Development of thermal-mechanical coupling program for heat pipe cooled reactor core

-

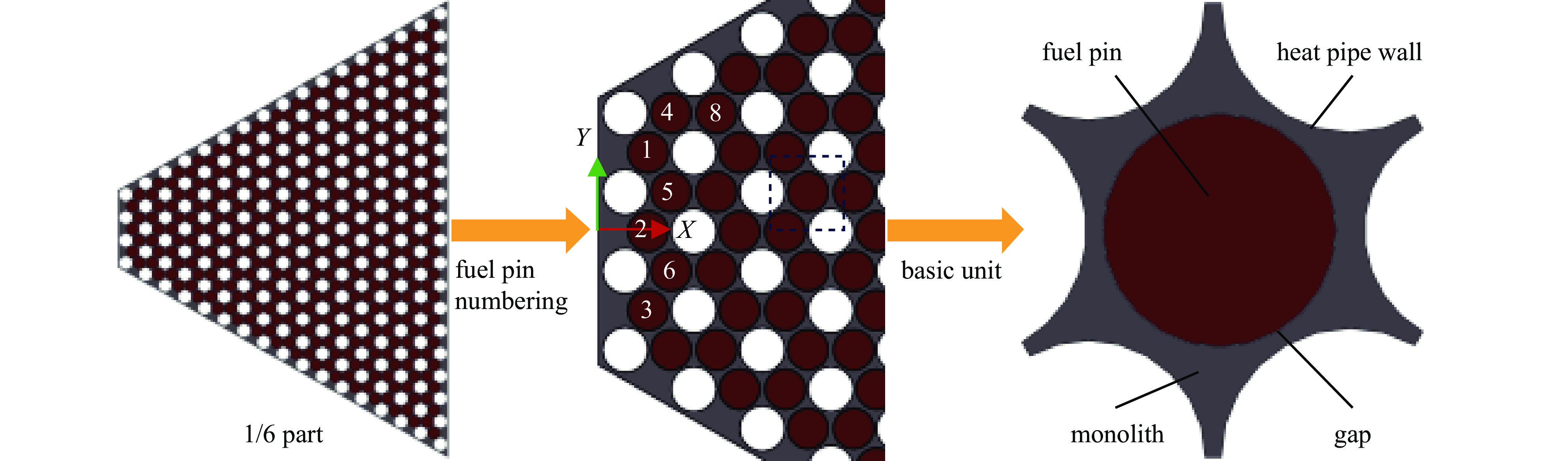

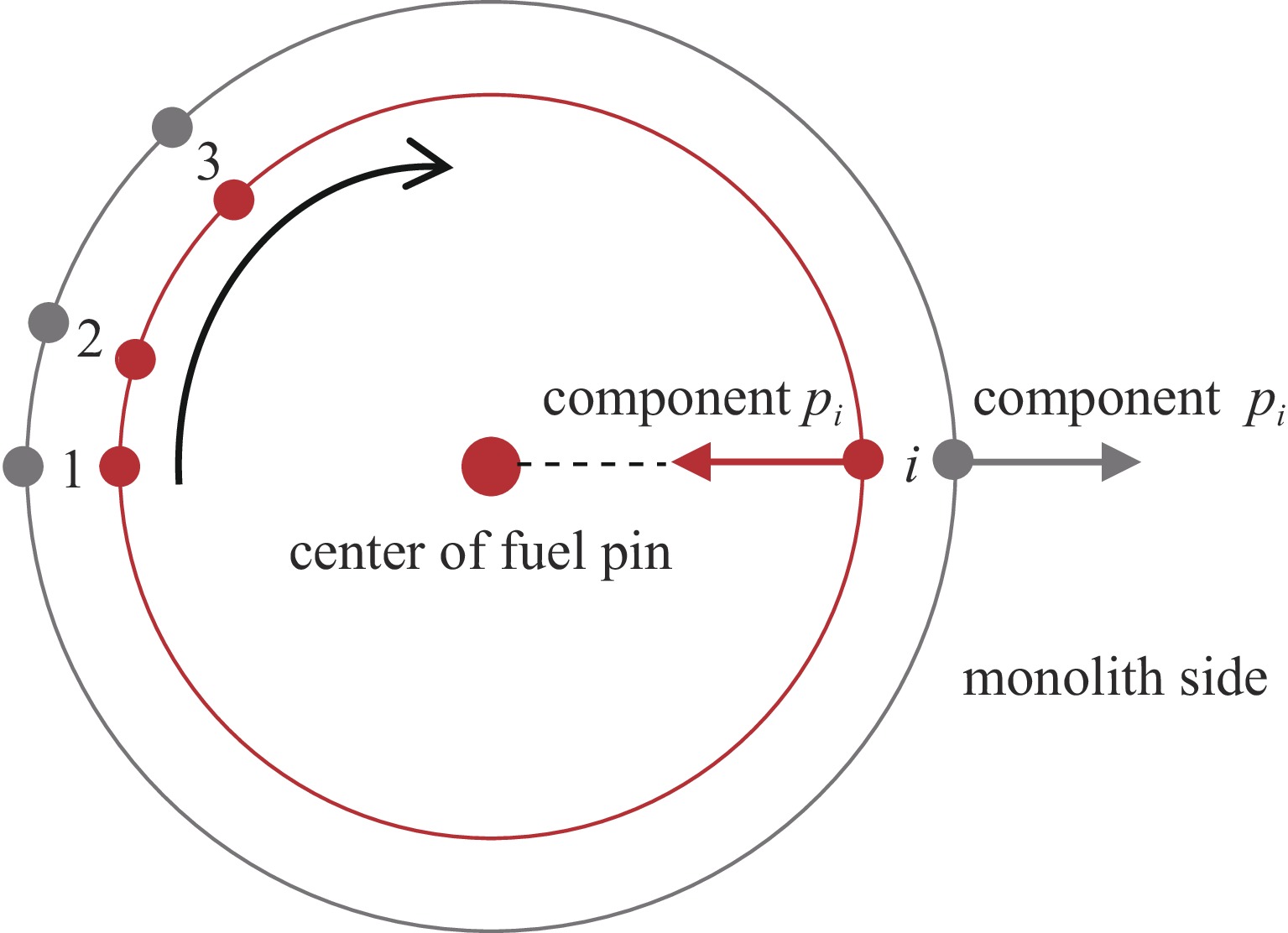

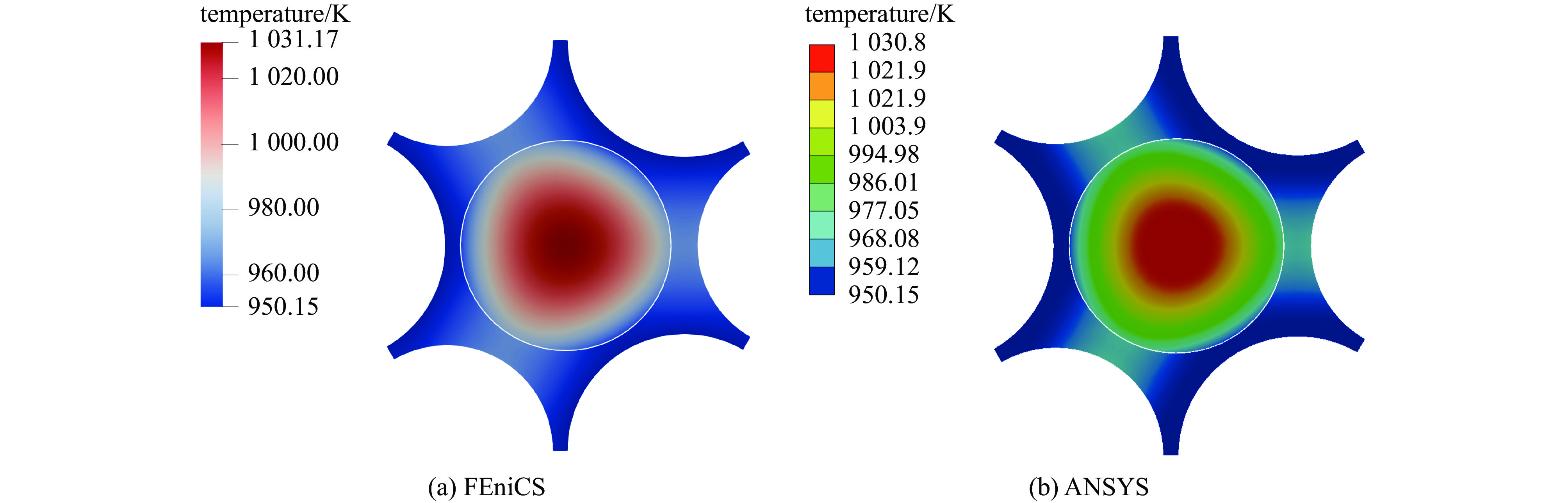

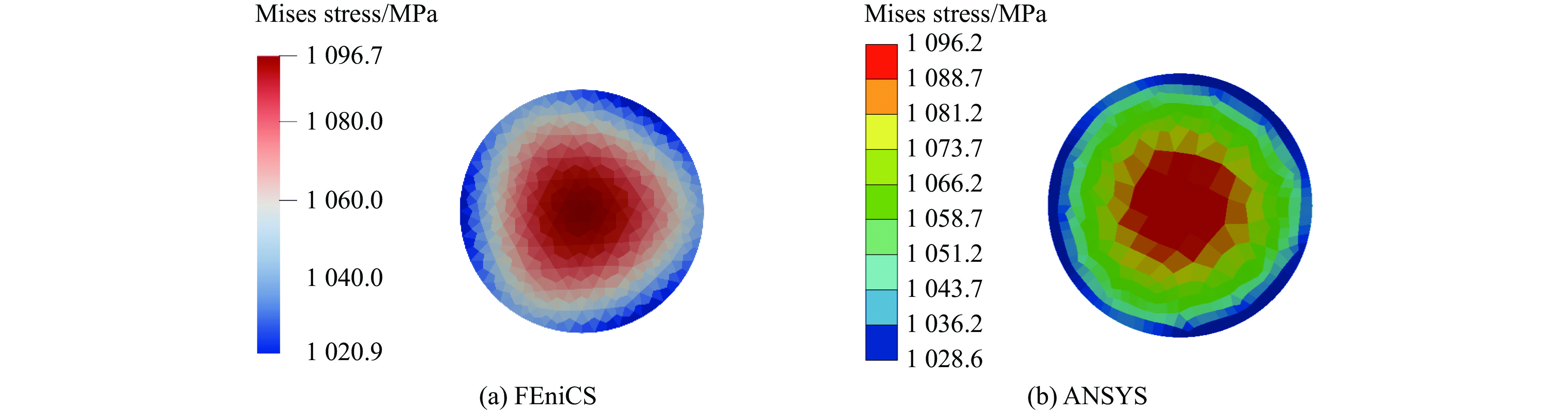

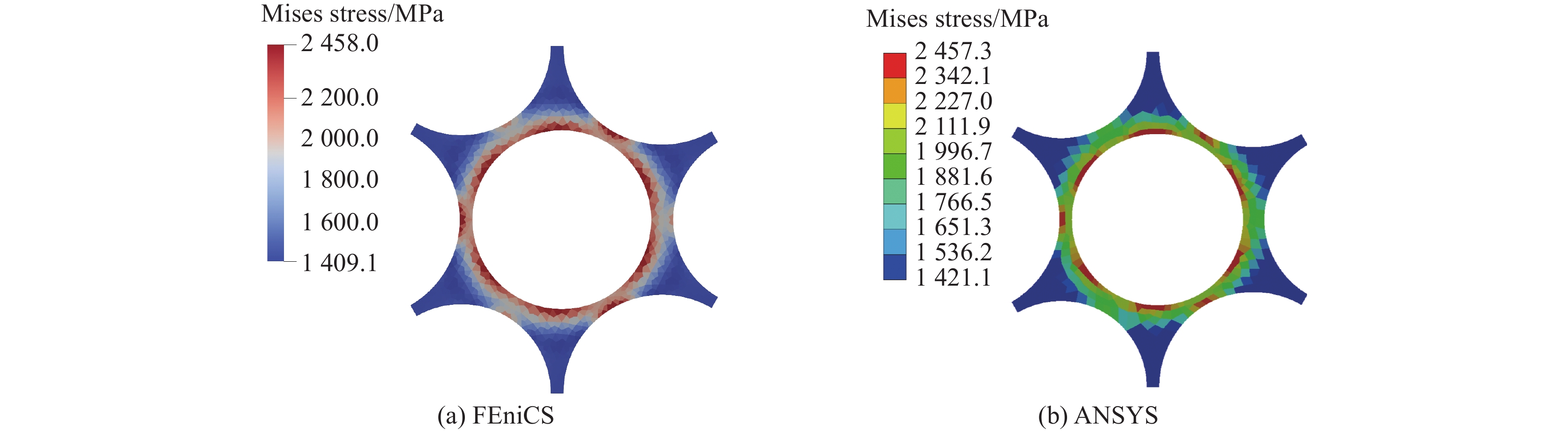

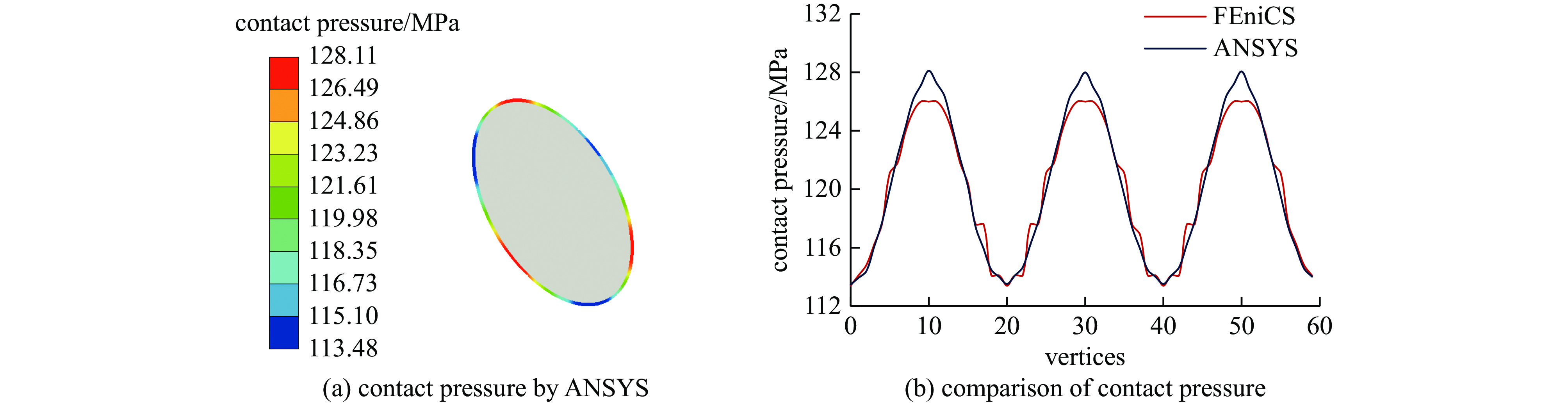

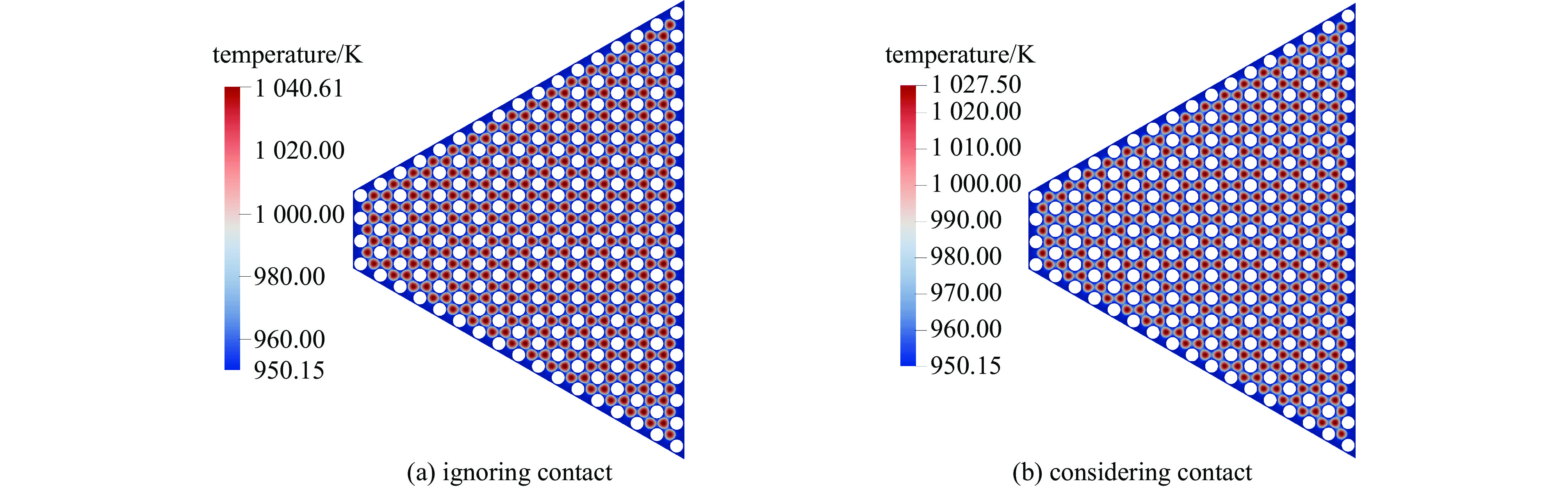

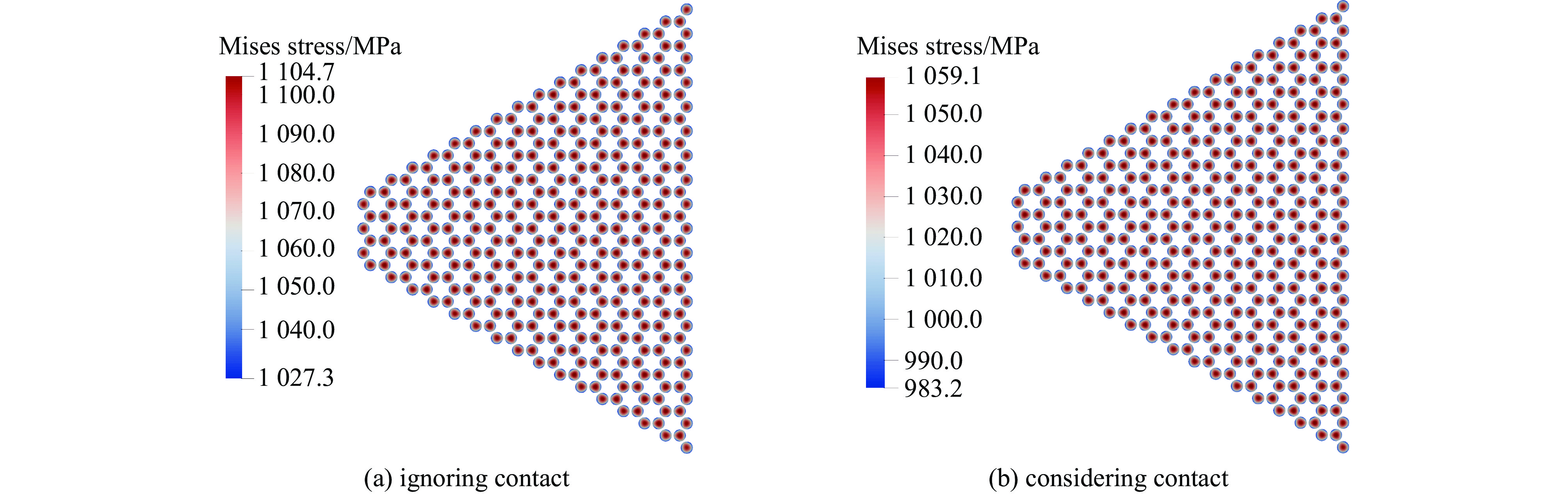

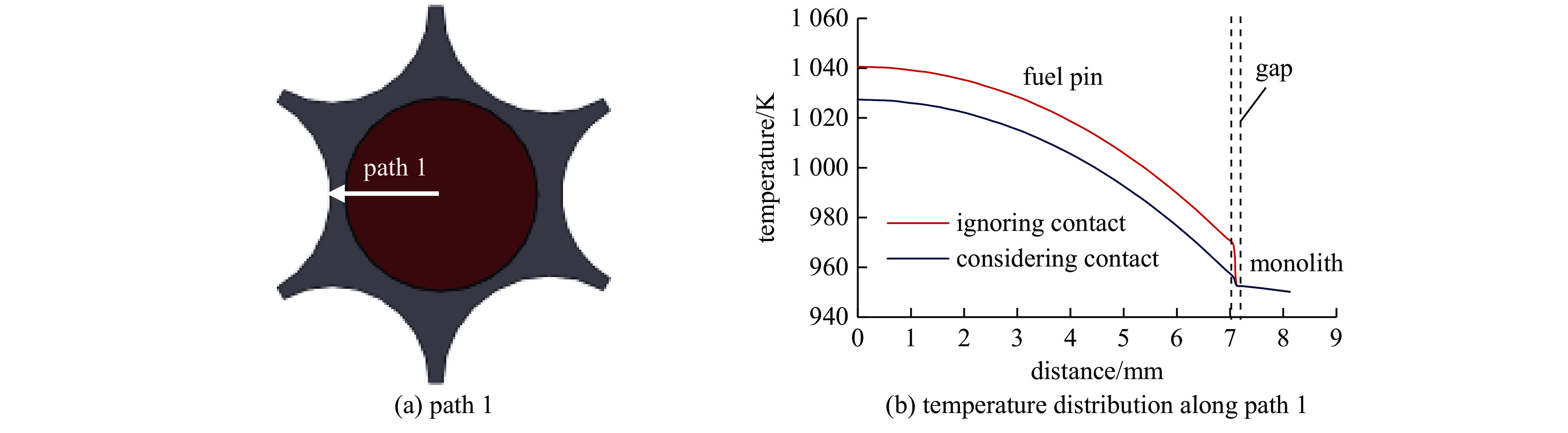

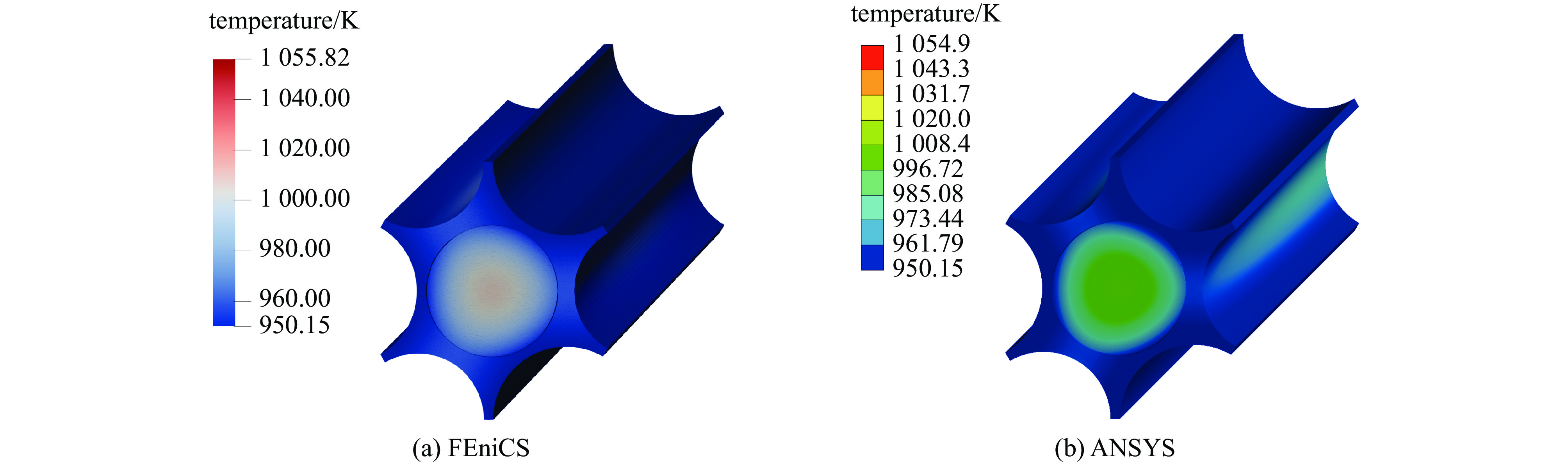

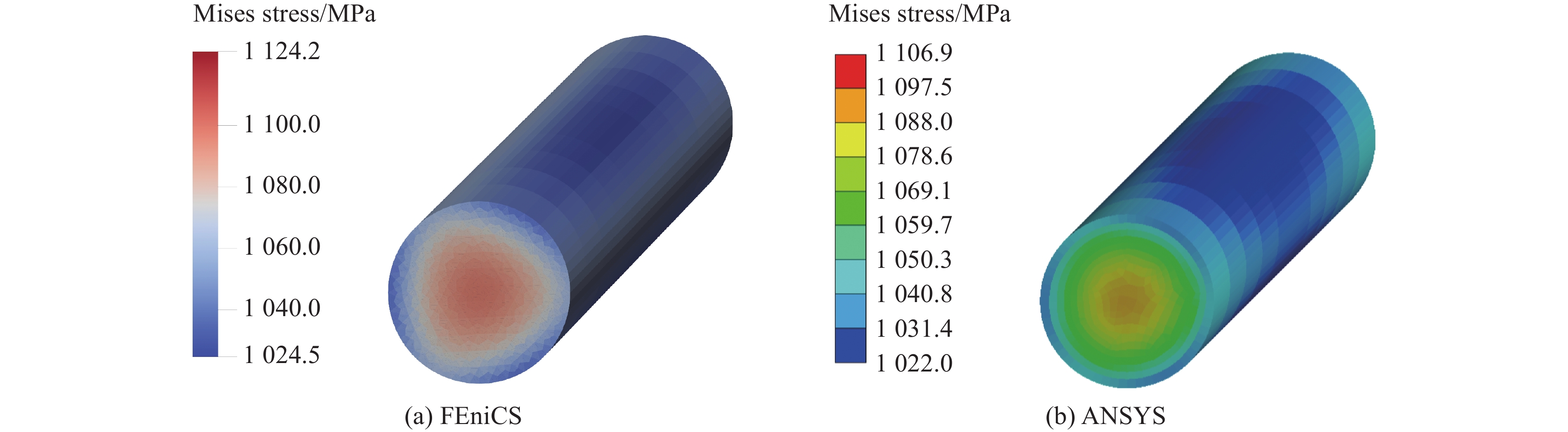

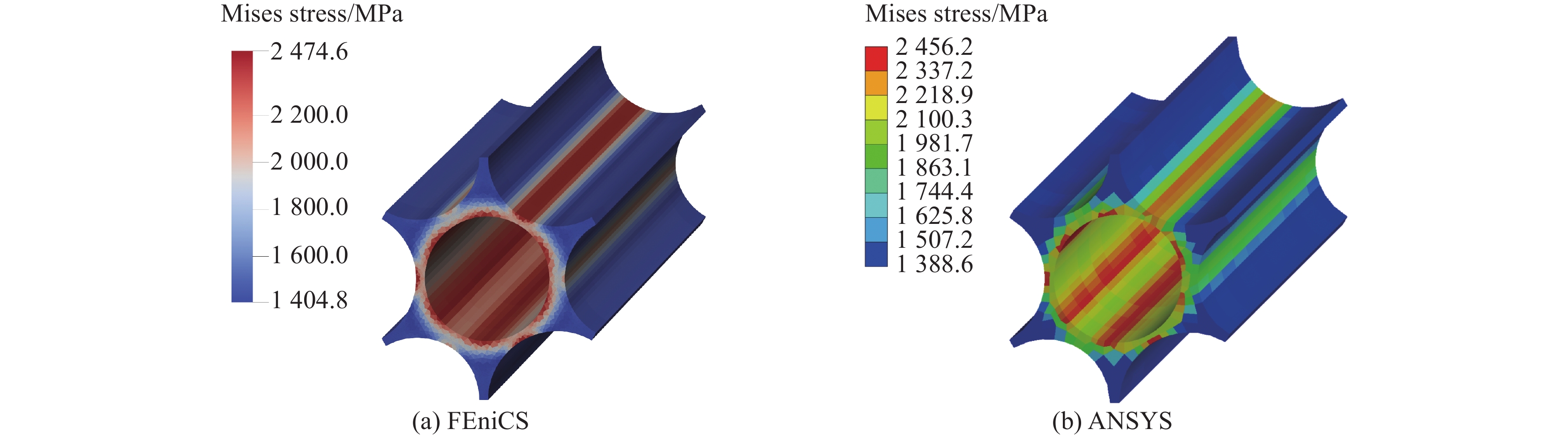

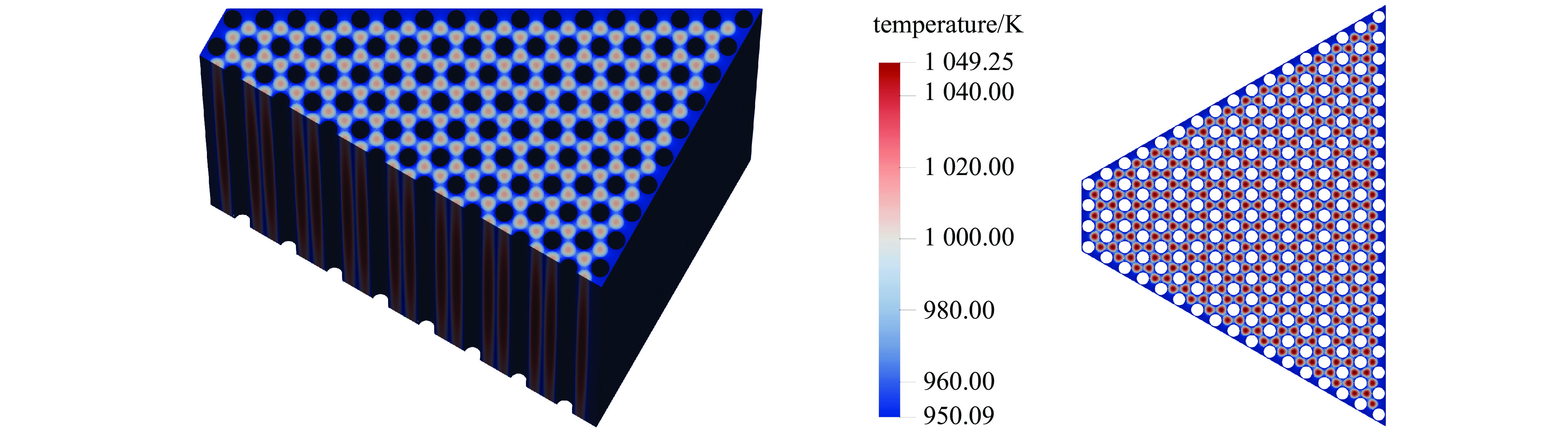

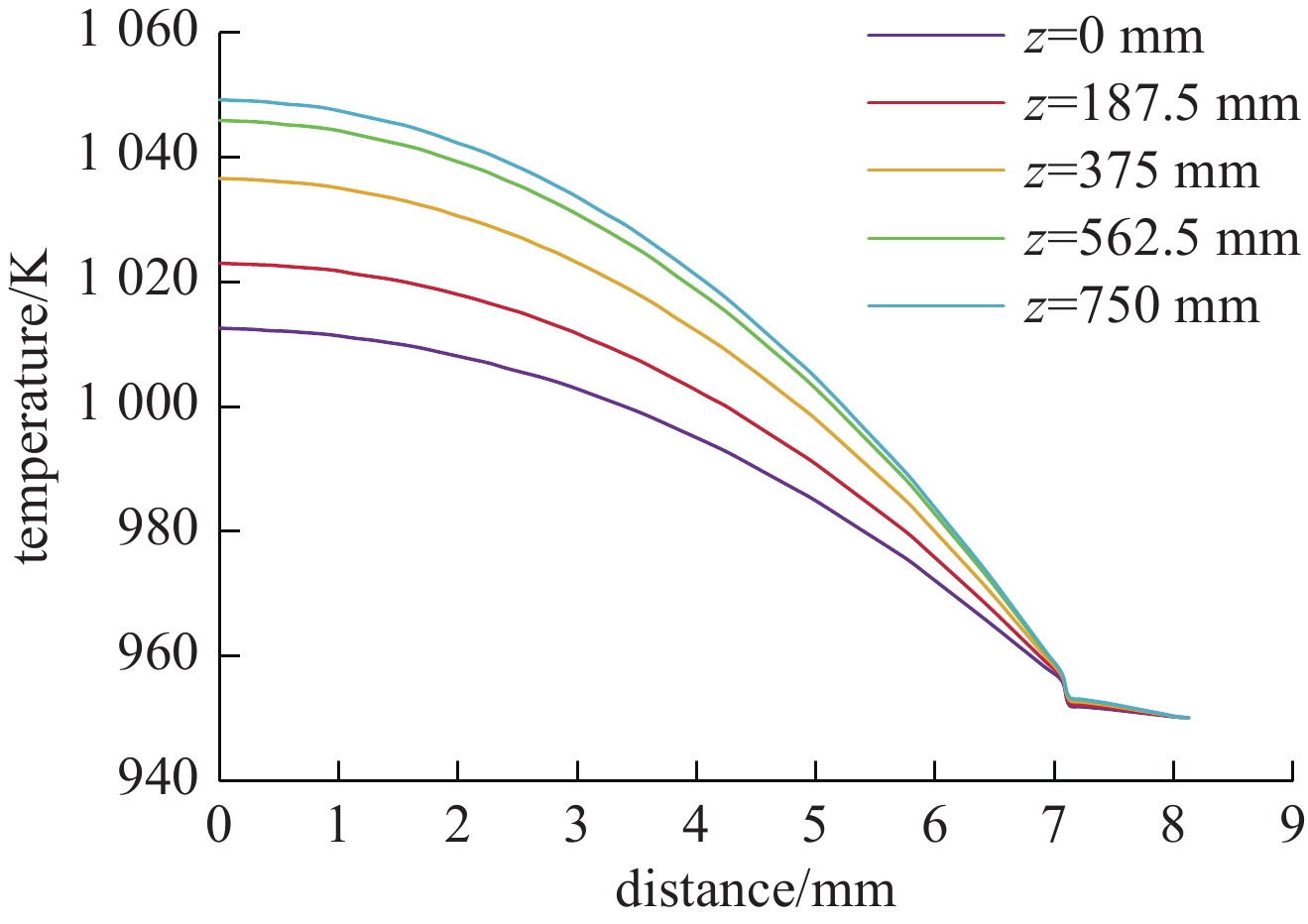

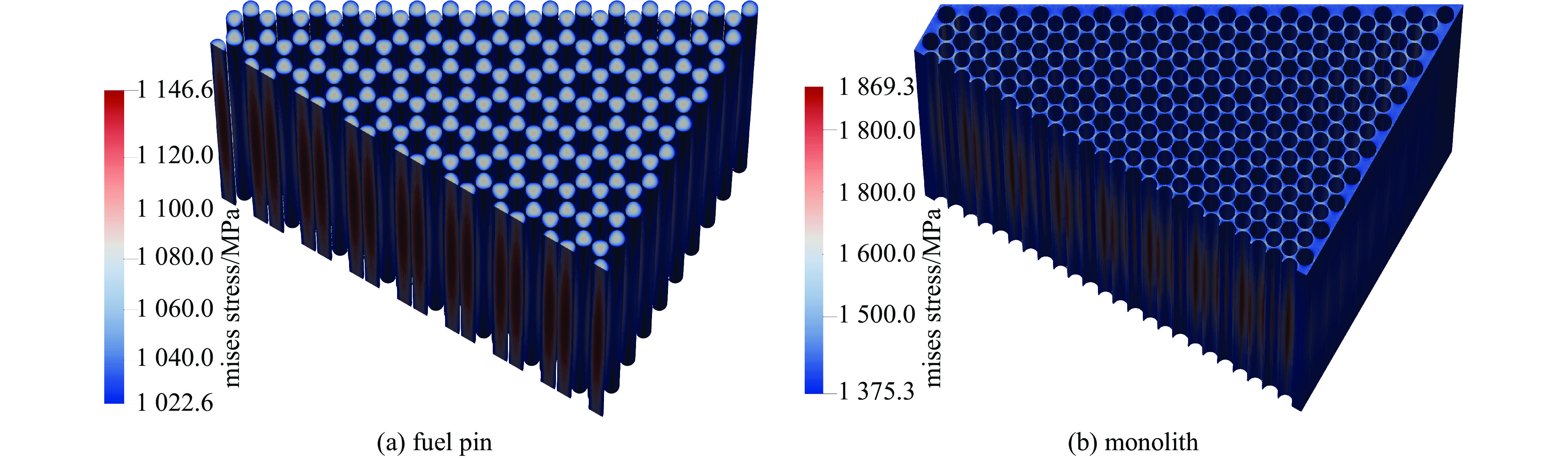

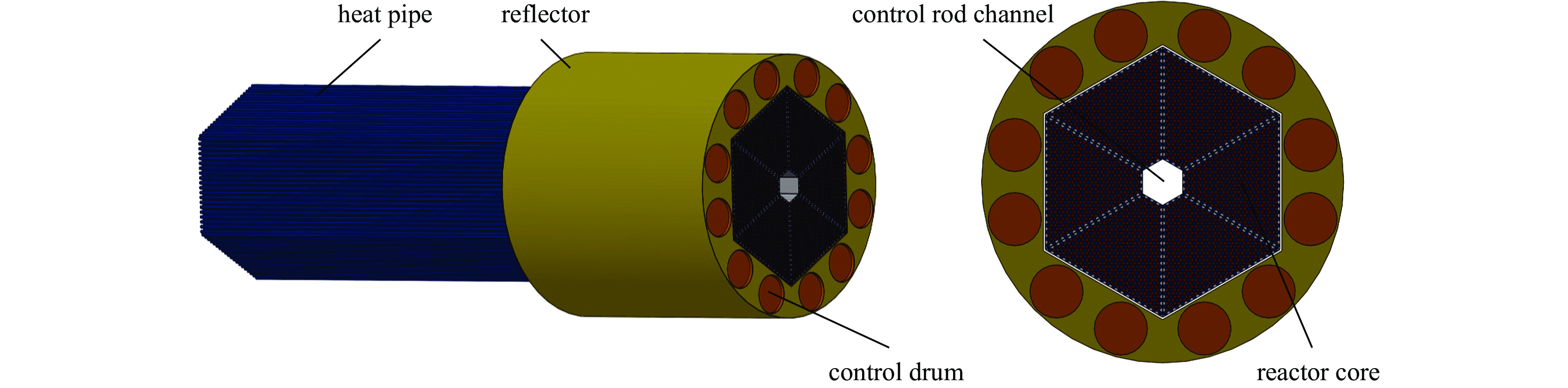

摘要: 为研究接触和轴向功率对热管冷却反应堆堆芯热力学性能的影响,基于FEniCS开源平台开发了一套热力耦合分析程序。该程序使用简化方法求解二维、三维接触压力,主要包括间隙传热模型、线弹性力学模型和多维接触压力求解模型。以MegaPower反应堆为对象,首先使用商业软件ANSYS验证了程序的准确性,然后对堆芯进行热力耦合模拟,分析温度及Mises应力场。结果表明:考虑接触时,燃料棒峰值温度显著降低,Mises应力有所减小;基体峰值温度变化不大,Mises应力却显著增大;轴向功率主要影响燃料棒Mises应力,基体Mises应力则主要受接触压力影响。Abstract: To investigate the effects of contact and axial power on the thermodynamic performance of the heat pipe cooled reactor core, a thermal-mechanical coupling program was developed based on the FEniCS platform. The program uses a simplified method to solve 2D and 3D contact pressure, primarily including gap heat transfer, linear elastic mechanics, and multidimensional contact pressure solution models. Taking the MegaPower reactor as the subject, the study first validated the accuracy of the program using ANSYS, and then a thermal-mechanical simulation of the core was performed to analyze temperature and Mises stress fields. The results indicate that when considering contact, the peak temperature of the fuel pin significantly decreases and the Mises stress decreases slightly; the peak temperature of the monolith changes little, but the Mises stress increases markedly. The axial power mainly affects the Mises stress of the fuel pin, while the Mises stress of the monolith is primarily influenced by contact pressure.

-

表 1 堆芯几何参数

Table 1. Parameters of reactor core

fuel pin outer

diameter/mmgas gap

thickness/mmfuel-to-fuel

pitch/mmheat pipe (HP) hole

diameter/mmfuel-to-HP

pitch/mmHP-to-HP

pitch/mmweb thickness between

HP-to-edge of block/mmheight/

mm14.12 0.065 16 15.75 16 27.713 1.5 1500 表 2 材料物性

Table 2. Properties of materials

element thermal conductivity/(W·mm−1·K−1) elastic modulus/MPa Poisson’s ratio thermal expansion coefficient/K−1 fuel 0.002 1.5×105 0.3 1.05×10−5 monolith 0.016 2.0×105 0.3 1.10×10−5 表 3 107号燃料棒中心的应力分量

Table 3. Stress components at the center of No.107 fuel pin

$ {\sigma }_{x} $/MPa $ {\sigma }_{y} $/MPa $ {\sigma }_{{\textit{z}}} $/MPa $ {\tau }_{xy} $/MPa $ {\tau }_{x{\textit{z}}} $/MPa $ {\tau }_{y{\textit{z}}} $/MPa ignoring contact −33.3 −33.4 − 1138.0 −0.004 − 0.0006 −0.025 considering contact −98.3 −98.4 − 1157.3 −0.016 − 0.0004 −0.024 表 4 107号基本单元基体侧应力集中区域某点的应力分量

Table 4. Stress components at a specific point in the stress concentration zone on the monolith side of No. 107 basic unit

$ {\sigma }_{x} $/MPa $ {\sigma }_{y} $/MPa $ {\sigma }_{{\textit{z}}} $/MPa $ {\tau }_{xy} $/MPa $ {\tau }_{x{\textit{z}}} $/MPa $ {\tau }_{y{\textit{z}}} $/MPa ignoring contact 0.88 −0.96 − 1488.4 0.155 − 0.0002 0.0015 considering contact −64.9 473.5 − 1365.7 −0.097 − 0.0003 − 0.1807 -

[1] Grover G M, Cotter T P, Erickson G F. Structures of very high thermal conductance[J]. Journal of Applied Physics, 1964, 35(6): 1990-1991. doi: 10.1063/1.1713792 [2] Ranken W A, Houts M G. Heat pipe cooled reactors for multi-kilowatt space power supplies[C]//9th Internationa1 Heat Pipe Conference. 1995. [3] Houts M G, Poston D I, Ranken W A. Heatpipe space power and propulsion systems[J]. AIP Conference Proceedings, 1996, 361(1): 1155-1162. [4] Mcclure P R, Poston D I, Dixon D D. Final results of Demonstration Using Flattop Fissions (DUFF) experiment[R]. US: LANL, 2012. [5] Vandyke M, Martin J. Non-nuclear testing of reactor systems in the early flight fission test facilities (EFF-TF)[C]//2004 International Congress on Advances in Nuclear Power Plants (ICAPP 2004). 2004. [6] Mcclure P R, Poston D I, Gibson M A, et al. Kilopower project: the KRUSTY fission power experiment and potential missions[J]. Nuclear Technology, 2020, 206(s1): S1-S12. [7] Sterbentz J W, Werner J E, Hummel A J, et al. Preliminary assessment of two alternative core design concepts for the special purpose reactor[R]. Idaho Falls: Idaho National Lab (INL), 2017. [8] Alnæs M S, Blechta J, Hake J, et al. The FEniCS project version 1.5[J]. Archive of Numerical Software, 2015, 3(100): 9-23. [9] Logg A, Mardal K A, Wells G. Automated solution of differential equations by the finite element method: the FEniCS book[M]. Heidelberg: Springer, 2012. [10] Sterbentz J W, Werner J E, Mckellar M G, et al. Special purpose nuclear reactor (5 MW) for reliable power at remote sites assessment report[R]. Idaho Falls: Idaho National Lab (INL), 2017: 5. [11] Ross A M, Stoute R L. Heat transfer coefficient between UO2 and zircaloy-2[R]. Ontario: Chalk River, 1962. [12] 李登伟. 超临界二氧化碳模块化小堆热工水力及安全分析[D]. 上海: 上海交通大学, 2020: 24-25Li Dengwei. Thermal hydraulics and safety analysis of a supercritical carbon-dioxide modular small reactor[D]. Shanghai: Shanghai Jiao Tong University, 2020: 24-25 [13] Lee K M, Ohn M Y, Lim H S, et al. Study on models for gap conductance between fuel and sheath for CANDU reactors[J]. Annals of Nuclear Energy, 1995, 22(9): 601-610. doi: 10.1016/0306-4549(95)00005-D [14] 杨世铭, 陶文铨. 传热学[M]. 4版. 北京: 高等教育出版社, 2007Yang Shiming, Tao Wenquan. Heat transfer[M]. 4th ed. Beijing: Higher Education Press, 2007 [15] 苏光辉, 秋穗正, 田文喜, 等. 核动力系统热工水力计算方法[M]. 北京: 清华大学出版社, 2013Su Guanghui, Qiu Suizheng, Tian Wenxi, et al. Thermal-hydraulic calculation methods for nuclear power systems[M]. Beijing: Tsinghua University Press, 2013 [16] Barber J R. Contact mechanics[M]. Cham: Springer, 2018. -

下载:

下载: