [7] 雍佳乐, 吴东. 飞秒激光仿生调控材料表面浸润性: 当前进展与挑战(特邀)[J]. 中国激光, 2024, 51:0102002 doi: 10.3788/CJL231364Yong Jiale, Wu Dong. Bioinspired controlling the surface wettability of materials by femtosecond laser: current progress and challenges (invited)[J]. Chinese Journal of Lasers, 2024, 51: 0102002 doi: 10.3788/CJL231364 [8] Marcinkevičius A, Juodkazis S, Watanabe M, et al. Femtosecond laser-assisted three-dimensional microfabrication in silica[J]. Optics Letters, 2001, 26(5): 277-279. doi: 10.1364/OL.26.000277 [9] Kiyama S, Matsuo S, Hashimoto S, et al. Examination of etching agent and etching mechanism on femotosecond laser microfabrication of channels inside vitreous silica substrates[J]. The Journal of Physical Chemistry C, 2009, 113(27): 11560-11566. doi: 10.1021/jp900915r [10] Sun Ke, Tan Dezhi, Fang Xinyuan, et al. Three-dimensional direct lithography of stable perovskite nanocrystals in glass[J]. Science, 2022, 375(6578): 307-310. doi: 10.1126/science.abj2691 [11] 黄彩丽, 蒋麒, 蔺晓超, 等. GH3230高温合金绿光飞秒激光的刻蚀特性[J]. 中国激光, 2023, 50:0802106 doi: 10.3788/CJL220933Huang Caili, Jiang Qi, Lin Xiaochao, et al. Ablation characteristics of GH3230 superalloy using green femtosecond laser[J]. Chinese Journal of Lasers, 2023, 50: 0802106 doi: 10.3788/CJL220933 [12] Li Zhenze, Fan Hua, Wang Lei, et al. Super-stealth dicing of transparent solids with nanometric precision[J]. Nature Photonics, 2024, 18(8): 799-808. doi: 10.1038/s41566-024-01437-8 [13] 班铭霞, 柴兆麟, 王曼诗, 等. 飞秒激光在镍基合金上加工深宽比>20的直孔和倒锥孔[J]. 中国激光, 2024, 51:1801009 doi: 10.3788/CJL240850Ban Mingxia, Chai Zhaolin, Wang Manshi, et al. Femtosecond laser processing of straight and inverted tapered holes with aspect ratio of >20 on nickel-based alloy[J]. Chinese Journal of Lasers, 2024, 51: 1801009 doi: 10.3788/CJL240850 [14] 刘军, 曾志男, 梁晓燕, 等. 超快超强激光及其科学应用发展趋势研究[J]. 中国工程科学, 2020, 22(3):42-48 doi: 10.15302/J-SSCAE-2020.03.007Liu Jun, Zeng Zhinan, Liang Xiaoyan, et al. Development trend of ultrafast and ultraintense lasers and their scientific application[J]. Strategic Study of CAE, 2020, 22(3): 42-48 doi: 10.15302/J-SSCAE-2020.03.007 [15] Sugioka K. Will GHz burst mode create a new path to femtosecond laser processing[J]. International Journal of Extreme Manufacturing, 2021, 3: 043001. doi: 10.1088/2631-7990/ac2479 [16] Zhang Dongshi, Liu Ruijie, Li Zhuguo. Irregular LIPSS produced on metals by single linearly polarized femtosecond laser[J]. International Journal of Extreme Manufacturing, 2022, 4: 015102. doi: 10.1088/2631-7990/ac376c [17] 何煦, 马云灿, 李军, 等. 非平整表面飞秒激光加工方法及应用[J]. 激光与光电子学进展, 2023, 60:1714009He Xu, Ma Yuncan, Li Jun, et al. Method and application of femtosecond laser processing on non-flat surfaces[J]. Laser & Optoelectronics Progress, 2023, 60: 1714009 [18] 郑崇. 飞秒激光内加工三维空腔微结构技术研究[D]. 北京: 北京工业大学, 2016Zheng Chong. 3D internal hollow microstructures manufacturing technology by femto-second laser[D]. Beijing: Beijing University of Technology, 2016 [19] 殷赳. 正前角金刚石端面磨具的飞秒激光制造及其磨削性能研究[D]. 长沙: 湖南大学, 2022Yin Jiu. Femtosecond laser fabrication of diamond grinding tool with positive rake angle and its grinding performance investigation[D]. Changsha: Hunan University, 2022 [20] 袁淦. 基于飞秒激光制备超疏水表面及其应用研究[D]. 长春: 中国科学院大学(中国科学院长春光学精密机械与物理研究所), 2022Yuan Gan. Fabrication of superhydrophobic surfaces by femtosecond laser and its application[D]. Changchun: University of Chinese Academy of Sciences (Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2022 [21] 吴兆奎, 马云灿, 何煦, 等. 基于LabVIEW的超快激光制造系统设计[J]. 强激光与粒子束, 2018, 30:031002 doi: 10.11884/HPLPB201830.170312Wu Zhaokui, Ma Yuncan, He Xu, et al. Design of ultrafast laser manufacturing system based on LabVIEW[J]. High Power Laser and Particle Beams, 2018, 30: 031002 doi: 10.11884/HPLPB201830.170312 [22] 何煦, 孟立民, 马云灿, 等. 高重复频率飞秒激光高效加工硬X射线复合折射透镜[J]. 中国激光, 2024, 51:1602405 doi: 10.3788/CJL231269He Xu, Meng Limin, Ma Yuncan, et al. Efficient fabrication of compound refractive lens for hard X-ray using high-repetition-rate femtosecond laser[J]. Chinese Journal of Lasers, 2024, 51: 1602405 doi: 10.3788/CJL231269 [23] Oliver M, Allen C H, Divol L, et al. Diffraction enhanced imaging utilizing a laser produced X-ray source[J]. Review of Scientific Instruments, 2022, 93: 093502. doi: 10.1063/5.0091348 [24] 王洪建, 冯永祯, 罗笔瀚, 等. 强激光加载下金属材料微喷诊断实验研究进展[J]. 强激光与粒子束, 2023, 35:101001 doi: 10.11884/HPLPB202335.230225Wang Hongjian, Feng Yongzhen, Luo Bihan, et al. Progress of experimental research on micro-ejection diagnosis of metal materials under intense laser loading[J]. High Power Laser and Particle Beams, 2023, 35: 101001 doi: 10.11884/HPLPB202335.230225 [25] Tian Chao, Yu Minghai, Shan Lianqiang, et al. Diagnosis of indirectly driven double shell targets with point-projection hard X-ray radiography[J]. Matter and Radiation at Extremes, 2024, 9: 027602. doi: 10.1063/5.0045112 [26] Duarte C A, Hamed A, Drake J D, et al. Void collapse in shocked-HMX single crystals: simulations and experiments[J]. Propellants, Explosives, Pyrotechnics, 2020, 45(2): 243-253. doi: 10.1002/prep.201900251 [27] 白志玲, 段卓平, 黄风雷. 高聚物粘结炸药冲击起爆统计热点反应速率模型[J]. 兵工学报, 2021, 42(11):2379-2387Bai Zhiling, Duan Zhuoping, Huang Fenglei. A statistical hot spot reaction rate model for shock initiation of PBX[J]. Acta Armamentarii, 2021, 42(11): 2379-2387 [28] 刘纯, 欧卓成, 段卓平, 等. 动态加载下高聚物粘结炸药中椭圆孔洞坍塌引起的热点温度及其半经验解析表达[J]. 兵工学报, 2022, 43(1):57-68Liu Chun, Ou Zhuocheng, Duan Zhuoping, et al. Hot spot temperature resulting from elliptical void collapse in PBX under dynamic loading and its semi-empirical analytical expression[J]. Acta Armamentarii, 2022, 43(1): 57-68 [29] Blum-Sorensen C J, Duarte C A, Drake J D, et al. Phase contrast X-ray imaging of the collapse of an engineered void in single-crystal HMX[J]. Propellants, Explosives, Pyrotechnics, 2022, 47: e202100297. doi: 10.1002/prep.202100297 [30] 郑贤旭, 王荣波, 谭多望, 等. 蓝宝石内部缺陷点在冲击压缩下的热点效应[J]. 火炸药学报, 2009, 32(3):12-15Zheng Xianxu, Wang Rongbo, Tan Duowang, et al. Hot spot effect of local defects in shocked sapphire crystal[J]. Chinese Journal of Explosives & Propellants, 2009, 32(3): 12-15 [31] 傅华, 赵峰, 谭多望, 等. 冲击作用下HMX晶体孔洞塌缩热点生成机制的细观数值模拟[J]. 高压物理学报, 2011, 25(1):8-14Fu Hua, Zhao Feng, Tan Duowang, et al. Mesoscale simulation of cavity collapse hot spot mechanism in HMX under shock loading[J]. Chinese Journal of High Pressure Physics, 2011, 25(1): 8-14 [32] Ma Xiao, Li Xinguo, Zheng Xianxu, et al. Weak shock loadings induce potential hot spots formation around an intergranular pore[J]. Journal of Applied Physics, 2017, 121: 115102. doi: 10.1063/1.4978355 [33] Ma Xiao, Zhang Kun, Shang Hailin, et al. Measuring crack growth and rise in temperature around a cylindrical defect in explosive simulants under low-pressure and long-pulse loadings[J]. Propellants, Explosives, Pyrotechnics, 2020, 45(10): 1654-1661. doi: 10.1002/prep.202000057 [34] Mirkarimi P B, Moua Y, Pease S T, et al. Fracture toughness and crack propagation in LX-17 and PBX 9502 insensitive high explosives[J]. International Journal of Solids and Structures, 2022, 250: 111721. doi: 10.1016/j.ijsolstr.2022.111721 [35] 李亮亮, 屈可朋, 沈飞, 等. 基于霍普金森压杆的RDX基含铝炸药装药双脉冲加载实验[J]. 火炸药学报, 2018, 41(1):52-56Li Liangliang, Qu Kepeng, Shen Fei, et al. Double-pulse loading experiment of RDX based aluminized explosive charge based on Hopkinson pressure bar[J]. Chinese Journal of Explosives & Propellants, 2018, 41(1): 52-56 [36] 伍俊英, 刘嘉锡, 杨利军, 等. 不同频率飞秒激光脉冲序列加工炸药过程安全性的数值计算[J]. 含能材料, 2021, 29(3):192-201Wu Junying, Liu Jiaxi, Yang Lijun, et al. Numerical calculation of the safety of processing explosives with femtosecond laser sequence with different frequencies[J]. Chinese Journal of Energetic Materials, 2021, 29(3): 192-201 [37] 刘嘉锡, 伍俊英, 杨利军, 等. 单脉冲飞秒激光烧蚀炸药过程的热效应研究[J]. 强激光与粒子束, 2020, 32:071007 doi: 10.11884/HPLPB202032.200061Liu Jiaxi, Wu Junying, Yang Lijun, et al. Analysis of thermal effect on explosives of single-pulse femtosecond laser ablation[J]. High Power Laser and Particle Beams, 2020, 32: 071007 doi: 10.11884/HPLPB202032.200061 [38] White W E, Robert A, Dunne M. The linac coherent light source[J]. Journal of Synchrotron Radiation, 2015, 22(3): 472-476. doi: 10.1107/S1600577515005196 [39] Zhao Zhentang, Wang Dong, Gu Qiang, et al. Status of the SXFEL facility[J]. Applied Sciences, 2017, 7: 607. doi: 10.3390/app7060607 [40] 贾豪彦, 黄森林, 焦毅, 等. 超快X射线自由电子激光研究进展[J]. 强激光与粒子束, 2022, 34:054001 doi: 10.11884/HPLPB202234.220056Jia Haoyan, Huang Senlin, Jiao Yi, et al. Research advances in ultrafast X-ray free-electron lasers[J]. High Power Laser and Particle Beams, 2022, 34: 054001 doi: 10.11884/HPLPB202234.220056 [41] 孟立民, 何煦, 马云灿, 等. 金刚石复合折射透镜的设计及加工初探[J]. 应用光学, 2023, 44(6):1273-1279 doi: 10.5768/JAO202344.0610015Meng Limin, He Xu, Ma Yuncan, et al. Preliminary study on design and processing of diamond compound refractive lens[J]. Journal of Applied Optics, 2023, 44(6): 1273-1279 doi: 10.5768/JAO202344.0610015 [42] Pikuz S A, Shelkovenko T A, Hammer D A. X-pinch. Part I[J]. Plasma Physics Reports, 2015, 41(4): 291-342. doi: 10.1134/S1063780X15040054 [43] Ryu J, Ham S, Lee J, et al. A modular X-pinch device for versatile X-pinch experiments at Seoul National University[J]. Review of Scientific Instruments, 2021, 92: 053533. doi: 10.1063/5.0041306 [44] Ham S, Ryu J, Lee H, et al. Estimation of plasma parameters of X-pinch with time-resolved X-ray spectroscopy[J]. Matter and Radiation at Extremes, 2023, 8: 036901. doi: 10.1063/5.0131369 [45] 何煦, 杨昊, 马云灿, 等. 高重频飞秒激光高效加工太赫兹滤波器核心结构[J]. 应用光学, 2024, 45(3):514-521 doi: 10.5768/JAO202445.0310004He Xu, Yang Hao, Ma Yuncan, et al. Core structure of terahertz filter fabricated by femtosecond laser with high repetition rate[J]. Journal of Applied Optics, 2024, 45(3): 514-521 doi: 10.5768/JAO202445.0310004 [46] 李毅. 高重复频率飞秒激光微纳加工中热效应的研究及应用[D]. 天津: 天津大学, 2012Li Yi. Heat accumulation in high repetition rate femtosecond laser micromachining and its applications[D]. Tianjin: Tianjin University, 2012 [47] 邱一, 刘壮, 李元成, 等. 飞秒激光扫描去除CFRP复合材料的热累积分析[J]. 应用激光, 2021, 41(5):1004-1010Qiu Yi, Liu Zhuang, Li Yuancheng, et al. Investigation of heat accumulation in scanning ablation of CFRP composite using femtosecond laser[J]. Applied Laser, 2021, 41(5): 1004-1010 -

下载:

下载: