Research progress on wettability of laser-textured aluminum alloy surfaces

-

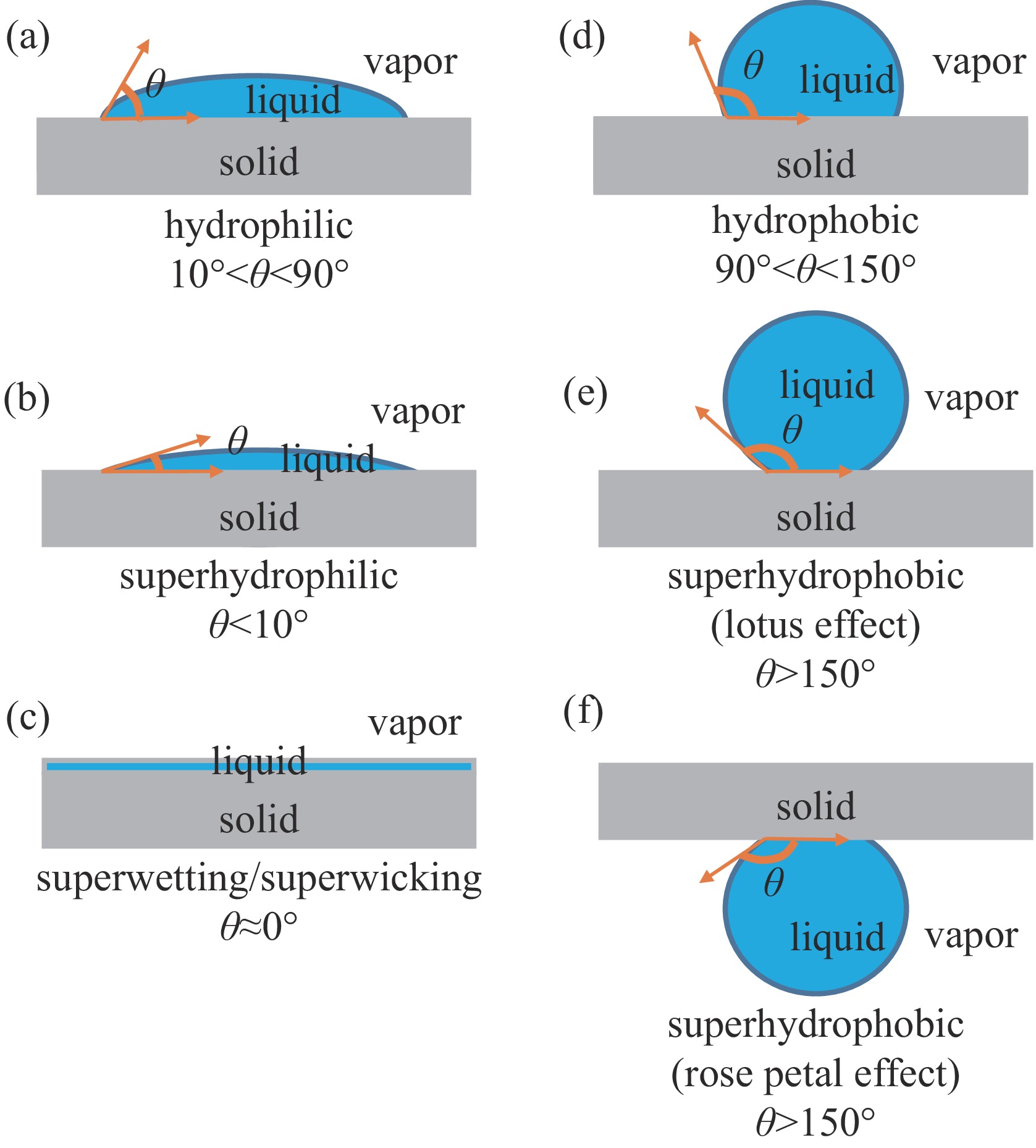

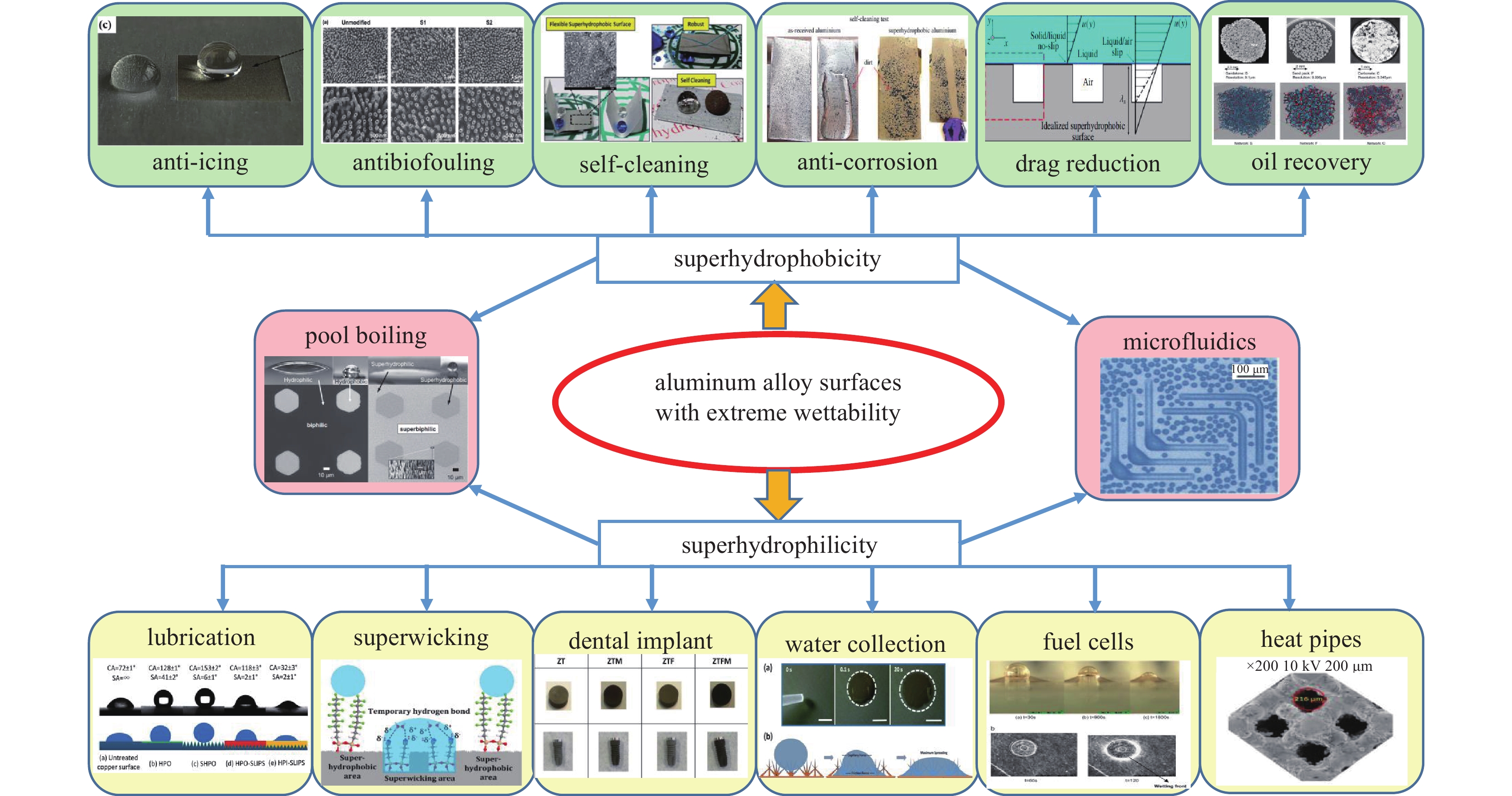

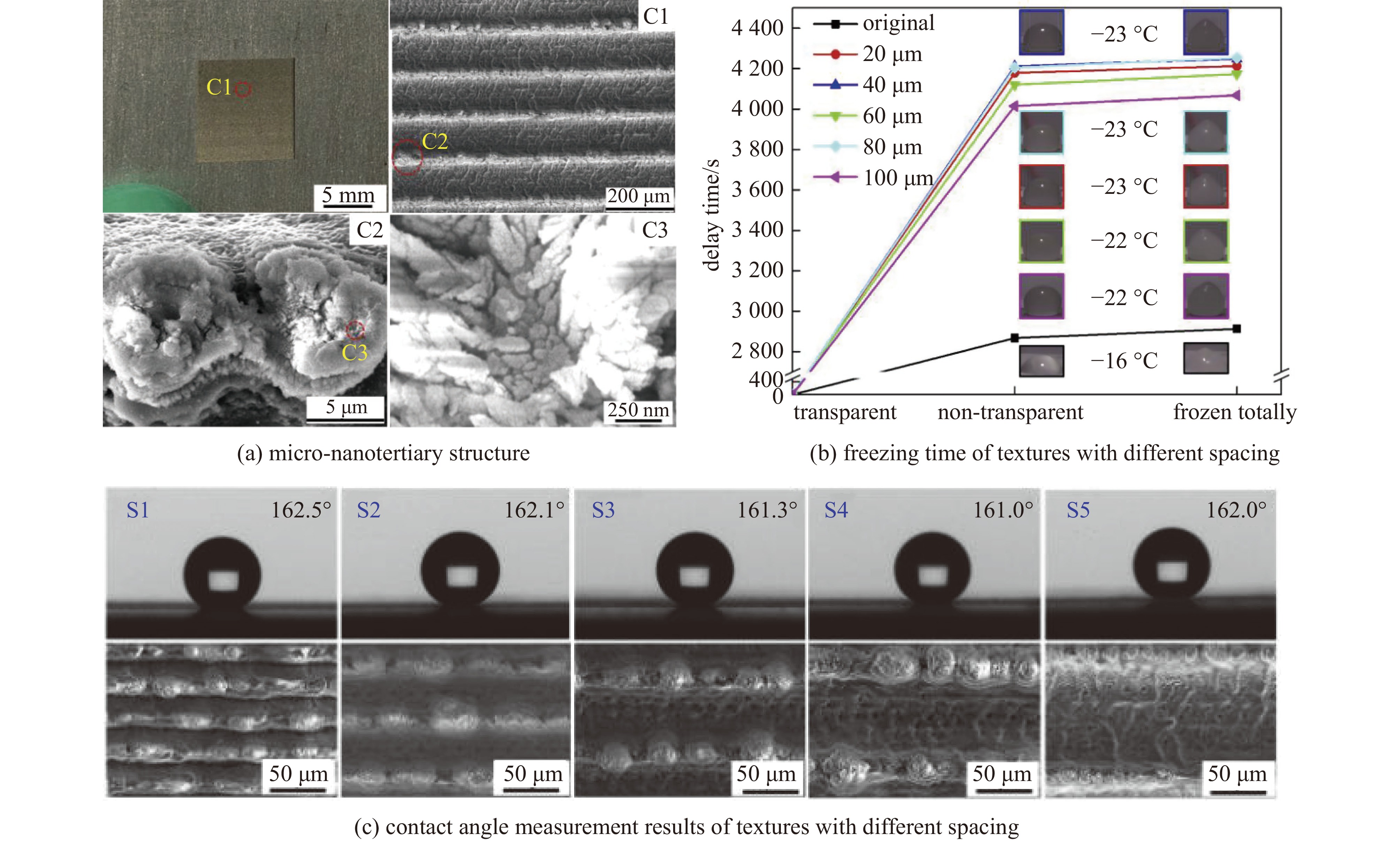

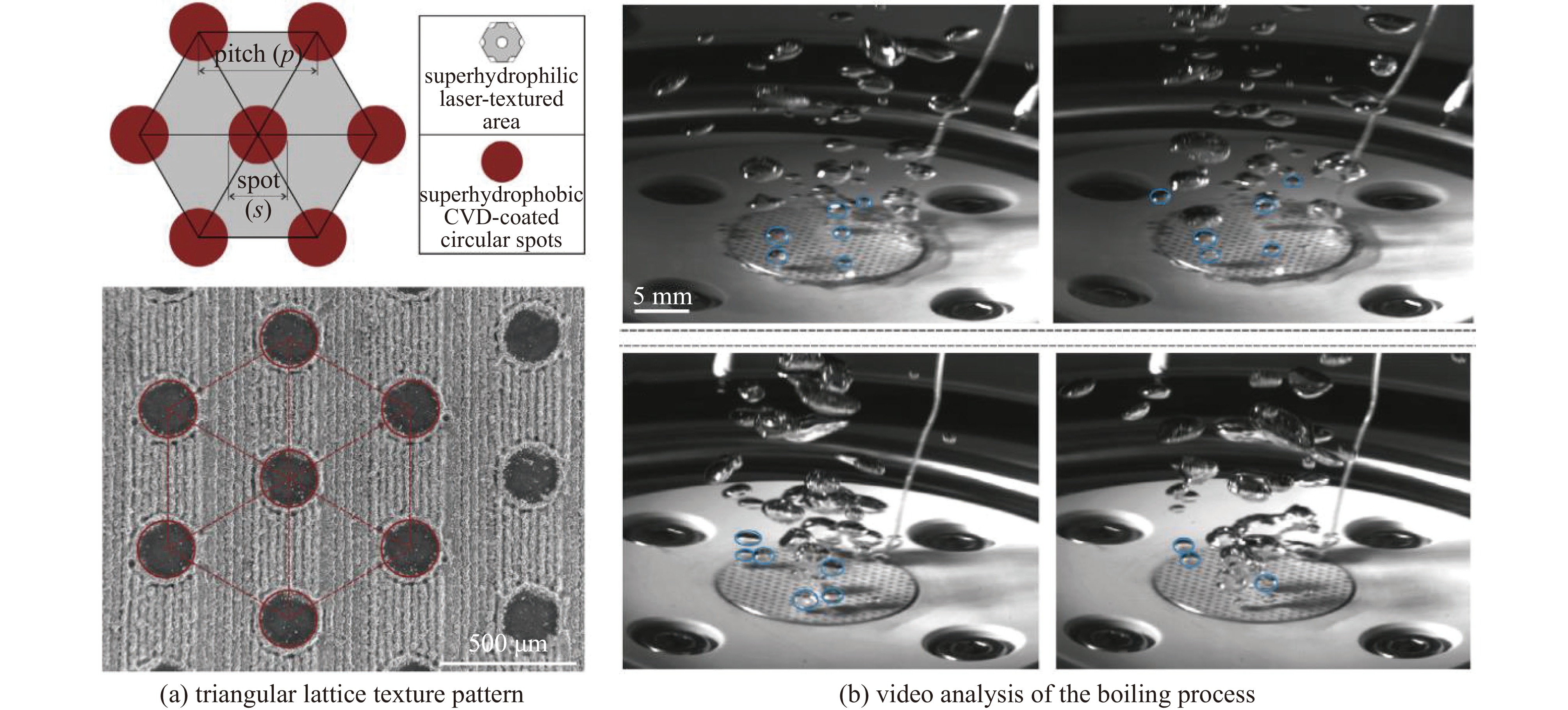

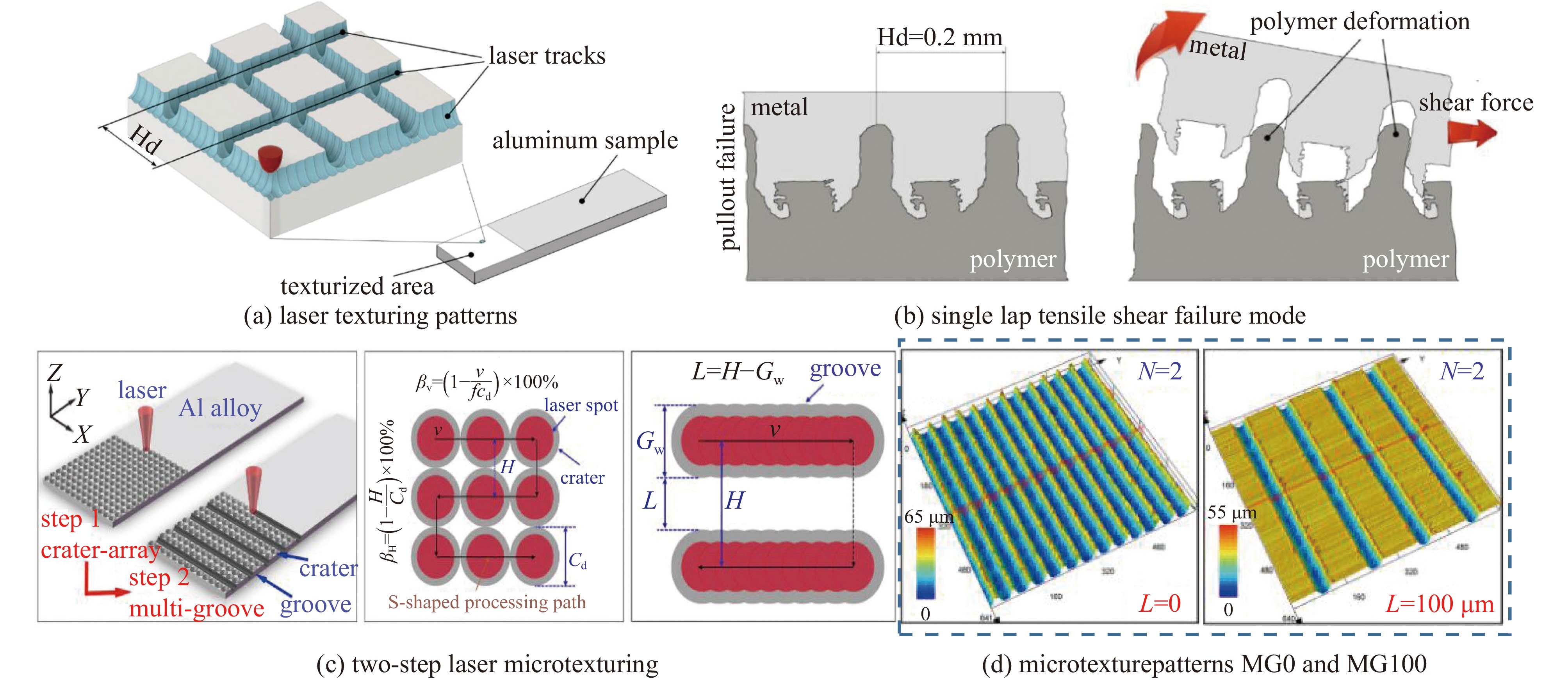

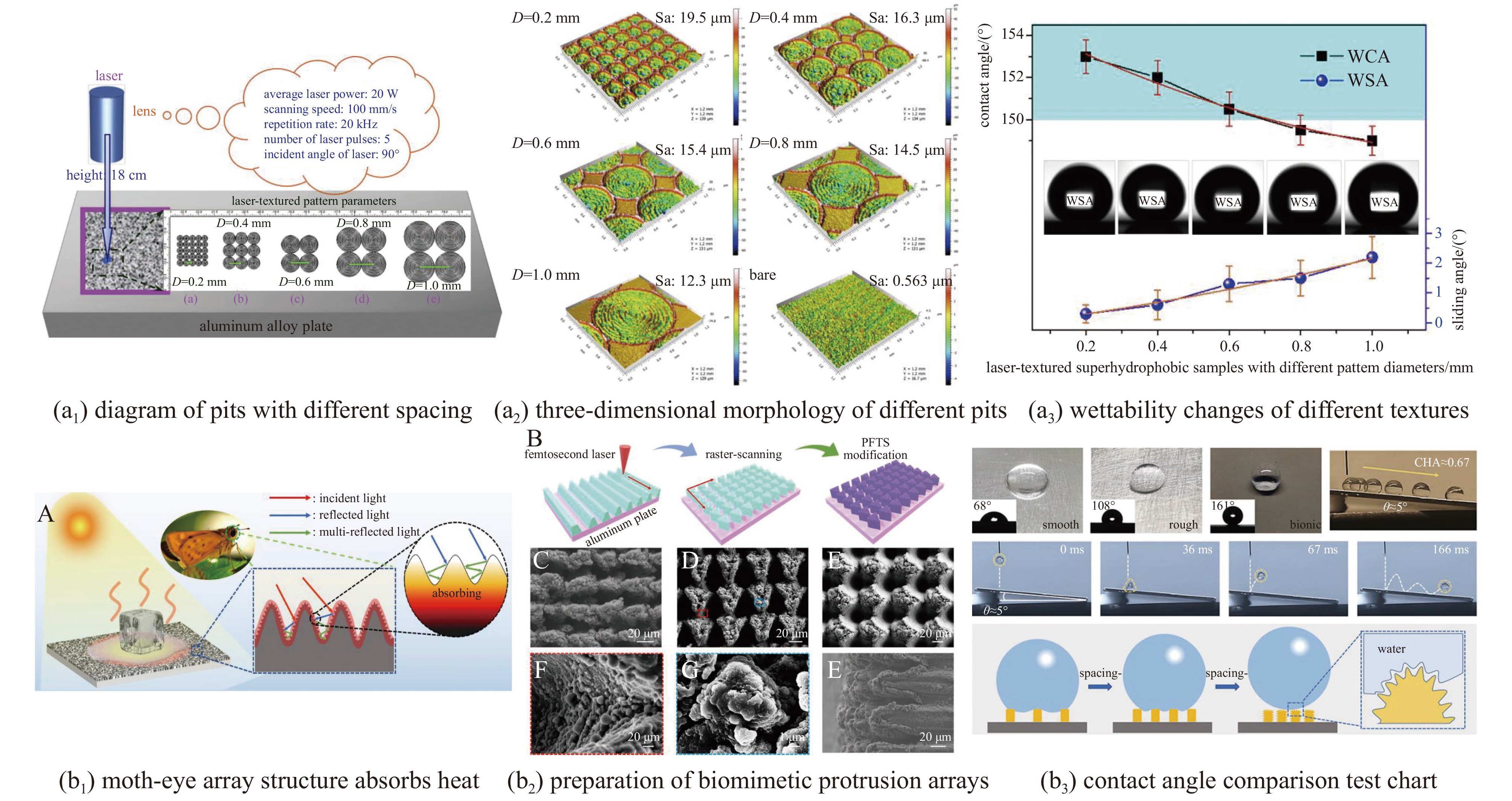

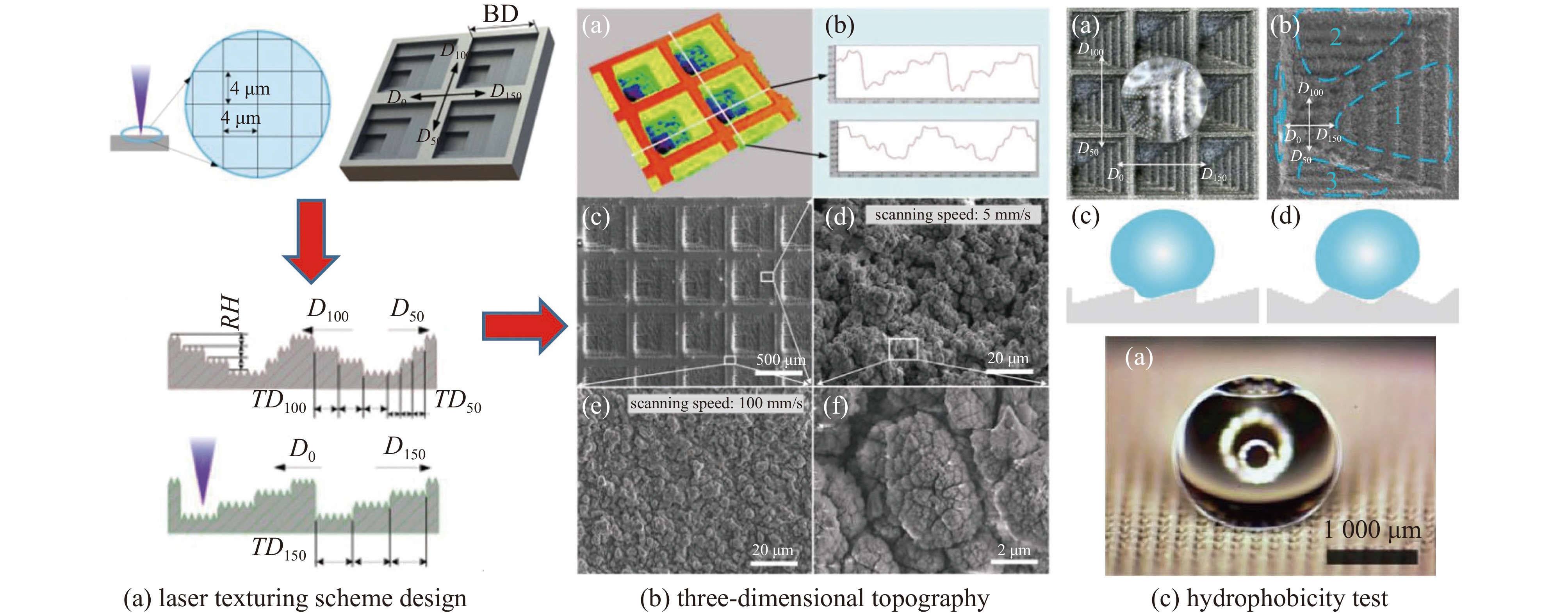

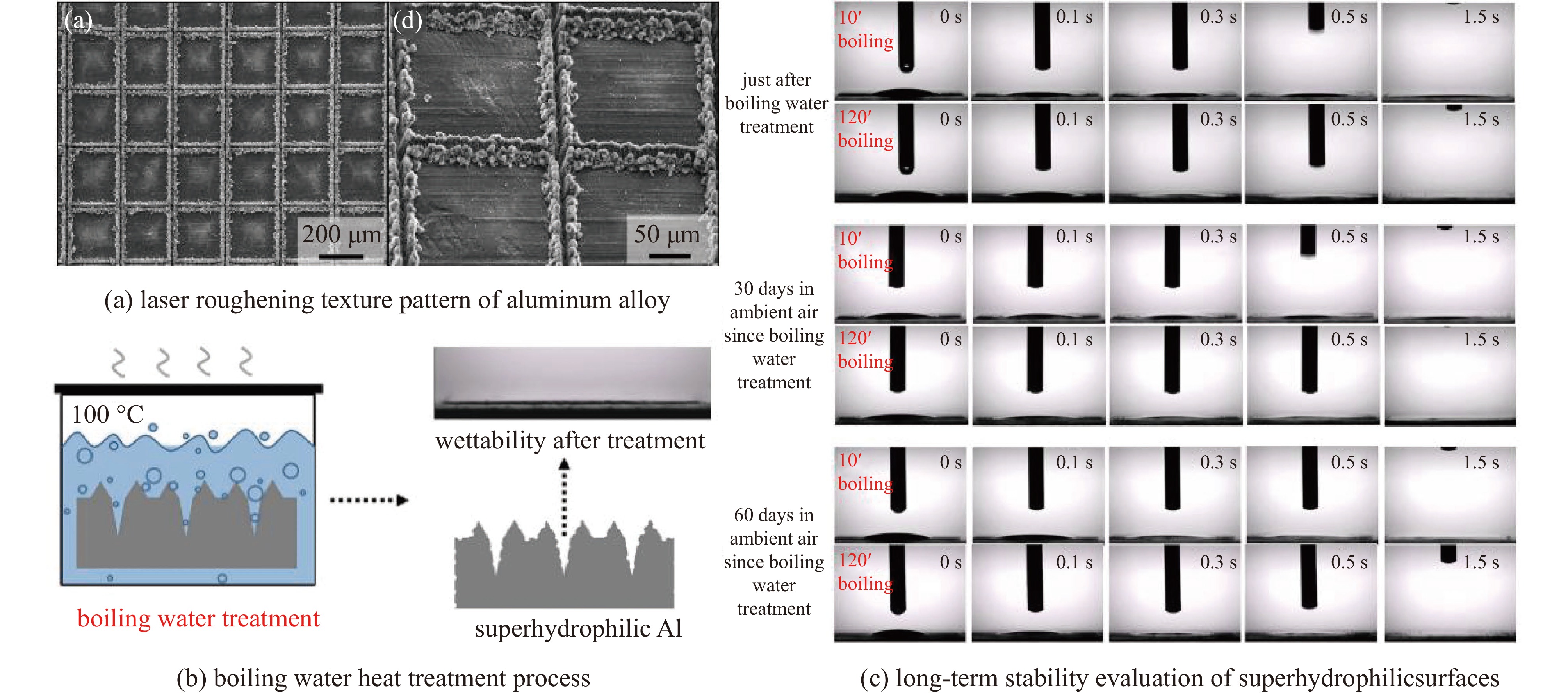

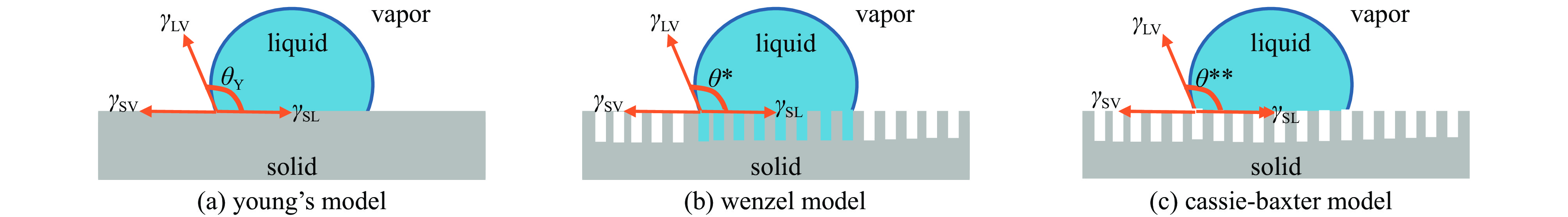

摘要: 作为轻量化设计的战略材料,铝合金凭借其低比重、耐腐蚀和良好的低温特性,在海洋装备、航空航天及交通运输领域中占据重要地位。值得注意的是,表面润湿特性作为铝合金功能化应用的关键界面参数,直接影响其工程服役性能。近年来,基于激光毛化织构的表面润湿性调控技术突破传统化学改性局限,为铝合金表面功能化提供了新的思路。本文系统阐释了润湿性基础理论体系,包括Young氏模型、Wenzel模型和Cassie-Baxter模型,分析了超短脉冲激光和长脉冲激光体系在铝合金表面仿生功能化构建中的应用差异,其中超短脉冲激光(飞秒/皮秒)凭借其极短脉宽和超高峰值功率的特性可实现亚微米级精密织构,而长脉冲激光则在大面积加工效率方面具有优势。研究显示,此类功能化表面在表面自清洁、低温防覆冰、耐Cl−腐蚀、高效沸腾传热、粘接及微流控等领域展现出显著优势,然而其实际应用仍受限于润湿稳定性衰退和环境耐受性不足等关键技术瓶颈。Abstract: As a strategic material for lightweight design, aluminum alloys occupy an important position in the fields of marine equipment, aerospace, and transportation due to their low specific gravity, corrosion resistance, and good low-temperature properties. It is worth noting that surface wettability, as a key interface parameter for the functionalization of aluminum alloys, directly affects their engineering service performance. In recent years, surface wettability control technology based on laser texturing has broken through the limitations of traditional chemical modification and provided new ideas for the functionalization of aluminum alloy surfaces. This article systematically explains the basic theoretical system of wettability, including the Young model, the Wenzel model, and the Cassie-Baxter model, and analyzes the differences in the application of ultrashort pulse lasers and long pulse laser systems in the construction of biomimetic functionalization of aluminum alloy surfaces. Among them, ultrashort pulse lasers (femtosecond/picosecond) can achieve submicron-level precision texturing due to their extremely short pulse width and ultra-high peak power, while long pulse lasers have advantages in large-area processing efficiency. Research has shown that these functionalized surfaces exhibit significant advantages in areas such as surface self-cleaning, low-temperature anti-icing, Cl− corrosion resistance, efficient boiling heat transfer, bonding, and microfluidics. However, their practical application is still limited by key technical bottlenecks such as wetting stability degradation and insufficient environmental tolerance.

-

Key words:

- laser surface texturing /

- aluminum alloy /

- wettability /

- biomimetic /

- micro-nano composite structure

-

表 1 超疏水性表面长效稳定性策略

Table 1. Strategies for long-term stability of superhydrophobic surfaces

team time optimization strategy stability improvement effect references Gou Yanqiang 2022 liquid nitrogen-assisted ultrasonic laser etching hardness increased by 18% and wear

rate reduced by 50%[78] Boinovich, et al. 2017 multiple laser treatment + fluorosilane modification immersed in 3M KCl for 30 d, corrosion

current <10−7 A/cm2[79] Lu, et al. 2025 self-healing coating design the contact angle recovery rate is more than

95% within 24 h after scratching[80] Xu, et al. 2022 multi-level structure contact angle >150° after 30 d of salt spray corrosion and no failure after 50 thermal shocks [81] Li, et al. 2018 bionic microgroove array contact angle decay under external force <1.1° [82] 表 2 超亲水性表面长效稳定性策略

Table 2. Strategies for long-term stability of superhydrophilic surfaces

team time optimization strategy stability improvement effect references Samanta, et al. 2020 pseudoboehmite (AlOOH) nanostructure contact angle <10° after 30 d [42] Holder, et al. 2025 laser treatment + PECVD oil-water separation efficiency >95% in 120 h [74] Samanta, et al. 2021 laser treatment + multiple chemistry modification capillary super wicking with contact angle $ \approx 0 $° [83] Jiang, et al. 2023 multiple laser treatment improved bonding strength [84] -

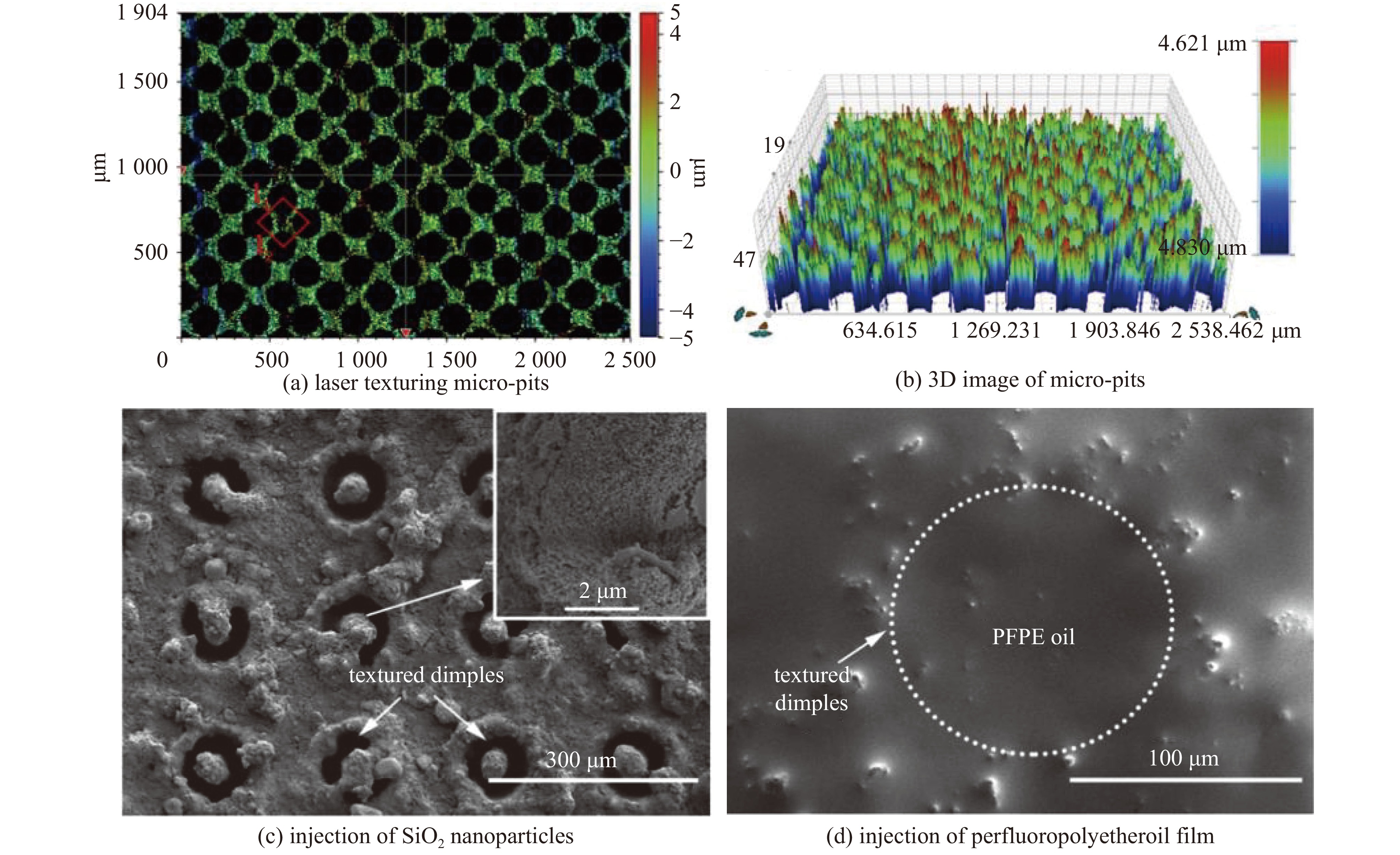

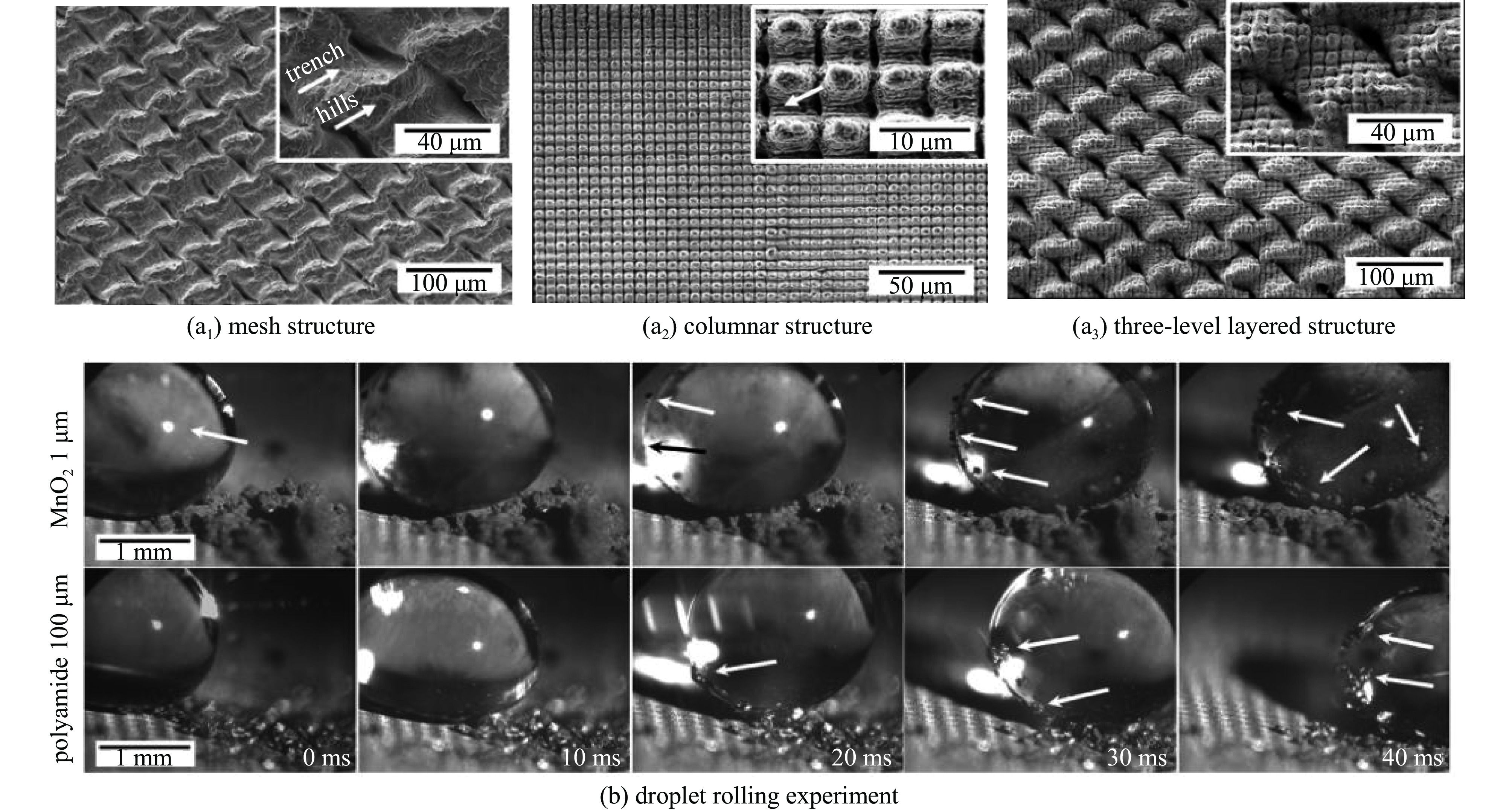

[1] 吴国荣, 黄诗雯, 郭跃, 等. 面向碳中和的汽车生命周期材料发展与展望[J]. 材料导报, 2023, 37: 22090281Wu Guorong, Huang Shiwen, Guo Yue, et al. Development and prospect of carbon neutral automotive life-cycle materials[J]. Materials Reports, 2023, 37: 22090281 [2] 徐艳龙, 李文戈, 喻忠翰, 等. 基于激光毛化技术的5052铝合金粘接试验研究[J]. 强激光与粒子束, 2022, 34: 031010Xu Yanlong, Li Wenge, Yu Zhonghan, et al. Research on bonding test of 5052 aluminum alloy based on laser texturing technology[J]. High Power Laser and Particle Beams, 2022, 34: 031010 [3] Deng Qing, Zhang Po, Li Xiaozhi, et al. Effect of seawater salinity on the fretting corrosion behavior of nickel-aluminum bronze (NAB) alloy[J]. Tribology International, 2024, 193: 109357. doi: 10.1016/j.triboint.2024.109357 [4] Xing Wei, Li Zu, Yang Haiou, et al. Anti-icing aluminum alloy surface with multi-level micro-nano textures constructed by picosecond laser[J]. Materials & Design, 2019, 183: 108156. [5] Milošev I. Corrosion inhibition of aluminium alloys by molybdate ions: a critical review of the chemistry, mechanisms and applications[J]. Corrosion Science, 2024, 229: 111854. doi: 10.1016/j.corsci.2024.111854 [6] Zhang Daquan, Yan Zixuan, Gao Lixin, et al. Corrosion behavior of AA5052 aluminum alloy in the presence of heavy metal ions in 3.5% NaCl solution under negative pressure[J]. Desalination, 2024, 570: 117082. doi: 10.1016/j.desal.2023.117082 [7] Nkoua C, Josse C, Proietti A, et al. Corrosion behaviour of the microbially modified surface of 5083 aluminium alloy[J]. Corrosion Science, 2023, 210: 110812. doi: 10.1016/j.corsci.2022.110812 [8] Rodič P, Kovač N, Kralj S, et al. Anti-corrosion and anti-icing properties of superhydrophobic laser-textured aluminum surfaces[J]. Surface and Coatings Technology, 2024, 494: 131325. doi: 10.1016/j.surfcoat.2024.131325 [9] Li Kai, Lei Xiaowei, Ding Zhihan, et al. Super anti-corrosion surface of Al-Li alloy via femtosecond laser ablation treatment in water[J]. Journal of Alloys and Compounds, 2024, 971: 172704. doi: 10.1016/j.jallcom.2023.172704 [10] Tian Ze, Lei Zhenglong, Chen Xi, et al. Nanosecond pulsed fiber laser cleaning of natural marine micro-biofoulings from the surface of aluminum alloy[J]. Journal of Cleaner Production, 2020, 244: 118724. doi: 10.1016/j.jclepro.2019.118724 [11] Guerrero-Vacas G, Fusco S, Rodríguez-Valverde M Á, et al. Manufacturing hydrophobic surfaces on aluminium substrates by micro-milling with end-ball nose tools[J]. Journal of Manufacturing Processes, 2024, 124: 24-37. doi: 10.1016/j.jmapro.2024.05.086 [12] Lambiase F, Genna S. Moisture-induced defects produced by direct laser joining of AA7075 aluminum and PEEK[J]. Optics & Laser Technology, 2023, 165: 109553. [13] 倪敬, 李斌, 许静. 激光微织构拉刀制备与能量残留[J]. 强激光与粒子束, 2016, 28: 099001Ni Jing, Li Bin, Xu Jing. Preparation of laser micro-textured broach and residual energy[J]. High Power Laser and Particle Beams, 2016, 28: 099001 [14] Young T. An essay on the cohesion of fluids[J]. Proceedings of the Royal Society of London, 1832, 1: 171-172. [15] Wenzel R N. Resistance of solid surfaces to wetting by water[J]. Industrial & Engineering Chemistry, 1936, 28(8): 988-994. [16] Cassie A B D, Baxter S. Wettability of porous surfaces[J]. Transactions of the Faraday Society, 1944, 40: 546-551. doi: 10.1039/tf9444000546 [17] Li Zhe, Wang Sijie, Zheng Wanqing, et al. A review of dynamic monitoring technology and application research of laser cleaning interface[J]. Measurement, 2024, 238: 115311. doi: 10.1016/j.measurement.2024.115311 [18] Hou Liangpeng, Yin Fengshi, Wang Sijie, et al. A review of thermal effects and substrate damage control in laser cleaning[J]. Optics & Laser Technology, 2024, 174: 110613. [19] Tong Wei, Xiong Dangsheng. Direct laser texturing technique for metal surfaces to achieve superhydrophobicity[J]. Materials Today Physics, 2022, 23: 100651. doi: 10.1016/j.mtphys.2022.100651 [20] Zhu Guodong, Xu Zhenhai, Jin Yang, et al. Mechanism and application of laser cleaning: a review[J]. Optics and Lasers in Engineering, 2022, 157: 107130. doi: 10.1016/j.optlaseng.2022.107130 [21] Wang Xincai, Zheng Hongyu, Wan Yinchi, et al. Picosecond laser surface texturing of a Stavax steel substrate for wettability control[J]. Engineering, 2018, 4(6): 816-821. doi: 10.1016/j.eng.2018.10.006 [22] Zhao Jingnan, Guo Jian, Shrotriya P, et al. A rapid one-step nanosecond laser process for fabrication of super-hydrophilic aluminum surface[J]. Optics & Laser Technology, 2019, 117: 134-141. [23] Ngo C V, Chun D M. Control of laser-ablated aluminum surface wettability to superhydrophobic or superhydrophilic through simple heat treatment or water boiling post-processing[J]. Applied Surface Science, 2018, 435: 974-982. doi: 10.1016/j.apsusc.2017.11.185 [24] Lu Yao, Ding Ye, Wang Maolu, et al. An environmentally friendly laser cleaning method to remove oceanic micro-biofoulings from AH36 steel substrate and corrosion protection[J]. Journal of Cleaner Production, 2021, 314: 127961. doi: 10.1016/j.jclepro.2021.127961 [25] Samanta A, Wang Qinghua, Shaw S K, et al. Roles of chemistry modification for laser textured metal alloys to achieve extreme surface wetting behaviors[J]. Materials & Design, 2020, 192: 108744. [26] Vorobyev A Y, Guo Chunlei. Making human enamel and dentin surfaces superwetting for enhanced adhesion[J]. Applied Physics Letters, 2011, 99: 193703. doi: 10.1063/1.3660579 [27] Qi Yingchun, Sha Pengwei, Yang Kun, et al. Construction and parameter optimization of LPBF-NiTi alloy bionic superhydrophobic surface based on laser processing[J]. Journal of Materials Research and Technology, 2023, 24: 9462-9475. doi: 10.1016/j.jmrt.2023.05.162 [28] Huang Wuji, Nelson B, Tian S, et al. Superhydrophobic surface processing for metal 3D printed parts[J]. Applied Materials Today, 2022, 29: 101630. doi: 10.1016/j.apmt.2022.101630 [29] Guo Shuaicheng, Si Ruizhe, Dai Qingli, et al. A critical review of corrosion development and rust removal techniques on the structural/environmental performance of corroded steel bridges[J]. Journal of Cleaner Production, 2019, 233: 126-146. doi: 10.1016/j.jclepro.2019.06.023 [30] Castaño J G, Velilla E, Correa L, et al. Ceramic insulators coated with titanium dioxide films: properties and self-cleaning performance[J]. Electric Power Systems Research, 2014, 116: 182-186. doi: 10.1016/j.jpgr.2014.06.009 [31] Kant K, Pitchumani R. Fractal textured glass surface for enhanced performance and self-cleaning characteristics of photovoltaic panels[J]. Energy Conversion and Management, 2022, 270: 116240. doi: 10.1016/j.enconman.2022.116240 [32] Li Xinlin, Wang Guoyong, Moita A S, et al. Fabrication of bio-inspired non-fluorinated superhydrophobic surfaces with anti-icing property and its wettability transformation analysis[J]. Applied Surface Science, 2020, 505: 144386. doi: 10.1016/j.apsusc.2019.144386 [33] Ateş A, Benam B P, Mohammadilooey M, et al. Pool boiling heat transfer on superhydrophobic, superhydrophilic, and superbiphilic surfaces at atmospheric and sub-atmospheric pressures[J]. International Journal of Heat and Mass Transfer, 2023, 201: 123582. doi: 10.1016/j.ijheatmasstransfer.2022.123582 [34] Betz A R, Jenkins J, Kim C J, et al. Boiling heat transfer on superhydrophilic, superhydrophobic, and superbiphilic surfaces[J]. International Journal of Heat and Mass Transfer, 2013, 57(2): 733-741. doi: 10.1016/j.ijheatmasstransfer.2012.10.080 [35] Çoban O, Bilgiç E, Akman E, et al. Laser treated novel textures for adhesion performance of aluminum alloy joints exposed to corrosion[J]. International Journal of Adhesion and Adhesives, 2024, 132: 103732. doi: 10.1016/j.ijadhadh.2024.103732 [36] Li Wenqin, Jin Yang, Gu Junyi, et al. Critical surface characteristics for coating adhesion and friction behavior of aluminum alloys after laser cleaning[J]. Journal of Materials Processing Technology, 2024, 332: 118549. doi: 10.1016/j.jmatprotec.2024.118549 [37] Milles S, Soldera M, Kuntze T, et al. Characterization of self-cleaning properties on superhydrophobic aluminum surfaces fabricated by direct laser writing and direct laser interference patterning[J]. Applied Surface Science, 2020, 525: 146518. doi: 10.1016/j.apsusc.2020.146518 [38] Rodrigues S P, Alves C F A, Cavaleiro A, et al. Water and oil wettability of anodized 6016 aluminum alloy surface[J]. Applied Surface Science, 2017, 422: 430-442. doi: 10.1016/j.apsusc.2017.05.204 [39] Zhang Yuliang, Li Xinxin, Lu Libin, et al. Anti-icing polyurethane coating on glass fiber-reinforced plastics induced by femtosecond laser texturing[J]. Applied Surface Science, 2024, 662: 160077. doi: 10.1016/j.apsusc.2024.160077 [40] Rico V, Mora J, García P, et al. Robust anti-icing superhydrophobic aluminum alloy surfaces by grafting fluorocarbon molecular chains[J]. Applied Materials Today, 2020, 21: 100815. doi: 10.1016/j.apmt.2020.100815 [41] Liu Dongdong, Liu Ri, Cao Liang, et al. Fabrication of periodic hierarchical structures with anti-icing performance by direct laser interference lithography and hydrothermal treatment[J]. Surface and Coatings Technology, 2023, 471: 129819. doi: 10.1016/j.surfcoat.2023.129819 [42] Wei Dongsong, Wang Jinguo, Wang Huiyuan, et al. Anti-corrosion behaviour of superwetting structured surfaces on Mg-9Al-1Zn magnesium alloy[J]. Applied Surface Science, 2019, 483: 1017-1026. doi: 10.1016/j.apsusc.2019.03.286 [43] Wang Wei, Li Xiangjin, Liu Weijun, et al. Experimental study on hydrophobic properties and corrosivity of laser cleaned 7075 aluminum alloy anodized film surface[J]. Optics & Laser Technology, 2023, 166: 109615. [44] 田泽. 铝合金表面海洋微生物膜层激光清洗及生长抑制机理[D]. 哈尔滨: 哈尔滨工业大学, 2020Tian Ze. Mechanisms of laser cleaning and growth inhibition of marine microbial film on the surface of aluminum alloys[D]. Harbin: Harbin Institute of Technology, 2020 [45] 郭乐扬, 阮海妮, 李文戈, 等. 船舶减阻表面工程技术研究进展[J]. 表面技术, 2022, 51(9): 53-64,73Guo Leyang, Ruan Haini, Li Wenge, et al. Research progress of surface engineering technology for ship drag reduction[J]. Surface Technology, 2022, 51(9): 53-64,73 [46] 刘克, 刘子源, 陶海岩, 等. 飞秒激光制备可调控铝合金表面微沟槽结构研究[J]. 长春理工大学学报(自然科学版), 2022, 45(3): 6-13Liu Ke, Liu Ziyuan, Tao Haiyan, et al. Research on femtosecond laser fabrication of adjustable micro-groove structure on aluminum alloy surface[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2022, 45(3): 6-13 [47] Li Jingcheng, Zhao Yixuan, Zhang Xueyan, et al. Influence of bionic texture on the mechanical properties of 6061Al/CFRTP laser joints[J]. Thin-Walled Structures, 2024, 205: 112393. doi: 10.1016/j.tws.2024.112393 [48] Lambiase F, Yanala P B, Leone C, et al. Influence of laser texturing strategy on thermomechanical joining of AA7075 aluminum alloy and PEEK[J]. Composite Structures, 2023, 315: 116974. doi: 10.1016/j.compstruct.2023.116974 [49] Leone C, Paoletti A, Babu Yanala P, et al. Improving bonding strength of aluminium-PEEK hybrid metal-polymer joints by two-step laser surface treatment[J]. Optics & Laser Technology, 2024, 170: 110304. [50] Li Rongyao, Feng Aixin, Li Xiao, et al. Study on nanosecond pulsed laser cleaning of FEP coatings on 6061-T6 aluminum alloy surface[J]. Optics & Laser Technology, 2025, 187: 112798. [51] Romoli L, Moroni F, Khan M M A. A study on the influence of surface laser texturing on the adhesive strength of bonded joints in aluminium alloys[J]. CIRP Annals, 2017, 66(1): 237-240. doi: 10.1016/j.cirp.2017.04.123 [52] 庄越, 刘峰, 储海靖, 等. 交流和纳秒脉冲Ar/H2O介质阻挡放电聚丙烯材料表面亲水改性对比研究[J]. 强激光与粒子束, 2021, 33: 065017Zhuang Yue, Liu Feng, Chu Haijing, et al. Comparison study of PP hydrophilic surface modification by Ar/H2O dielectric barrier discharge excited by AC and nanosecond pulse voltage[J]. High Power Laser and Particle Beams, 2021, 33: 065017 [53] Ijaola A O, Bamidele E A, Akisin C J, et al. Wettability transition for laser textured surfaces: a comprehensive review[J]. Surfaces and Interfaces, 2020, 21: 100802. doi: 10.1016/j.surfin.2020.100802 [54] Mao Yingchang, Zhu Yu, Deng Chenman, et al. Analysis of localized corrosion mechanism of 2024 aluminum alloy at a simulated marine splash zone[J]. Engineering Failure Analysis, 2022, 142: 106759. doi: 10.1016/j.engfailanal.2022.106759 [55] Jagdheesh R, Hauschwitz P, Mužík J, et al. Non-fluorinated superhydrophobic Al7075 aerospace alloy by ps laser processing[J]. Applied Surface Science, 2019, 493: 287-293. doi: 10.1016/j.apsusc.2019.07.035 [56] Khdair A I, Aghakhani S, Thi N H, et al. Molecular dynamics of wettability and condensation on nanostructured surfaces: fundamentals and hybrid wetting[J]. International Communications in Heat and Mass Transfer, 2025, 161: 108516. doi: 10.1016/j.icheatmasstransfer.2024.108516 [57] Qin Yongkun, Li Yan, Zhang Dong, et al. Wettability, durability and corrosion properties of slippery laser-textured aluminum alloy surface under water impact[J]. Surface and Coatings Technology, 2020, 394: 125856. doi: 10.1016/j.surfcoat.2020.125856 [58] Yan Huangping, Abdul Rashid M R B, Khew S Y, et al. Wettability transition of laser textured brass surfaces inside different mediums[J]. Applied Surface Science, 2018, 427: 369-375. doi: 10.1016/j.apsusc.2017.08.218 [59] Boinovich L B, Emelyanenko A M, Modestov A D, et al. Corrosion behavior of superhydrophobic aluminum alloy in concentrated potassium halide solutions: when the specific anion effect is manifested[J]. Corrosion Science, 2016, 112: 517-527. doi: 10.1016/j.corsci.2016.08.019 [60] 孙文, 褚福强, 李淑昕, 等. 光热超疏水材料防除冰机理及应用研究进展[J]. 表面技术, 2022, 51(12): 39-51Sun Wen, Chu Fuqiang, Li Shuxin, et al. Research progress on anti-icing mechanisms and applications of photothermal superhydrophobic materials[J]. Surface Technology, 2022, 51(12): 39-51 [61] Li Guifeng, Li Xiashuang, Wang Fan, et al. Enhanced mechanical durability and anti-icing properties of TiN surface preparation and 2D code marking through laser nitriding and texturing[J]. Optics & Laser Technology, 2025, 180: 111506. [62] Cui Jing, Wang Yifan, Wang Chengxuan, et al. Anti-icing and weatherability study of superhydrophobic titanium metal matrix composites surface[J]. Colloid and Interface Science Communications, 2024, 58: 100759. doi: 10.1016/j.colcom.2023.100759 [63] Zhang Zhen, Liu Denghua, Zhang Yi, et al. Fabrication and droplet impact performance of superhydrophobic Ti6Al4V surface by laser induced plasma micro-machining[J]. Applied Surface Science, 2022, 605: 154661. doi: 10.1016/j.apsusc.2022.154661 [64] Cheng Xin, Yang Guang, Wu Jingyi. Spontaneously grown boehmite structures improve pool boiling heat transfer on aluminium surfaces[J]. International Journal of Heat and Mass Transfer, 2022, 192: 122937. doi: 10.1016/j.ijheatmasstransfer.2022.122937 [65] Udaya Kumar G, Suresh S, Sujith Kumar C S, et al. A review on the role of laser textured surfaces on boiling heat transfer[J]. Applied Thermal Engineering, 2020, 174: 115274. doi: 10.1016/j.applthermaleng.2020.115274 [66] Može M, Zupančič M, Golobič I. Pattern geometry optimization on superbiphilic aluminum surfaces for enhanced pool boiling heat transfer[J]. International Journal of Heat and Mass Transfer, 2020, 161: 120265. doi: 10.1016/j.ijheatmasstransfer.2020.120265 [67] Zhang Chong, Zhang Yongkang, Chen Lingyu, et al. Effect of laser micromachining crater-array–multi-grooves on the bonding strength and failure mode of aluminum alloy adhesive joints[J]. Optics & Laser Technology, 2024, 175: 110803. [68] Wan Hailang, Li Shuangshuang, Lin Jianping, et al. Dominant role of laser-generated nano-structures on enhancement of interfacial bonding strength by laser surface modification[J]. Applied Surface Science, 2024, 657: 159708. doi: 10.1016/j.apsusc.2024.159708 [69] Tong Wei, Cui Lingling, Qiu Rongxian, et al. Laser textured dimple-patterns to govern the surface wettability of superhydrophobic aluminum plates[J]. Journal of Materials Science & Technology, 2021, 89: 59-67. [70] Zhao Weiran, Xiao Lin, He Xuyao, et al. Moth-eye-inspired texturing surfaces enabled self-cleaning aluminum to achieve photothermal anti-icing[J]. Optics & Laser Technology, 2021, 141: 107115. [71] Xu Shizhen, Tan Liang, Yao Caizhen, et al. Anti-reflective and wetting properties of femtosecond pulsed laser textured Al alloy surfaces[J]. Optik, 2021, 242: 167293. doi: 10.1016/j.ijleo.2021.167293 [72] Meng Shaopeng, Yu Yanqing, Zhang Xinbin, et al. Investigations on electrochemical corrosion behavior of 7075 aluminum alloy with femtosecond laser modification[J]. Vacuum, 2024, 221: 112911. doi: 10.1016/j.vacuum.2023.112911 [73] 徐良, 李康宁, 杨海锋, 等. 微织构特征对铝合金-CFRTP激光焊接头力学性能的影响[J]. 焊接学报, 2024, 45(2): 75-81Xu Liang, Li Kangning, Yang Haifeng, et al. Effect of microtexturing characteristics on the performance of laser welded aluminum alloy-CFRTP joints[J]. Transactions of the China Welding Institution, 2024, 45(2): 75-81 [74] Holder D, Reichle P, Umlauf G, et al. Tunable, permanent and instantly available super-wettability states on metal surfaces by laser texturing and plasma coating[J]. Scientific Reports, 2025, 15: 27595. doi: 10.1038/s41598-025-11750-z [75] Meena Narayana Menon D, Giardino M, Janner D. Tunable pulsewidth nanosecond laser texturing: from environment friendly superhydrophobic to superamphiphobic surfaces[J]. Applied Surface Science, 2023, 610: 155356. doi: 10.1016/j.apsusc.2022.155356 [76] Rajab F H, Liu Zhu, Li Lin. Long term superhydrophobic and hybrid superhydrophobic/superhydrophilic surfaces produced by laser surface micro/nano surface structuring[J]. Applied Surface Science, 2019, 466: 808-821. doi: 10.1016/j.apsusc.2018.10.099 [77] Zhou Xikang, Xue Wei, Liu Wenwen, et al. Quadri-directionally anisotropic droplets sliding surfaces fabricated by selective laser texturing of aluminum alloy plates[J]. Applied Surface Science, 2020, 509: 145406. doi: 10.1016/j.apsusc.2020.145406 [78] 缑延强. 无吸收层激光喷丸制备2024-T351铝合金超疏水表面及性能研究[D]. 镇江: 江苏大学, 2024Gou Yanqiang. Preparation of 2024-T351 aluminum alloy superhydrophobic surface by laser peening without coating and its properties[D]. Zhenjiang: Jiangsu University, 2024 [79] Boinovich L B, Modin E B, Sayfutdinova A R, et al. Combination of functional nanoengineering and nanosecond laser texturing for design of superhydrophobic aluminum alloy with exceptional mechanical and chemical properties[J]. ACS Nano, 2017, 11(10): 10113-10123. doi: 10.1021/acsnano.7b04634 [80] Lu Yanning, Li Jie, Shi Wentian, et al. Laser-induced biomimetic honeycomb structures synergizing with nanocomposites to build durable copper-based superhydrophobic coatings[J]. Applied Surface Science, 2025, 706: 163592. doi: 10.1016/j.apsusc.2025.163592 [81] 许骏杰, 康嘉杰, 岳文, 等. 纳秒激光制备Fe基非晶合金涂层表面织构的疏水性研究[J]. 材料导报, 2022, 36: 21120134Xu Junjie, Kang Jiajie, Yue Wen, et al. Study on hydrophobicity of surface texture on Fe-based amorphous alloy coating treated by nanosecond laser[J]. Materials Reports, 2022, 36: 21120134 [82] Li Jing, Fan Fengyu, Zhao Yanhui, et al. Influence of laser surface texturing on a low-adhesion and superhydrophobic aluminium alloy surface[J]. Micro & Nano Letters, 2018, 13(3): 389-392. [83] Samanta A, Huang Wuji, Parveg A S M S, et al. Enabling superhydrophobicity-guided superwicking in metal alloys via a nanosecond laser-based surface treatment method[J]. ACS Applied Materials & Interfaces, 2021, 13(34): 41209-41219. [84] Jiang Shulan, Zhang Ao, Zhan Xiaobin, et al. Surface microtexturing design, laser-etching and adhesive failure of aluminum alloy single-lap-joint: experiment and simulation[J]. Thin-Walled Structures, 2023, 193: 111237. doi: 10.1016/j.tws.2023.111237 -

下载:

下载: