Research on the method of removing bubbles from water in closed chamber

-

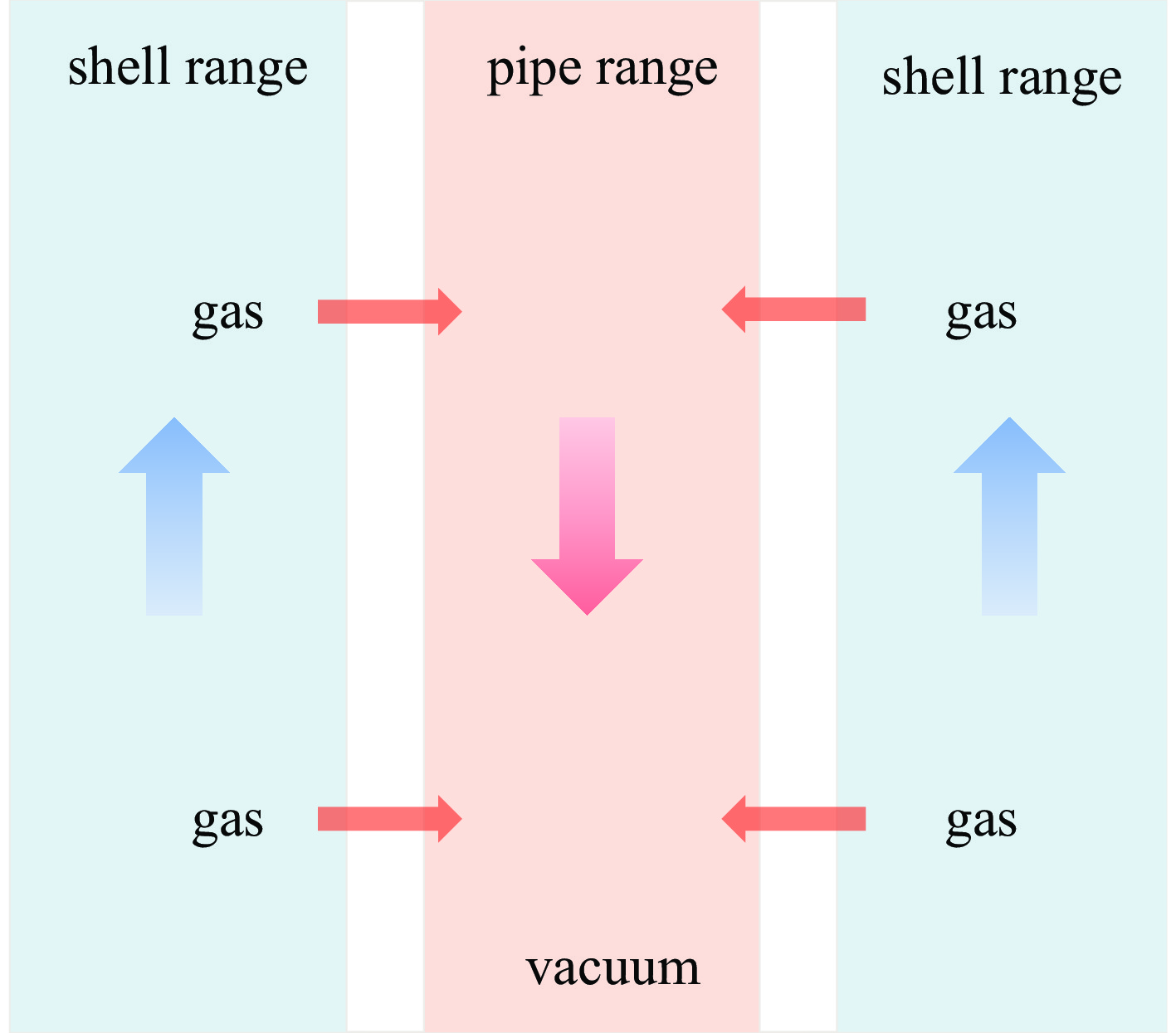

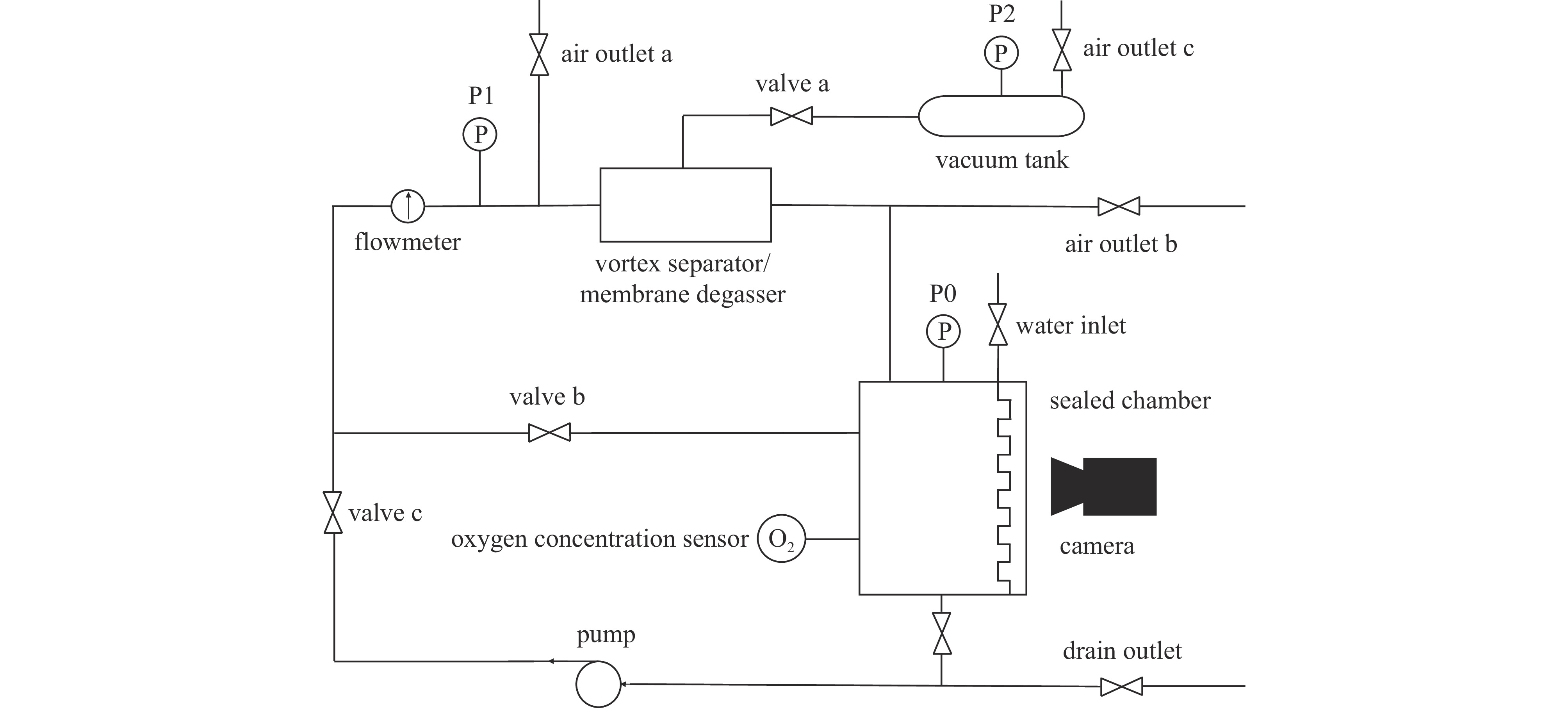

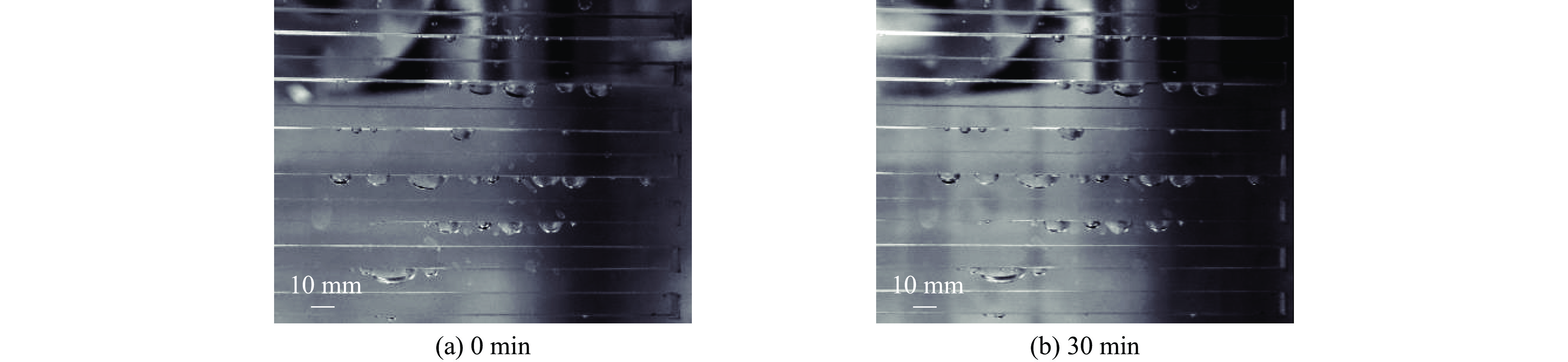

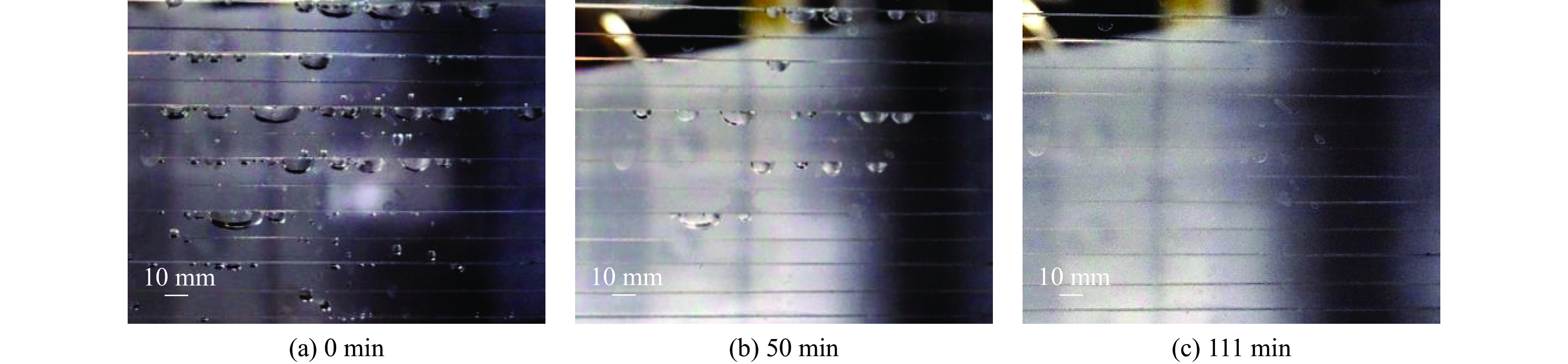

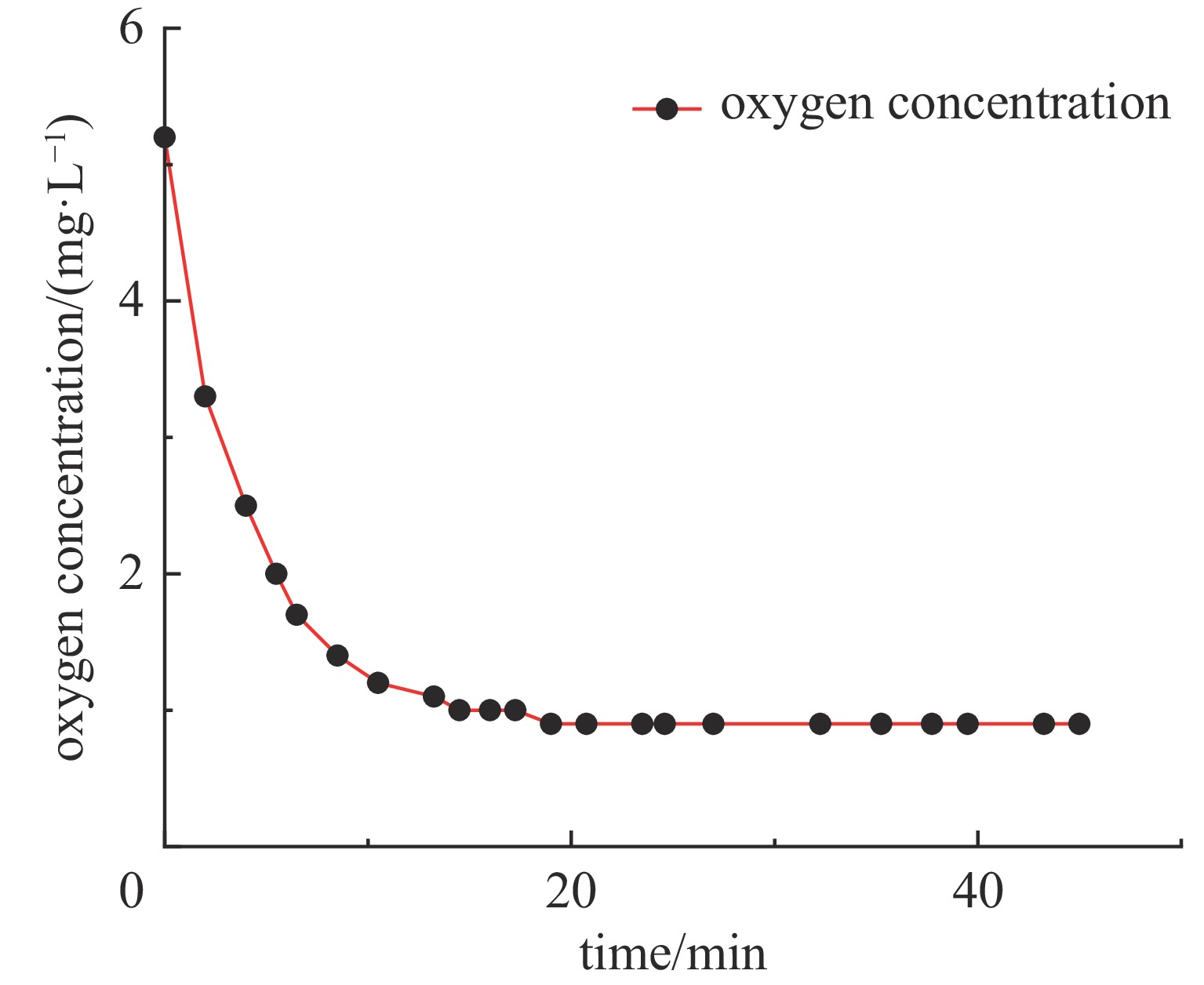

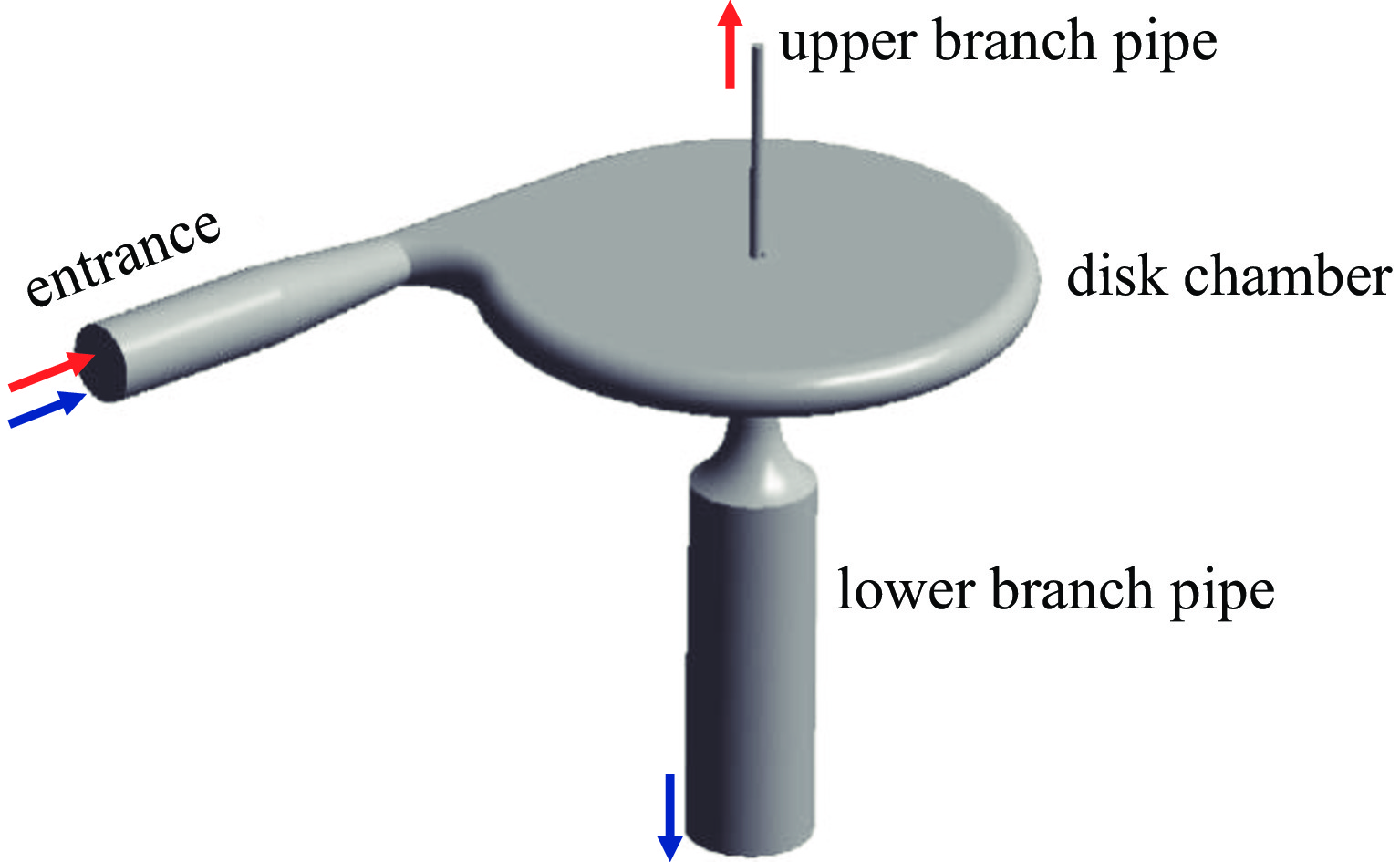

摘要: 水介质的绝缘性能影响脉冲功率装置的运行状态,水中气泡是引起水介质击穿的主要因素。为去除水介质中的气泡和溶解性气体,分析了水介质中产生气泡的原因,针对水介质中的体相气泡和表面吸附气泡去除问题,比较了涡流式分离器和反渗透膜的脱气方法,并对其气泡脱除性能进行实验研究。研究结果表明,涡流式分离器的旋流强度低造成分离效率较低,反渗透膜脱气通过降低气体在水中的溶解度使得表面吸附气泡重新溶解,分离效率较高,可以去除水中气泡和溶解性气体,对脉冲功率装置的稳定运行具有重要意义。Abstract: The insulating property of water medium affects the operation status of pulse power device, and air bubbles in water are the main factor causing breakdown of water medium. In order to remove air bubbles and dissolved gases in the water medium, the causes of air bubbles in the water medium are analyzed, and for the removal of body-phase air bubbles and surface adsorption air bubbles in the water medium, the methods of removing air bubbles by using vortex separators and reverse osmosis membranes are compared, and experimental research is carried out to study the performance of their air bubble removal. The results show that the vortex separator's low cyclonic strength leads to low separation efficiency, and the reverse osmosis membrane degassing makes the surface adsorbed bubbles re-dissolve by reducing the solubility of the gas in the water, and the separation efficiency is high, which can remove the gas bubbles and dissolved gases in the water, and it is of great significance for the stable operation of the pulsed power device.

-

表 1 涡流式分离器实验工况表

Table 1. Table of experimental conditions of vortex separator

flow rate/(L/min) vacuum degree of upper branch pipe/MPa import pressure/kPa inlet and outlet differential pressure/kPa 11.7 −0.06 6.4 66.6 11.7 −0.04 10.4 50.4 11.7 −0.02 13.2 33.2 9.9 −0.06 0.3 60.3 9.9 −0.04 3.7 43.7 9.9 −0.02 7.4 27.4 8.1 −0.06 −5.5 54.5 8.1 −0.04 2.0 42 8.1 −0.02 1.0 21 5.9 −0.06 −12.0 48.0 5.9 −0.04 −7.6 32.4 5.9 −0.02 −3.5 16.5 -

[1] 邱孟通, 呼义翔, 吴伟, 等. 西北核技术研究所强脉冲辐射模拟装置近年发展综述[J]. 现代应用物理, 2024, 15:030101 doi: 10.12061/j.issn.2905-6223.2024.030101Qiu Mengtong, Hu Yixiang, Wu Wei, et al. Overview of the recent development of strong pulse radiation simulation device in Northwest Institute of Nuclear Technology[J]. Modern Applied Physics, 2024, 15: 030101 doi: 10.12061/j.issn.2905-6223.2024.030101 [2] 赵海龙, 董烨, 周海京, 等. 基于NEPTUNE3D开展的脉冲功率装置汇流区三维PIC数值模拟[J]. 强激光与粒子束, 2020, 32:075005 doi: 10.11884/HPLPB202032.200066Zhao Hailong, Dong Ye, Zhou Haijing, et al. 3D particle-in-cell simulations of current convolute structure on pulsed power facility using NEPTUNE3D[J]. High Power Laser and Particle Beams, 2020, 32: 075005 doi: 10.11884/HPLPB202032.200066 [3] 赵亮, 李锐, 程杰, 等. 脉冲功率装置中混合绝缘结构设计方法[J]. 现代应用物理, 2022, 13:040411Zhao Liang, Li Rui, Cheng Jie, et al. Composite insulation design method for pulsed power generators[J]. Modern Applied Physics, 2022, 13: 040411 [4] 刘锡三. 高功率脉冲技术[M]. 北京: 国防工业出版社, 2005Liu Xisan. High pulsed power technology[M]. Beijing: National Defence Industry Press, 2005 [5] 张永民, 邱爱慈, 黄建军, 等. 几项新技术在“闪光二号”加速器上的应用[J]. 强激光与粒子束, 2008, 20(5):876-880Zhang Yongmin, Qiu Aici, Huang Jianjun, et al. Application of new techniques to “Flash-Ⅱ” accelerator[J]. High Power Laser and Particle Beams, 2008, 20(5): 876-880 [6] Wang Chaoyang, Yang Qiang, Xu Xiao, et al. Computational fluid dynamics simulation of the impact of structure on the degassing efficiency of a cyclone[J]. Chemical Engineering & Technology, 2016, 39(3): 522-528. [7] 刘新庆. 纯水应用中五种脱气装置的比较[J]. 电子与封装, 2004, 4(2):54-62,30 doi: 10.3969/j.issn.1681-1070.2004.02.013Liu Xinqing. The comparison of five kinds of degasifiers in purewater application[J]. Electronics & Packaging, 2004, 4(2): 54-62,30 doi: 10.3969/j.issn.1681-1070.2004.02.013 [8] 钱雅兰, 杨灵芳, 张婷婷, 等. 新型旋叶分离器分离特性与机理研究[J]. 核动力工程, 2021, 42(2):29-34Qian Yalan, Yang Lingfang, Zhang Tingting, et al. Study on separation characteristics and mechanism of a new swirl vane separator[J]. Nuclear Power Engineering, 2021, 42(2): 29-34 [9] Yin Junlian, Qian Yalan, Zhang Tingting, et al. Measurement on the flow structure of a gas-liquid separator applied in TMSR[J]. Annals of Nuclear Energy, 2019, 126: 20-32. doi: 10.1016/j.anucene.2018.11.009 [10] 张永民, 任书庆, 黄建军, 等. 水中气泡问题小议[C]//第九届高功率粒子束学术交流会. 2004: 79-82Zhang Yongmin, Ren Shuqing, Huang Jianjun, et al. Small discussion on air bubbles in water[C]//High-Power Particle Beam Symposium. 2004: 79-82 [11] 何敬涛, 梁漫春, 陈安滢, 等. 利用脱气膜技术检测水中14C[J]. 清华大学学报(自然科学版), 2020, 60(4):341-347He Jingtao, Liang Manchun, Chen Anying, et al. Detection of 14C in water using degassing membrane technique[J]. Journal of Tsinghua University (Science and Technology), 2020, 60(4): 341-347 [12] 刘启迪, 吴哲, 施运杏, 等. 基于膜脱气的光声光谱系统在线实时监测变压器油中溶解气体含量的方法构建[J]. 理化检验-化学分册, 2024, 60(6):549-555 doi: 10.11973/lhjy-hx220558Liu Qidi, Wu Zhe, Shi Yunxing, et al. Method construction of photoacoustic spectroscopy system equipped with membrane degassing module for on-line real-time monitoring dissolved gases in transformer oil[J]. Physical Testing and Chemical Analysis (Part B: Chemical Analysis), 2024, 60(6): 549-555 doi: 10.11973/lhjy-hx220558 [13] 赵冰, 王军, 田蒙奎. 我国膜分离技术及产业发展现状[J]. 现代化工, 2021, 41(2):6-10Zhao Bing, Wang Jun, Tian Mengkui. China’s development status of membrane separation technology and industry[J]. Modern Chemical Industry, 2021, 41(2): 6-10 [14] Zhao Lixin, Jiang Minghu, Xu Baorui, et al. Development of a new type high-efficient inner-cone hydrocyclone[J]. Chemical Engineering Research and Design, 2012, 90(12): 2129-2134. doi: 10.1016/j.cherd.2012.05.013 [15] 张泽楷, 张婷婷, 尹莎莎, 等. 涡流式分离器气液两相分离数值模拟研究[J]. 核动力工程, 2022, 43(6):201-208Zhang Zekai, Zhang Tingting, Yin Shasha, et al. Numerical simulation of gas-liquid two-phase separation in vortex separator[J]. Nuclear Power Engineering, 2022, 43(6): 201-208 [16] Lu Xiaotian, Huang Jiachen, Pinelo M, et al. Modelling and optimization of pervaporation membrane modules: a critical review[J]. Journal of Membrane Science, 2022, 664: 121084. doi: 10.1016/j.memsci.2022.121084 [17] Lohse D, Zhang Xuehua. Surface nanobubbles and nanodroplets[J]. Reviews of Modern Physics, 2015, 87(3): 981-1035. doi: 10.1103/RevModPhys.87.981 [18] Liu Yawei, Zhang Xianren. A unified mechanism for the stability of surface nanobubbles: contact line pinning and supersaturation[J]. The Journal of Chemical Physics, 2014, 141: 134702. doi: 10.1063/1.4896937 [19] Lohse D, Zhang Xuehua. Pinning and gas oversaturation imply stable single surface nanobubbles[J]. Physical Review E, 2015, 91: 031003. doi: 10.1103/PhysRevE.91.031003 [20] 侯涛, 吴元明, 冯金玲. AP1000除氧技术分析[J]. 核科学与工程, 2016, 36(1): 141-146Hou Tao, Wu Yuanming, Feng Jinling. Analysis of AP1000 deoxygenation technology[J]. Nuclear Science and Engineering, 2016, 36(1): 141-146 -

下载:

下载: