Design of microwave plasma reactor based on compressed electric field

-

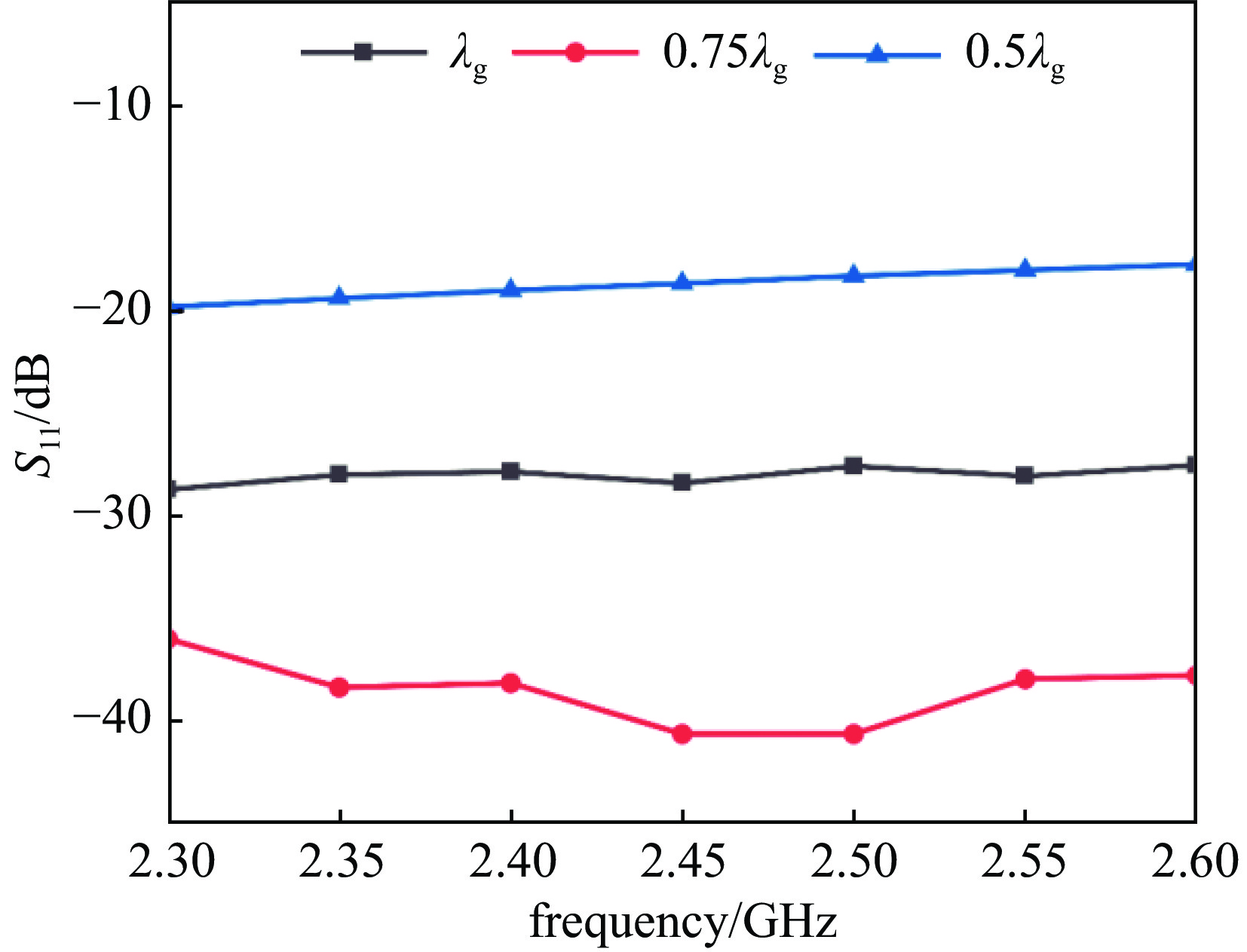

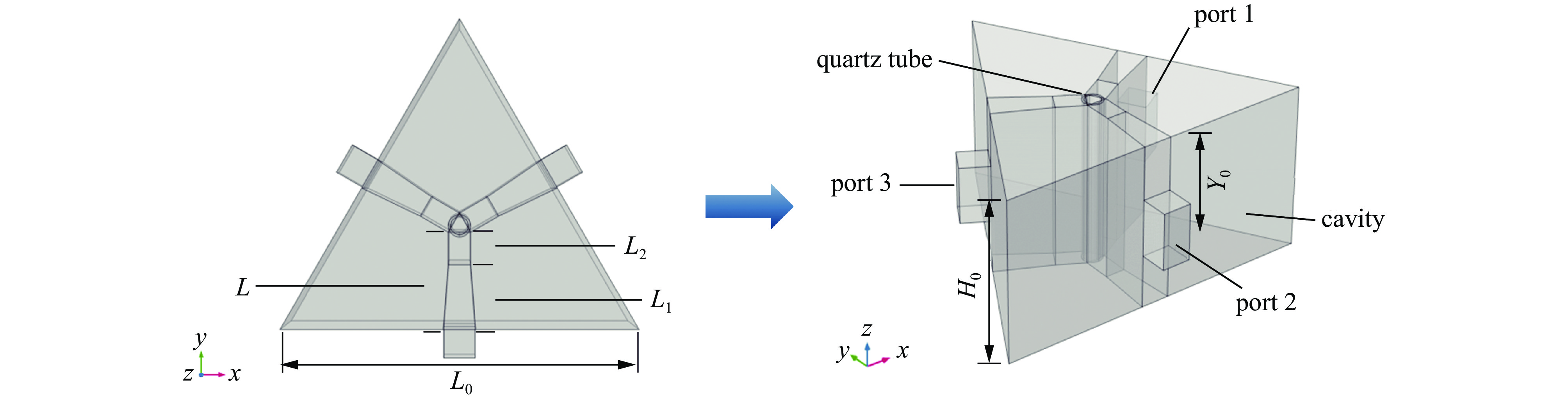

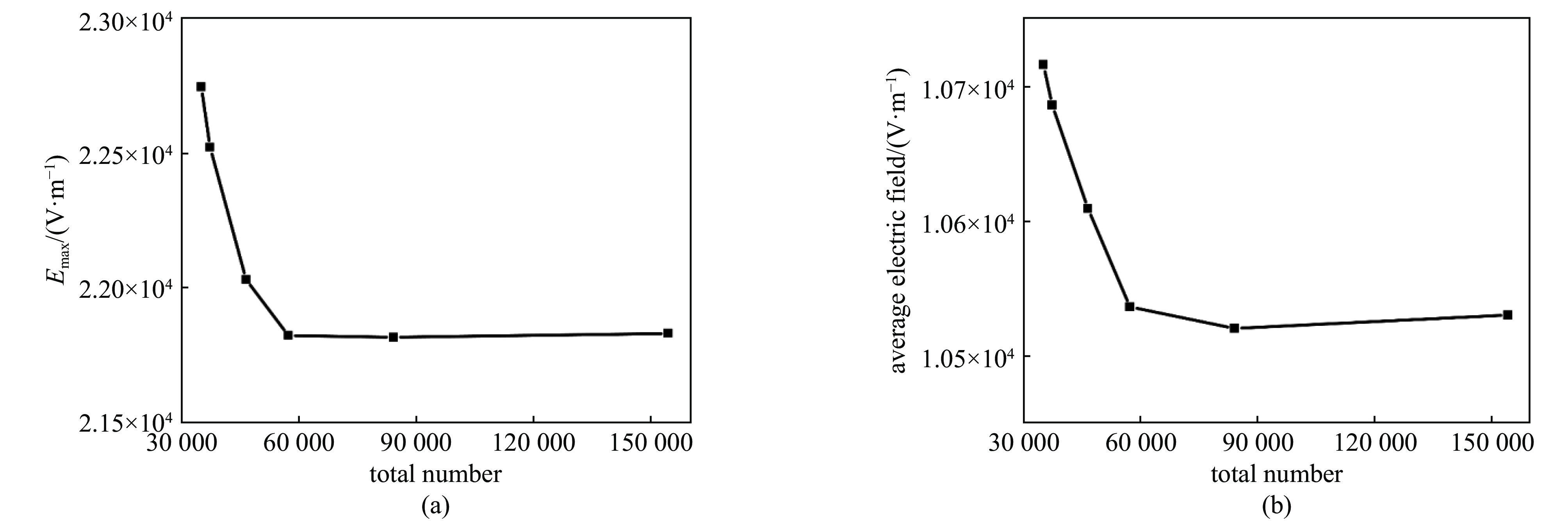

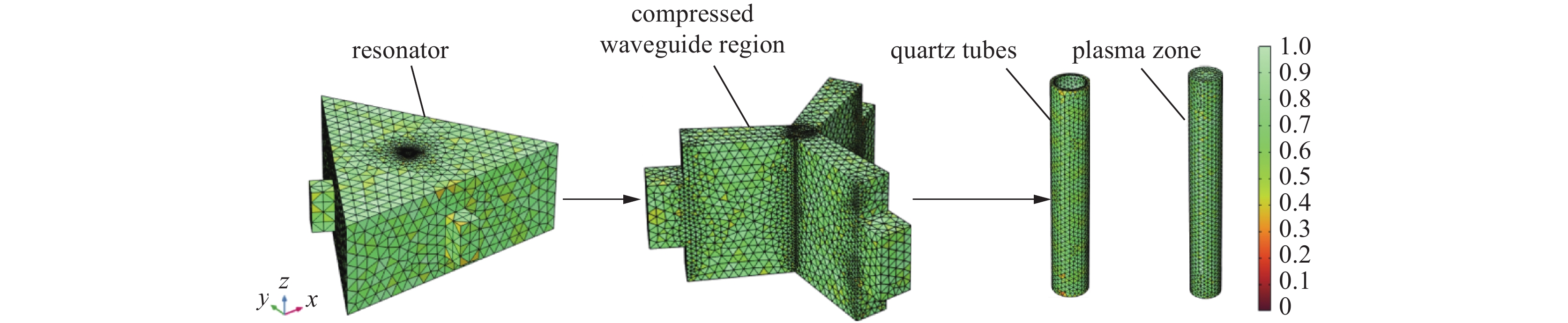

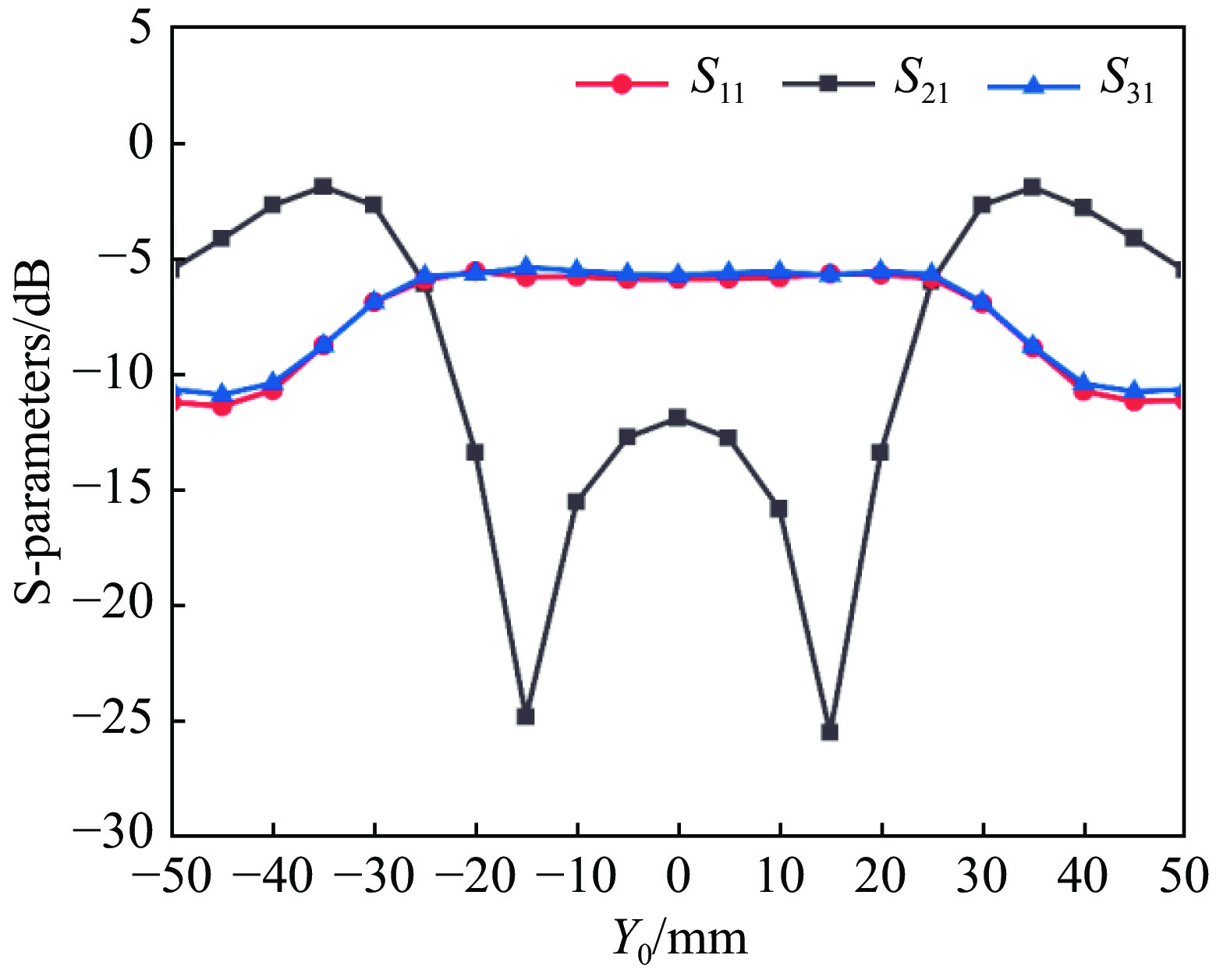

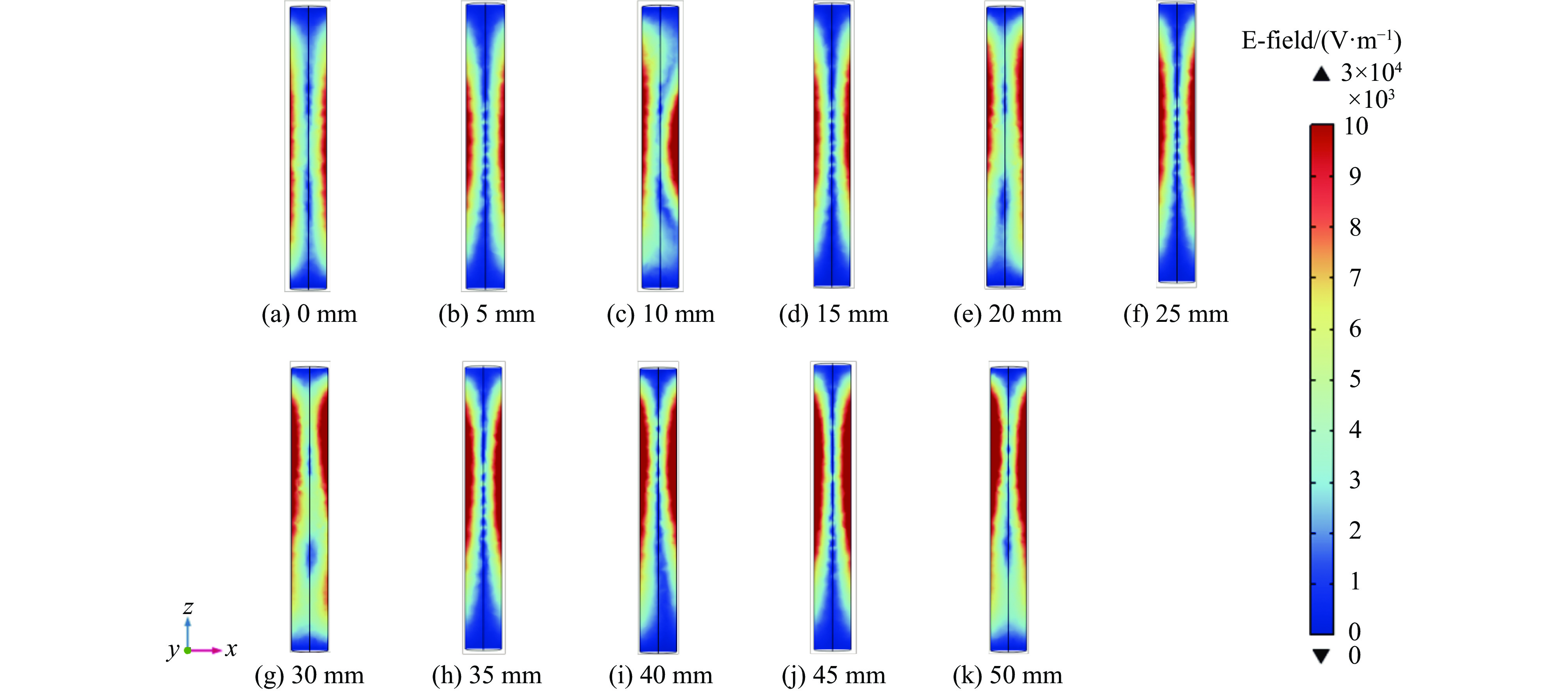

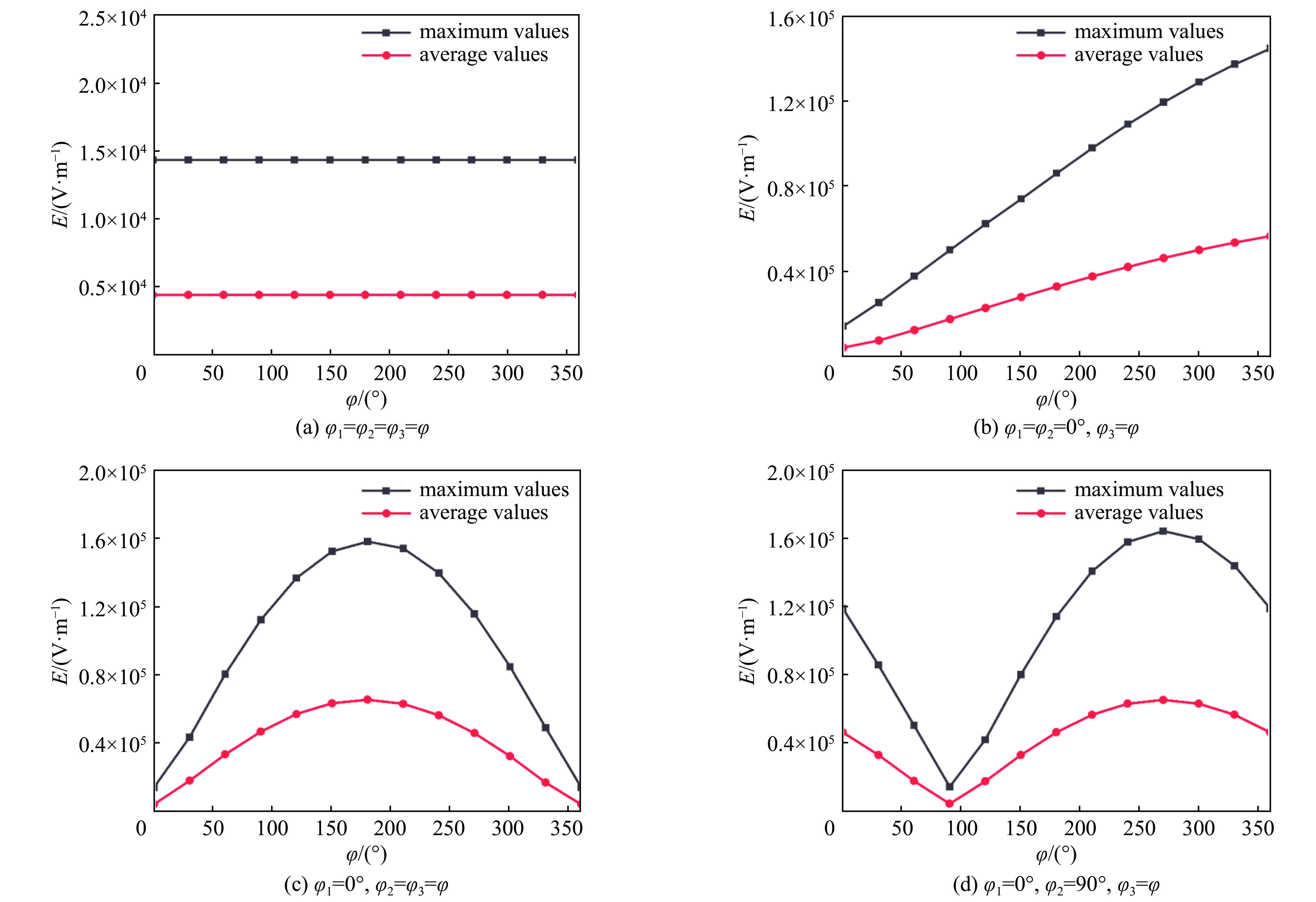

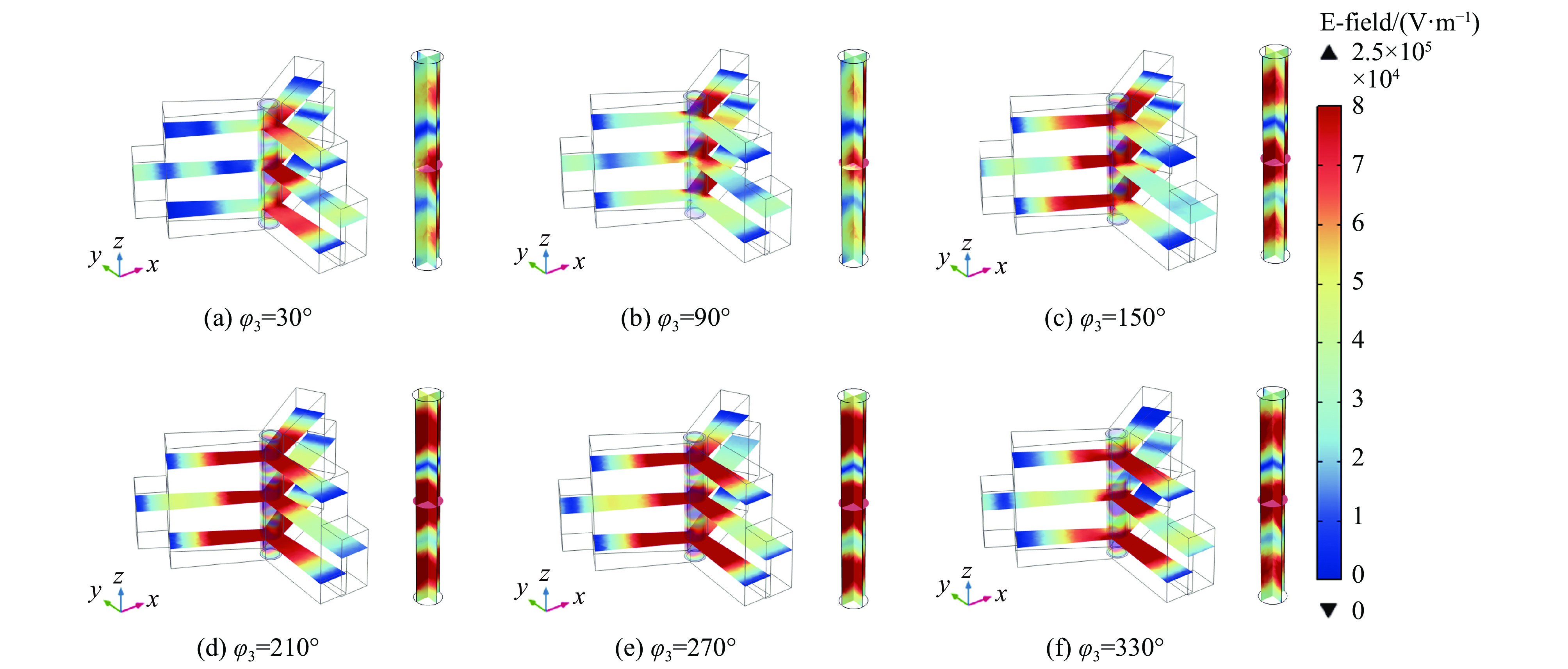

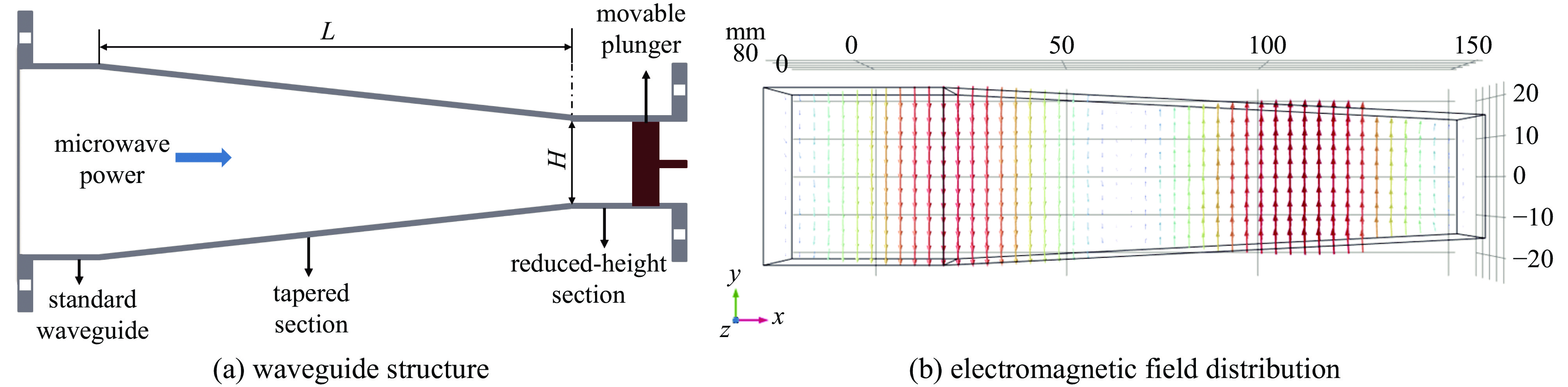

摘要: 微波等离子体因其高电子密度和功率利用效率等优势,在材料合成和化工催化等领域都展现出显著优势。为解决传统反应器反应区小,限制其大规模应用的问题,基于压缩波导原理创新性地提出了一种三棱柱式微波等离子体反应器结构。设计采用三端口对称构型,并在腔体内部引入压缩波导结构,以实现电场的有效叠加和增强;运用多物理场耦合计算方法,系统分析了端口位置和微波相位对腔体内部反射系数和电场分布特性的影响规律。结果显示,优化端口位置可以降低反射系数,提高能量利用利效率;调控端口相位能有效增强电场的叠加效应,使电场集中且广泛分布在石英管区域,峰值场强高达1.64×105 V/m,满足大面积等离子体的激发条件,为后续微波等离子体化学反应的研究奠定了基础。Abstract: Microwave plasma has shown significant advantages in the fields of materials synthesis and chemical catalysis due to its high electron density and power utilization efficiency. To solve the problem that the small reaction area of traditional reactor limits its large-scale application, a three-prism microwave plasma reactor structure is innovatively proposed based on the principle of compressed waveguide. The design adopts a three-port symmetric configuration and introduces a compressed waveguide structure inside the cavity to achieve effective superposition and enhancement of the electric field. In addition, the influence of the port positions and microwave phases on the reflection coefficient and electric field distribution characteristics inside the cavity is systematically analyzed by using the multi-physical field coupling calculation method. The results show that optimizing the port position can reduce the reflection coefficient and improve the efficiency of energy utilization, regulating the port phase can effectively enhance the superposition effect of the electric field, so that the electric field is concentrated and widely distributed in the area of the quartz tube, and the peak field strength is as high as 1.64×105 V/m, which can satisfy the excitation conditions of the large-area plasma, and lays a foundation for the subsequent research of microwave plasma chemical reaction.

-

Key words:

- plasma /

- microwave /

- rectangular waveguide /

- reactor /

- phases

-

表 1 模型尺寸参数

Table 1. Model size parameters

L0/mm H0/mm L/mm R0/mm d/mm 480 186 130 15 3 表 2 网格独立性

Table 2. Grid independent validation of the geometry model

No. element size element number mesh element quality minimum average Ⅰ coarse 35 136 0.192 3 0.651 0 Ⅱ normal 37 386 0.215 2 0.659 0 Ⅲ fine 46 568 0.253 2 0.661 4 Ⅳ finer 57 345 0.204 3 0.665 3 Ⅴ extra fine 84 252 0.203 0 0.666 2 Ⅵ extremely fine 154 392 0.183 3 0.672 3 -

[1] Bárdoš L, Baránková H. Microwave plasma sources and methods in processing technology[M]. Hoboken: John Wiley & Sons, Inc. , 2022. [2] Bhat K S, Sreedevi K, Ravi M. Thermal analysis of electron gun for travelling wave tubes[J]. Applied Surface Science, 2006, 253(2): 679-682. doi: 10.1016/j.apsusc.2005.12.154 [3] Siores E, Do Rego D. Microwave applications in materials joining[J]. Journal of Materials Processing Technology, 1995, 48(1/4): 619-625. [4] 曾凯凯, 莫荣珍, 李宇浩, 等. 等离子表面处理在汽车密封条粘接工艺上的应用[J]. 汽车维修技师, 2024(22):104-106 doi: 10.3969/j.issn.1671-279X.2024.22.050Zeng Kaikai, Mo Rongzhen, Li Yuhao, et al. Application of plasma surface treatment in the bonding process of automobile sealing strip[J]. Auto Maintenance, 2024(22): 104-106 doi: 10.3969/j.issn.1671-279X.2024.22.050 [5] Xiao Wei, Huang Kama, He Jianbo, et al. A novel high-efficiency stable atmospheric microwave plasma device for fluid processing based on ridged waveguide[J]. Journal of Physics D: Applied Physics, 2017, 50: 385201. doi: 10.1088/1361-6463/aa82fe [6] Liu Zhuang, Zhang Wencong, Tao Junwu, et al. A microwave-induced room-temperature atmospheric-pressure plasma jet[J]. IEEE Transactions on Plasma Science, 2019, 47(4): 1749-1753. doi: 10.1109/TPS.2019.2904053 [7] Chan I M, Cheng Wengcheng, Hong F C. Enhanced performance of organic light-emitting devices by atmospheric plasma treatment of indium tin oxide surfaces[J]. Applied Physics Letters, 2002, 80(1): 13-15. doi: 10.1063/1.1428624 [8] 傅文杰, 鄢扬. 高功率微波在等离子体填充波导中的传播特性[J]. 强激光与粒子束, 2005, 17(12):1852-1856Fu Wenjie, Yan Yang. Propagation characteristics of a high-power microwave in plasma-filled waveguide[J]. High Power Laser and Particle Beams, 2005, 17(12): 1852-1856 [9] Gu Yajun, Lu J, Grotjohn T, et al. Microwave plasma reactor design for high pressure and high power density diamond synthesis[J]. Diamond and Related Materials, 2012, 24: 210-214. doi: 10.1016/j.diamond.2012.01.026 [10] Li X J, Tang W Z, Wang F Y, et al. A compact ellipsoidal cavity type microwave plasma reactor for diamond film deposition[J]. Diamond and Related Materials, 2011, 20(3): 374-379. doi: 10.1016/j.diamond.2011.01.025 [11] Shen Qinghao, Huang Run, Xu Zili, et al. Numerical 3D modeling: microwave plasma torch at intermediate pressure[J]. Applied Sciences, 2020, 10: 5393. doi: 10.3390/app10155393 [12] 张瑶圃, 吴丽, 黄卡玛. 一种基于矩形压缩波导的5.8 GHz微波等离子体激发装置[J]. 真空电子技术, 2022(2):82-85,106Zhang Yaopu, Wu Li, Huang Kama. 5.8 GHz microwave plasma source based on compression rectangular waveguides[J]. Vacuum Electronics, 2022(2): 82-85,106 [13] Hu Yedai, Zhang Wencong, Han Jiahui, et al. Design and study of a large-scale microwave plasma torch with four ports[J]. Processes, 2023, 11: 2589. doi: 10.3390/pr11092589 [14] 周蓉, 杨晓庆. 一种用于激发微波等离子体的新型矩形压缩波导仿真设计[J]. 真空电子技术, 2016(3):51-53,64 doi: 10.3969/j.issn.1002-8935.2016.03.013Zhou Rong, Yang Xiaoqing. Simulation design of a novel rectangular compression waveguide for microwave plasma generating[J]. Vacuum Electronics, 2016(3): 51-53,64 doi: 10.3969/j.issn.1002-8935.2016.03.013 [15] Hong Y C, Uhm H S. Properties of plasma flames sustained by microwaves and burning hydrocarbon fuels[J]. Physics of Plasmas, 2006, 13: 113501. doi: 10.1063/1.2363348 [16] Kuo S P, Bivolaru D, Lai H, et al. Characteristics of an arc-seeded microwave plasma torch[J]. IEEE Transactions on Plasma Science, 2004, 32(4): 1734-1741. doi: 10.1109/TPS.2004.832517 [17] 廖承恩. 微波技术基础[M]. 北京: 国防工业出版社, 1984Liao Cheng’en. Fundamentals of microwave technology[M]. Beijing: National Defense Industry Press, 1984 [18] Zuo S S, Yaran M K, Grotjohn T A, et al. Investigation of diamond deposition uniformity and quality for freestanding film and substrate applications[J]. Diamond and Related Materials, 2008, 17(3): 300-305. doi: 10.1016/j.diamond.2007.12.069 [19] Tachibana T, Ando Y, Watanabe A, et al. Diamond films grown by a 60-kW microwave plasma chemical vapor deposition system[J]. Diamond and Related Materials, 2001, 10(9/10): 1569-1572. [20] Santos T, Valente M A, Monteiro J, et al. Electromagnetic and thermal history during microwave heating[J]. Applied Thermal Engineering, 2011, 31(16): 3255-3261. doi: 10.1016/j.applthermaleng.2011.06.006 [21] Wang Nan, Yu Jianglong, Tahmasebi A, et al. Experimental study on microwave pyrolysis of an indonesian low-rank coal[J]. Energy & Fuels, 2014, 28(1): 254-263. [22] Zhou Jie, Yang Xiaoqing, Ye Jinghua, et al. Arbitrary Lagrangian-Eulerian method for computation of rotating target during microwave heating[J]. International Journal of Heat and Mass Transfer, 2019, 134: 271-285. doi: 10.1016/j.ijheatmasstransfer.2019.01.007 [23] Więckowski A, Korpas P, Krysicki M, et al. Efficiency optimization for phase controlled multi-source microwave oven[J]. International Journal of Applied Electromagnetics and Mechanics, 2014, 44(2): 235-241. doi: 10.3233/JAE-141764 [24] 包玉, 何湘, 陈建平, 等. 等离子体对高频微波传输特性的影响[J]. 强激光与粒子束, 2025, 37:013003 doi: 10.11884/HPLPB202537.240296Bao Yu, He Xiang, Chen Jianping, et al. Effect of plasma on transmission characteristics of high-frequency microwave[J]. High Power Laser and Particle Beams, 2025, 37: 013003 doi: 10.11884/HPLPB202537.240296 [25] Verma K, Yang Ran, Gan Hao, et al. An integrated numerical and analytical model to understand the effect of relative phase in a dual-port solid-state microwave heating process[J]. Journal of Food Engineering, 2024, 367: 111869. doi: 10.1016/j.jfoodeng.2023.111869 -

下载:

下载: