| [1] |

Zhan Jianbin, Wu Jinzhou, Ma Ruijin, et al. Effect of microstructure on the superelasticity of high-relative-density Ni-rich NiTi alloys fabricated by laser powder bed fusion[J]. Journal of Materials Processing Technology, 2023, 317: 117988. doi: 10.1016/j.jmatprotec.2023.117988

|

| [2] |

Ji Chen, Li Kun, Zhan Jianbin, et al. The effects and utility of homogenization and thermodynamic modeling on microstructure and mechanical properties of SS316/IN718 functionally graded materials fabricated by laser-based directed energy deposition[J]. Journal of Materials Processing Technology, 2023, 319: 118084. doi: 10.1016/j.jmatprotec.2023.118084

|

| [3] |

Zhan Jianbin, Wu Jinzhou, Ma Ruijin, et al. Tuning the functional properties by laser powder bed fusion with partitioned repetitive laser scanning: toward editable 4D printing of NiTi alloys[J]. Journal of Manufacturing Processes, 2023, 101: 1468-1481. doi: 10.1016/j.jmapro.2023.07.009

|

| [4] |

Guo Dongming. High-performance manufacturing[J]. International Journal of Extreme Manufacturing, 2024, 6: 060201. doi: 10.1088/2631-7990/ad7426

|

| [5] |

Zhao Jiangtao, Li Chang, Zhan Hao, et al. Study on laser quenching of aircraft gears with rectangular beam based on multi-field coupling mechanism[J]. Applied Physics A, 2025, 131: 47. doi: 10.1007/s00339-024-08174-3

|

| [6] |

Song Jingyu, Huang Hui, Wang Xigui, et al. Status and prospects of surface texturing: design, manufacturing and applications[J]. Surface Science and Technology, 2023, 1: 21. doi: 10.1007/s44251-023-00022-5

|

| [7] |

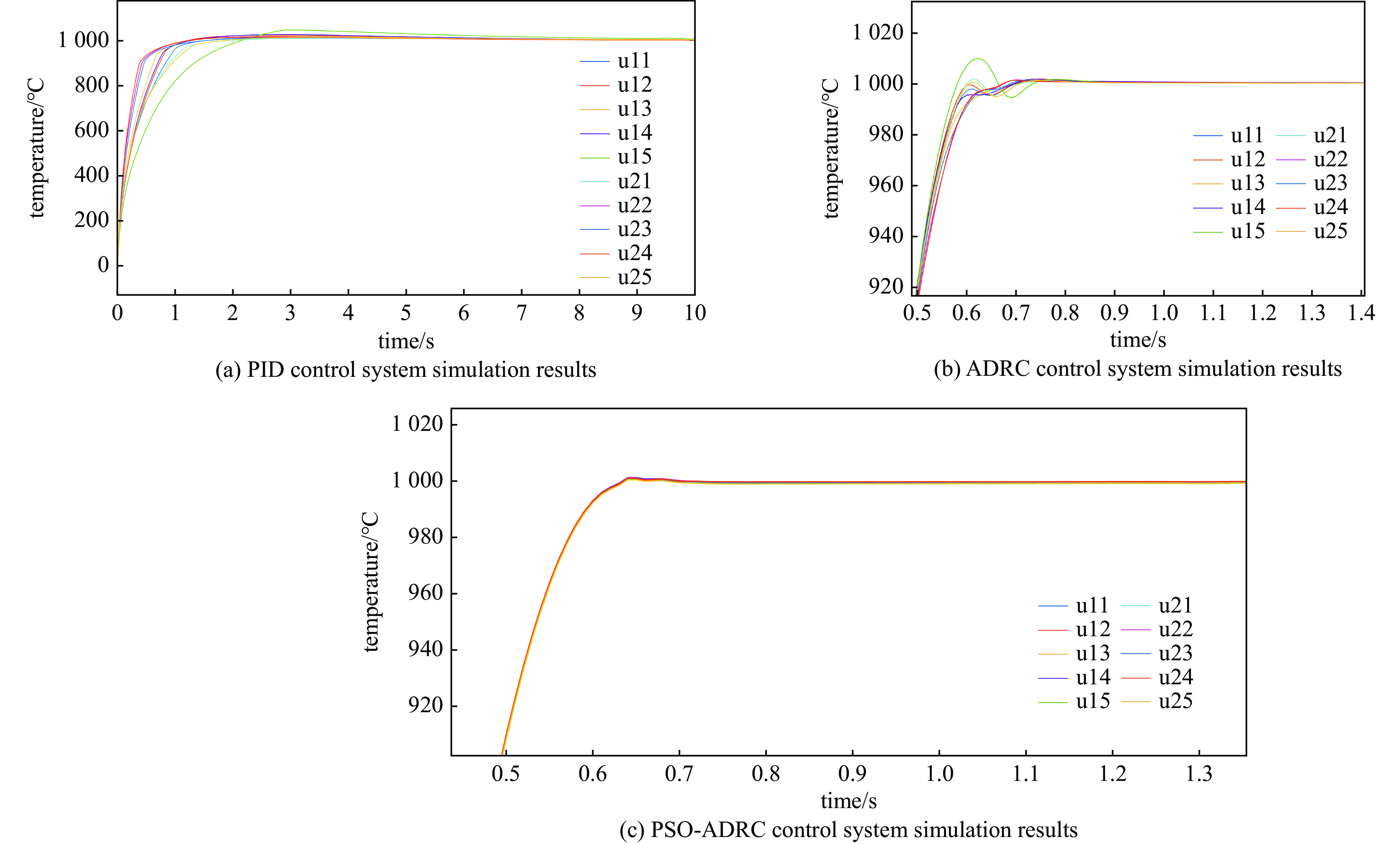

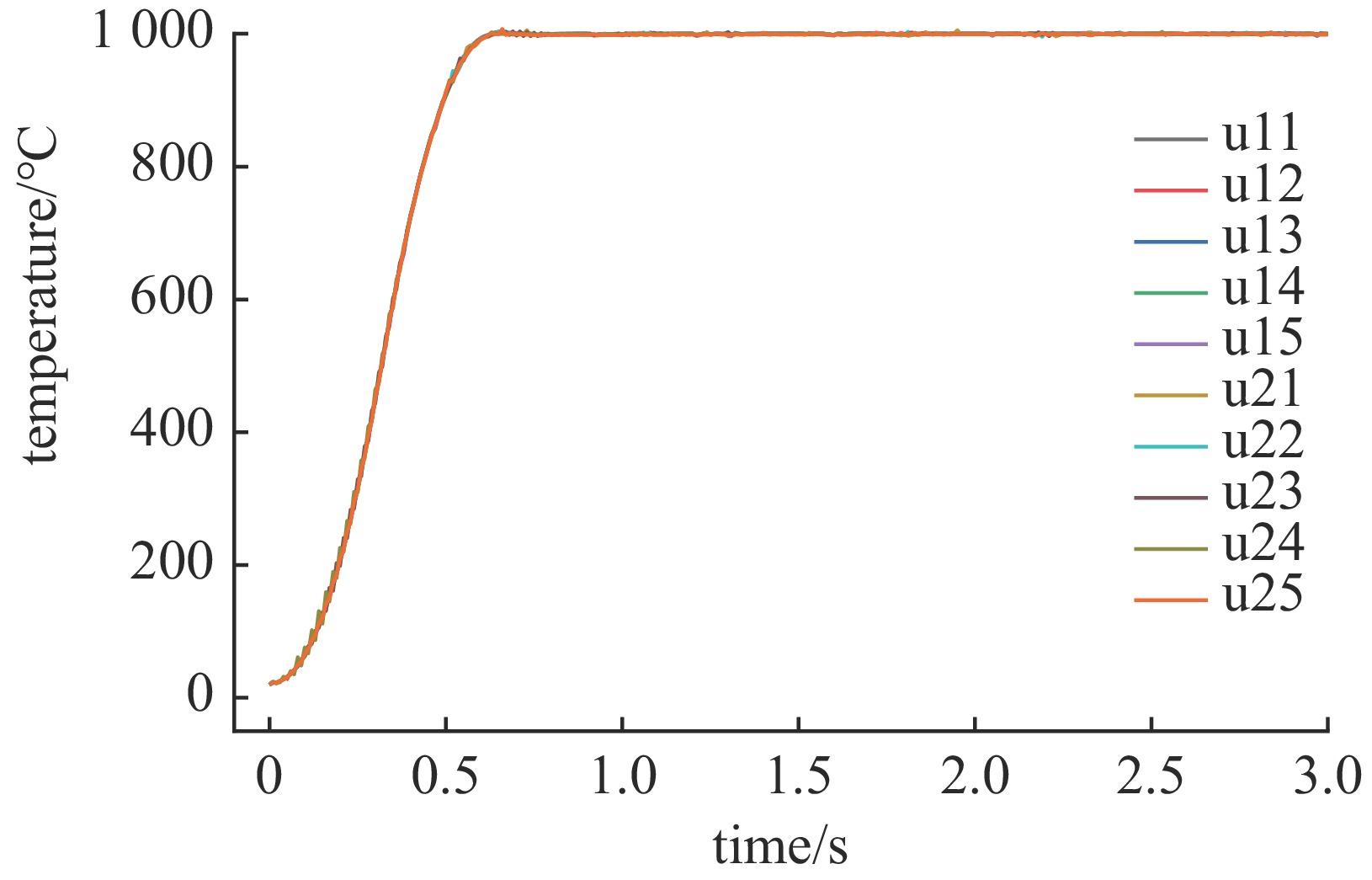

秦跃舟, 朱国力. 基于非线性参数整定PI控制算法的激光淬火温度控制研究[J]. 应用激光, 2020, 40(1):110-114Qin Yuezhou, Zhu Guoli. Study on laser quenching temperature control based on nonlinear adjusted parameter for PI control[J]. Applied Laser, 2020, 40(1): 110-114

|

| [8] |

尚军, 李敏娟, 徐宏伟. 基于模糊控制的激光淬火控制算法研究[J]. 应用激光, 2015, 35(1):40-43 doi: 10.3788/AL20153501.0040Shang Jun, Li Minjuan, Xu Hongwei. Study on laser quench controlling algorithm based on fussy control[J]. Applied Laser, 2015, 35(1): 40-43 doi: 10.3788/AL20153501.0040

|

| [9] |

徐小刚. 激光相变硬化数值模拟与温度控制技术研究[D]. 济南: 山东大学, 2022Xu Xiaogang. Research on numerical simulation and temperature control technology of laser phase transformation hardening[D]. Jinan: Shandong University, 2022

|

| [10] |

Lesyk D A, Martinez S, Mordyuk B N, et al. Effects of laser heat treatment combined with ultrasonic impact treatment on the surface topography and hardness of carbon steel AISI 1045[J]. Optics & Laser Technology, 2019, 111: 424-438.

|

| [11] |

张群莉, 李国昌, 董浩芃, 等. 42CrMo钢激光-电磁感应复合淬火过程应力与变形研究[J]. 表面技术, 2024, 53(21):142-152Zhang Qunli, Li Guochang, Dong Haopeng, et al. Stress and deformation of 42CrMo steel during laser-electromagnetic induction hybrid quenching process[J]. Surface Technology, 2024, 53(21): 142-152

|

| [12] |

Da Silva S L E F. Newton’s cooling law in generalised statistical mechanics[J]. Physica A: Statistical Mechanics and its Applications, 2021, 565: 125539. doi: 10.1016/j.physa.2020.125539

|

| [13] |

王威, 李少甫, 吴昊, 等. 基于反向传播神经网络PID的高功率微波炉温度控制[J]. 强激光与粒子束, 2024, 36:013010 doi: 10.11884/HPLPB202436.230280Wang Wei, Li Shaofu, Wu Hao, et al. Research on temperature control of high power microwave oven based on back propagation neural network PID[J]. High Power Laser and Particle Beams, 2024, 36: 013010 doi: 10.11884/HPLPB202436.230280

|

| [14] |

Schilders W H A, Vorst H A Rommes J. Model order reduction: theory, research aspects and applications[M]. Berlin: Springer, 2008: 1-10.

|

| [15] |

蒋耀林. 模型降阶方法[M]. 北京: 科学出版社, 2010: 86-89Jiang Yaolin. Model reduction methods[M]. Beijing: Science Press, 2010: 86-89

|

| [16] |

Castagnotto A, Varona M C, Jeschek L, et al. sss & sssMOR: analysis and reduction of large-scale dynamic systems in MATLAB[J]. at - Automatisierungstechnik, 2017, 65(2): 134-150. doi: 10.1515/auto-2016-0137

|

| [17] |

韩京清. 从PID技术到“自抗扰控制”技术[J]. 控制工程, 2002, 9(3):13-18 doi: 10.3969/j.issn.1671-7848.2002.03.003Han Jingqing. From PID technology to active disturbance rejection control technology[J]. Control Engineering of China, 2002, 9(3): 13-18 doi: 10.3969/j.issn.1671-7848.2002.03.003

|

| [18] |

Lozgachev G I. On a method of construction of Lyapunov functions[J]. Automation and Remote Control, 1998, 59(10): 1365-1368.

|

| [19] |

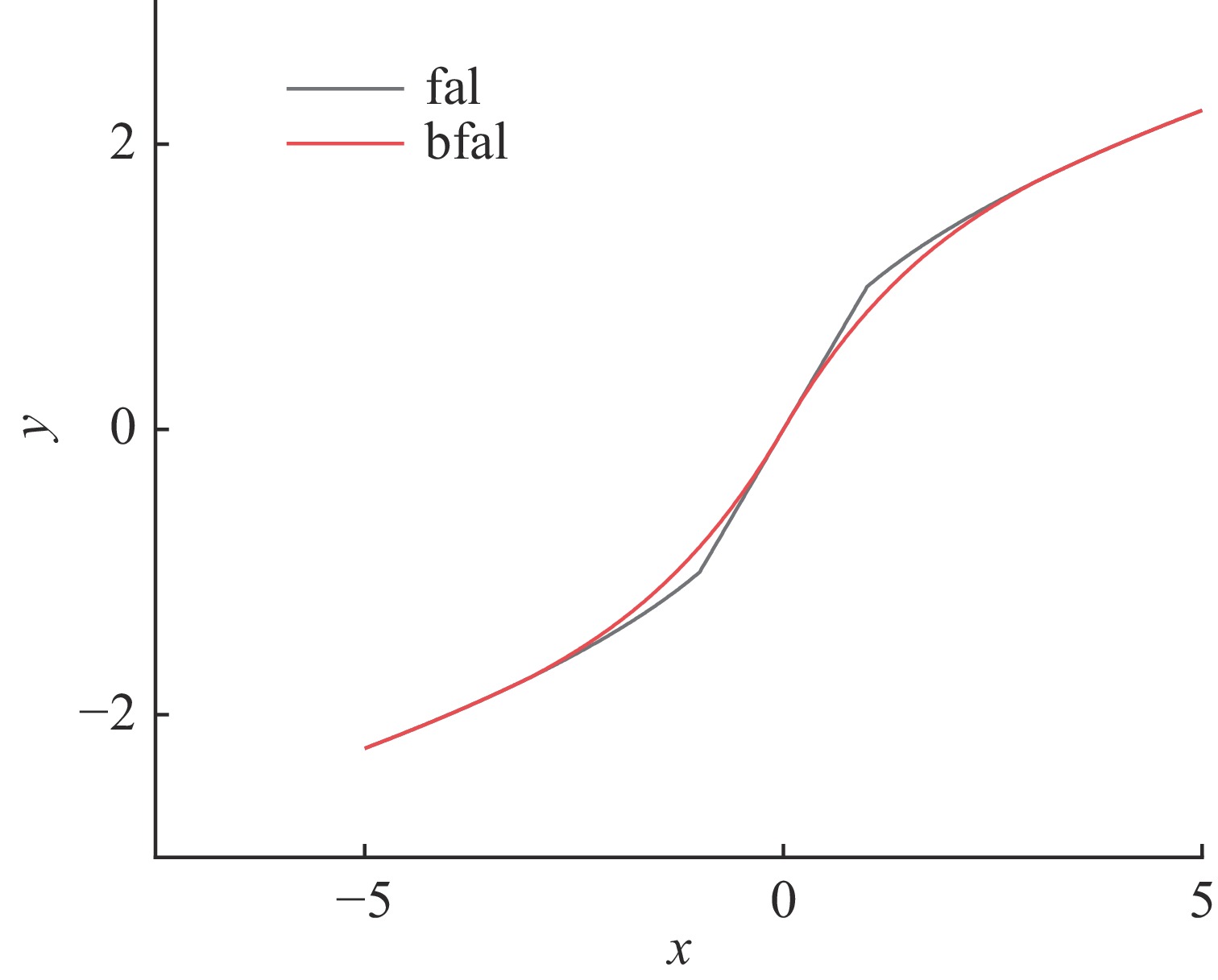

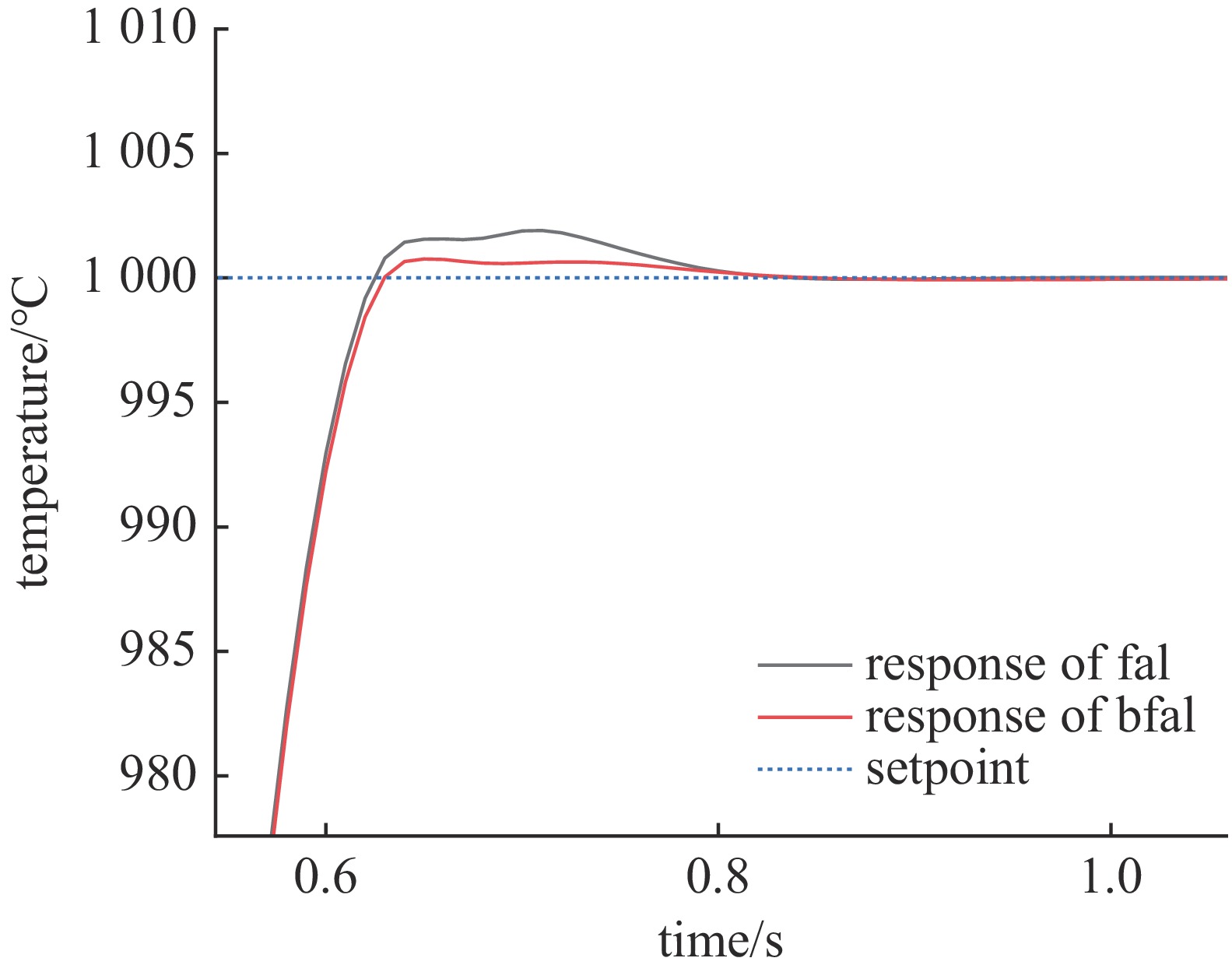

陈志旺, 张子振, 曹玉洁. 自抗扰fal函数改进及在四旋翼姿态控制中的应用[J]. 控制与决策, 2018, 33(10):1901-1907Chen Zhiwang, Zhang Zizhen, Cao Yujie. Fal function improvement of ADRC and its application in quadrotor aircraft attitude control[J]. Control and Decision, 2018, 33(10): 1901-1907

|

| [20] |

李昌龙, 陈松, 吴炫炫, 等. 基于PSO-ELM的316L不锈钢细长管磁粒研磨内表面粗糙度预测模型[J]. 中国表面工程, 2023, 36(2):212-221 doi: 10.11933/j.issn.1007-9289.20220513001Li Changlong, Chen Song, Wu Xuanxuan, et al. Inner surface roughness prediction model of 316L stainless steel slender tube by magnetic abrasive finishing based on PSO-ELM[J]. China Surface Engineering, 2023, 36(2): 212-221 doi: 10.11933/j.issn.1007-9289.20220513001

|

| [21] |

Li T Y, Yorke J A. Period three implies chaos[J]. The American Mathematical Monthly, 1975, 82(10): 985-992. doi: 10.1080/00029890.1975.11994008

|

下载:

下载: