Cavity ring-down method based performance characterization and defect analysis of large-aperture sampling optics

-

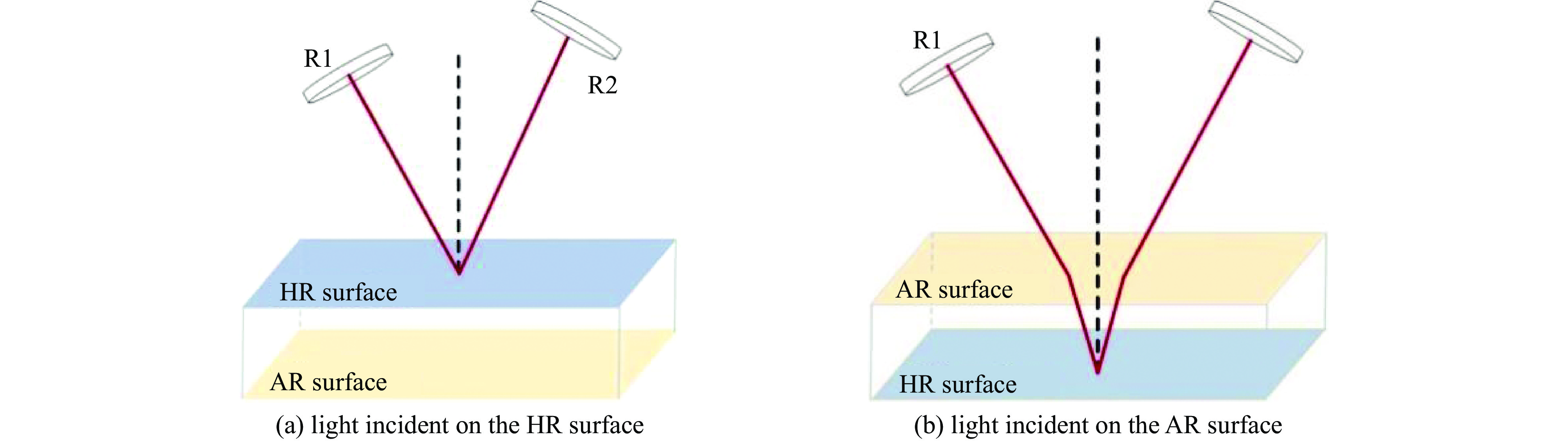

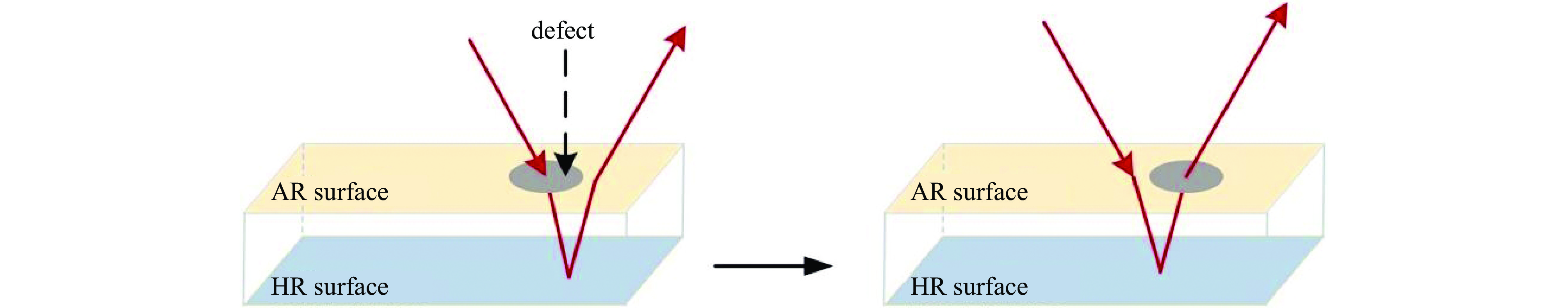

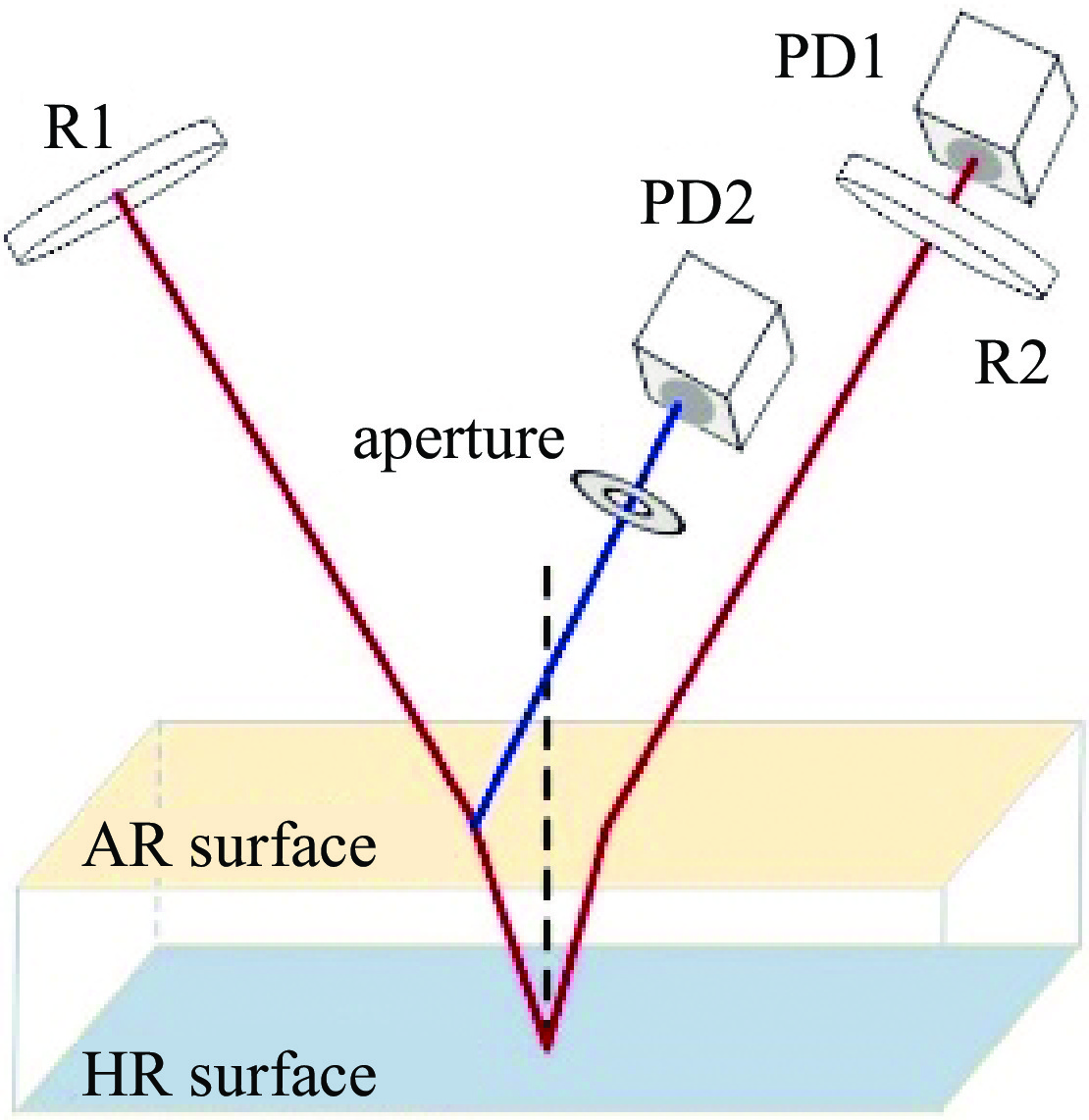

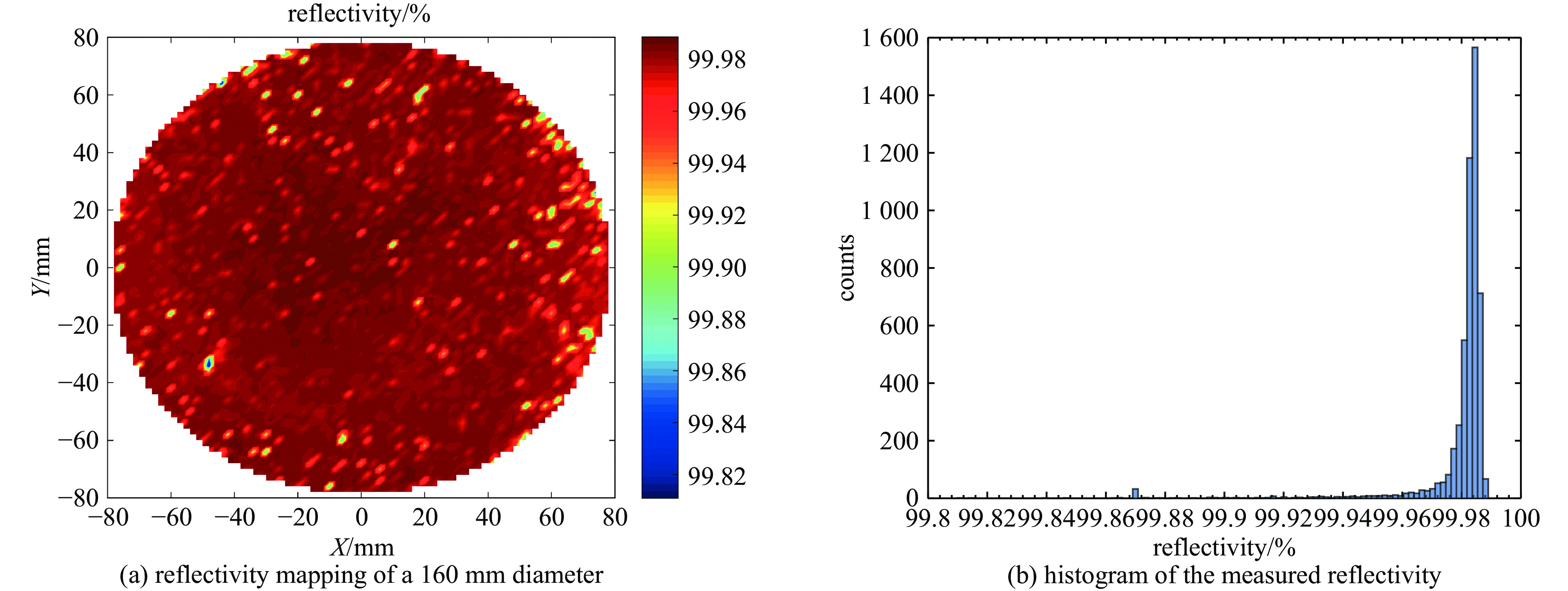

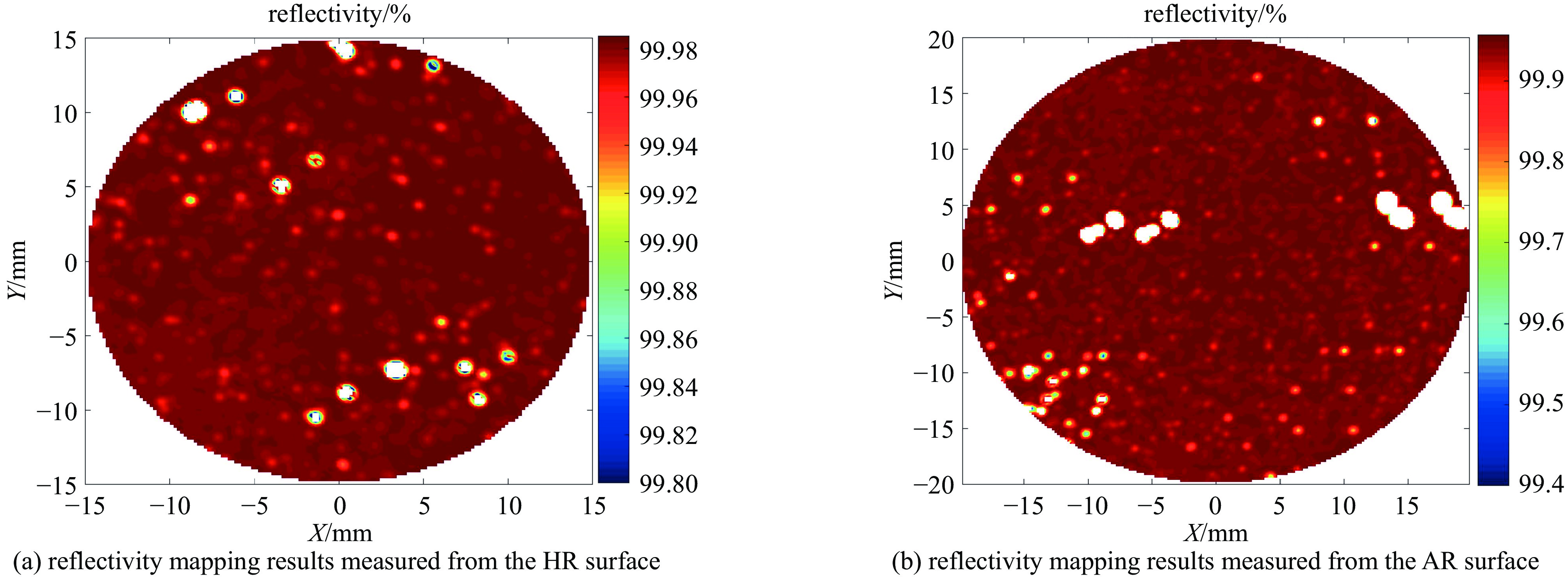

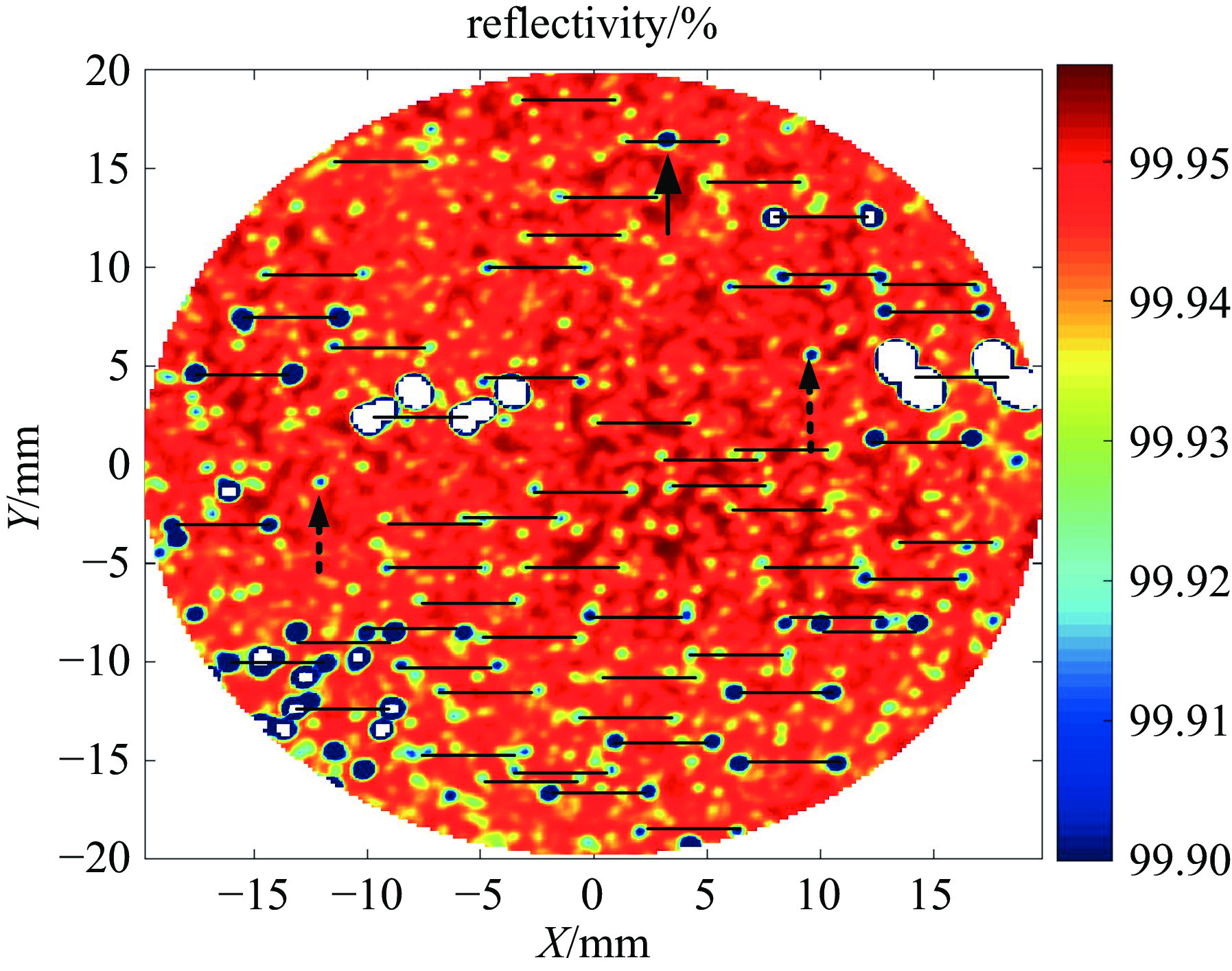

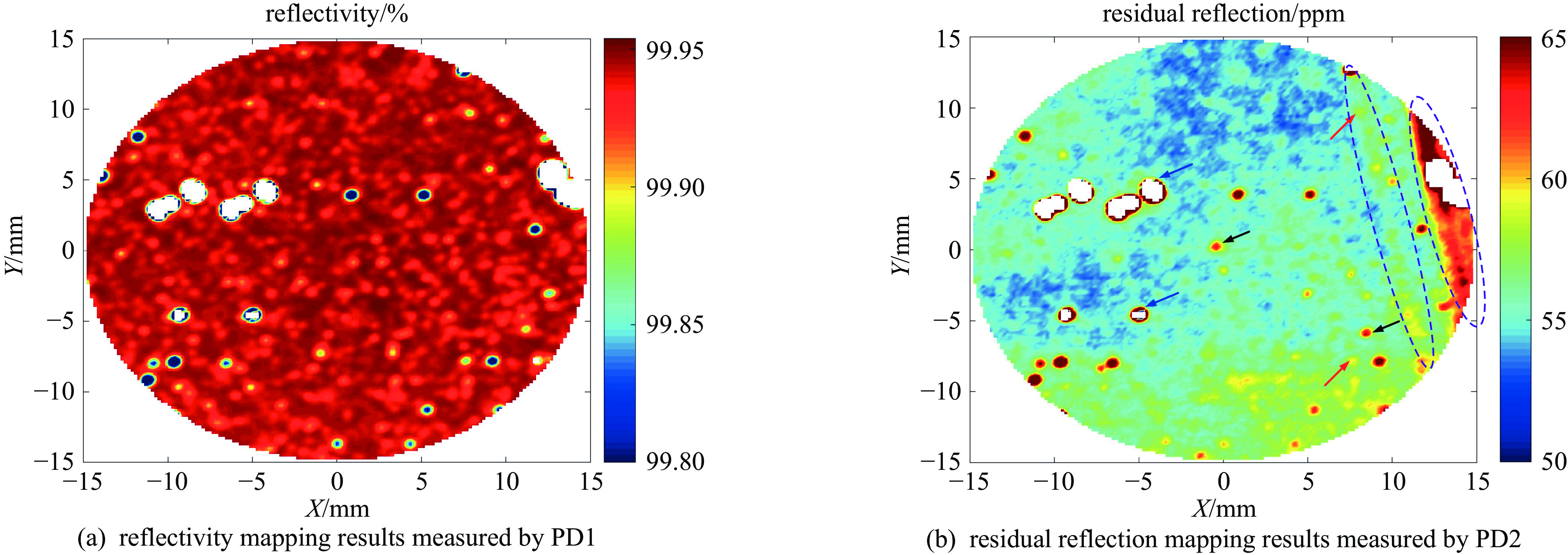

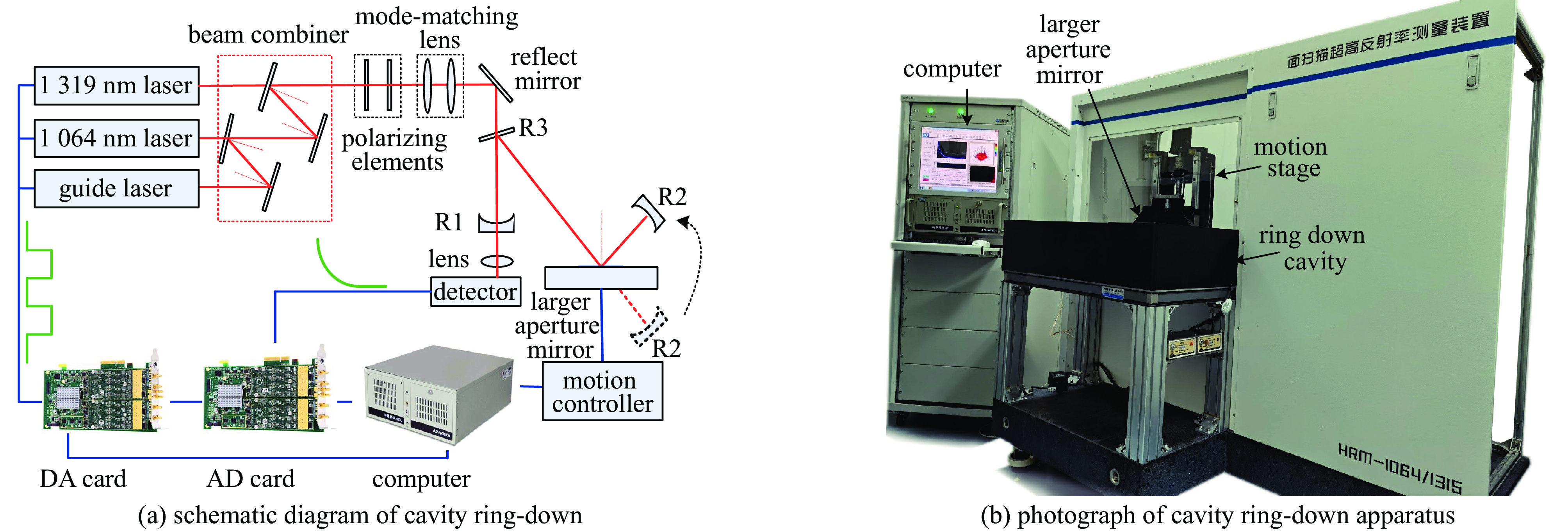

摘要: 针对前表面高反、后表面增透的取样光学元件的性能测试需求,基于光腔衰荡大口径光学元件反射率均匀性测试实验装置,分别从反射膜面入射和增透膜面入射,扫描测量得到该取样光学元件的反射率分布及光学损耗、缺陷高分辨扫描成像;并进一步通过对比分析缺陷分布图,实现取样光学元件反射膜、透射膜以及基片缺陷分类;另外通过建立双通道光腔衰荡实验装置,获取增透膜的剩余反射率分布以及透射膜缺陷类型;实现了大口径取样光学元件光谱和缺陷特性的准确测量。Abstract: In high-energy laser systems, the performance parameters of large-aperture sampling optics determine the accuracy of beam testing and evaluation, as well as the precision of overall system performance control. This paper focuses on the performance testing requirements of sampling optics with high-reflectivity (HR) on the front surface and anti-reflectivity (AR) on the back surface. Utilizing the cavity ring-down (CRD) based reflectivity uniformity testing of large-aperture sampling optics, the reflectivity distribution, optical loss, and high-resolution scanning imaging of defects of sampling optics are obtained by scanning measuring the incident light form both the reflective film surface and the anti-reflective film surface, respectively. Furthermore, by comparing and analyzing the defect distribution maps, the classification of defects in the reflective film, transmissive film, and substrate of the sampling optics can be achieved. Finally, by establishing a dual channel CRD system, the residual reflectance distribution of anti-reflective film and the types of defects in the transmissive film were obtained. The testing and analysis method proposed in this paper provides a systematic and comprehensive characterization tool for the performance evaluation and defect analysis of sampling optics.

-

表 1 反射膜面和增透膜面入射测试的反射率统计结果比较

Table 1. Comparison of Reflectance Statistics between Reflective Film Surface and Anti reflective Film Surface in Incident Testing

average reflectivity/% maximum reflectivity/% maximum-probability reflectivity/% measured from HR surface 99.9804 99.9886 99.9855 measured from AR surface 99.9442 99.9695 99.9593 reflectivity difference 0.0362 0.0191 0.0262 -

[1] Cook J. High-energy laser weapons since the early 1960s[J]. Optical Engineering, 2012, 52: 021007. doi: 10.1117/1.OE.52.2.021007 [2] Stewart A F, Bonsall L, Bettis J R, et al. Laser damage in multispectral optical coatings for the ABL[C]//Proceedings of SPIE 3578, Laser-Induced Damage in Optical Materials. 1999, 162-171. [3] Yang Dekun, Wang Du, Huang Qiushi, et al. The development of laser-produced plasma EUV light source[J]. Chip, 2022, 1: 100019. doi: 10.1016/j.chip.2022.100019 [4] Mizoguchi H, Nakarai H, Usami Y, et al. High-power LPP-EUV source for semiconductor HVM: lithography and other applications[C]//Proceedings of SPIE 12292, International Conference on Extreme Ultraviolet Lithography 2022. 2022: 122920X. [5] Wisoff P J. Diode pumped alkaline laser system: a high powered, low SWaP directed energy option for ballistic missile defense high-level summary[R]. LLNL-TR-730237, 2017. [6] 许晓军. 高能激光六十年: 回顾与展望[J]. 强激光与粒子束, 2020, 32:011007 doi: 10.11884/HPLPB202032.0480Xu Xiaojun. Retrospect and prospect on 60-year development of high energy laser[J]. High Power Laser and Particle Beams, 2020, 32: 011007) doi: 10.11884/HPLPB202032.0480 [7] Zuo Jiexi, Lin Xuechun. High-power laser systems[J]. Laser & Photonics Review, 2022, 16: 2100741. [8] Liu Zejin, Jin Xiaoxi, Su Rongtao, et al. Development status of high power fiber lasers and their coherent beam combination[J]. Science China Information Sciences, 2019, 62: 41301. doi: 10.1007/s11432-018-9742-0 [9] Ciofini M, Lapucci A, Lolli S. Diffractive optical components for high power laser beam sampling[J]. Journal of Optics A: Pure and Applied Optics, 2023, 5(3): 186-191. [10] 易亨瑜, 彭勇, 胡晓阳, 等. 大口径元件反射率的镜面扫描精密测量系统[J]. 强激光与粒子束, 2005, 17(11): 1601-1604Yi Hengyu, Peng Yong, Hu Xiaoyang, et al. Precise measurement system for reflectivity scanning of large aperture components[J]. High Power Laser and Particle Beams, 2005, 17(11): 17(11): 1601-1604 [11] 周文超, 魏千翯, 彭琛, 等. 2.7~3.0 μm波段高反镜反射率测量研究[J]. 强激光与粒子束, 2024, 36:011002 doi: 10.11884/HPLPB202436.240014Zhou Wenchao, Wei Qianhe, Peng Chen, et al. Reflectivity measurement of highly reflective mirrors at spectral band of 2.7−3.0 μm[J]. High Power Laser and Particle Beams, 2024, 36: 011002) doi: 10.11884/HPLPB202436.240014 [12] ISO 13142: 2021, Optics and photonics – lasers and laser-related equipment – cavity ring-down method for high-reflectance and high-transmittance measurement[S]. [13] Xiao Shilei, Li Bincheng, Wang Jing. Precise measurements of super-high reflectance with cavity ring-down technique[J]. Metrologia, 2020, 57: 055002. doi: 10.1088/1681-7575/ab9d2d [14] Han Yanling, Li Bincheng, Gao Lifeng, et al. Reflectivity mapping of large-aperture mirrors with cavity ringdown technique[J]. Applied Optics, 2017, 56(4): C35-C40. doi: 10.1364/AO.56.000C35 [15] Cui Hao, Li Bincheng, Xiao Shilei, at al. Simultaneous mapping of reflectance, transmittance and optical loss of highly reflective and anti-reflective coatings with two-channel cavity ring-down technique[J]. Optics Express, 2017, 25(5): 5807-5820. doi: 10.1364/OE.25.005807 [16] Gong Yuan, Li Bincheng, Han Yanling. Optical feedback cavity ring-down technique for accurate measurement of ultra-high reflectivity[J]. Applied Physics B, 2008, 93(2): 355-360. doi: 10.1007/s00339-008-4864-9 -

下载:

下载: